Documente Academic

Documente Profesional

Documente Cultură

Risk Assessment For Material Handling PDF

Încărcat de

Hein Sithu Kyaw0 evaluări0% au considerat acest document util (0 voturi)

110 vizualizări15 paginiTitlu original

305716399-Risk-Assessment-for-Material-Handling.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

110 vizualizări15 paginiRisk Assessment For Material Handling PDF

Încărcat de

Hein Sithu KyawDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 15

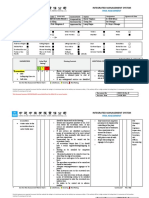

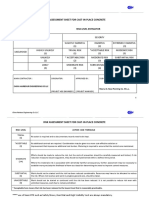

MATERIAL HANDLING RISK ASSESSMENT

RA DESCRIPTION Material Handling

PROJECT NDIA Pasenger Terminal

LOCATION CP 18 Work Areas DATE: 23-02-12

RISK ASSESSMENT TEAM SITE REPRESENTATION

NAME DESIGNATION SIGNATURE NAME DESIGNATION SIGNATURE

Risk Assessment for material handling

Page 1 of 15 Date: 20/09/2012

Rev No.: Revision 0

DESIGNATION INITIALS & SURNAME APPROVED COMMENTS

R/A ORIGINATOR Goutam Sarkar N/A

CONTRACT MANAGER YES NO

SAFETY MANAGER Rahman Majumder YES NO

OBI REPRESENTATIVE. YES NO

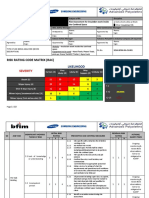

SEVERITY CONSEQUENCE RATING SEVERITY OUTCOME

CATASTROPHIC 5 10 15 20 25 5 FATALITY

CRITICAL 4 8 12 16 20 4 MAJOR INJURY / ILLNESS

SERIOUS 3 6 9 12 15 3 SERIOUS INJURY / ILLNESS

MEDIUM 2 4 6 8 10 2 MINOR INJURY / ILLNESS

MINIMAL 1 2 3 4 5 1 NONE OR SMALL FA

1 2 3 4 5

LIKELYHOOD

IF NOT VERY ALMOST

CONTROLLED UNLIKELY LIKELY VERY LIKELY

UNLIKELY CERTAIN

RISK RANKING (RR) / PRIORITY FACTOR RATING

SCORE 1-2 POTENTIALLY MINOR / ACTION TO BE TAKEN WITHIN 7 DAYS L

SCORE 3 -6 POTENTIALLY SERIOUS / ACTION TO BE TAKEN WITHIN 48 HRS M

SCORE 7 - 10 POTENTIALLY MAJOR / ACTION TO BE TAKEN WITHIN 12 HRS H

SCORE 11 - 25 POTENTIALLY CATASTROPHIC / ACTION NEEDED IMMEDIATELY H+

Risk Assessment for material handling

Page 2 of 15 Date: 20/09/2012

Rev No.: Revision 0

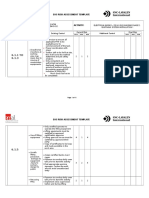

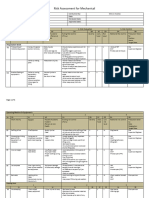

RISK ASSESSMENT

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

1. Off loading of glass Hit by plant and equipment 3 4 12 HS STARRT briefing 2 4 8

crates from flatbed Causing injury Reverse alarm

trailer for storing in Banksman

warehouse Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Load failure 3 5 15 HS STARRT 2 5 10

Causing injury and/or Inspection of lifting equipments

property damage Lift plan

Toppling of forklift/ Competent rigger

telescopic handler Third party certified operators

Poor visiblity of operator Exclusion zone

Broken Crate Banksman

Adequately secured load

Suitable weather condition (wind)

Leveled and firm ground surface

Supervisor and operator must know the weight of the load

before unloading

Broken crates to be additionally supported before

unloading

2. Offloading glass Tilting and falling of glass 3 4 12 HS STARRT

panels from broken crate Adequate and competant supervision

crates Sliding glass panels Use pnumetic glass sucker to handle glasses

Stabilizing crates by additional supports

Secure glassess

Group handling

Eqipment daily check

Inspection of glass suckers by competant person

3. Transportation Load failure 3 4 12 HS STARRT 2 4 8

(including loading Sliding and falling of crates Inspection of lifting equipments

and offloading) of

Risk Assessment for material handling

Page 3 of 15 Date: 20/09/2012

Rev No.: Revision 0

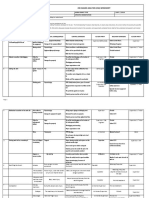

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

glass crates to site Lift plan

Competent rigger

Third party certified operators

Exclusion zone

Banksman

Restraining of load

Maintain load capacity of boom truck

Adequate and competent supervision (if training required

it should be covered)

4. Opening of glass Fall of crates & fall 3 5 15 HS STARRT briefing 2 5 10

crates in warehouse of glass Placement of glass crates on firm and level ground

for segregation of Incline glass crates at an angle (at least 5 degree)

glass opposite to the side being opened

Structure to support against the inclination

Trained and competent workers

Adequate supervision

Use of glass sucker

Appropriate PPE

Place on ‘A’ Frame for storage

5. Transportation of Fall of glass 3 4 12 HS Load glass secured on A frame 2 4 8

segregated glass to Third party cerfication required for A frame if being

site and offloading handled by crane

Exclusion zone

Competent Rigger / Banksman

Lift plan

6. Transportation of Manual task 3 3 9 HS STARRT 2 3 6

segregated glass to Uneven/ Assessmnet of load prior to work

work location obstructed surface Assessment of movement surface prior to work

(manual) Slip from hand Group / machanical shifting if required

PPE

7. Storage of loose Fall of glass 3 3 9 HS Locate store area away from work activity 2 2 4

glasses on site Glass hit by Store segregated glass only on A frame

moving plant and Secure storage area with barricade

equipment Place warning signage

Risk Assessment for material handling

Page 4 of 15 Date: 20/09/2012

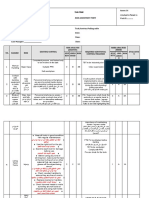

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

Glass hit by

pedestrians

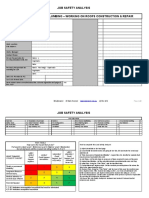

8. Off loading of Hit by plant and 3 5 15 HS STARRT 2 5 10

gypsum board equipment Align container base with the ramp

bundle for storage Load failure Competent forklift operator

in laydown Banksman

Reverse alarm & light

Daily checklist completed ( equipment)

Use lifting equipment and accessories appropriate for

weight been lifted

9. Transportation of Load failure 3 4 12 HS STARRT briefing 2 4 8

gypsum boards to Hit by plant and Reverse alarm

site by boom truck equipment Banksman

and offloading by Exclusion zone (authorised persons only)

forklift Competent workforce

Adequate supervision

Restraining of load

Maintain load capacity of boom truck

Adequate and competent supervision (if training required

it should be covered)

Inspection of lifting equipments

Lift plan

10. Transportation of Toppling of trolley 3 4 12 HS STARRT 2 4 8

gyspum boards to Trolley run away Assessment of the load and weight

work location by Hit permanent Use of appropriate trolley

trolley structure Assessment of load balance

Pinch points Assessment of material shiftment route

Uneven surface Adequate number of personal

Interfce with Appropriate PPE

electrical cables

Watchman

11. Off loading Hit by plant and 3 4 12 HS STARRT briefing 2 4 8

Risk Assessment for material handling

Page 5 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

ceiling/roof panels equipment Reverse alarm

from Load failure Banksman

container/flatbed Exclusion zone (authorised persons only)

truck for storage in Competent workforce

loaydown Adequate supervision

Restraining of load

Maintain load capacity of boom truck

Adequate and competent supervision (if training required

it should be covered)

Inspection of lifting equipments

Lift plan

12. Transportation of Load failure 3 4 12 HS STARRT 2 4 8

ceiling/roof panels Sliding and falling of panels Inspection of lifting equipments

to site Lift plan

Competent rigger

Third party certified operators

Exclusion zone

Banksman

Restraining of load

Adequate and competent supervision (if training required

it should be covered)

13. Transportation of Manual task 3 3 9 HS STARRT 2 3 6

ceiling/roof panels Uneven/ Assessmnet of load prior to work

to work location obstructed surface Assessment of movement surface prior to work

(manually) Group / machanical lifting if required

PPE

14. Off loading of Hit by plant and 3 4 12 HS STARRT 2 4 8

stones/tiles from equipment Align container base with the ramp

container Load failure Competent forklift operator

Banksman

Reverse alarm & light

Exclusion zone

Risk Assessment for material handling

Page 6 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

Daily checklist completed ( equipment)

15. Transportation of Load failure 3 5 15 HS STARRT briefing 2 5 10

stones/tiles to site Hit by plant and Reverse alarm

by boom truck and equipment Banksman

offloading by forklift Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Restraining of load

Maintain load capacity of boom truck

Inspection of lifting equipments

Lift plan

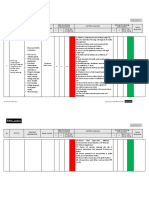

16. Transportation of Sliding of load 3 4 12 HS STARRT 2 4 8

stones / tiles to Failure of hydrolic Assessment of the load and weight

work locations by control Use of appropriate jack pallet / trolley

jack pallets Uneven / Assessment of load balance

obstructed shifting Assessment of material shifting route

routes Adequate number of personal

Run away from Appropriate PPE

ramp

Watchman

Wooden angle stand for handling , transporation &

storage of tiles & stones

Scheduled maintainance of equipment

17. Off loading of steel Fall from height ( 3 5 15 HS STARRT 2 5 10

frames/GI channels from top of Use of secondary fall protection

from open top container) Use of secured platform (Podium ladder) for opening

container/ flatbed Hit by plant and container top

trailer equipment Banksman

Load failure Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Appropriate and certified lifting equipment

18. Transportation ( Load failure 3 4 12 HS STARRT briefing 2 4 8

including loading Hit by plant and Reverse alarm

Risk Assessment for material handling

Page 7 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

and off loading by equipment Banksman

forklift) of steel Exclusion zone (authorised persons only)

frames/ GI Competent workforce

channhels to site by Adequate supervision

boom truck Restraining of load

Maintain load capacity of boom truck

Inspection of lifting equipments

Lift plan

19. Transportation of Toppling of trolley 3 4 12 HS STARRT 2 4 8

steel frames/GI Trolley run away Assessment of the load and weight

channhels to work Hit permanent Use of appropriate trolley

location structure Secured load by tying to the trolley

Pinch points Assessment of load balance

Uneven surface Assessment of material shifting route

Interfce with Adequate number of personal

electrical cables

Appropriate PPE

Watchman

20. Transportation of Sharpe corners 3 3 9 HS STARRT 2 3 6

ducts to site / work Manual lifting Assessment of load and weight

location Appropriate PPE including anti abrasive gloves

Use of group lifting

21. Off loading of Hit by plant and 3 4 12 HS STARRT 2 4 8

conduit pipes from equipment Use of secondary fall protection

container/flatbed Load failure Use of secured ladder (podium)

trailer Banksman

Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Appropriate and certified lifting equipments

Risk Assessment for material handling

Page 8 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

22. Transaportation and Load failure 3 4 12 HS STARRT briefing 2 4 8

offloading of conduit Hit by plant and Reverse alarm

pipes to site equipment Banksman

Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Maintain load capacity of boom truck

Inspection of lifting equipments

Lift plan

23. Transportation of Sharpe edge 3 3 9 HS STARRT 2 3 6

conduit pipes to Manual lifting Assessment of load and weight

work location Appropriate PPE including anti abrasive gloves

(manually) Use of group lifting

24. Off loading cables Load failure 3 4 12 HS STARRT briefing 2 4 8

from flatbed trailer Hit by plant and Banksman / Rigger

by crane equipment Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Maintain load capacity

Inspection of lifting equipments

Lift plan

25. Transportation of Load failure 3 4 12 HS STARRT briefing 2 4 8

cables to site and Hit by plant and Reverse alarm

offloading by Boom equipment Banksman

truck Competent workforce

Adequate supervision

Maintain load capacity of boom truck

Inspection of lifting equipments

Lift plan

26. Transportation of Uncontroled load 3 3 9 HS STARRT 2 3 6

cables to work Hit pedestrian or Isolation of the area by barricading

Risk Assessment for material handling

Page 9 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

location by rolling of structures Watchman

cable drum Pinch point Controlled group lifting

Manual task Trained and competent manpower

PPE

27. Off loading panel Load failure 3 4 12 HS STARRT briefing 2 4 8

boards Hit by plant and Reverse alarm

equipment Banksman

Competent workforce

Adequate supervision

Maintain load capacity of boom truck

Inspection of lifting equipments

Lift plan

28. Transportation of Sliding of load 3 4 12 HS STARRT 2 4 8

panel boards to Failure of hydraulic Assessment of the load and weight

work location by control Use of appropriate jack pallet / trolley

jack pallet Uneven / Assessment of load balance

obstructed shifting Assessment of material shifting route

routes Adequate number of personnel

Run away from Appropriate PPE

ramp

Watchman

Scheduled maintainance of equipment

29. Off loading fire Load failure 3 4 12 EHS STARRT briefing 2 4 8

proofing materials Hit by plant and Reverse alarm

by forklift equipment Banksman

/telehandler Competent workforce

Adequate supervision

Maintain load capacity

Exclusion zone

MSDS

Spill kit available

Inspection of lifting equipment

Risk Assessment for material handling

Page 10 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

30. Transportation of Load failure 3 3 9 HS STARRT briefing 2 3 6

fire proofing Hit by plant and Banksman

materials to site by equipment Competent workforce

truck Adequate supervision

Inspection of lifting equipment

31. Transportation of Sliding of load 3 4 12 EHS STARRT 2 4 8

fire proofing Failure of hydrolic Assessment of the load and weight

materials to work control Use of appropriate jack pallet / trolley

location Uneven / Assessment of load balance

obstructed shifting Assessment of material shifting route

routes MSDS

Run away from Spill kit available

ramp

Adequate number of personal

Appropriate PPE

Watchman

Scheduled maintainance of equipment

32. Loading of terrazzo Load failure 3 3 9 HS STARRT briefing 2 3 6

sand bags on to Hit by plant and Banksman

boom truck and equipment Competent workforce

offloading of site Adequate supervision

Inspection of lifting equipment

33. Transportation of Load failure 3 5 15 HS STARRT briefing 2 5 10

terrazzo sand bags Hit by plant and Banksman / Rigger

to work location by equipment Competent workforce

crane Adequate supervision

Inspection of lifting equipment

Lift plan

Completion of daily equipment checklist

Exclusion zone

Risk Assessment for material handling

Page 11 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

34. Transportation of Load failure / 3 5 15 EHS STARRT briefing 2 5 10

terrazzo chemical displacement Inspection of pallets integrity

drums to site by Hit by plant and Securing load with straps

truck and offloading equipment Banksman

by forklift Competent workforce

Adequate supervision

Inspection of lifting equipment

MSDS

Spill kit

35. Transportation of Sliding of load 3 4 12 EHS STARRT 2 4 8

terrazzo chemical Failure of hydraulic Assessment of the load and weight

drums to onsite control Use of appropriate jack pallet / trolley

storage area/ work Uneven / Assessment of load balance

location by jack obstructed shifting Assessment of material shiftment route

pallet routes Adequate number of personal

Run away from Appropriate PPE

ramp

Watchman

Wooden angle stand for handling , transporation &

storage of tiles & stones

MSDS & spill kit

Scheduled maintainance of equipment

36. Offloading of water Load failure 3 4 12 HS STARRT briefing 2 4 8

proofing sheets Hit by plant and Reverse alarm

equipment Banksman

Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Maintain load capacity

Inspection of lifting equipments

Risk Assessment for material handling

Page 12 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

37. Transportation of Toppling of trolley 3 3 9 HS STARRT 2 3 6

water proofing Trolley run away Assessment of the load and weight

sheets to work Hit permanent Use of appropriate trolley

location structure Secured load by tying to the trolley

Uneven surface Assessment of load balance

Interfce with Assessment of material shifting route

electrical cables Adequate number of personal

Appropriate PPE

Watchman

38. Offloading conveyor Load failure 3 5 15 HS STARRT briefing 2 5 10

parts Hit by plant and Reverse alarm

equipment Banksman

Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Maintain load capacity

Inspection of lifting equipments

39. Transporting Load failure 3 5 15 HS STARRT briefing 2 5 10

conveyor parts to Hit by plant and Banksman/ Rigger

site by flatbed trailer equipment Exclusion zone (authorised persons only)

and offloading by Competent workforce

crane Adequate supervision

Maintain load capacity

Inspection of lifting equipments

Lift plan

40. Transportation of Load failure 3 4 12 HS STARRT briefing 2 4 8

conveyor parts to Hit by plant and Reverse alarm

work location by equipment Banksman

forklift / pallet trolley Exclusion zone (authorised persons only)

Risk Assessment for material handling

Page 13 of 15 Date: 20/09/2012

Rev No.: Revision 0

Worst EH Controlled

No TASKS / ACTIVITY HAZARD AND case S PREVENTATIVE & CONTROL MEASURES Rating

RISK IDENTIFICATION Rating L S R

L S R

Competent workforce

Adequate supervision

Maintain load capacity

Appropriate PPE

Inspection of lifting equipments

41. Off loading PCA Load failure 3 5 15 HS STARRT briefing 2 5 10

units Hit by plant and Banksman

equipment Exclusion zone (authorised persons only)

Competent workforce

Adequate supervision

Maintain load capacity

Inspection of lifting equipments

Lift plan

42. Shifting PCA units Toppling of trolley 3 4 12 HS STARRT

to work location Trolley run away Assessment of the load and weight

Hit permanent Use of appropriate trolley

structure Secured load by tying to the trolley

Uneven surface Assessment of load balance

Assessment of material shifting route

Adequate number of personal

Appropriate PPE

Watchman

43.

Risk Assessment for material handling

Page 14 of 15 Date: 20/09/2012

Rev No.: Revision 0

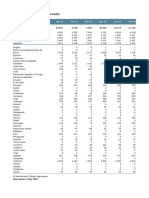

RISK ASSESSMENT COMMUNICATIONS FORM.

I, THE UNDERSIGNED HEREBY ACKNOWLEDGE THAT THIS RISK ASSESSMENT HAS BEEN DISCUSSED WITH ME AND THAT I UNDERSTAND THE

CONTENTS AND THE RISKS INVOLVED IN THE TASK TO BE PERFORMED. I HAVE ALSO BEEN INSTRUCTED ON THE SAFE METHODS TO

PERFORM THIS TASK.

NAME CO. NO SIGNATURE NAME CO. NO SIGNATURE

Risk Assessment for material handling

Page 15 of 15 Date: 20/09/2012

Rev No.: Revision 0

S-ar putea să vă placă și

- Electrical WorksDocument3 paginiElectrical WorksSaleem Basha50% (2)

- Laying of Road Crossing Duct For Irrigation WorksDocument9 paginiLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 paginiIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisÎncă nu există evaluări

- HIRA Cage Ladder & Life Line Installation01Document3 paginiHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- Installation of Diesel GeneratorDocument12 paginiInstallation of Diesel Generatoramal100% (1)

- Risk Assessment of Fabrication, Welding, Cutting WorkDocument7 paginiRisk Assessment of Fabrication, Welding, Cutting WorkAbdul MujeebÎncă nu există evaluări

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 paginiRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- Hydro Static Test: Risk AssessmentDocument10 paginiHydro Static Test: Risk Assessmentmohammed a hseÎncă nu există evaluări

- AHA Conduit and Wiring Installation - TEMPLATEDocument7 paginiAHA Conduit and Wiring Installation - TEMPLATEKCV Coretech100% (1)

- AHA - Working On Slope RoofDocument2 paginiAHA - Working On Slope RoofTopsun EnergyÎncă nu există evaluări

- Task /activity: Installation of Abseil HooksDocument10 paginiTask /activity: Installation of Abseil HooksfrancisbautistaÎncă nu există evaluări

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 paginiRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayÎncă nu există evaluări

- Installation of Electrical Earthing System REV 2Document15 paginiInstallation of Electrical Earthing System REV 2amal100% (1)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 paginiTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreÎncă nu există evaluări

- RA - Plumbing Works Rev. BDocument8 paginiRA - Plumbing Works Rev. BResearcherÎncă nu există evaluări

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pagini2.8c Risk Assessment Rev.02 - BlankShafie ZubierÎncă nu există evaluări

- Brazing (Oxygen and Acetylene)Document6 paginiBrazing (Oxygen and Acetylene)My Zain100% (1)

- Risk Assessment RevisionDocument6 paginiRisk Assessment RevisionAneesh100% (1)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pagini012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanÎncă nu există evaluări

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 paginiTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubÎncă nu există evaluări

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 paginiLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINÎncă nu există evaluări

- Job Hazard Analysis (Jha) WorksheetDocument4 paginiJob Hazard Analysis (Jha) WorksheetSamer AlsumaryÎncă nu există evaluări

- Risk Assessment Relocation Overhead LineDocument5 paginiRisk Assessment Relocation Overhead Lineghada gattouchÎncă nu există evaluări

- 2 - Pulling CablesDocument5 pagini2 - Pulling CablesAhmed KhaledÎncă nu există evaluări

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pagini13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 paginiCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoÎncă nu există evaluări

- RA - Welding Grinding & Cutting WorksDocument5 paginiRA - Welding Grinding & Cutting WorksResearcherÎncă nu există evaluări

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 paginiRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanÎncă nu există evaluări

- Risk Assessment For Mechanical: Preparation WorkDocument3 paginiRisk Assessment For Mechanical: Preparation Workahmedalderbi801Încă nu există evaluări

- Risk Assessment ProjectDocument4 paginiRisk Assessment Projectحموده فراس عبيداتÎncă nu există evaluări

- Risk Assessment For External Façade & Canopies CleaningDocument6 paginiRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 paginiJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanÎncă nu există evaluări

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 paginiRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuÎncă nu există evaluări

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 paginăRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig740% (1)

- Precast Erection JSWDocument6 paginiPrecast Erection JSWPrabhakaran GurunathanÎncă nu există evaluări

- Job Safety Analysis: M Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument2 paginiJob Safety Analysis: M Risk Assessment Code (RAC) Matrix Severity ProbabilityShunmuganathanÎncă nu există evaluări

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 paginiRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Al Door&WindowDocument1 paginăAl Door&WindowChandruÎncă nu există evaluări

- Brick Masonry - EHS Risk AssessmentDocument2 paginiBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Risk Assessment For Trial Pit Excavation-RevDocument15 paginiRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandÎncă nu există evaluări

- AHA Roofing SystemDocument8 paginiAHA Roofing SystemLawrence adeleke Omisakin100% (1)

- Plant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingDocument11 paginiPlant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingRAMAÎncă nu există evaluări

- Coshh Risk Assessemnt PDFDocument29 paginiCoshh Risk Assessemnt PDFerwinÎncă nu există evaluări

- Risk Assessment DrivingDocument3 paginiRisk Assessment Drivingghada gattouch100% (2)

- 10 - Updated - LV Cable Installation and TerminationDocument22 pagini10 - Updated - LV Cable Installation and TerminationShah Muzzamil100% (1)

- Job Hazards AnalysisDocument3 paginiJob Hazards AnalysismohamedÎncă nu există evaluări

- Cast-In Place Concrete - Risk Assessment SheetDocument3 paginiCast-In Place Concrete - Risk Assessment SheetYash SharmaÎncă nu există evaluări

- Risk AssessmentDocument3 paginiRisk AssessmentSam HodgsonÎncă nu există evaluări

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 paginiRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleÎncă nu există evaluări

- 011 Duct Lifter SWMSDocument2 pagini011 Duct Lifter SWMSJ JohnsonÎncă nu există evaluări

- Risk Assessment - T&C For Medium Voltage SwitchgearDocument8 paginiRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad Irfan0% (1)

- Welding SopDocument6 paginiWelding SopNikhil VaidyaÎncă nu există evaluări

- Risk Assessment For .TESTING AND COMMISSIONING OF LV CABLEDocument19 paginiRisk Assessment For .TESTING AND COMMISSIONING OF LV CABLEarun kurlan100% (3)

- Risk Assessment For Earth Works (Excavation Back Filling) Require...Document13 paginiRisk Assessment For Earth Works (Excavation Back Filling) Require...khalid khan100% (1)

- Risk Assessment Record Activity: Installation ofDocument17 paginiRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- 5-Star Safety and Health Management SystemDocument5 pagini5-Star Safety and Health Management SystemSn Ahsan100% (1)

- Backfilling, Leveling RISK ASSESSMENTDocument6 paginiBackfilling, Leveling RISK ASSESSMENTVimal ViswanathÎncă nu există evaluări

- Epoxy PaintingDocument4 paginiEpoxy PaintingSaleem BashaÎncă nu există evaluări

- Screeding WorksDocument2 paginiScreeding WorksSaleem Basha100% (1)

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 paginăRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- You Exec - Pricing Strategies FreeDocument49 paginiYou Exec - Pricing Strategies FreeHein Sithu KyawÎncă nu există evaluări

- Monthly Data of Last Six Month ExportDocument1 paginăMonthly Data of Last Six Month ExportHein Sithu KyawÎncă nu există evaluări

- You Exec - Pricing Strategies Part 2 FreeDocument15 paginiYou Exec - Pricing Strategies Part 2 FreeHein Sithu KyawÎncă nu există evaluări

- Montthly Data of Last Six Month ImportDocument1 paginăMontthly Data of Last Six Month ImportHein Sithu KyawÎncă nu există evaluări

- Preview NCDT 2020 ReportDocument21 paginiPreview NCDT 2020 ReportHein Sithu KyawÎncă nu există evaluări

- NDA SampleDocument5 paginiNDA SampleHein Sithu KyawÎncă nu există evaluări

- Dock Leveler From EVERLIFT 20180713Document1 paginăDock Leveler From EVERLIFT 20180713Hein Sithu KyawÎncă nu există evaluări

- Intraco PalletDocument25 paginiIntraco PalletHein Sithu KyawÎncă nu există evaluări

- Aisle MasterDocument9 paginiAisle MasterHein Sithu KyawÎncă nu există evaluări

- EP T8 Diesel ForkliftsDocument7 paginiEP T8 Diesel ForkliftsHein Sithu KyawÎncă nu există evaluări

- ASRSDocument24 paginiASRSHein Sithu KyawÎncă nu există evaluări

- IsaqbDocument26 paginiIsaqbSyed HussainiÎncă nu există evaluări

- Yuasa Technical Data Sheet: The World's Leading Battery ManufacturerDocument1 paginăYuasa Technical Data Sheet: The World's Leading Battery ManufacturerAshraf Sayed ShabaanÎncă nu există evaluări

- Fujikura FSM40S Service Manual PDFDocument67 paginiFujikura FSM40S Service Manual PDFAndrey Nikollas BuckoÎncă nu există evaluări

- University of Central Punjab: Object Oriented ProgrammingDocument3 paginiUniversity of Central Punjab: Object Oriented ProgrammingChoudhary MuneebÎncă nu există evaluări

- Sherman Notes PDFDocument213 paginiSherman Notes PDFAbdul Hamid Bhatti100% (1)

- Spring 2010 MidTerm OPKST CS101 Bc100200572Document6 paginiSpring 2010 MidTerm OPKST CS101 Bc100200572cs619finalproject.comÎncă nu există evaluări

- Land SurveyingDocument174 paginiLand SurveyingArifulmakrif Hailee100% (2)

- Links of XII Physics Investigatory Project Allowtment 2Document3 paginiLinks of XII Physics Investigatory Project Allowtment 2yashtomarsoop07Încă nu există evaluări

- Manual of Avionics PDFDocument300 paginiManual of Avionics PDFJhony BhatÎncă nu există evaluări

- The Child and Adolescent Learners and Learning PrinciplesDocument8 paginiThe Child and Adolescent Learners and Learning PrinciplesAragon KhailÎncă nu există evaluări

- BSBPMG632 Manage Program RiskDocument221 paginiBSBPMG632 Manage Program RiskgurpreetÎncă nu există evaluări

- GRADE 8 3rd Quarter DLP in EnglishDocument484 paginiGRADE 8 3rd Quarter DLP in EnglishJulius Salas100% (4)

- Daftar Ebook Tentang LeanDocument2 paginiDaftar Ebook Tentang LeanChilmar Buchari100% (1)

- 5 Levels of Leadership AnswersDocument4 pagini5 Levels of Leadership Answersk98hk8wnnbÎncă nu există evaluări

- 1.vedantu - Class 3 To 5 - BrochureDocument1 pagină1.vedantu - Class 3 To 5 - BrochureDeepak SharmaÎncă nu există evaluări

- Getting Good Grades in School Is What Kids Are Supposed To Be Doing.Document6 paginiGetting Good Grades in School Is What Kids Are Supposed To Be Doing.The QUEENÎncă nu există evaluări

- Winsome Hin-Shin LEE CV (Feb 2017)Document5 paginiWinsome Hin-Shin LEE CV (Feb 2017)Winsome LeeÎncă nu există evaluări

- Behaviour Modification Testbank PDFDocument118 paginiBehaviour Modification Testbank PDFjade tagabÎncă nu există evaluări

- Dubai Holding FactsheetDocument2 paginiDubai Holding FactsheetHarley soulÎncă nu există evaluări

- Etrade Bank-StatementDocument5 paginiEtrade Bank-StatementMark Galanty100% (4)

- The Child's Learning of English Morphology: WORDDocument29 paginiThe Child's Learning of English Morphology: WORDCatnis TomÎncă nu există evaluări

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Document32 paginiMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriÎncă nu există evaluări

- Komatsu Wheel Loaders Wa250pz 5 Shop ManualDocument20 paginiKomatsu Wheel Loaders Wa250pz 5 Shop Manualmarcia100% (48)

- So You Want To Have Your Own Cosmetics BrandDocument3 paginiSo You Want To Have Your Own Cosmetics BrandCarlosÎncă nu există evaluări

- 747Document12 pagini747GurdevBaines100% (3)

- Approaches To Curriculum DesigningDocument20 paginiApproaches To Curriculum DesigningCristel CatapangÎncă nu există evaluări

- SRMDocument4 paginiSRMinocente333Încă nu există evaluări

- CC Course IntroDocument11 paginiCC Course IntroSaid TahatÎncă nu există evaluări

- Pro Tester ManualDocument49 paginiPro Tester ManualRobson AlencarÎncă nu există evaluări

- Ped 5 FTDocument39 paginiPed 5 FTJoy Grace TablanteÎncă nu există evaluări