Documente Academic

Documente Profesional

Documente Cultură

Documentation

Încărcat de

PetruDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Documentation

Încărcat de

PetruDrepturi de autor:

Formate disponibile

CLUTCH FITTING

TECHNICAL NOTE

1

1 After disassembling the gearbox from the engine :

20 Nm

3 Fasten the flywheel:

1. Check engine crankshaft seal: Verify that there is not oil 1. Position carfully the new flywheel Valeo on

contaminating the flywheel. In case of presence of oil the crankshaft center and tightenning the

leack, after remove the flywheel, change the crankshaft bolts M10x1 mm with a progessive torque

seal. following a star sequence. Avoiding to apply

excessive torque on this one. Tigtenning

2. Check gearbox input shaft splines checking that there is torque: 110Nm

not damage or show excessive wear along the spline

length.

3. Block the flywheel in rotation and remove the flywheel

fixing bolts. 4 Fasten the cluth:

4. Check the gear box input shaft seal: verify that there is

not oil comming from the gearbox. In case of presence of 2. Position the driven plate in the flywheel

oil repair the gearbox changing the input shaft seal. thanks to the centering tool (to see photo)

3. Fasten the cover assy centering it with the

5. Check the hydraulic bearing: pins and hand thightening 3 screws at

120º and checking that the driven plate

a. Check that the bearing is well rotating under axial remains stable and well centered with the

hand load: smooth rotation without hard points. centering tool.

110Nm 4. Tighten smoothly each screw respecting a

b. Check the wear on the bearing contact ring with

the diaphragm. The contact marks have to be not star-like sequence as for the thightening

excessive (less than 0,5mm) of the flywheel. The diaphragm fingers

c. Check that there is not oil comming from the have to move as uniform as possible.

interior of the hydraulic bearing Repeat the complete sequence

approximately 3 times. Use screws

6. Check that the push road at receiver cylinder can move Use the appropriate device to assembly M7x1 mm.

sliding smooth when is pushed and it doesn’t leak oil. and disassembly the gearbox. The operator 5. Complete the fastening applying a torque

never must support the weight of gearbox. of 20Nm thanks to a torque wrench

respecting the previous sequence.

5 Re-assemble the gearbox

1. Check that the block pins are existing and that

they are not damaged.

2. Position the gearbox coaxially with the engine

crankshaft, supporting the gearbox weight with the

6 After the assembly

appropriate tools.

3. Introduce the gearbox input shaft into the driven Verify that the clutch is well working:

plate hub spline.

2 Prepare the clutch for assembly :

Apply a small quantity of grease

Centering tool

4. Take care that the input shaft is introduced without

shock. If necessary rotate the crankshaft to make

easier the input shaft fitting.

- Disengage and reengage the clutch shifting each gear

ratio (including reverse)

- Check that there is not abnormal noise when

engaging and disengaging operation

Avoid that the weight of the gearbox be supported by the - In neutral speed up to 4.000 rpm and check that

1. Apply a small quantity of grease in the hub splines at approximatly 5 mm of the hub extremity driven plate of the clutch during the assembly. there’s not abnormal vibration or noises.

2. Position the driven plate in the flywheel thanks to the centering tool. - Check there is not abnormal clutch sliding in driving

3. Fasten the cover assy centering it with the pins and hand thightening 3 screws at 120º and checking that the 5. Check that the gearbox is in full contact with the conditions.

driven plate remains stable and well centered with the centering tool. engine block and that the centering pins are well

4. Use clutchl bolts (M7X1) P/N 699311Q0 fitted.

6. Finally fasten the gearbox to the engine block NT-V110012

tightening the screws with the appropriate torque. 20/05/2011

S-ar putea să vă placă și

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- Fasten The Flywheel and The ClutchDocument1 paginăFasten The Flywheel and The ClutchPlamenÎncă nu există evaluări

- Shafting, Pulleys, Belting and Rope TransmissionDe la EverandShafting, Pulleys, Belting and Rope TransmissionÎncă nu există evaluări

- Electric Chainsaw: Instruction ManualDocument10 paginiElectric Chainsaw: Instruction Manualshabab_14Încă nu există evaluări

- Chery SQR372 0.8LDocument8 paginiChery SQR372 0.8Lferran_alfonsoÎncă nu există evaluări

- Front Crankshaft SealDocument4 paginiFront Crankshaft Sealcristi cristiÎncă nu există evaluări

- Bracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyDocument2 paginiBracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyHaingÎncă nu există evaluări

- 5G Timing BeltDocument10 pagini5G Timing Beltraúl_palomo_10% (1)

- Sisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Document59 paginiSisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Сергей ПриймакÎncă nu există evaluări

- KONE 3000 TranSys - Part Brake AdjustDocument9 paginiKONE 3000 TranSys - Part Brake Adjustthanggimme.phanÎncă nu există evaluări

- Fiat Barchetta: EngineDocument15 paginiFiat Barchetta: EngineHallex OliveiraÎncă nu există evaluări

- Volvo Penta AQ125A - AQ145A Engine Unit Workshop Manual (En) (38-74)Document37 paginiVolvo Penta AQ125A - AQ145A Engine Unit Workshop Manual (En) (38-74)Edgar MaldonadoÎncă nu există evaluări

- TSE Installation Manual Rev5Document2 paginiTSE Installation Manual Rev5eyya 007Încă nu există evaluări

- Dokumen - Tips - Engine Mechanical DaihatsuDocument33 paginiDokumen - Tips - Engine Mechanical DaihatsuJovie GrohlÎncă nu există evaluări

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine PartsDocument3 paginiHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Partszakki ahmadÎncă nu există evaluări

- 3gr-Fse-Em6-Drive BeltDocument3 pagini3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcÎncă nu există evaluări

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFDocument3 paginiHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFArnold Mhlanga50% (2)

- Timing Manual Galant ST v6!24!1998 2005 PDFDocument8 paginiTiming Manual Galant ST v6!24!1998 2005 PDFArya RamadhanÎncă nu există evaluări

- Mantenimiento de Caja Chery QQ PDFDocument14 paginiMantenimiento de Caja Chery QQ PDFJose FerrerÎncă nu există evaluări

- Techlok PocketguideDocument1 paginăTechlok PocketguideJacobus CalvelageÎncă nu există evaluări

- Engine: Cam TimingDocument86 paginiEngine: Cam TimingXimena Justiniano LeytonÎncă nu există evaluări

- Manual de Instalação WarnerDocument8 paginiManual de Instalação WarnerЭлектроника EletroeletrônicaÎncă nu există evaluări

- Tabla Tension Correas Gates PDFDocument4 paginiTabla Tension Correas Gates PDFHarold BurgosÎncă nu există evaluări

- Valve Clearance Check and AdjustmentDocument3 paginiValve Clearance Check and AdjustmentRodrigo MuñozÎncă nu există evaluări

- MSA5TCD97L3692Document3 paginiMSA5TCD97L3692Mudflap CalizayaÎncă nu există evaluări

- Ignition Switch - 4. HeadlightDocument6 paginiIgnition Switch - 4. HeadlightRodrigo SalgueroÎncă nu există evaluări

- Equipment Definition: Component LiteratureDocument4 paginiEquipment Definition: Component LiteratureAbbas AkbarÎncă nu există evaluări

- BR3 007 ManualDocument5 paginiBR3 007 ManualRodrigo Jechéla BarriosÎncă nu există evaluări

- GW491QE Petrol Engine Service Manual ClutchDocument4 paginiGW491QE Petrol Engine Service Manual ClutchAlbert BriceñoÎncă nu există evaluări

- Mahula de PeçasDocument411 paginiMahula de PeçasRUBSONMOTAÎncă nu există evaluări

- Tugas Diferensial PDFDocument3 paginiTugas Diferensial PDFBgas StwnÎncă nu există evaluări

- Torque Converter Clutch Case: Automatic TransmissionDocument4 paginiTorque Converter Clutch Case: Automatic TransmissionAnton FortovÎncă nu există evaluări

- Gear Selector Control, Adjustment Volvo TransmissionDocument2 paginiGear Selector Control, Adjustment Volvo TransmissionHamilton MirandaÎncă nu există evaluări

- SKF SAF and SAFS Installation and Maintenance OMs English 1 PDFDocument4 paginiSKF SAF and SAFS Installation and Maintenance OMs English 1 PDFjaime San Martin PulgarÎncă nu există evaluări

- RTL Sleevoil Instruction Manual 499970Document11 paginiRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाÎncă nu există evaluări

- Fontaine Quinta RuedaDocument2 paginiFontaine Quinta RuedaHamilton MirandaÎncă nu există evaluări

- Maintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinDocument2 paginiMaintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinedilsonÎncă nu există evaluări

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 paginiSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenÎncă nu există evaluări

- HDBIDocument5 paginiHDBIkevlar315Încă nu există evaluări

- Manual 600 NEWDocument5 paginiManual 600 NEWabhayuietÎncă nu există evaluări

- Daihatsu Engine Mechanical EJ-DE and EJ-VEDocument61 paginiDaihatsu Engine Mechanical EJ-DE and EJ-VEJohnny Vanther96% (25)

- MANUAL BOOK DifferentialDocument14 paginiMANUAL BOOK DifferentialHaris100% (2)

- Manual Servicio Cámaras de FrenoDocument2 paginiManual Servicio Cámaras de FrenoJuan Jose PerdomoÎncă nu există evaluări

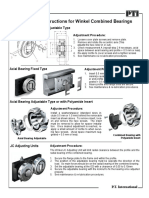

- Winkel Bearing Adjustment Re Lube Instructions 0719Document2 paginiWinkel Bearing Adjustment Re Lube Instructions 0719huseyinÎncă nu există evaluări

- Propeller Shaft: A: On-Car ServiceDocument3 paginiPropeller Shaft: A: On-Car ServicemiguelÎncă nu există evaluări

- QL5, DHD350: Disassembly Exploded ViewDocument1 paginăQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.Încă nu există evaluări

- GX100 Ajuste de MotorDocument1 paginăGX100 Ajuste de MotorThu Naing TunÎncă nu există evaluări

- Single Speed Powershift Transmission Hyster H30-60H Repair ManualDocument39 paginiSingle Speed Powershift Transmission Hyster H30-60H Repair ManualArmando OrtaÎncă nu există evaluări

- MASTILDocument16 paginiMASTILluis tocoraÎncă nu există evaluări

- CAT Compression Brake Lash - AdjustDocument2 paginiCAT Compression Brake Lash - Adjustbenge henrique100% (2)

- Manual For Furling Mast TYPE RB - RC - Seldén MastDocument16 paginiManual For Furling Mast TYPE RB - RC - Seldén MastDaniel LovatÎncă nu există evaluări

- 11 1964 CH-ClutchDocument4 pagini11 1964 CH-ClutchJose LaproviteraÎncă nu există evaluări

- 40 90 Mechanical Seal Kits SWIDocument2 pagini40 90 Mechanical Seal Kits SWIWong DaÎncă nu există evaluări

- Removal: 2Uz-Fe Engine Mechanical - CamshaftDocument14 paginiRemoval: 2Uz-Fe Engine Mechanical - CamshaftmarranÎncă nu există evaluări

- Parte 5 Md200Document22 paginiParte 5 Md200samuelÎncă nu există evaluări

- 160d 7e RemovalDocument16 pagini160d 7e RemovalJorge RojasÎncă nu există evaluări

- Installation Instructions: WarningDocument6 paginiInstallation Instructions: WarningrobÎncă nu există evaluări

- Nstructions OR Amshaft Earing OOL: I F C B TDocument2 paginiNstructions OR Amshaft Earing OOL: I F C B TcunÎncă nu există evaluări

- E32 Autobox DismantlingDocument23 paginiE32 Autobox DismantlingSteven J Baynes100% (1)

- (OM) Operation ManualDocument5 pagini(OM) Operation ManualDennys GuizarÎncă nu există evaluări

- Teikin Catalog Vol 18-Automotive General MotorDocument3 paginiTeikin Catalog Vol 18-Automotive General MotorJuan Esteban Ordoñez BonillaÎncă nu există evaluări

- Concor : - The Furure Prospective With ICD NeemranaDocument13 paginiConcor : - The Furure Prospective With ICD Neemranahaidersyed06Încă nu există evaluări

- Vossloh Espana Euro 4000 Us PDFDocument6 paginiVossloh Espana Euro 4000 Us PDFRizki Fajar NovantoÎncă nu există evaluări

- Suzuki gd110Document70 paginiSuzuki gd110Keith Fabila75% (4)

- Cable-Throttle Engines: (Select) (01 - Engine) (Measuring Blocks - 08)Document2 paginiCable-Throttle Engines: (Select) (01 - Engine) (Measuring Blocks - 08)mÎncă nu există evaluări

- A DaimlerChrysler CompanyDocument19 paginiA DaimlerChrysler Companycmarqcs100% (1)

- E Catalogue PDFDocument98 paginiE Catalogue PDFKavita NalekarÎncă nu există evaluări

- Joyner Sand Viper 800 User Parts Manual 2009Document222 paginiJoyner Sand Viper 800 User Parts Manual 2009emadeus7776682100% (1)

- CAN ID To J1939 - N2K PGN ConverterDocument260 paginiCAN ID To J1939 - N2K PGN Converterdhanssmart100% (1)

- Auto Cruise Control System: SectionDocument70 paginiAuto Cruise Control System: SectionAlex WellmanÎncă nu există evaluări

- Injection Compensation For OCT To NOV 2015 - 6Document4 paginiInjection Compensation For OCT To NOV 2015 - 6Kasturi SarawanaÎncă nu există evaluări

- Despiece Eje Delantero Massey PDFDocument66 paginiDespiece Eje Delantero Massey PDFraul100% (1)

- Blue Bird Propane-Powered Vision Activity/MFSAB Specification SheetDocument2 paginiBlue Bird Propane-Powered Vision Activity/MFSAB Specification SheetMacAllister MachineryÎncă nu există evaluări

- 340fte17313 50Document47 pagini340fte17313 50sesoto100% (1)

- Kioti Daedong DK45S Tractor Parts Catalogue Manual PDFDocument30 paginiKioti Daedong DK45S Tractor Parts Catalogue Manual PDFfjjsekfkskeme0% (1)

- White Genset Catalog 3pgs-1 LowDocument2 paginiWhite Genset Catalog 3pgs-1 LowprajaktakattiÎncă nu există evaluări

- CV Ravi ShenkerDocument6 paginiCV Ravi ShenkerRavi ShenkerÎncă nu există evaluări

- VW Diesel Industrial Engines, Workshop Manual.Document641 paginiVW Diesel Industrial Engines, Workshop Manual.Álvaro Manuel OliveiraÎncă nu există evaluări

- Stall English Questions-12022015Document22 paginiStall English Questions-12022015danishGoldfishahamadÎncă nu există evaluări

- EXPERT VIN DeCoder and Truck Curb Weight PDFDocument12 paginiEXPERT VIN DeCoder and Truck Curb Weight PDFCarlos Ediver Arias RestrepoÎncă nu există evaluări

- T5 Facelift To T5.1 How-ToDocument7 paginiT5 Facelift To T5.1 How-ToliviuvistaÎncă nu există evaluări

- QSK38 M1 1400hk 1600Document2 paginiQSK38 M1 1400hk 1600Luis Lillo GuerreroÎncă nu există evaluări

- LAND ROVER DEFENDER 90 DEFENDER X-DYNAMIC HSE Ingenium 3,0 Litre 6-Cylinder 400PS Turbocharged Petrol MHEV (Automatic) All Wheel DriveDocument29 paginiLAND ROVER DEFENDER 90 DEFENDER X-DYNAMIC HSE Ingenium 3,0 Litre 6-Cylinder 400PS Turbocharged Petrol MHEV (Automatic) All Wheel DrivetabledekasiÎncă nu există evaluări

- Polaris 570 Sportsman Service ManualDocument456 paginiPolaris 570 Sportsman Service Manualtonyeld88% (25)

- List of Chrysler Dealers To Be ClosedDocument41 paginiList of Chrysler Dealers To Be ClosedDealBook100% (58)

- Marine Diesel Engine: Yanmar Europe B.V. Product GuideDocument24 paginiMarine Diesel Engine: Yanmar Europe B.V. Product GuideAllans_NavalÎncă nu există evaluări

- Operating Manual TP-401: Schenectady, N. YDocument21 paginiOperating Manual TP-401: Schenectady, N. YLocomotiva Bb36Încă nu există evaluări

- Carmix - 3 5TTDocument2 paginiCarmix - 3 5TTZola1stÎncă nu există evaluări

- Bosch Braking ComponentDocument16 paginiBosch Braking ComponentTùng Anh DươngÎncă nu există evaluări