Documente Academic

Documente Profesional

Documente Cultură

Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical Anchoring PDF

Încărcat de

Gibbs PerTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical Anchoring PDF

Încărcat de

Gibbs PerDrepturi de autor:

Formate disponibile

29.

1 TruBolt™

STUD ANCHORS

29.1 GENERAL INFORMATION

PERFORMANCE RELATED MATERIAL SPECIFICATION INSTALLATION RELATED

Mechanical Anchoring

Product Le

The TruBolt™ Anchor is a heavy duty, torque setting

expansion anchor. db = dh

Benefits, Advantages and Features

Maximum shear capacity for hole size:

• Stud diameter equals hole diameter.

Faster installation:

• Through fixing eliminates marking out and repositioning of fixtures. Principal Applications

High clamp load:

• Stud design ensures pull-down on fixture. • Structural beams and columns

Superior corrosion resistance: • Bottom plate and batten fixing

• AISI 316(A4) Stainless Steel. • Formwork support

s pp rt

Outstanding exterior durability: • Installing signs, handrails, balustrades and gates

• 42 micron Hot Dip Galvanised coating. • Safety barriers

barrier

Superior strength:

• Cold forged steel construction.

Installation

1. Drill or core a hole to the recommended diameter (same as the

TruBolt™)and depth using the fixture as a template. Clean the hole

thoroughly with a hole cleaning brush. Remove the debris with a

hand pump, compressed air, or vacuum.

2. Insert the anchor through the fixture and drive with a hammer until

the washer contacts the fixture.

3. Tighten the nut with a torque wrench to the specified assembly

torque.

www.ramset.co.nz 0800 RAMSET www.ramset.com.au 1300 780 063 201

29.2 TruBolt™

STUD ANCHORS

Installation and performance details

Installation details Optimum dimensions* Reduced Characteristic Capacity

Anchor Steel Concrete

Drilled Fixture hole Anchor Tightening Edge Anchor

Size, db Tension, ØNuc (kN)**

Hole diam., diameter, effective torque, distance, spacing, ac Shear,

(mm) Concrete compressive strength, f'c

dh (mm) df (mm) depth, h (mm) Tr (Nm) ec (mm) (mm) ØVus (kN)

Mechanical Anchoring

20 MPa 25 MPa 32 MPa

M6 6 8 24 10 45 70 5.7 3.1 3.5 4.0

M8 8 9 32 20 55 100 9.8 4.8 5.4 6.1

M10 10 12 40 35 60 120 13.5 6.7 7.5 8.5

M12 12 14 48 50 75 150 17.1 8.8 9.9 11.2

M16 16 18 64 155 100 200 28.8 13.6 15.2 17.2

M20 20 24 80 355 120 240 54.7 19.0 21.3 24.0

* Note: For shear loads acting towards an edge or where these optimum dimensions are not achievable, please use the simplified strength limit state design process to verify capacity.

**Note: Reduced characteristic ultimate concrete tensile capacity = ØNuc where Ø = 0.60 and Nuc = Characteristic ultimate concrete tensile capacity.

For conversion to Working Load Limit MULTIPLY ØNuc x 0.55

29.2 DESCRIPTION AND PART NUMBERS

Hole Effective Part No. Effective depth, h (mm)

Anchor

diameter, length, Le

size, db Zn Gal S/S

dh (mm) (mm)

38 T06055 – T06055SS h = Le - t

68 T06085 – T06085SS t = total thickness of material(s)

M6 6 103 T06120 – – being fixed

133 T06150 – –

163 T06180 – –

45 T08065 – T08070SSA Substrate thickness, bm

M8 8

70 T08090 T08090GH T08090SSA bm = 2 x h

52 T10075 – T10075SSA

M10 10 67 T10090 T10090GH T10095SSA

97 T10120 – T10120SSA Drilled hole depth, h1 (mm)

58 T12080 T12080GH T12080SSA h1 = h + ( 2 x dh )

71 T12100 T12100GH T12100SSA

h = Effective depth

M12 12 93 T12120 – –

111 T12140 T12140GH T12140SSA

151 T12180 T12180GH –

70 T16110 T16110GH –

85 T16125 T16125GH T16125SSA

M16 16

110 T16150 T16150GH T16150SSA

135 T16175 T16175GH T16170SSA

95 T20140 T20140GH T20140SS

M20 20 115 T20160 T20160GH T20160SS

170 T20215 T20215GH –

202 www.ramset.com.au 1300 780 063 www.ramset.co.nz 0800 RAMSET

29.3 TruBolt™

STUD ANCHORS

29.3 ENGINEERING PROPERTIES - Carbon Steel

Anchors with strengths higher in the reduced section than in the

threaded section, are formed by cold working. The reduced section is

located under the expansion sleeve.

Mechanical Anchoring

For shear loads, the critical plane is located in the threaded section,

and for tensile loads, the critical plane is located at the reduced

section.

Stress area Minimum Threaded section Reduced section Section

Anchor thread section, As diameter reduced Yield strength, fy UTS, fu Yield strength, fy UTS, fu modulus, Z

size, db (mm2) section, dm (mm) (MPa) (MPa) (MPa) (MPa) (mm3)

M6 20.1 4.2 460 570 660 830 12.7

M8 36.6 5.8 430 540 600 750 31.2

M10 58 7.6 380 470 480 600 62.3

M12 84.3 8.9 330 410 450 560 109.2

M16 157 12.1 290 370 400 500 277.5

M20 245 16.1 360 450 360 450 540.9

ENGINEERING PROPERTIES - Stainless Steel

Stress area Minimum Threaded section Reduced section Section

Anchor thread section, As diameter reduced Yield strength, fy UTS, fu Yield strength, fy UTS, fu modulus, Z

size, db (mm2) section, dm (mm) (MPa) (MPa) (MPa) (MPa) (mm3)

M6 20.1 4.2 320 400 470 590 12.7

M8 36.6 5.6 420 620 780 900 31.2

M10 58 7.3 420 620 780 900 62.3

M12 84.3 8.6 420 620 780 900 109.2

M16 157 11.7 420 620 780 900 277.5

M20 245 16.1 480 600 480 600 540.9

www.ramset.co.nz 0800 RAMSET www.ramset.com.au 1300 780 063 203

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

STEP 1 Select anchor to be evaluated

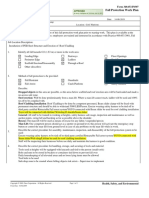

Table 1a Indicative combined loading – interaction diagram

30

Mechanical Anchoring

25 Notes:

~ Shear limited by steel capacity

~ Tension limited by pull-through capacity

~ No edge or spacing effects.

Design tensile action effect, N* (kN)

20 ~ f'c = 32 MPa

M20

15

M16

10

M12

M10

5

M8

M6

0

0 10 20 30 40 50 60

Design shear action effect, V* (kN)

Table 1b Absolute minimum edge distance and anchor spacing values, em and am (mm)

Anchor size, db M6 M8 M10 M12 M16 M20

Min. Anchor spacing - am 30 35 40 45 50 60

Min. Edge distance - em 45 55 60 65 75 95

Step 1c Calculate anchor effective depth, h (mm)

Refer to “Description and Part Numbers” table on page 202.

Effective depth, h (mm)

h = Le - t

t = total thickness of material(s) being fixed

1 Anchor size determined, absolute minima compliance achieved, effective depth (h) calculated.

204 www.ramset.com.au 1300 780 063 www.ramset.co.nz 0800 RAMSET

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

STEP 2 Verify concrete tensile capacity - per anchor

Table 2a - Reduced characteristic ultimate concrete tensile capacity, ØNuc (kN), Øc = 0.6, f’c = 32 MPa

Anchor size, db M6 M8 M10 M12 M16 M20

Mechanical Anchoring

Hole diameter, dh (mm) 6 8 10 12 16 20

Effective depth, h (mm)

25 4.2

30 5.5

35 6.9 6.9

40 8.5 8.5 8.5

50 11.9 11.9 11.9 11.9

65 17.6 17.6 17.6 17.6 17.6

80 24.0 24.0 24.0 24.0 24.0 24.0

95 31.0 31.0 31.0 31.0 31.0

110 38.7 38.7 38.7 38.7

125 46.8 46.8 46.8

145 58.5 58.5 58.5

160 67.8 67.8

180 81.0

Note: Effective depth, h must be * 4 x drilled hole diameter, dh for anchor to achieve tabled shear capacities.

Table 2b - Concrete compressive strength effect, tension, Xnc

f’c (MPa) 20 25 32 40 50

Xnc 0.79 0.88 1.00 1.00 1.00

Table 2c Edge distance effect, tension, Xne

Edge distance, e (mm) 50 60 70 80 100 125 150 175 200 230

Effective depth, h (mm)

25

30 1

35 0.97

40 0.88 1 1

50 0.77 0.86 0.95 1

65 0.66 0.73 0.80 0.87 1

80 0.59 0.65 0.71 0.77 0.88 1

95 0.55 0.59 0.64 0.69 0.79 0.91 1

110 0.51 0.55 0.60 0.64 0.72 0.83 0.94 1

125 0.49 0.52 0.56 0.60 0.67 0.77 0.86 0.95 1

145 0.46 0.49 0.53 0.56 0.62 0.70 0.78 0.86 0.94 1

160 0.45 0.48 0.50 0.53 0.59 0.66 0.74 0.81 0.88 0.97

www.ramset.co.nz 0800 RAMSET www.ramset.com.au 1300 780 063 205

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

Table 2d Anchor spacing effect, end of a row, tension, Xnae

Note: For single anchor designs, Xnae = 1.0

Anchor spacing, a (mm) 30 40 50 60 80 100 125 150 175 200 250 300 350 400

Effective depth, h (mm)

25 0.70 0.77 0.83 0.90 1

Mechanical Anchoring

30 0.67 0.72 0.78 0.83 0.94 1

35 0.64 0.69 0.74 0.79 0.88 0.98

40 0.63 0.67 0.71 0.75 0.83 0.92 1

50 0.60 0.63 0.67 0.70 0.77 0.83 0.92 1 1

65 0.58 0.60 0.63 0.65 0.71 0.76 0.82 0.88 0.95 1

80 0.56 0.58 0.60 0.63 0.67 0.71 0.76 0.81 0.86 0.92 1

95 0.55 0.57 0.59 0.61 0.64 0.68 0.72 0.76 0.81 0.85 0.94 1

110 0.55 0.56 0.58 0.59 0.62 0.65 0.69 0.73 0.77 0.80 0.88 0.95 1

125 0.54 0.55 0.57 0.58 0.61 0.63 0.67 0.70 0.73 0.77 0.83 0.90 0.97 1

145 0.53 0.55 0.56 0.57 0.59 0.61 0.64 0.67 0.70 0.73 0.79 0.84 0.90 0.96

160 0.54 0.55 0.56 0.58 0.60 0.63 0.66 0.68 0.71 0.76 0.81 0.86 0.92

Table 2e Anchor spacing effect, internal to a row, tension, Xnai

Note: For single anchor designs, Xnai = 1.0

Anchor spacing, a (mm) 30 40 50 60 80 100 125 150 175 200 250 300 350 400

Effective depth, h (mm)

25 0.40 0.53 0.67 0.80 1

30 0.33 0.44 0.56 0.67 0.89 1

35 0.29 0.38 0.48 0.57 0.76 0.95

40 0.25 0.33 0.42 0.50 0.67 0.83 1

50 0.20 0.27 0.33 0.40 0.53 0.67 0.83 1 1

65 0.15 0.21 0.26 0.31 0.41 0.51 0.64 0.77 0.90 1

80 0.13 0.17 0.21 0.25 0.33 0.42 0.52 0.63 0.73 0.83 1

95 0.11 0.14 0.18 0.21 0.28 0.35 0.44 0.53 0.61 0.70 0.88 1

110 0.09 0.12 0.15 0.18 0.24 0.30 0.38 0.45 0.53 0.61 0.76 0.91 1

125 0.11 0.13 0.16 0.21 0.27 0.33 0.40 0.47 0.53 0.67 0.80 0.93 1

145 0.09 0.11 0.14 0.18 0.23 0.29 0.34 0.40 0.46 0.57 0.69 0.80 0.92

160 0.10 0.13 0.17 0.21 0.26 0.31 0.36 0.42 0.52 0.63 0.73 0.83

2 Design reduced ultimate concrete tensile capacity, ØNurc

ØNurc = ØNuc * Xnc * Xne * ( Xnae or Xnai )

206 www.ramset.com.au 1300 780 063 www.ramset.co.nz 0800 RAMSET

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

STEP 3 Verify anchor tensile capacity - per anchor

Table 3a Reduced characteristic ultimate steel tensile capacity, ØNus (kN), Øn = 0.8

Anchor size, db M6 M8 M10 M12 M16 M20

Mechanical Anchoring

Carbon steel 9.1 15.7 21.8 27.8 45.5 72.5

316 Stainless steel 6.4 12.6 21.8 29.9 55.2 97.7

Table 3b - Reduced characteristic ultimate pull-through capacity**, ØNup (kN), Øp = 0.65, f’c = 32 MPa

Anchor size, db *M6 M8 M10 M12 M16 *M20

Drill hole dia, dh (mm) 6 8 10 12 16 20

Effective depth, h (mm)

25 4.6

35 7.5

40 9.2

50 12.9

65 19.0

80 26.0

**Note: Reduced characteristic ultimate Pull-through capacity is not influenced by reduced anchor spacing or edge distance.

3aa Design reduced ultimate pull through capacity, ØNurp

ØNurp = ØNup* Xnc

3b

3b Design reduced ultimate tensile capacity, ØNur

ØNur = minimum of ØNurc, ØNus, ØNurp

Check N* / ØNur ) 1,

If not satisfied return to step 1

www.ramset.co.nz 0800 RAMSET www.ramset.com.au 1300 780 063 207

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

Tensile performance conversion table

Concrete Tensile Performance Pull-Through Performance Steel Tensile Performance

Performance Required Concrete Pull-Through Carbon Steel

Notation Notation Notation

Tension Capacity Tension Capacity Tension Capacity

Strength Limit State ØNurc MULTIPLY ØNurc x 1.00 ØNup MULTIPLY ØNup x 1.00 ØNus MULTIPLY ØNus x 1.00

Mechanical Anchoring

Working Load Limit Nac MULTIPLY ØNurc x 0.55 Nap MULTIPLY ØNup x 0.51 Nas MULTIPLY ØNus x 0.56

Cyclic Loading Nyc MULITPLY ØNurc x 0.19 Nyp MULITPLY ØNup x 0.18 Nys MULITPLY ØNus x 0.19

Fire Resistance NRk,c,fi,t Refer to pages 238-257 NRk,p,fi,t Refer to pages 238-257 NRk,s,fi,t Refer to pages 238-257

0

Cracked Concrete/Tension Zone N Rd,p Refer to pages 258-298 NRd,p Refer to pages 258-298 NRd,s Refer to pages 258-298

0

Seismic N Rd,p,sis Refer to pages 299-325 NRd,p,sis Refer to pages 299-325 NRd,s,sis Refer to pages 299-325

NOTE: Design Tensile Capacity is the minimum of Concrete Tension and Steel Tension Capacities

STEP 4 Verify concrete shear capacity - per anchor

Table 4a Reduced characteristic ultimate concrete edge shear capacity, ØVuc (kN), Øq = 0.6, f’c = 32 MPa

Anchor size, db M6 M8 M10 M12 M16 M20

Edge distance, e (mm)

45 3.1

60 4.7 5.4 6.1

75 6.6 7.6 8.5 9.3 10.8

100 10.1 11.7 13.1 14.3 16.6 18.5

150 18.6 21.5 24.1 26.4 30.4 34.0

200 28.7 33.1 37.0 40.6 46.9 52.4

250 40.1 46.3 51.8 56.7 65.5 73.2

300 52.7 60.9 68.0 74.5 86.1 96.2

350 76.7 85.7 93.9 108.5 121.3

450 136.9 158.1 176.8

600 272.2

850

Note: Effective depth, h must be * 4 x drilled hole diameter, dh for anchor to achieve tabled shear capacities.

Table 4b Concrete compressive strength effect, concrete edge shear, Xvc

f’c (MPa) 20 25 32 40 50

Xvc 0.79 0.88 1.00 1.12 1.25

_

V* Table 4c Load direction effect, concrete edge shear, Xvd

Angle, _° 0 10 20 30 40 50 60 70 80 90 - 180

Xvd 1.00 1.04 1.16 1.32 1.50 1.66 1.80 1.91 1.98 2.00

Load direction effect,

conc. edge shear, Xvd

208 www.ramset.com.au 1300 780 063 www.ramset.co.nz 0800 RAMSET

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

Table 4d Anchor spacing effect, concrete edge shear, Xva

Note: For single anchor designs, Xva = 1.0

Edge distance, e (mm) 45 60 75 100 150 200 250 300 350 450 600 850

Anchor spacing, a (mm)

30 0.63 0.60 0.58 0.56 0.54 0.53 0.52 0.52 0.52 0.51 0.51 0.51

Mechanical Anchoring

50 0.72 0.67 0.63 0.60 0.57 0.55 0.54 0.53 0.53 0.52 0.52 0.51

60 0.77 0.70 0.66 0.62 0.58 0.56 0.55 0.54 0.53 0.53 0.52 0.51

80 0.86 0.77 0.71 0.66 0.61 0.58 0.56 0.55 0.55 0.54 0.53 0.52

100 0.94 0.83 0.77 0.70 0.63 0.60 0.58 0.57 0.56 0.54 0.53 0.52

125 1.00 0.92 0.83 0.75 0.67 0.63 0.60 0.58 0.57 0.56 0.54 0.53

150 1.00 0.90 0.80 0.70 0.65 0.62 0.60 0.59 0.57 0.55 0.54

200 1.00 0.90 0.77 0.70 0.66 0.63 0.61 0.59 0.57 0.55

250 1.00 0.83 0.75 0.70 0.67 0.64 0.61 0.58 0.56

300 0.90 0.80 0.74 0.70 0.67 0.63 0.60 0.57

400 1.00 0.90 0.82 0.77 0.73 0.68 0.63 0.59

500 1.00 0.90 0.83 0.79 0.72 0.67 0.62

600 0.98 0.90 0.84 0.77 0.70 0.64

800 1.00 1.00 0.96 0.86 0.77 0.69

1000 1.00 0.94 0.83 0.74

1500 1.00 1.00 0.85

2000 0.97

Table 4e Multiple anchors effect, concrete edge shear, Xvn

Note: For single anchor designs, Xvn = 1.0

Anchor spacing /

0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.25 2.50

Edge distance, a / e

Number of anchors, n

2 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

3 0.72 0.76 0.80 0.83 0.86 0.88 0.91 0.93 0.95 0.96 0.98 1.00

4 0.57 0.64 0.69 0.74 0.79 0.82 0.86 0.89 0.92 0.94 0.97 1.00

5 0.49 0.57 0.63 0.69 0.74 0.79 0.83 0.87 0.90 0.93 0.97 1.00

6 0.43 0.52 0.59 0.66 0.71 0.77 0.81 0.85 0.89 0.93 0.96 1.00

7 0.39 0.48 0.56 0.63 0.69 0.75 0.80 0.84 0.88 0.92 0.96 1.00

8 0.36 0.46 0.54 0.61 0.68 0.74 0.79 0.84 0.88 0.92 0.96 1.00

9 0.34 0.44 0.52 0.60 0.67 0.73 0.78 0.83 0.87 0.91 0.96 1.00

10 0.32 0.42 0.51 0.59 0.66 0.72 0.77 0.82 0.87 0.91 0.96 1.00

15 0.26 0.37 0.47 0.55 0.63 0.70 0.76 0.81 0.86 0.90 0.95 1.00

20 0.23 0.35 0.45 0.54 0.61 0.68 0.75 0.80 0.85 0.90 0.95 1.00

Table 4f Anchor at a corner effect, concrete edge shear, Xvs

Note: For e1/e2 > 1.25, Xvs = 1.0

Shear Force

Edge distance, e2 (mm) 25 30 35 50 60 75 125 200 300 400 600 900

e1

Edge dustance, e1 (mm)

25 0.86 0.77 0.70 0.58 0.53 0.49 0.41 0.37 0.35 0.34 0.32 0.32

e2

Failure

wedge

30 0.97 0.86 0.78 0.64 0.58 0.52 0.43 0.38 0.36 0.34 0.33 0.32

35 1.00 0.95 0.86 0.69 0.63 0.56 0.46 0.40 0.37 0.35 0.33 0.32

Concrete edges

50 1.00 1.00 1.00 0.86 0.77 0.67 0.52 0.44 0.39 0.37 0.35 0.33

ANCHOR AT A CORNER

60 1.00 1.00 1.00 0.97 0.86 0.75 0.57 0.47 0.41 0.38 0.36 0.34

75 1.00 1.00 1.00 1.00 1.00 0.86 0.64 0.51 0.44 0.41 0.37 0.35

125 1.00 1.00 1.00 1.00 1.00 1.00 0.86 0.65 0.53 0.48 0.42 0.38

200 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.86 0.67 0.58 0.49 0.42

300 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.86 0.72 0.58 0.49

400 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.86 0.67 0.55

500 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.77 0.61

600 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.86 0.67

900 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.86

www.ramset.co.nz 0800 RAMSET www.ramset.com.au 1300 780 063 209

29.4 TruBolt™

STRENGTH LIMIT STATE DESIGN

4 Design reduced ultimate concrete edge shear capacity, ØVurc

ØVurc = ØVuc * Xvc * Xvd * Xva * Xvn * Xvs

Mechanical Anchoring

STEP 5 Verify anchor shear capacity - per anchor

Table 5a Reduced characteristic ultimate steel shear capacity, ØVus (kN), Øv = 0.8

Anchor size, db M6 M8 M10 M12 M16 M20

Carbon steel 5.7 9.8 13.5 17.1 28.8 54.7

316 Stainless steel 4.0 7.8 13.5 18.9 46.7 72.9

Step 5b Reduced characteristic ultimate bolt steel shear capacity, ØVsf (kN)

Not appropriate for this product.

5 Design reduced ultimate shear capacity, ØVur

ØVur = minimum of ØVurc, ØVus

Check V* / ØVur ) 1, if not satisfied return to step 1

Shear performance conversion table

Concrete Shear Performance Steel Shear Performance

Performance Required Concrete Carbon Steel

Notation Notation

Shear Capacity Shear Capacity

Strength Limit State ØVuc MULTIPLY ØVuc x 1.00 ØVus MULTIPLY ØVus x 1.00

Working Load Limit Vac MULTIPLY ØVuc x 0.55 Vas MULTIPLY ØVus x 0.50

Cyclic Loading Vyc MULITPLY ØVuc x 0.55 Vys MULITPLY ØVus x 0.50

Fire Resistance VRk,c,fi,t Refer to pages 238-257 VRk,s,fi,t Refer to pages 238-257

0 0

Cracked Concrete/Tension Zone V Rd,c Refer to pages 258-298 V Rd,s

Refer to pages 258-298

0 0

Seismic V Rd,c,sis Refer to pages 299-325 V Rd,s,sis

Refer to pages 299-325

NOTE: Design Shear Capacity is the minimum of Concrete Shear and Steel Shear Capacities

STEP 6 Combined loading and specification

6 Check

N*/ØNur + V*/ØVur ) 1.2, if not satisfied return to step 1

Example

Specify Ramsett™ TruBo

TruBoltt™ Anchor,

Ramsett TruBoltt Anchor,

™ ™

M20 (T20160).

(Anchor Size) ((Part Number)). Maximum fixed thickness to be 20 mm.

Maximum fixed

f thickness to be (t) mm. To be installed in accordance with

Ramsett™ Technical Data Sheet..

210 www.ramset.com.au 1300 780 063 www.ramset.co.nz 0800 RAMSET

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Between The World and MeDocument2 paginiBetween The World and Meapi-3886294240% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Doctrines On Persons and Family RelationsDocument69 paginiDoctrines On Persons and Family RelationsCarla VirtucioÎncă nu există evaluări

- Konosuba! Volume:7Document359 paginiKonosuba! Volume:7SaadAmirÎncă nu există evaluări

- Procedure - Fit-Up & AssemblyDocument8 paginiProcedure - Fit-Up & AssemblyRakesh RanjanÎncă nu există evaluări

- MS Chequered Plate Sizes Weights Thickness Length kgDocument1 paginăMS Chequered Plate Sizes Weights Thickness Length kgतरकश के तीर0% (1)

- Agreement InvestmentDocument5 paginiAgreement InvestmentEricka Kim100% (6)

- 79.1 Enrico vs. Heirs of Sps. Medinaceli DigestDocument2 pagini79.1 Enrico vs. Heirs of Sps. Medinaceli DigestEstel Tabumfama100% (1)

- JAR23 Amendment 3Document6 paginiJAR23 Amendment 3SwiftTGSolutionsÎncă nu există evaluări

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument18 paginiSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument18 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Sigmacover™ 380: Product Data SheetDocument5 paginiSigmacover™ 380: Product Data SheetGibbs PerÎncă nu există evaluări

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument18 paginiSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument12 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument13 paginiSafety Data Sheet: Section 1. Chemical Product and Company IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument14 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument16 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument17 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument13 paginiSafety Data Sheet: Section 1. Chemical Product and Company IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument14 paginiSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingGibbs PerÎncă nu există evaluări

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 paginăSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument18 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument18 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- Safety Data Sheet Hazard InformationDocument12 paginiSafety Data Sheet Hazard InformationGibbs PerÎncă nu există evaluări

- Amercoat® 114 A: (Formerly Nu-Klad 114A Also Branded As Megaseal CF)Document5 paginiAmercoat® 114 A: (Formerly Nu-Klad 114A Also Branded As Megaseal CF)Gibbs PerÎncă nu există evaluări

- Sigmacover 280 (Primer) For HDG SurfaceDocument6 paginiSigmacover 280 (Primer) For HDG SurfaceRauf AliyevÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument18 paginiSafety Data Sheet: Section 1. IdentificationGibbs PerÎncă nu există evaluări

- White : Exterior Wall PrimerDocument2 paginiWhite : Exterior Wall PrimerGibbs PerÎncă nu există evaluări

- FRENIC Solar Pump Controller Compatible with Induction and PMSM Pumps Installation Over 15000 Across IndiaDocument4 paginiFRENIC Solar Pump Controller Compatible with Induction and PMSM Pumps Installation Over 15000 Across IndiaGibbs PerÎncă nu există evaluări

- Sigmadur™ 550: Product Data SheetDocument5 paginiSigmadur™ 550: Product Data SheetAneesh Lie A YoungÎncă nu există evaluări

- Technical Data Sheet For Zinc SprayDocument1 paginăTechnical Data Sheet For Zinc SprayGibbs PerÎncă nu există evaluări

- Sigmazinc 109hs PDFDocument5 paginiSigmazinc 109hs PDFAneesh Lie A YoungÎncă nu există evaluări

- Fall Protection Work Plan - Roof CladdingDocument2 paginiFall Protection Work Plan - Roof CladdingGibbs PerÎncă nu există evaluări

- Renault: Live For MoreDocument9 paginiRenault: Live For MoreSanthosh Raj KumarÎncă nu există evaluări

- Eco-Hopper Ref ListDocument2 paginiEco-Hopper Ref ListGibbs PerÎncă nu există evaluări

- NF-S-200-335-300HP - CL Engine-Rev01Document1 paginăNF-S-200-335-300HP - CL Engine-Rev01Gibbs PerÎncă nu există evaluări

- NF S 200 335 300HP - e Tefc Rev01Document1 paginăNF S 200 335 300HP - e Tefc Rev01Gibbs PerÎncă nu există evaluări

- Mx. Gad 2023Document3 paginiMx. Gad 2023Wany BerryÎncă nu există evaluări

- Application No. 2140 6100 0550: OJEE FORM F - Application Form For B.Tech (SPECIAL) 2021Document1 paginăApplication No. 2140 6100 0550: OJEE FORM F - Application Form For B.Tech (SPECIAL) 2021Siba BaiÎncă nu există evaluări

- The Big Mac TheoryDocument4 paginiThe Big Mac TheoryGemini_0804Încă nu există evaluări

- Courts Jamaica Accounting and Financing ResearchDocument11 paginiCourts Jamaica Accounting and Financing ResearchShae Conner100% (1)

- Multimodal Transport Bill of Lading PDFDocument3 paginiMultimodal Transport Bill of Lading PDFJulia TombakÎncă nu există evaluări

- Charity Extends Help To Seniors: Donating Is Made EasierDocument16 paginiCharity Extends Help To Seniors: Donating Is Made EasierelauwitÎncă nu există evaluări

- New Funding Pushes Convoy Valuation To $3.8 BillionDocument3 paginiNew Funding Pushes Convoy Valuation To $3.8 BillionTrang BùiÎncă nu există evaluări

- Vodafone service grievance unresolvedDocument2 paginiVodafone service grievance unresolvedSojan PaulÎncă nu există evaluări

- List of Presidents of Pakistan Since 1947 (With Photos)Document4 paginiList of Presidents of Pakistan Since 1947 (With Photos)Humsafer ALiÎncă nu există evaluări

- LG 2 06 Disomangcop V Secretary of Public Works PDFDocument1 paginăLG 2 06 Disomangcop V Secretary of Public Works PDFirene ibonÎncă nu există evaluări

- Can You Dribble The Ball Like A ProDocument4 paginiCan You Dribble The Ball Like A ProMaradona MatiusÎncă nu există evaluări

- REVISION 3 Chuyên đề 1-12 multiple choice questionsDocument11 paginiREVISION 3 Chuyên đề 1-12 multiple choice questionsAn NguyễnÎncă nu există evaluări

- TallerDocument102 paginiTallerMarie RodriguezÎncă nu există evaluări

- Solar Power Is The Last Energy Resource That Isn't Owned Yet - Nobody Taxes The Sun Yet.Document5 paginiSolar Power Is The Last Energy Resource That Isn't Owned Yet - Nobody Taxes The Sun Yet.Norhanifa HADJI AMERÎncă nu există evaluări

- Student-Led School Hazard MappingDocument35 paginiStudent-Led School Hazard MappingjuliamarkÎncă nu există evaluări

- DJANGODocument4 paginiDJANGOprashanth ambalaÎncă nu există evaluări

- ITMS (Intelligent Transit Management System) : 1. Name of Project: 2. BackgroundDocument6 paginiITMS (Intelligent Transit Management System) : 1. Name of Project: 2. Backgroundashish dhakalÎncă nu există evaluări

- Cost of DebtDocument3 paginiCost of DebtGonzalo De CorralÎncă nu există evaluări

- Pub. 127 East Coast of Australia and New Zealand 10ed 2010Document323 paginiPub. 127 East Coast of Australia and New Zealand 10ed 2010joop12Încă nu există evaluări

- Class Xi BST Chapter 6. Social Resoposibility (Competency - Based Test Items) Marks WiseDocument17 paginiClass Xi BST Chapter 6. Social Resoposibility (Competency - Based Test Items) Marks WiseNidhi ShahÎncă nu există evaluări

- Management of HBLDocument14 paginiManagement of HBLAnnaya AliÎncă nu există evaluări

- Case Study Format Hvco Srce UhvDocument2 paginiCase Study Format Hvco Srce Uhvaayushjn290Încă nu există evaluări

- Hwa Tai AR2015 (Bursa)Document104 paginiHwa Tai AR2015 (Bursa)Muhammad AzmanÎncă nu există evaluări

- Con PhilDocument48 paginiCon PhilConica BurgosÎncă nu există evaluări