Documente Academic

Documente Profesional

Documente Cultură

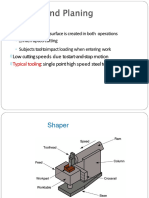

Workholding Playing

Încărcat de

Miguel Angel GarcíaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Workholding Playing

Încărcat de

Miguel Angel GarcíaDrepturi de autor:

Formate disponibile

Can be moved on a hinge and then A universal vise allows to machine

Can be set using gage blocks for

More rigid than the other styles of Allows angular positioning of locked to position work at nearly compound angles in one set-up,

very precise angular positioning.

vises. workpieces. any desired angle. which is very useful in mould and

die making shops.

Is a workholding device specifically

Consists of sleeve, with four or

designed to accommodate a Available for most of standard hole Used to hold number of identical Used for holding workpieces

more slots cut lengthwise, fitted

specific workpiece while machining sizes. parts for machining operation. having a threaded hole.

over solid mandrel.

operations are performed on it.

May be fitted to tapered hold in A slot extends all the way to one Designed to clamp many different

Has a bend or step in the middle so

headstock spindle. Is simply a sturdy flatbar. end so the clamp can slide out of sized workpieces without step

a smaller step can be used.

the way quickly. blocks.

A piece which may be driven into a

A piece with a head of square or

Has a finger extending from one board to receive a bolt inserted

rectangular shape intended to fit a Supports the strap clamp opposite Are often used to level the work

end of the clamp. from the opposite side

T slot. the work. and raise it above the vise base.

A practical, versatile means of

Are versatile accessories which can Are used for accurately holding

clamping and holding work in a

be used to clamp and hold work in work on a vertical plane for

Provide adjustable height support Is a thin and often tapered vertical position for layout,

a vertical position for planning, precision boring, milling, or drilling

for machining or measurement or wedged piece of material, used machining, and inspection, or for a

milling, or drilling. Work can be operations. One-piece

operations. to fill small gaps or spaces vertical reference. Also ideal for

clamped and rotated through construction with heavy support

between objects. use as time-saving, reusable fixture

several planes for measurement or ribbing to help prevent distortion

components.

machining without repositioning. under heavy loads.

Work can be clamped to either

face for measurement or Are work-holding fixtures for

machining and rotated through precision machining large work Support round work for drilling.

Is a narrow bar with rolls near each

three planes without the need for pieces on planer or boring mill Some are fitted with clamps to Is a wider version of a sine bar.

end and is used to measure angles

reclamping. Can be used as fixture operations. They can be used hold the work.

on relatively small parts.

components or for checking individually or in combinations.

squareness and parallelism.

Can be used for rapid mounting

fixtures for machine set-up, layout,

or inspection. They are heavily

1. A 5.00” sine bar is elevated 2. Determine the elevation for 30˚

Is similar to a sine bar except with It is used for measuring compound ribbed for strength and rigidity.

1.50”. Calculate the angle. using 5.00” sine bar.

a larger area to hold larger parts. angles Sides and ends are machine

finished.

S-ar putea să vă placă și

- 320d WiringDocument2 pagini320d WiringMohamed Harb100% (5)

- Chapter 4 Drilling MachinesDocument24 paginiChapter 4 Drilling MachinesPRASAD326100% (14)

- Appendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1Document3 paginiAppendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1gonzalesÎncă nu există evaluări

- Cam ViseDocument14 paginiCam Visesundar_subash25Încă nu există evaluări

- 3-In-1 Drill Press Upgrade Derevyannoe KruzhevoDocument12 pagini3-In-1 Drill Press Upgrade Derevyannoe KruzhevoTanja MartinovicÎncă nu există evaluări

- HP4Document88 paginiHP4Alexander Neyra100% (4)

- Clamping Devices and ElementsDocument12 paginiClamping Devices and ElementssunilÎncă nu există evaluări

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsDe la EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsÎncă nu există evaluări

- Jigs & FixturesDocument63 paginiJigs & FixturesRishikesh KaushikÎncă nu există evaluări

- ManufacturaDocument87 paginiManufacturaMiguel Angel GarcíaÎncă nu există evaluări

- Pre Requisites For Project ImplementationDocument3 paginiPre Requisites For Project ImplementationTage NobinÎncă nu există evaluări

- Company Names and Number UAEDocument35 paginiCompany Names and Number UAESoju Suresh100% (1)

- Reinforced Concrete Design BS 8110Document15 paginiReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingDe la EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingÎncă nu există evaluări

- Rftmdc6a PDFDocument17 paginiRftmdc6a PDFShakeebÎncă nu există evaluări

- Material Handling GrooverDocument50 paginiMaterial Handling GrooverMiguel Angel GarcíaÎncă nu există evaluări

- Material Turbina A GásDocument47 paginiMaterial Turbina A GásGetúlio RibeiroÎncă nu există evaluări

- UNIT-1 Locating and Clamping: S.Dharani KumarDocument86 paginiUNIT-1 Locating and Clamping: S.Dharani KumarSaivineeth Gampa100% (1)

- Gibbscam Rotary Milling and Gibbscam 4-Axis OptionsDocument2 paginiGibbscam Rotary Milling and Gibbscam 4-Axis OptionssimioncristescuÎncă nu există evaluări

- CH 8 IndexingDocument7 paginiCH 8 IndexingsobheysaidÎncă nu există evaluări

- Nuts and Washers PDFDocument2 paginiNuts and Washers PDFraja mohanÎncă nu există evaluări

- CHAPTER 2 - DrillingDocument6 paginiCHAPTER 2 - DrillingHarish Nagoor NahooranÎncă nu există evaluări

- ch8 13Document1 paginăch8 13Dumisani SitholeÎncă nu există evaluări

- Jig FixtureDocument59 paginiJig FixtureHrishikeshÎncă nu există evaluări

- IE Workholding DevicesDocument9 paginiIE Workholding DevicesFaith GoÎncă nu există evaluări

- ContentsDocument6 paginiContentshecavodÎncă nu există evaluări

- Sigma Institute of Engineering Mechanical Engineering DepartmentDocument37 paginiSigma Institute of Engineering Mechanical Engineering DepartmentSHIVAM PARIHARÎncă nu există evaluări

- SalvagniniDocument9 paginiSalvagniniHemaprakash TigerÎncă nu există evaluări

- WK2 Types and Functions of Jigs and FixturesDocument39 paginiWK2 Types and Functions of Jigs and FixturesChris EvanÎncă nu există evaluări

- Alatan TanganDocument12 paginiAlatan TanganMaruan MuhammadÎncă nu există evaluări

- 11 - Other Locating ApproachesDocument2 pagini11 - Other Locating ApproachesMFÎncă nu există evaluări

- Machine Picture / Diagram Function and Application Machine OperationDocument6 paginiMachine Picture / Diagram Function and Application Machine OperationArabella PASAHOLÎncă nu există evaluări

- Machine Key Features: Function Form FITDocument8 paginiMachine Key Features: Function Form FITPablo Valenzuela ArredondoÎncă nu există evaluări

- Turning Methods & Machines: Upcoming Chapters Metal RemovalDocument8 paginiTurning Methods & Machines: Upcoming Chapters Metal RemovalburakÎncă nu există evaluări

- Jigs and FixturesDocument26 paginiJigs and Fixturesjineesha p jÎncă nu există evaluări

- EDF CatalogDocument20 paginiEDF Catalogbitconcepts9781Încă nu există evaluări

- Group 3 - Machine Shop ToolsDocument16 paginiGroup 3 - Machine Shop ToolsAljohn NanezÎncă nu există evaluări

- Standard Chucking MechanismsDocument28 paginiStandard Chucking Mechanismscalidad_bogotaÎncă nu există evaluări

- Drilling MachinesDocument68 paginiDrilling MachinesDeenaKriShnanÎncă nu există evaluări

- UMC SystemScaffoldingDocument3 paginiUMC SystemScaffoldingSayed AbbasÎncă nu există evaluări

- Descriptions of Tools in InmatproDocument6 paginiDescriptions of Tools in InmatproArabella PASAHOLÎncă nu există evaluări

- The Chuck Stops Here: Machinist's CornerDocument3 paginiThe Chuck Stops Here: Machinist's Cornerjotajo2009Încă nu există evaluări

- REVIEWERDocument7 paginiREVIEWERMathew Louie SullanoÎncă nu există evaluări

- Double E - Safety ChucksDocument6 paginiDouble E - Safety ChucksYanci JhoeÎncă nu există evaluări

- Jigs and FixturesDocument20 paginiJigs and FixturesRenjith RajendraprasadÎncă nu există evaluări

- Lathe MachineDocument5 paginiLathe MachineHuda FahimÎncă nu există evaluări

- Advanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedDocument57 paginiAdvanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedxanderÎncă nu există evaluări

- Boring Head: For P/N 3049, Metric VersionDocument2 paginiBoring Head: For P/N 3049, Metric VersionMd. Alam HasnatÎncă nu există evaluări

- Tecnica-Chirurgica-Abbreviata-NEW-NexGen-LCCK-4in1 NewDocument2 paginiTecnica-Chirurgica-Abbreviata-NEW-NexGen-LCCK-4in1 NewFilip starcevicÎncă nu există evaluări

- Design of Gears For Drilling MachineDocument4 paginiDesign of Gears For Drilling MachineVishal KhalkarÎncă nu există evaluări

- Running A Regal 1946 2of2Document34 paginiRunning A Regal 1946 2of2Julien LemayÎncă nu există evaluări

- Double e Safety ChucksDocument6 paginiDouble e Safety Chucksjacobpm2010Încă nu există evaluări

- Tle CSS9 Q3 M6Document13 paginiTle CSS9 Q3 M6caberjhandereugeneÎncă nu există evaluări

- Design and Fabrication of Cam Vice ReportDocument40 paginiDesign and Fabrication of Cam Vice ReportSendhilNathan67% (3)

- ClassnotesforyouDocument50 paginiClassnotesforyouVishnu Mohan M SÎncă nu există evaluări

- Shaper and PlannerDocument11 paginiShaper and PlannerAmman ButtÎncă nu există evaluări

- Manufacturing Processes-1 (131903) : Ch-3 Drilling Machines Meet PatelDocument68 paginiManufacturing Processes-1 (131903) : Ch-3 Drilling Machines Meet PatelPawan Kumar GoyalÎncă nu există evaluări

- Mesas Taktomat - Posições FixasDocument40 paginiMesas Taktomat - Posições FixasvictorsantangeloÎncă nu există evaluări

- Full-Circle Casing Scraper: Instruction Manual 6255Document6 paginiFull-Circle Casing Scraper: Instruction Manual 6255Jubin JacobÎncă nu există evaluări

- 3077-Cutting Keyways in ShaftsDocument1 pagină3077-Cutting Keyways in ShaftsS280RILEYÎncă nu există evaluări

- Buku Ajar 3.2Document8 paginiBuku Ajar 3.2Cynthia Sasmita DewiÎncă nu există evaluări

- Drillingmachines 150429104000 Conversion Gate01 PDFDocument57 paginiDrillingmachines 150429104000 Conversion Gate01 PDFTushar PatelÎncă nu există evaluări

- Stratos 100 200 300 PDFDocument14 paginiStratos 100 200 300 PDFLucian Catalin CalinÎncă nu există evaluări

- R Series Automated Dispensing SystemsDocument2 paginiR Series Automated Dispensing SystemsscribdpinoÎncă nu există evaluări

- TwcbrochureDocument8 paginiTwcbrochurerimenÎncă nu există evaluări

- Sistema de Leva y Seguidor PDFDocument6 paginiSistema de Leva y Seguidor PDFMiguel Angel GarcíaÎncă nu există evaluări

- Circuit Analysis 4Document1 paginăCircuit Analysis 4Miguel Angel GarcíaÎncă nu există evaluări

- Circuit AnalysisDocument1 paginăCircuit AnalysisMiguel Angel GarcíaÎncă nu există evaluări

- Circuit Analysis 2Document1 paginăCircuit Analysis 2Miguel Angel GarcíaÎncă nu există evaluări

- Somta Drill Sizes For Tapping PDFDocument1 paginăSomta Drill Sizes For Tapping PDFabhinishane100% (1)

- Lectura Sistemas y Elementos de UniónDocument18 paginiLectura Sistemas y Elementos de UniónMiguel Angel GarcíaÎncă nu există evaluări

- Pat Rapp Engineers Black BookDocument87 paginiPat Rapp Engineers Black BookMiguel Angel García67% (3)

- Programming ActivitiesDocument1 paginăProgramming ActivitiesMiguel Angel GarcíaÎncă nu există evaluări

- Drill Operating Parameters: Cutting Speed Material Cutting SpeedDocument2 paginiDrill Operating Parameters: Cutting Speed Material Cutting SpeedMiguel Angel GarcíaÎncă nu există evaluări

- Sistema de Leva y SeguidorDocument6 paginiSistema de Leva y SeguidorMiguel Angel GarcíaÎncă nu există evaluări

- 17 Micrometers PDFDocument12 pagini17 Micrometers PDFdjuka65Încă nu există evaluări

- Sistemas de Transmisión - CalculosDocument36 paginiSistemas de Transmisión - CalculosMiguel Angel GarcíaÎncă nu există evaluări

- Drill Operating Parameters: Cutting Speed Material Cutting SpeedDocument2 paginiDrill Operating Parameters: Cutting Speed Material Cutting SpeedMiguel Angel GarcíaÎncă nu există evaluări

- Memorama Workholding Devices - Parte2Document1 paginăMemorama Workholding Devices - Parte2Miguel Angel GarcíaÎncă nu există evaluări

- 1-2-3 BLOCKS: 1 Parallel After GrindingDocument5 pagini1-2-3 BLOCKS: 1 Parallel After GrindingMiguel Angel GarcíaÎncă nu există evaluări

- Calculo Motor A PasosDocument23 paginiCalculo Motor A PasosMiguel Angel GarcíaÎncă nu există evaluări

- Flange Template ProcedureDocument1 paginăFlange Template ProcedureMiguel Angel GarcíaÎncă nu există evaluări

- Tipos de Esfuerzos Con Apuntes1Document20 paginiTipos de Esfuerzos Con Apuntes1Miguel Angel GarcíaÎncă nu există evaluări

- Props Mecs Mats Clase090519 AnotacionesDocument14 paginiProps Mecs Mats Clase090519 AnotacionesMiguel Angel GarcíaÎncă nu există evaluări

- Oxyfuel Cutting PracticeDocument10 paginiOxyfuel Cutting PracticeMiguel Angel GarcíaÎncă nu există evaluări

- CON EDML 039 Work Holding DeviceDocument16 paginiCON EDML 039 Work Holding DeviceÂvï JâísÎncă nu există evaluări

- GU Pipette Quick Check ENDocument20 paginiGU Pipette Quick Check ENCeren Alim DavutluoğluÎncă nu există evaluări

- Precast Capping Beam Formers DatasheetDocument2 paginiPrecast Capping Beam Formers Datasheetsantoshgpr100% (1)

- A Primer On Spray Drying Chemical Engineering Nov09Document7 paginiA Primer On Spray Drying Chemical Engineering Nov09Hikmah Triana HadiÎncă nu există evaluări

- PLC Programming Case Study For Hydraulic PositioniDocument6 paginiPLC Programming Case Study For Hydraulic PositioniDicky DarmawanÎncă nu există evaluări

- Rashid Ch10 ImagesDocument47 paginiRashid Ch10 ImagesAtiq Ur RehmanÎncă nu există evaluări

- Instrument and Control Designer Rev01Document5 paginiInstrument and Control Designer Rev01masilamaniÎncă nu există evaluări

- PD 8010 2 Presentation April 2005 NewDocument40 paginiPD 8010 2 Presentation April 2005 NewSuphi YükselÎncă nu există evaluări

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsDocument46 pagini5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- Textile Shop Management SystemDocument6 paginiTextile Shop Management SystemVedha TechnologiesÎncă nu există evaluări

- Series 3501 & 3503Document4 paginiSeries 3501 & 3503Tim Stubbs100% (2)

- Veritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - SolDocument614 paginiVeritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - Solakkati123Încă nu există evaluări

- Technical Delivery Condition of S500MCDocument4 paginiTechnical Delivery Condition of S500MCdcevipin100% (1)

- fr19 21Document8 paginifr19 21ErmanÎncă nu există evaluări

- Deep Bar and Double Cage 010223Document20 paginiDeep Bar and Double Cage 010223Debankan ChatterjeeÎncă nu există evaluări

- Pmled 6 5K 10a 66Document6 paginiPmled 6 5K 10a 66Eduardo SalgadoÎncă nu există evaluări

- UNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmDocument2 paginiUNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmArjun BhargavaÎncă nu există evaluări

- A DEH PR-2011-0149-GB MultiMAXX-HN DF R6-10-2015 150dpi PDFDocument120 paginiA DEH PR-2011-0149-GB MultiMAXX-HN DF R6-10-2015 150dpi PDFConstantin294Încă nu există evaluări

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Document3 paginiOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaÎncă nu există evaluări

- Raymond Scott - Cindy ElectroniumDocument2 paginiRaymond Scott - Cindy ElectroniumJen HillÎncă nu există evaluări

- Expansion Joint PDFDocument7 paginiExpansion Joint PDFPramit RajKarnikarÎncă nu există evaluări

- HPSIM Command Line InterfaceDocument107 paginiHPSIM Command Line Interfacegverma80Încă nu există evaluări

- Paver BlockDocument16 paginiPaver BlockRavinder Singh100% (1)