Documente Academic

Documente Profesional

Documente Cultură

Bussman - How To Size A Fuse

Încărcat de

SJS68Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bussman - How To Size A Fuse

Încărcat de

SJS68Drepturi de autor:

Formate disponibile

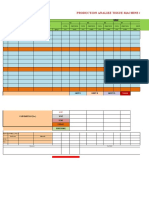

Fuse Diagnostic Sizing Charts

Ballasts

Fuse & Holder Recommendations

Indoor Fluorescent Consult fixture manufacturer for size and type.

Fuse Holder(s) Fuse Holder(s)

GLR HLR GLQ HLQ

GMF GMQ

GRF

All Other (Mercury, Fuse & Holder Recommendations

Consult fixture manufacturer for size and type. Fuse Holder(s) Fuse Holder(s) Fuse Holder(s)

Sodium, etc.)

BAF HPF KTK-R HPS-RR SC 0-15 HPF-EE

BAN HPS FNQ-R HPF-RR HPS-EE

KTK LP-CC SC 20 HPF-JJ

FNM HPS-JJ

FNQ KTQ HPS-L SC 25-30 HPF-FF

FNW BBS HPF-L HPS-FF

Fuse & Holder Recommendations

Outdoor Mercury, Sodium, etc. Consult fixture manufacturer for size and type. Fuse Holder(s) Fuse Holder(s)

BAF HEB KTK-R HEY

BAN HEX FNQ-R

KTK HPC-D LP-CC

FNM

FNQ

FNW

Capacitors (NEC® 460)

Protected by

150% to 175% of Full Load Current Fuse Recommendations

Time-Delay Fuses.

Volts Fuse(s)

0-250 LPN-RK_SP, FRN-R

0-600 LPS-RK_SP, FRS-R

0-600 LPJ_SP, LP-CC,

FNQ-R, TCF

Protected by Fuse Recommendations

250% to 300% of Full Load Current.

Non-Time-Delay Fuses. Volts Fuse(s)

0-250 KTN-R, NON

0-300 JJN

0-600 KTS-R, NOS

On Load Side of Motor Running 0-600 JKS, KTK-R

Protection recommended as shown, but not required.

Overcurrent Device. 0-600 JJS

202 ©2005 Cooper Bussmann

Fuse Diagnostic Sizing Charts

Electric Heat (NEC® 424)

Size at 125% or next size larger but in no case larger than 60 Fuse Recommendation

Electric Space Heating amps for each subdivided load. Volts Fuse(s)

0-250 LPN-RK_SP

FRN-R, NON

0-300 JJN

0-480 SC 25 to SC 60

0-600 LPS-RK_SP

FRS-R, NOS

0-600 JJS

0-600 LPJ_SP, LP-CC

Electric Boilers with Resistance Size at 125% or next size larger but in no case larger than 150 FNQ-R, JKS, KTK-R,

Type Immersion Heating amps for each subdivided load. TCF, SC 1⁄2 to SC 20

Elements in an ASME Rated and

Stamped Vessel

Mains, Feeders, Branches

Feeder Circuits

No Motor Load 100% of non-continuous load plus 125% of continuous load. Fuse Recommendations

(600A & Less) Volts Fuse(s)

0-250 LPN-RK_SP, FRN-R

0-300 JJN

0-600 LPS-RK_SP, FRS-R

0-600 JJS

0-600 LPJ_SP, LP-CC

JKS, KTK-R

Combination Motor Loads 150%* of the FLA of largest motor (if there are two or more motors of

and Other Loads same size, one is considered to be the largest) plus the sum of all

the FLA for all other motors plus 100% of non-continuous, non-motor

Fuse Recommendations

load plus 125% of continuous, non-motor load.

Volts Fuse(s)

0-25O LPN-RK_SP, FRN-R

0-600 LPS-RK_SP, FRS-R

Motor Loads 150%* of the FLA of largest motor (if there are two or more motors 0-600 LPJ- SP, LP-CC

of same size, one is considered to be the largest) plus the sum of all

the FLA for all other motors.

*A max. of 175% (or the next standard size if 175% does not corre-

spond to a standard size) is allowed for all but wound rotor and all dc

motors.

Main, Branch & 150% to 225% of full load current of largest motor plus 100% of full Fuse Recommendation

Feeder Circuits load current of all other motors plus 125% of continuous non-motor Volts Fuse(s)

(601-6000A) load plus 100% of non-continuous non-motor load. 0-600 KRP-C_SP

©2005 Cooper Bussmann 203

Fuse Diagnostic Sizing Charts

Motor Loads (NEC® 430)

Fuse Sized For:

Fuse Recommendations

Backup Overload w/ Motor

Protected by Time- Volts Fuse(s)

600V & Less Starter & Short-Circuit 125% of motor FLA or next size larger.

Delay Fuses 0-250 FRN-R

Protection

0-600 FRS-R

Fuse Recommendations

130% of motor FLA or next size larger. Volts Fuse(s)

0-250 LPN-RK_SP

0-600 LPS-RK_SP

175%* of motor FLA or next size larger. (If 175% does not corre-

Short-Circuit Only spond to a standard size). If this will not allow motor to start, due to Fuse Recommendations

higher than normal inrush currents or longer than normal Volts Fuse(s)

acceleration times (5 sec. or greater), fuse may be sized up to 225% 0-250 LPN-RK_SP, FRN-R

or next size smaller. 0-600 LPS-RK_SP, FRS-R

0-600 LPJ_SP, TCF

Protected by Non-Time

Delay Fuses & all Short-Circuit Only Max. of 300%* of motor FLA or next size larger (if 300% does not Fuse Recommendations

Class CC Fuses correspond to a standard size). If this will not allow motor to start

Volts Fuse(s)

due to higher than normal inrush currents or longer than normal

0-250 KTN-R, NON

acceleration times (5 sec. or greater), fuses through 600 amps may

0-300 JJN

be sized up to 400% or next size smaller.

0-600 KTS-R, NOS

0-600 JJS

0-600 LP-CC, JKS, KTK-R

*150% for wound rotor and all DC motors.

Compare the min. melting time-current characteristics of the fuses with the time-current characteristics of the overload relay curve. The

Fuse Recommendations

Above 600V Volts Fuse(s)

size fuse which is selected should be such that short.circuit protection is provided by the fuse and overload protection is provided by the

controller overload relays. 2400 JCK, JCK-A, JCH

4800 JCL, JCL-A, JCG

7200 JCR, 7.2 WKMSJ

Solenoids (Coils)

Fuse Recommendation

Branch Circuit Volts Fuse(s)

Size at 125% or next size smaller.

Fuses 0-250 Best: LPN-RK_SP

FRN-R

0-600 LPS-RK_SP

FRS-R

0-600 LPJ_SP, LP-CC

FNQ-R, TCF

Supplementary Fuse Recommendation

Size at 125% or next size larger.

Fuses Volts Fuse(s)

0-32 MDL 9-30A,

FNM 20-30A

0-125 MDA 25-30A,

FNM 12-15A

0-250 MDL 1⁄16-8A,

MDA 2⁄10-20A,

FNM 1⁄10-10A,

FNW 12-30A,

MDQ 1⁄100-7A

0-500 FNQ 1⁄10-30A

204 ©2005 Cooper Bussmann

Fuse Diagnostic Sizing Charts

Transformers 600V Nominal or Less (NEC® 450.3)

Optimum Protection NEC® Maximums

Note: Components on the secondary still need

Max. 300% or next size smaller (See

Primary overcurrent protection Rated primary current less

125% or next size larger NEC® 430.72(C) for control circuit trans-

Protection than 2 amps

former maximum of 500%

Only

Rated primary current greater

than or equal to 2 amps but 125% or next size larger Max. 167% or next size smaller

less than 9 amps

Rated primary current greater

125% or next size larger Max. of 125% or next larger*

than or equal to 9 amps

Primary And Without Thermal Rated secondary current less A A

Secondary Overload Protection than 9 amps

Protection

Rated secondary current 9 B B

% of Primary FLA

amps or greater

(or next FLA size smaller)

A = 250%

Transformer B = 250%

With Thermal Rated secondary current less C C C = 600%

Impedance of 6%

Overload Protection than 9 amps Primary and secondary D = 600%

or Less

fuses at 125% of primary E = 400%

and secondary FLA or F = 400%

Rated secondary current 9 D next size larger D

amps or greater % of Secondary FLA

A = 167% or next size smaller

B = 125% or next size larger*

Transformer Rated secondary current less E E C = 167% or next size smaller

Impedance of More than 9 amps D = 125% or next size larger*

Than 6% But Less E = 167% or next size smaller

Than 10% F = 125% or next size larger*

Rated secondary current 9 F F

amps or greater

*When 125% of FLA corresponds to a

standard rating, the next larger size is

not permitted.

Fuse Recommendations

Volts Fuse(s)

250V LPN-RK_SP, FRN-R

600V KRP-C_SP, LPJ_SP, LPS-RK_SP, FNQ-R, FRS-R, TCF

©2005 Cooper Bussmann 205

Fuse Diagnostic Sizing Charts

Transformers Over 600V Nominal (NEC® 450.3)

Note: Components on the secondary still need

Primary Primary at code max. of 250% or next overcurrent protection

Supervised

Protection standard size if 250% does not corre-

Installations Only spond to a standard rating

Primary

Primary and Transformer Secondary at

at code Secondary

Secondary Impedance Less Than code max. of

max. of Over 600V

Protection or Equal to 6% 250%

300%

Secondary Secondary at

600V or code max. of

Below 250% Fuse Recommendations

Volts Fuse(s)

250V LPN-RK_SP, FRN-R

Transformer Primary

Secondary at 600V LPS-RK_SP, LPJ-_SP,

Impedance Greater at code Secondary

code max. of KRP-C_SP, FRS-R, FNQ-R,

Than 6% But Less max. of Over 600V

225% TCF

Than 10% 300%

2475V JCD

2750V JCX

2750/5500V JCW

Secondary Secondary at

5500V JCE, JCQ, JCY, JCU,

600V or code max. of

5.5 ABWNA, 5.5 AMWNA,

Below 250%

5.5 FFN

7200V 7.2 ABWNA, 7.2 SDLSJ,

Primary at code max. of 300% Secondary at code max. of 7.2 SFLSJ

Transformer 8300V JCZ, JDZ, 8.25 FFN

Unsupervised or next standard size if 300% Secondary 250% or next standard size if

Impedance Less Than 15500V JCN, JDN, JDM, 15.5 CAVH

Installations does not correspond to a Over 600V 250% does not correspond to

or Equal to 6% 17500V 17.5 CAV, 17.5 SDM

standard rating a standard rating

24000V 24 SDM, 24 SFM, 24 FFM

36000V 36 CAV, 36 SDQ, 36 SFQ

Secondary at code max. of 38000V 38 CAV

Secondary

125% or next standard size if

600V or

125% does not correspond to

Below

a standard rating

Transformer Primary at code max. of 300% Secondary at code max. of

Impedance Greater or next standard size if 300% Secondary 225% or next standard size if

Than 6% But Less does not correspond to a Over 600V 225% does not correspond to

Than 10% standard rating a standard rating

Secondary at code max. of

Secondary

125% or next standard size if

600V or

125% does not correspond to

Below

a standard rating

Solid State Devices (Diodes, SCRs, Triacs, Transistors)

Short-Circuit Fuse Recommendations

“F,” “S,” “K,” & 170M Series fuses sized up to several sizes larger Volts Fuse(s)

Protection Only than full load RMS or dc rating of device. 0-130 FWA

0-250 FWX

0-500 FWH

0-600 FWC, KAC, KBC

0-700 FWP, 170M Series,

SPP

0-1000 FWJ, 170M Series,

SPJ

206 ©2005 Cooper Bussmann

Fuse Sizing Guide

Building Electrical System

General guidelines are given for selecting fuse amp ratings for most circuits. Some 10. Transformer Primary Fuse (without secondary fuse protection). When

specific applications may warrant other fuse sizing; in these cases the load transformer primary current is equal to or greater than 9 amps, the dual-element,

characteristics and appropriate NEC® sections should be considered. The time-delay fuse should be sized at 125% of transformer primary current or the

selections shown here are not, in all cases, the maximum or minimum amp ratings next size larger. Note: Secondary conductors must be protected from overcurrent

damage.

permitted by the NEC®. Demand factors as permitted per the NEC® are not

included in these guidelines. 11. Transformer Primary Fuse (with secondary fuse protection). May be sized at

Fuse Recommendations

250% of transformer primary current if,

601 to 6000A Low-Peak Time-Delay Fuse

KRP-C_SP

1/10 to 600A Low-Peak

12. The secondary fuse is sized at no more than 125% of secondary full-load

Dual-Element, Time-Delay Fuses

LPN-RK_SP(250V); LPS-RK_S P(600V) or

current. Note: Secondary conductors must be protected at their ampacities.

LPJ_SP (600V)

1 Fusetron Dual-Element Fuses

FRN-R (250V); FRS-R(600V) Non-Time-Delay and all Class CC Fuses (JKS, KTS-R,

KTN-R, JJS, JJN, LP-CC, KTK-R, and FNQ-R)

Fuse Feeder Feeder Feeder

10 8

Greater

Than 2

With

No 3

With

All 4

With

Combin- 11 1. Main service. Size fuse according to method in 4.

600 Amps Motor Motor ation

Load Load Motor

And Non 2. Feeder Circuit With No Motor Loads. The fuse size must be at least 125% of

Motor Motor

Starter

Over-

Load the continuous load† plus 100% of the non-continuous load. Do not size larger

Loads

Relays 6 7 7 than the ampacity of the wire.

3. Feeder Circuit With All Motor Loads. Size the fuse at 300% of the full-load

M Large

Motor 12

current of the largest motor plus the full-load current of all other motors. Do not

size fuse larger than the conductor capacity.

M M M

4. Feeder Circuit With Mixed Loads. Size fuse at sum of:

a. 300% of the full-load current of the largest motor plus

b. 100% of the full-load current of all other motors plus

5 5 5 7 7 7 5 5

c. 125% of the continuous, non-motor load† plus

9

d. 100% of the non-continuous, non-motor load.

M M M

Continuous Non Power Continuous 5. Branch Circuit With No Motor Loads. The fuse size must be at least 125% of

Loads Continuous Factor Loads

Lighting

Heating

Loads Correction

Capacitor

the continuous load† plus 100% of the non-continuous load. Do not size larger

than the ampacity of conductor.*

Dual-Element, Time-Delay Fuses (LPJ_SP, 6. Motor Branch Circuit With Overload Relays. Size the fuse as close to but not

LPS-RK_SP, LPN-RK_SP, FRS-R, FRN-R and TCF) exceeding 300% of the motor running full load current. Provides ground fault and

1. Main Service. Size fuse according to method in 4. short-circuit protection only.

2. Feeder Circuit With No Motor Loads. The fuse size must be at least 125% of 7. Motor Branch Circuit With Fuse Protection Only. Non-time-delay fuses cannot

the continuous load† plus 100% of the non-continuous load. Do not size larger be sized close enough to provide motor running overload protection. If sized for

than ampacity of conductor*. motor overload protection, non-time-delay fuses would open due to motor starting

3. Feeder Circuit With All Motor Loads. Size the fuse at 150%N of the full load current. Use dual-element fuses.

current of the largest motor plus the full-load current of all other motors∆.

Conductor Ampacity Selection

4. Feeder Circuit With Mixed Loads∆. Size fuse at sum of:

1. Feeder Circuit And Main Circuit With Mixed Loads. Conductor ampacity at

a. 150%†† of the full-load current of the largest motor plus

least sum of:

b. 100% of the full-load current of all other motors plus

a. 125% of continuous non-motor load plus

c. 125% of the continuous, non-motor load† plus

b. 100% of non-continuous non-motor load plus

d. 100% of the non-continuous, non-motor load.

c. 125% of the largest motor full-load current plus

5. Branch Circuit With No Motor Load. The fuse size must be at least 125% of the d. 100% of all other motors' full-load current.

continuous load† plus 100% of the non-continuous load. Do not size larger than

2. Feeder Circuit With No Motor Load. Conductor ampacity at least 125% of the

ampacity of conductor*.

continuous load plus 100% of the non-continuous load.

6. Motor Branch Circuit With Overload Relays. Where overload relays are sized

3. Feeder Circuit With All Motor Loads. Conductor ampacity at least 125% of the

for motor running overload protection, the following provide backup, ground fault,

largest motor full-load amps plus 100% of all other motors’ full-load amps.

and short-circuit protection:

4. Feeder Circuit With Mixed Loads. Size according to method 1 above.

a. Size FRS-R and FRN-R, RK5, & LPS-RK_SP and LPN-RK_SP, RK1, fuses

at 125% & 130% of motor full-load current respectively or next higher size. 5. Branch Circuit With No Motor Load. Conductor ampacity at least 125% of the

continuous load plus 100% of the non-continuous load.

7. Motor Branch Circuit With Fuse Protection Only. Where the fuse is the only

motor protection, the following FRS-R and FRN-R, Class RK5, fuses provide 6, 7, & 8. Motor Branch Circuits. Conductor ampacity at least 125% of the motor

motor running overload protection and short-circuit protection: full-load current.

a. Motor 1.15 service factor or 40°C rise: size the fuse at 110% to 125% of 9. Conductor ampacity at least 135% of capacitor rated current. The ampacity of

the motor full-load current. conductors for a capacitor connected to a motor circuit must be 1⁄3 the ampacity of

b. Motor less than 1.15 service factor or over 40°C rise: size fuse at 100% the motor circuit conductors.

to 115% of motor full-load current. 10, 11. Conductor ampacity minimum 125% of transformer full-load current.

8. Large Motor Branch Circuit. Fuse larger than 600 amps. For large motors, size 12. Conductor ampacity per 1 above.

KRP-C_SP Low-Peak time-delay fuse at 175% to 300% of the motor full-load † 100% of the continuous load can be used rather than 125% when the switch and fuse are listed for 100% continuous operation. Most

bolted pressure switches and high pressure contact switches 400A to 6000A with Class L fuses are listed for 100% continuous operation.

current, depending on the starting method; i.e. part-winding starting, reduced volt- * Where conductor ampacity does not correspond to a standard fuse rating, next higher rating fuse is permitted when 800 amps or less

[(240.3(B)].

age starting, etc. ∆ In many motor feeder applications dual-element fuses can be sized at ampacity of feeder conductors.

• Available short-circuit current and the clearing time of the overcurrent device must be considered so that the conductor’s ICEA (P32.382)

9. Power Factor Correction Capacitors. Size dual-element fuses as low as withstand rating is not exceeded.

practical, typically 150% to 175% of capacitor rated current. †† NEC® allows a maximum of 175% or the next standard size if 175% does not correspond with a standard fuse size, for all but wound rotor

and DC motors.

©2005 Cooper Bussmann 207

Fuse Specifications

Suggestions

General 3. Switchboards, Panelboards, Load Centers

Fuses shall not be installed until equipment is ready to be energized. This The manufacturer shall supply equipment utilizing fully rated and listed compo-

measure prevents fuse damage during shipment of the equipment from the nents. This equipment shall be tested, listed and labeled for the available short-

manufacturer to the job site, or from water that may contact the fuse before circuit current.

the equipment is installed. Final tests and inspections shall be made prior to (Where series-rated fuse/circuit breaker systems are acceptable, the systems

energizing the equipment. This shall include a thorough cleaning, tightening, shall utilize tested, recognized components. The manufacturer shall supply

and review of all electrical connections and inspection of all grounding switchboards, panelboards and load centers which have been tested, listed,

conductors. All fuses shall be furnished and installed by the electrical and labeled for the available short-circuit current, and those combinations

contractor. All fuses shall be of the same manufacturer. Fuses shall be as specified on the drawings.)

follows: 4. Marking

A. Main, Feeder, and Branch Circuit Fuses Fuses shall be “Low-Peak in color. “Low-Peak NOTICE labels to alert the end

user of the engineered level of protection of the electrical equipment shall be field

1. Circuits 601 through 6000 amps

installed by the electrical contractor. They shall be marked with the proper fuse

Circuits 601 through 6000 amps shall be protected by current-limiting Cooper rating, per the specifications, and placed in a conspicuous location on the

Bussmann Low-Peak Time-Delay Fuses KRP-C(amp)SP. Fuses shall be time- enclosure. These labels are available upon request from Bussmann.

delay and shall hold 500% of rated current for a minimum of 4 seconds, clear 20

times rated current in .01 seconds or less, with an interrupting rating of 300,000 B. Supplementary - Light Fixture Protective Fuses

amps RMS symmetrical, and be listed by a nationally recognized testing 1. Fluorescent fixtures shall be protected by Cooper Bussmann GLR or GMF Fuses

laboratory. Peak let-through currents and I2t let-through energies shall not exceed in HLR Holders. These fixtures shall have individual protection on the line side of

the values established for Class L fuses. Larger Hp motors shall be protected by the ballast. A fuse and holder shall be mounted within, or as part of, the fixture.

these fuses, with ratings as shown on the drawings. Size and type of fuse to be recommended by the fixture manufacturer.

2. Circuits 0 through 600 amps 2. All other ballast-controlled light fixtures shall be protected by Bussmann KTK or

Circuits 0 through 600 amps shall be protected by current-limiting Cooper FNQ Fuses in HEB HEX, HEY, HPF, or HPS Holders. These fixtures shall have

Bussmann Low-Peak Dual-Element, Time-Delay Fuses LPN-RK(amp)SP/LPS- individual protection on the line side of the ballast. Fuse and holder shall be

RK(amp)SP (or LPJ(amp)SP. All fuses shall have separate overload and short- mounted in a location convenient for changing fuses. Holder shall be mounted in

circuit elements. Fuses shall incorporate a spring activated thermal overload protected location or be an in-line waterproof holder (HEB, HEX, or HEY). Size

element that has a 284 degrees Fahrenheit melting point alloy. The fuses shall and type of fuse to be recommended by the fixture manufacturer or as indicated

hold 500% of rated current for a minimum of 10 seconds (30A, 250V Class RK1 on plans.

case size may be a minimum of 8 seconds at 500% of rated current) with an

interrupting rating of 300,000 amps RMS symmetrical, and be listed by a national- C. Spares

ly recognized testing laboratory. Peak let-through currents and I2t let-through Upon completion of the building, the electrical contractor shall provide the

energies shall not exceed the values established for Class RK1 or J fuses. owner with spare fuses as shown below:

Motor Circuits - All individual motor circuits with full-load amp ratings (F.L.A.) of 1. 10% (minimum of 3) of each type and rating of installed fuses shall be supplied as

461 (or 400) amps or less shall be protected by Cooper Bussmann Low-Peak spares.

Dual-Element, Time-Delay Fuses LPN-RK(amp)SP/LPS-RK(amp)SP (or

2. Cooper Bussmann spare fuse cabinets - Catalog No. SFC - shall be provided to

LPJ(amp)SP). The following guidelines apply for motors protected by properly store the above spares. A supply of “Low-Peak NOTICE Labels shall be provided

sized overload relays: LPN-RK(amp)SP/LPS-RK(amp)SP fuses shall be along with the spare fuses in the spare fuse cabinet.

installed in ratings of 130% (or 150% for LPJ(amp)SP fuses) of motor full-load

current (or next size larger if this does not correspond to a fuse size), except D. Substitution Approvals

where high ambient temperatures prevail, or where the motor drives a heavy The electrical contractor’s proposal shall be based upon the fuses specified,

revolving part which cannot be brought up to full speed quickly, such as large using the manufacturer’s catalog numbers as called for in the specification or

fans. Under such conditions the fuse may be 175%* of the motor full-load on the drawings. Coordination and current limitation requirements for

current, or the next standard size larger if 175%* does not correspond to a protection of each part of the electrical system have been engineered on the

standard fuse size. If this will not allow the motor to start due to higher than basis of the type, class and manufacturer specified.

normal inrush currents or longer than normal acceleration times (5 seconds or In the event that the electrical contractor wishes to furnish materials other than

greater), fuses may be sized up to 225% (or next size smaller). those specified, a written request, along with a complete short-circuit,

Motor Controllers - NEMA and IEC Style motor controllers shall be protected component protection and selective coordination study, shall be submitted to

from short-circuits by Cooper Bussmann Low-Peak Dual-Element, Time-Delay the engineer for evaluation at least two weeks prior to bid date. If the

Fuses in order to provide testing agency-witnessed Type 2 coordination for the engineer’s evaluation indicates acceptance, a written addendum will be issued

controller. This provides “no damage” protection for the controller, under low listing the other acceptable manufacturer.

and high level fault conditions, as required by IEC Publication947-4-1 and UL

508E (Outline of Investigation).

*150% for wound rotor and all DC motors.

208 ©2005 Cooper Bussmann

Fuse Specifications

Suggested Fuse and Fusible Equipment Specifications

Cooper Bussmann provides fuse and fusible equipment specifications

available on line at www.cooperbussmann.com/apen/fusible/.

The information contained within these documents constitutes what Cooper

Bussmann considers to be a complete, comprehensive, performance based

construction specification. These documents can be viewed or downloaded in

Microsoft Word or PDF format.

The specifications are arranged per the recommended CSI MasterFormat™

Sections. In some cases, the number for these specifications has been left

open for the specifier to choose the appropriate number and the title can be

adjusted to best suit their project manual. The specifications include:

16011 Electrical System Studies

• Short Circuit, Component Protection, Flash Hazard, and Selective

Coordination Study

16411 Enclosed Switches

• Enclosed Disconnect Switches (Fused and Non-Fused)

• Elevator Shunt-Trip Fused Disconnect Switches

164XX Open Disconnect Switches

• Open Disconnect Switches (Fused and Non-Fused)

16421 Enclosed Controllers

• Enclosed Fused Combination Motor Controllers

16441 Switchboards

• Fused Main and Distribution Switchboards

16442 Panelboards

• Fused Distribution Panelboards

• Elevator Shunt-Trip Fused Distribution Panel

• Fused Lighting and Appliance Panelboards

16443 Motor Control Centers

• Fused Motor Control Centers

16451 Busway

• Busway and Fused Busplugs

16491 Fuses

• Fuses

©2005 Cooper Bussmann 209

Cooper Bussmann Current-Limiting Fuse Let-Through Data

See pages 67 to 69 for current-limiting definition and how to analyze these charts.

Low-Peak Class L Time-Delay Fuses KRP-C_SP Fuse – RMS Let-Through Currents (kA)

KRP-C_SP Fuse Size

Prosp.

1000000

Short 601 800 1200 1600 2000 2500 3000 4000 5000 6000

900000

800000 B

700000 C.C. IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS

600000

500000 5,000 5 5 5 5 5 5 5 5 5 5

400000

6000A 10,000 8 10 10 10 10 10 10 10 10 10

300000

5000A

4000A 15,000 9 12 15 15 15 15 15 15 15 15

3000A

INSTANTANEOUS PEAK LET THRU CURRENT IN AMPERES

200000

2500A 20,000 10 13 17 20 20 20 20 20 20 20

2000A

1600A 25,000 11 14 19 22 25 25 25 25 25 25

100000 1200A

90000

80000

800A

30,000 11 14 20 24 27 30 30 30 30 30

70000

60000 601A 35,000 12 15 21 25 29 35 35 35 35 35

50000

40000 AMPERE 40,000 13 16 22 26 30 35 40 40 40 40

RATING

30000

50,000 14 17 23 28 32 37 50 50 50 50

20000 60,000 15 18 25 30 34 40 49 60 60 60

70,000 15 19 26 32 36 42 52 62 70 70

10000

9000 80,000 16 20 27 33 38 44 54 65 76 80

8000

7000

6000

90,000 17 21 29 34 39 45 56 67 79 90

5000

100,000 17 22 30 36 41 47 58 70 81 100

4000

3000 150,000 20 25 34 41 47 54 67 80 93 104

2000

A 200,000 22 27 37 45 51 59 73 87 102 114

250,000 24 29 40 49 55 64 79 94 110 123

1000

300,000 25 31 43 52 59 68 84 100 117 30

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

200000

300000

Note: For IRMS value at 300,000 amperes, consult Factory.

PROSPECTIVE SHORT CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES

Low-Peak Class J, Dual-Element Time-Delay Fuses LPJ_SP Fuse – RMS Let-Through Currents (kA)

LPJ_SP

Fuse Size

Prosp.

B Short 15 30 60 100 200 400 600

100000

90000

80000

70000

C.C. IRMS IRMS IRMS IRMS IRMS IRMS IRMS

60000 600A

50000

40000 400A 1,000 1 1 1 1 1 1 1

30000

200A

3,000 1 1 1 2 2 3 3

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES

20000

100A 5,000 1 1 1 2 3 5 5

10000

60A 10,000 1 1 2 2 4 6 8

9000

8000

7000

6000

30A 15,000 1 1 2 3 4 7 9

5000

4000 15A

20,000 1 1 2 3 4 7 10

3000

25,000 1 1 2 3 5 8 10

AMPERE

RATING

2000

30,000 1 1 2 3 5 8 11

1000

900

35,000 1 1 2 4 5 9 12

800

700

600

40,000 1 2 3 4 6 9 12

500

400 50,000 1 2 3 4 6 10 13

300

A

60,000 1 2 3 4 6 11 14

200

80,000 1 2 3 5 7 12 15

100 100,000 1 2 4 5 8 12 17

100

200

300

400

500

600

700

800

900

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

200000

300000

150,000 1 2 4 6 9 14 19

PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES 200,000 2 3 4 6 9 16 21

250,000 2 3 5 7 10 17 23

300,000 2 3 5 7 11 18 24

Note: For IRMS value at 300,000 amperes, consult Factory.

210 ©2005 Cooper Bussmann

Cooper Bussmann Current-Limiting Fuse Let-Through Data

See pages 67 to 69 for current-limiting definition and how to analyze these charts.

Low-Peak Class RK1 Dual-Element Time-Delay Fuses LPN-RK_SP – RMS Let-Through Currents (kA)

LPN-RK_SP Fuse Size

B

Prosp.

Short 30 60 100 200 400 600

400,000

C.C. IRMS IRMS IRMS IRMS IRMS IRMS

300,000

1,000 1 1 1 1 1 1

200,000

2,000 1 1 2 2 2 2

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES

3,000 1 1 2 3 3 3

AMPERE

RATING

100,000

90,000

80,000 5,000 1 2 2 3 5 5

70,000

60,000 10,000 1 2 3 4 7 9

50,000

600A

40,000 400A 15,000 1 2 3 5 8 11

30,000

200A

20,000 1 3 3 5 8 11

20,000 25,000 1 3 3 5 9 12

100A 30,000 2 3 4 6 9 12

60A

10,000 35,000 2 3 4 6 10 13

9,000

8,000

7,000 30A 40,000 2 3 4 6 10 13

6,000

5,000

50,000 2 3 4 7 11 14

4,000 60,000 2 3 4 7 11 16

3,000

70,000 2 3 4 7 12 16

A

2,000 80,000 2 4 5 8 12 16

90,000 2 4 5 7 13 17

1,000 100,000 2 4 5 8 13 17

100,000

200,000

300,000

10,000

20,000

30,000

40,000

60,000

80,000

1,000

2,000

3,000

4,000

6,000

8,000

150,000 2 4 6 9 15 19

200,000 3 5 6 11 16 20

PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES

250,000 3 5 7 11 17 21

300,000 3 6 7 12 18 22

Low-Peak Class RK1 Dual-Element Time-Delay Fuses LPS-RK_SP – RMS Let-Through Currents (kA)

LPS-RK_SP Fuse Size

Prosp.

B 30 60 100 200 400 600

400,000

Short

C.C. IRMS IRMS IRMS IRMS IRMS IRMS

300,000

1,000 1 1 1 1 1 1

200,000

2,000 1 1 2 2 2 2

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES

3,000 1 1 2 3 3 3

AMPERE

RATING

100,000

90,000

80,000 5,000 1 2 2 3 5 5

70,000

60,000 600A 10,000 1 2 3 4 7 10

50,000

40,000

400A 15,000 1 2 3 5 8 11

30,000 200A 20,000 2 3 3 5 9 12

20,000 25,000 2 3 4 6 9 12

100A

60A 30,000 2 3 4 6 10 13

10,000 35,000 2 3 4 6 10 13

9,000

30A

8,000

7,000

40,000 2 3 4 6 10 14

6,000

5,000

50,000 2 3 5 7 11 15

4,000 60,000 2 4 5 7 12 15

3,000

70,000 2 4 5 8 13 16

A

2,000 80,000 2 4 5 8 13 16

90,000 2 4 5 8 13 17

1,000

100,000 2 4 6 9 14 17

100,000

200,000

300,000

10,000

20,000

30,000

40,000

60,000

80,000

1,000

2,000

3,000

4,000

6,000

8,000

150,000 3 5 6 10 15 19

PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES 200,000 3 5 7 11 16 21

250,000 3 6 7 12 17 22

300,000 3 6 7 12 18 23

©2005 Cooper Bussmann 211

Cooper Bussmann Current-Limiting Fuse Let-Through Data

See pages 67 to 69 for current-limiting definition and how to analyze these charts.

Fusetron Class RK5 Dual-Element Time-Delay Fuses FRN-R – RMS Let-Through Currents (kA)

FRN-R Fuse Size

B Prosp.

400000

Short 30 60 100 200 400 600

300000 C.C. IRMS IRMS IRMS IRMS IRMS IRMS

200000 5,000 1 2 3 5 5 5

AMPERE

10,000 2 3 4 7 10 10

RATING

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES

100000 15,000 2 3 5 8 11 15

90000

80000

70000 600A 20,000 2 4 5 8 12 16

60000 400A

50000 25,000 2 4 6 9 13 17

200A

40000

30,000 2 4 6 10 14 18

30000

100A 35,000 2 4 6 10 15 19

20000 40,000 2 5 7 11 15 20

60A

50,000 3 5 7 11 17 21

10000

9000 30A

60,000 3 5 8 12 18 22

8000

7000 70,000 3 6 8 13 19 23

6000

5000 80,000 3 6 8 13 19 24

4000

90,000 3 6 9 14 20 25

3000

A 100,000 3 6 9 14 21 26

2000

150,000 4 7 10 16 24 29

200,000 4 8 11 18 26 32

1000

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

200000

PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES

Fusetron Class RK5 Dual-Element Time-Delay Fuses FRS-R – RMS Let-Through Currents (kA)

FRS-R Fuse Size

Prosp.

Short 30 60 100 200 400 600

400000

B

C.C. IRMS IRMS IRMS IRMS IRMS IRMS

300000

5,000 1 1 3 4 5 5

200000

10,000 1 2 4 5 9 10

15,000 1 2 4 6 10 14

AMPERE

RATING

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES

100000

90000 20,000 2 2 5 7 11 15

80000

70000 600A 25,000 2 2 5 7 12 17

60000

400A

50000 30,000 2 3 5 8 13 18

40000

200A 35,000 2 3 5 8 13 18

30000

40,000 2 3 6 9 14 19

20000 100A

50,000 2 3 6 9 14 20

60A 60,000 2 3 6 10 15 22

10000

9000 30A 70,000 3 4 7 11 17 23

8000

7000

6000

80,000 3 4 7 12 17 23

5000

90,000 3 4 7 12 17 24

4000

3000

100,000 3 4 8 13 18 25

A 150,000 3 5 9 14 21 27

2000

200,000 4 6 9 16 23 32

1000

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

200000

PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES

212 ©2005 Cooper Bussmann

Cooper Bussmann Current-Limiting Fuse Let-Through Data

See pages 67 to 69 for current-limiting definition and how to analyze these charts.

Tron Class T Fast-Acting Fuses JJN – RMS Let-Through Current (kA)

JJN Fuse Size

Prosp.

B 15 30 60 100 200 400 600 800 1200

400,000 Short

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPS

300,000 C.C. IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS

200,000

500 1 1 1 1 1 1 1 1 1

AMPERE

RATING

100,000 1,000 1 1 1 1 1 1 1 1 1

80,000

5,000 1 1 1 1 2 3 5 5 5

60,000 1200

40,000

800 10,000 1 1 1 2 2 4 6 7 9

600

30,000 15,000 1 1 1 2 3 4 6 9 10

20,000

400

200 20,000 1 1 1 2 3 5 7 10 11

100

10,000 25,000 1 1 2 2 3 5 7 10 12

8,000 60

6,000 30,000 1 1 2 2 3 5 8 11 13

30

4,000 15 35,000 1 1 2 3 4 6 8 11 13

3,000

40,000 1 1 2 3 4 6 9 11 13

2,000

50,000 1 1 2 3 4 7 9 12 15

1,000 60,000 1 1 2 3 4 7 10 13 16

800

600 70,000 1 1 2 3 5 7 10 14 17

400 80,000 1 2 2 3 5 8 11 15 17

300

A 90,000 1 2 2 3 6 8 11 15 18

200

10,000

20,000

30,000

40,000

60,000

80,000

100

200

300

400

600

800

1,000

2,000

3,000

4,000

6,000

8,000

100,000

200,000

100,000 1 2 2 4 6 8 12 16 19

150,000 1 2 3 4 6 9 13 17 22

PROSPECTIVE SHORT-CIRCUIT CURRENT–SYMMETRICAL RMS AMPS

200,000 2 2 3 4 7 9 15 19 23

Tron Class T Fast-Acting Fuses JJS – RMS Let-Through Current (kA)

JJS Fuse Size

Prosp.

B 15 30 60 100 200 400 600 800

400,000 Short

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPS

300,000 C.C. IRMS IRMS IRMS IRMS IRMS IRMS IRMS IRMS

AMPERE

RATING

200,000

500 1 1 1 1 1 1 1 1

100,000 1,000 1 1 1 1 1 1 1 1

80,000 800

60,000

5,000 1 1 1 2 3 4 5 5

600

40,000 400 10,000 1 1 1 2 3 6 8 9

30,000

15,000 1 1 2 3 4 7 10 11

20,000 200

100

20,000 1 1 2 3 4 7 10 12

10,000 60 25,000 1 1 2 3 5 7 11 13

8,000

30 30,000 1 1 2 3 5 8 12 14

6,000

15

4,000 35,000 1 1 2 3 5 9 13 15

3,000

40,000 1 2 2 4 5 9 13 15

2,000

50,000 1 2 2 4 6 10 14 17

1,000

800

60,000 1 2 3 4 6 10 16 18

600 70,000 1 2 3 4 7 11 17 19

400

80,000 1 2 3 4 7 11 17 20

300

A 90,000 1 2 3 4 7 12 18 21

200

10,000

20,000

30,000

40,000

60,000

80,000

100

200

300

400

600

800

1,000

2,000

3,000

4,000

6,000

8,000

100,000

200,000

100,000 2 2 3 5 7 12 19 22

150,000 2 3 4 6 8 14 22 25

PROSPECTIVE SHORT-CIRCUIT CURRENT–SYMMETRICAL RMS AMPS

200,000 2 3 4 6 9 16 24 28

©2005 Cooper Bussmann 213

Cooper Bussmann Current-Limiting Fuse Let-Through Data

See pages 67 to 69 for current-limiting definition and how to analyze these charts.

Low-Peak Class CC Time-Delay Fuses LP-CC – RMS Let-Through Currents (A)

LP-CC Fuse Size

Prosp.

Short 11/4 2 8/10 15 20 25 30

C.C. IRMS IRMS IRMS IRMS IRMS IRMS

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPS

1,000 100 135 240 305 380 435

3,000 140 210 350 440 575 580

5,000 165 255 420 570 690 710

10,000 210 340 540 700 870 1000

20,000 260 435 680 870 1090 1305

30,000 290 525 800 1030 1300 1520

40,000 315 610 870 1150 1390 1700

50,000 340 650 915 1215 1520 1820

60,000 350 735 1050 1300 1650 1980

80,000 390 785 1130 1500 1780 2180

100,000 420 830 1210 1600 2000 2400

200,000 525 1100 1600 2000 2520 3050

PROSPECTIVE SHORT-CIRCUIT CURRENT–SYMMETRICAL RMS AMPS

Limitron Class J Fast-Acting Fuses JKS – RMS Let-Through Currents (kA)

JKS Fuse Size

Prosp.

B 30 60 100 200 400 600

400,000 Short

300,000 C.C. IRMS IRMS IRMS IRMS IRMS IRMS

INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPS

200,000 5,000 1 1 2 3 4 5

AMPERE

10,000 1 2 3 4 6 9

RATING

100,000 15,000 1 2 3 4 7 10

80,000

20,000 1 2 3 5 8 11

60,000

600 25,000 2 3 3 6 9 12

50,000

40,000

400 30,000 2 3 3 6 9 13

30,000

200 35,000 2 3 4 6 9 13

20,000

40,000 2 3 4 7 10 14

100

60 50,000 2 3 4 7 10 15

10,000

8,000 60,000 2 3 5 7 11 16

6,000 30 70,000 2 3 5 8 11 17

5,000

4,000 80,000 2 3 5 8 12 17

3,000 90,000 2 4 6 9 13 18

A

2,000 100,000 2 4 6 9 13 18

150,000 2 5 6 9 14 22

1,000 200,000 3 5 7 10 16 24

1,000

2,000

3,000

4,000

5,000

6,000

8,000

100,000

200,000

10,000

20,000

30,000

40,000

50,000

60,000

80,000

PROSPECTIVE SHORT-CIRCUIT CURRENT–SYMMETRICAL RMS AMPS

214 ©2005 Cooper Bussmann

Glossary

Common Electrical Terminology

Ampere (Amp) Class T Fuses

The measurement of intensity of rate of flow of electrons in an electric circuit. An amp is An industry class of fuses in 300V and 600V ratings from 1 amp through 1200 amps.

the amount of current that will flow through a resistance of one ohm under a pressure of They are physically very small and can be applied where space is at a premium. They

one volt. are fast-acting fuses, with an interrupting rating of 200,000 amps RMS.

Amp Rating Classes of Fuses

The current-carrying capacity of a fuse. When a fuse is subjected to a current above its The industry has developed basic physical specifications and electrical performance

amp rating, it will open the circuit after a predetermined period of time. requirements for fuses with voltage ratings of 600V or less. These are known as

standards. If a type of fuse meets the requirements of a standard, it can fall into that

Amp Squared Seconds, l2t class. Typical classes are K, RK1, RK5, G, L, H, T, CC, and J.

The measure of heat energy developed within a circuit during the fuse’s clearing. It can

be expressed as “Melting l2t”, “Arcing l2t” or the sum of them as “Clearing l2t”. “l” stands Clearing Time

for effective let-through current (RMS), which is squared, and “t” stands for time of The total time between the beginning of the overcurrent and the final opening of the

opening, in seconds. circuit at rated voltage by an overcurrent protective device. Clearing time is the total of

the melting time and the arcing time.

Arcing Time

The amount of time from the instant the fuse link has melted until the overcurrent is Current-Limitation

interrupted, or cleared. A fuse operation relating to short-circuits only. When a fuse operates in its current-

limiting range, it will clear a short-circuit in less than 1⁄2 cycle. Also, it will limit the

Breaking Capacity

instantaneous peak let-through current to a value substantially less than that obtainable

(See Interrupting Rating)

in the same circuit if that fuse were replaced with a solid conductor of equal impedance.

Cartridge Fuse Dual-Element Fuse

A fuse consisting of a current responsive element inside a fuse tube with terminals on

Fuse with a special design that utilizes two individual elements in series inside the fuse

both ends.

tube. One element, the spring actuated trigger assembly, operates on overloads up to

Class CC Fuses 5 - 6 times the fuse current rating. The other element, the short-circuit section, operates

600V, 200,000 amp interrupting rating, branch circuit fuses with overall dimensions of on short-circuits up to its interrupting rating.

13

⁄32" x 1 1⁄2" Their design incorporates a rejection feature that allows them to be inserted

Electrical Load

into rejection fuse holders and fuse blocks that reject all lower voltage, lower interrupting

That part of the electrical system which actually uses the energy or does the work

rating 13⁄32" x 1 1⁄2" fuses. They are available from 1⁄10 amp through 30 amps.

required.

Class G Fuses

1

Fast Acting Fuse

⁄2 - 20A @ 600Vac, 25-604@480Vac, 100,000 amp interrupting rating branch circuit

A fuse which opens on overload and short circuits very quickly. This type of fuse is not

fuses that are size rejecting to eliminate overfusing. The fuse diameter is 13⁄32" while the

designed to withstand temporary overload currents associated with some electrical

length varies from 1 5/16" to 2 1⁄4". These are available in ratings from 1⁄2 amp through 60

loads, when sized near the full load current of the circuit.

amps.

Fuse

Class H Fuses An overcurrent protective device with a fusible link that operates and opens the circuit

250V and 600V, 10,000 amp interrupting rating branch circuit fuses that may be

on an overcurrent condition.

renewable or non-renewable. These are available in amp ratings of 1 amp through 600

amps. High Speed Fuses

Fuses with no intentional time-delay in the overload range and designed to open as

Class J Fuses quickly as possible in the short-circuit range. These fuses are often used to protect

These rejection style fuses are rated to interrupt a minimum of 200,000 amps AC. They

solid-state devices.

are labeled as “Current-Limiting”, are rated for 600Vac, and are not interchangeable with

other classes. They are available from 1 through 600 amps. Inductive Load

An electrical load which pulls a large amount of current – an inrush current – when first

Class K Fuses

2

energized. After a few cycles or seconds the current “settles down” to the full-load

These are fuses listed as K-1, K-5, or K-9 fuses. Each subclass has designated I t and

running current.

lp maximums. These are dimensionally the same as Class H fuses, and they can have

interrupting ratings of 50,000, 100,000, or 200,000 amps. These fuses are current- Interrupting Capacity

limiting. However, they are not marked “current-limiting” on their label since they do not Actual test current an overcurrent device sees during the short circuit test.

have a rejection feature.

Interrupting Rating

Class L Fuses The rating which defines a fuse’s ability to safely interrupt and clear short-circuits. This

These fuses are rated for 601 through 6000 amps, and are rated to interrupt a minimum rating is much greater than the amp rating of a fuse. The NEC® defines Interrupting

of 200,000 amps AC. They are labeled “current-limiting” and are rated for 600Vac. They Rating as “The highest current at rated voltage that an overcurrent protective device is

are intended to be bolted into their mountings and are not normally used in clips. Some intended to interrupt under standard test conditions.”

Class L fuses have designed in time-delay features for all purpose use.

Melting Time

Class R Fuses The amount of time required to melt the fuse link during a specified overcurrent. (See

These are high performance fuses rated 1⁄10 - 600 amps in 250 volt and 600V ratings. All Arcing Time and Clearing Time.)

are marked “current-limiting” on their label and all have a minimum of 200,000 amp

“NEC” Dimensions

interrupting rating. They have identical outline dimensions with the Class H fuses but

These are dimensions once referenced in the National Electrical Code®. They are

have a rejection feature which prevents the user from mounting a fuse of lesser

common to Class H and K fuses and provide interchangeability between manufacturers

capabilities (lower interrupting capacity) when used with special Class R Clips. Class R

for fuses and fusible equipment of given amp and voltage ratings.

fuses will fit into either rejection or non-rejection clips.

©2005 Cooper Bussmann 215

Glossary

Common Electrical Terminology

Ohm Semiconductor Fuses

The unit of measure for electric resistance. An ohm is the amount of resistance that will Fuses used to protect solid-state devices. See “High Speed Fuses.”

allow one amp to flow under a pressure of one volt.

Short-Circuit

Ohm’s Law Can be classified as an overcurrent which exceeds the normal full load current of a

The relationship between voltage, current, and resistance, expressed by the equation E circuit by a factor many times (tens, hundreds or thousands greater). Also characteristic

= IR, where E is the voltage in volts, I is the current in amps, and R is the resistance in of this type of overcurrent is that it leaves the normal current carrying path of the circuit

ohms. – it takes a “short cut” around the load and back to the source.

One Time Fuses Short-Circuit Current Rating

Generic term used to describe a Class H nonrenewable cartridge fuse, with a single The maximum short-circuit current an electrical component can sustain without the

element. occurrence of excessive damage when protected with an overcurrent protective device.

Overcurrent Single-Phasing

A condition which exists on an electrical circuit when the normal load current is That condition which occurs when one phase of a three-phase system opens, either in a

exceeded. Overcurrents take on two separate characteristics – overloads and short- low voltage (secondary) or high voltage (primary) distribution system. Primary or

circuits. secondary single-phasing can be caused by any number of events. This condition

results in unbalanced currents in polyphase motors and unless protective measures are

Overload taken, causes overheating and failure.

Can be classified as an overcurrent which exceeds the normal full load current of a

circuit. Also characteristic of this type of overcurrent is that it does not leave the normal Threshold Current

current carrying path of the circuit – that is, it flows from the source, through the The symmetrical RMS available current at the threshold of the current-limiting range,

conductors, through the load, back through the conductors, to the source again. where the fuse becomes current-limiting when tested to the industry standard. This

value can be read off of a peak let-through chart where the fuse curve intersects the

Peak Let-Through Current, lp A - B line. A threshold ratio is the relationship of the threshold current to the fuse’s

The instantaneous value of peak current let-through by a current-limiting fuse, when it

continuous current rating.

operates in its current-limiting range.

Time-Delay Fuse

Renewable Fuse (600V & below) A fuse with a built-in delay that allows temporary and harmless inrush currents to pass

A fuse in which the element, typically a zinc link, may be replaced after the fuse has

without opening, but is so designed to open on sustained overloads and short-circuits.

opened, and then reused. Renewable fuses are made to Class H standards.

Voltage Rating

Resistive Load The maximum open circuit voltage in which a fuse can be used, yet safely interrupt an

An electrical load which is characteristic of not having any significant inrush current.

overcurrent. Exceeding the voltage rating of a fuse impairs its ability to clear an overload

When a resistive load is energized, the current rises instantly to its steady-state value,

or short-circuit safely.

without first rising to a higher value.

Withstand Rating

RMS Current The maximum current that an unprotected electrical component can sustain for a

The RMS (root-mean-square) value of any periodic current is equal to the value of the

specified period of time without the occurrence of extensive damage.

direct current which, flowing through a resistance, produces the same heating effect in

the resistance as the periodic current does.

Electrical Formulas

To Find Single-Phase Two-Phase Three-Phase Direct Current

kVA ≈ 1000 kVA ≈ 1000 kVA ≈ 1000

Amperes when kVA is known Not Applicable

E E≈2 E ≈ 1.73

HP ≈ 746 HP ≈ 746 HP ≈ 746 HP ≈ 746

Amperes when horsepower is known

E ≈ % eff. ≈ pf E ≈ 2 ≈ % eff. ≈ pf E ≈ 1.73 ≈ % eff. ≈ pf E ≈ % eff.

kW ≈ 1000 kW ≈ 1000 kW ≈ 1000 kW ≈ 1000

Amperes when kilowatts are known

E ≈ pf E ≈ 2 pf E ≈ 1.73 ≈ pf E

I ≈ E ≈ pf I ≈ E ≈ 2 ≈ pf I ≈ E ≈ 1.73 ≈ pf I≈E

Kilowatts

1000 1000 1000 1000

I≈E I≈E≈2 I ≈ E ≈1.73

Kilovolt-Amperes Not Applicable

1000 1000 1000

I ≈ E % eff. ≈ pf I ≈ E ≈ 2 ≈ % eff. ≈ pf I ≈ E ≈ 1.73 ≈ % eff. ≈ pf I ≈ E ≈ % eff.

Horsepower

746 746 746 746

Watts E ≈ I ≈ pf I ≈ E ≈ 2 ≈ pf I ≈ E ≈ 1.73 ≈ pf E≈I

Energy Efficiency = Load Horsepower ≈ 746

Load Input kVA ≈ 1000

Power Factor = pf = Power Consumed = W or kW = cosθ

Apparent Power VA kVA

I = Amperes E = Volts kW = Kilowatts kVA = Kilovolt-Amperes

HP = Horsepower % eff. = Percent Efficiency pf = Power Factor

216 ©2005 Cooper Bussmann

S-ar putea să vă placă și

- Floodlight FLMDocument1 paginăFloodlight FLMEliasÎncă nu există evaluări

- Schematic Diagrams: KD-G455, KD-G405Document5 paginiSchematic Diagrams: KD-G455, KD-G405heyjuÎncă nu există evaluări

- Fuse, Bussman Time Delay FNQ-RDocument3 paginiFuse, Bussman Time Delay FNQ-RSerÎncă nu există evaluări

- HT Cable ScheduleDocument2 paginiHT Cable ScheduletceterexÎncă nu există evaluări

- Comparação Fabricantes de Discos e PainéisDocument5 paginiComparação Fabricantes de Discos e PainéisRogerio FernandesÎncă nu există evaluări

- Bussman Fuses - A PDFDocument444 paginiBussman Fuses - A PDFMark FosterÎncă nu există evaluări

- Bus Ele Cat 1007 FLC 2018 PDFDocument470 paginiBus Ele Cat 1007 FLC 2018 PDFjoy symÎncă nu există evaluări

- Inventory Engine PumpDocument1 paginăInventory Engine PumpFandy saputraÎncă nu există evaluări

- 1103 & 1104 GE0 ENGINE Wiring SchematicDocument7 pagini1103 & 1104 GE0 ENGINE Wiring Schematicmahmoud ElmasryÎncă nu există evaluări

- Elecraft kx3 SCH PDFDocument19 paginiElecraft kx3 SCH PDFBlagoja GjakovskiÎncă nu există evaluări

- NewAge CatalogueDocument26 paginiNewAge CatalogueAlienated GatanÎncă nu există evaluări

- Kia Depo CatelogueDocument34 paginiKia Depo CatelogueParts Gallary Auto Spare Parts Trading LLC BR-1Încă nu există evaluări

- McQuay M5RT Technical Manual RusDocument93 paginiMcQuay M5RT Technical Manual RusLeonardusÎncă nu există evaluări

- Spare Part List Modified StampedDocument1 paginăSpare Part List Modified StampedzakalyÎncă nu există evaluări

- Imr 2023 MLKFLR CpsDocument1 paginăImr 2023 MLKFLR Cpsmaziah.medaniÎncă nu există evaluări

- Spare Part List Modified Stamped - 2Document1 paginăSpare Part List Modified Stamped - 2zakalyÎncă nu există evaluări

- CATV Cable ProductsDocument6 paginiCATV Cable ProductsNghi NguyenÎncă nu există evaluări

- KX FL423Document24 paginiKX FL42301.wra1th.01Încă nu există evaluări

- Drain Schedule BTPS-500 PDFDocument3 paginiDrain Schedule BTPS-500 PDFnksatnamiÎncă nu există evaluări

- BG16112022 Bateel at Khalifa MECH DESIGN REV01-M0002Document1 paginăBG16112022 Bateel at Khalifa MECH DESIGN REV01-M0002FareethAbdullahÎncă nu există evaluări

- Packaged Air Conditioner Rooftop B Series: Technical ManualDocument93 paginiPackaged Air Conditioner Rooftop B Series: Technical ManualJf OngÎncă nu există evaluări

- ITEM 10 Data Sheet M006-2T1Document1 paginăITEM 10 Data Sheet M006-2T1gmendezcadena974Încă nu există evaluări

- NASPO 2021 Ceragon Price ListDocument115 paginiNASPO 2021 Ceragon Price Listpayam79bÎncă nu există evaluări

- Datasheet 3 Pcs 01Document24 paginiDatasheet 3 Pcs 01StarburstÎncă nu există evaluări

- Kenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgDocument21 paginiKenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgNenadBlaškovićÎncă nu există evaluări

- Mir d245s & d45ks Rev.2Document1 paginăMir d245s & d45ks Rev.2open hartigÎncă nu există evaluări

- Fuse-ANSI StandardDocument24 paginiFuse-ANSI StandardVasu IyerÎncă nu există evaluări

- HS-TA .. ../ .. ./ ./ .Total .. HS-TA .. ../ .. ./ ./ .Total .Document7 paginiHS-TA .. ../ .. ./ ./ .Total .. HS-TA .. ../ .. ./ ./ .Total .Punthep PunnotokÎncă nu există evaluări

- BT-1 BV-1: Kroma LTD Aesseal Burgmann John Crane Roten Vulcan Sterling Flowserve ПрочиеDocument2 paginiBT-1 BV-1: Kroma LTD Aesseal Burgmann John Crane Roten Vulcan Sterling Flowserve ПрочиеАйрат ГараевÎncă nu există evaluări

- Acrobat Document1Document199 paginiAcrobat Document1Donald Santana BautistaÎncă nu există evaluări

- JVC KD r430 PDFDocument13 paginiJVC KD r430 PDFAleksÎncă nu există evaluări

- Head TripDocument15 paginiHead TripAnonymous gQHmr3tUmÎncă nu există evaluări

- Floodlight FLMS9Document1 paginăFloodlight FLMS9EliasÎncă nu există evaluări

- Master ProDocument57 paginiMaster ProDen limboongÎncă nu există evaluări

- MV Power Cable Schedule (Stage-1)Document1 paginăMV Power Cable Schedule (Stage-1)Anand Mohan PandeyÎncă nu există evaluări

- Ca Choke Valve Series: Technical Data Sheet For Maximum Trim Size of 1.18"Document4 paginiCa Choke Valve Series: Technical Data Sheet For Maximum Trim Size of 1.18"shyamÎncă nu există evaluări

- PDS Commodity Code BreakdownDocument29 paginiPDS Commodity Code BreakdownShahfaraz AhmadÎncă nu există evaluări

- Sei Green Flash PVT LTD - 33Kv Power Cable Schedule & TerminationDocument3 paginiSei Green Flash PVT LTD - 33Kv Power Cable Schedule & Terminationpriyanka236Încă nu există evaluări

- Ga BomDocument1 paginăGa BomSACHIN PATELÎncă nu există evaluări

- RSSWP 24mcch FRDocument4 paginiRSSWP 24mcch FRAgustin CanaveseÎncă nu există evaluări

- ValvesDocument456 paginiValvesayaaithassi19Încă nu există evaluări

- All Radio Sales - CB Radio Alignments - Cobra 148GTL (PC-412)Document7 paginiAll Radio Sales - CB Radio Alignments - Cobra 148GTL (PC-412)Gerardo HernándezÎncă nu există evaluări

- CircuitsDocument41 paginiCircuitsriajulÎncă nu există evaluări

- New-Project Tata SteelDocument24 paginiNew-Project Tata Steelsomnath banerjeeÎncă nu există evaluări

- Quick Purchasing Guide 2017Document11 paginiQuick Purchasing Guide 2017boroumandÎncă nu există evaluări

- Grilles-Registers Cross-Reference PDFDocument12 paginiGrilles-Registers Cross-Reference PDFRaymond CunÎncă nu există evaluări

- Emerson Motor Company: DATE: 2/25/2004 P.O. NO.: USEM Order/Line NO.: NA TO: Model Number: Catalog Number: RevisionsDocument8 paginiEmerson Motor Company: DATE: 2/25/2004 P.O. NO.: USEM Order/Line NO.: NA TO: Model Number: Catalog Number: RevisionsFrancisco MartinezÎncă nu există evaluări

- FKSM 71-8 May 2011 BFSB UpdateDocument26 paginiFKSM 71-8 May 2011 BFSB Updateghasdga0% (1)

- Presentation Anil May-10Document215 paginiPresentation Anil May-10devgankaranÎncă nu există evaluări

- JVC Car Stereo KD-S595 Schematic DiagramDocument10 paginiJVC Car Stereo KD-S595 Schematic DiagramAnonymous j5apk2AumÎncă nu există evaluări

- Basics of Electric Locomotive: Presentation by Design Centre, MSDPL, HyderabadDocument23 paginiBasics of Electric Locomotive: Presentation by Design Centre, MSDPL, HyderabadAshutosh Pandey100% (1)

- 10-Sedecal Parts Manual 1005R2Document22 pagini10-Sedecal Parts Manual 1005R2jaime munozÎncă nu există evaluări

- Estacion Reductora-Propuesta ComercialDocument5 paginiEstacion Reductora-Propuesta Comercialcamilo diazÎncă nu există evaluări

- Substation Secondary CircuitDocument10 paginiSubstation Secondary CircuitTuấn Anh NguyễnÎncă nu există evaluări

- Kenwood Kac-X4dDocument32 paginiKenwood Kac-X4dMario Rodriguez JuradoÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Nema 2014WMS PDFDocument106 paginiNema 2014WMS PDFspidervinoÎncă nu există evaluări

- Field Inspection & Testing of New Electrical Equip.Document25 paginiField Inspection & Testing of New Electrical Equip.noormohammedah100% (2)

- Approaches To Arc Flash Hazard Mitigation in 600 Volt Power SysteDocument145 paginiApproaches To Arc Flash Hazard Mitigation in 600 Volt Power SysteSJS68Încă nu există evaluări

- 420 HSB Recommended Practice For Electrical Preventive MaintenanceDocument13 pagini420 HSB Recommended Practice For Electrical Preventive MaintenanceAris CahyonoÎncă nu există evaluări

- Changes To 70E-2012 - UpTime MagazineDocument6 paginiChanges To 70E-2012 - UpTime MagazineBigBaby JulianÎncă nu există evaluări

- NEMA TR 1-2013 TransformersDocument21 paginiNEMA TR 1-2013 Transformersraghavendran raghu100% (2)

- Noise No Load and LoadDocument8 paginiNoise No Load and LoadSudhakara Rao YanamadalaÎncă nu există evaluări

- Arc Flash HazardDocument8 paginiArc Flash HazardSJS68Încă nu există evaluări

- 420 HSB Recommended Practice For Electrical Preventive MaintenanceDocument13 pagini420 HSB Recommended Practice For Electrical Preventive MaintenanceAris CahyonoÎncă nu există evaluări

- Reliability Facilityelectrical Preventive Maintenance & InspectionDocument6 paginiReliability Facilityelectrical Preventive Maintenance & InspectionSJS68Încă nu există evaluări

- 2013 IREC Interconnection Model ProceduresDocument65 pagini2013 IREC Interconnection Model ProceduresSJS68Încă nu există evaluări

- RC Property BUL Electricalpreventativemain CNADocument4 paginiRC Property BUL Electricalpreventativemain CNASJS68Încă nu există evaluări

- How To Build A Safe Effective Electrical Maintenance ProgramDocument80 paginiHow To Build A Safe Effective Electrical Maintenance ProgramSJS68100% (3)

- Ansi C84.1-1995 (R2005)Document26 paginiAnsi C84.1-1995 (R2005)SJS68Încă nu există evaluări

- Lighting SystemsDocument1 paginăLighting SystemsSJS68Încă nu există evaluări

- Short Circuit Coord Arcflash Studies DC r0Document20 paginiShort Circuit Coord Arcflash Studies DC r0SJS68Încă nu există evaluări

- CL&P Yellow BookDocument184 paginiCL&P Yellow BookSJS68Încă nu există evaluări

- Electrical EbooksDocument5 paginiElectrical Ebooksindra_agustian44% (25)

- Project Management For Non-Project Managers: What You'll LearnDocument2 paginiProject Management For Non-Project Managers: What You'll LearnSJS68Încă nu există evaluări

- CL&P Net Metering BrochureDocument1 paginăCL&P Net Metering BrochureSJS68Încă nu există evaluări

- Electrical Training: Professional Catalog 2011Document20 paginiElectrical Training: Professional Catalog 2011Maham Khan75% (4)

- GroundingDocument11 paginiGroundingarunv19Încă nu există evaluări

- Electrical Training: Professional Catalog 2011Document20 paginiElectrical Training: Professional Catalog 2011Maham Khan75% (4)

- Effects Voltage Sags Industry ApplicationsDocument8 paginiEffects Voltage Sags Industry ApplicationsSJS68Încă nu există evaluări

- Utility PolesDocument33 paginiUtility PolesSJS68Încă nu există evaluări

- Making Money The Old Fashioned Way: by Joe MartinDocument62 paginiMaking Money The Old Fashioned Way: by Joe MartinSJS68Încă nu există evaluări

- Comparing AvailabilityDocument22 paginiComparing Availability(unknown)Încă nu există evaluări

- Assessing Health of Facility Electrical SystemDocument20 paginiAssessing Health of Facility Electrical SystemSJS68Încă nu există evaluări

- EPA2000 BO HW InstructionsDocument7 paginiEPA2000 BO HW InstructionsSJS68Încă nu există evaluări

- Ev200haana RelayDocument2 paginiEv200haana RelaySJS68Încă nu există evaluări

- Myth or Fact-Worksheet 1Document1 paginăMyth or Fact-Worksheet 1Zahraa LotfyÎncă nu există evaluări

- Vehicles 6-Speed PowerShift Transmission DPS6 DescriptionDocument3 paginiVehicles 6-Speed PowerShift Transmission DPS6 DescriptionCarlos SerapioÎncă nu există evaluări

- Interventional Studies 2Document28 paginiInterventional Studies 2Abdul RazzakÎncă nu există evaluări

- Sailpoint Topic Wise SyllabusDocument2 paginiSailpoint Topic Wise SyllabusKishore KodaliÎncă nu există evaluări

- Math 10 Week 3-4Document2 paginiMath 10 Week 3-4Rustom Torio QuilloyÎncă nu există evaluări

- ShotcreteDocument7 paginiShotcreteafuhcivÎncă nu există evaluări

- Jmac TempDocument5 paginiJmac TempDan GerÎncă nu există evaluări

- Project 2 Analysis of Florida WaterDocument8 paginiProject 2 Analysis of Florida WaterBeau Beauchamp100% (1)

- Functions of The Gastrointestinal Organs: Muhammad ImranDocument21 paginiFunctions of The Gastrointestinal Organs: Muhammad ImranSalman KhanÎncă nu există evaluări

- Rizal Noli Me TangereDocument35 paginiRizal Noli Me TangereKristine Cantilero100% (2)

- Operator Training ManualDocument195 paginiOperator Training ManualIgnacio MuñozÎncă nu există evaluări

- Business Mathematics (Matrix)Document3 paginiBusiness Mathematics (Matrix)MD HABIBÎncă nu există evaluări

- Limited Alembic: Employee Related DataDocument4 paginiLimited Alembic: Employee Related DataTp EarningsÎncă nu există evaluări

- LANY Lyrics: "Thru These Tears" LyricsDocument2 paginiLANY Lyrics: "Thru These Tears" LyricsAnneÎncă nu există evaluări

- Exchange 2010 UnderstandDocument493 paginiExchange 2010 UnderstandSeKoFieÎncă nu există evaluări

- English 9 Week 5 Q4Document4 paginiEnglish 9 Week 5 Q4Angel EjeÎncă nu există evaluări

- Thesis Statement On Lionel MessiDocument4 paginiThesis Statement On Lionel Messidwham6h1100% (2)

- Attitude of Tribal and Non Tribal Students Towards ModernizationDocument9 paginiAttitude of Tribal and Non Tribal Students Towards ModernizationAnonymous CwJeBCAXpÎncă nu există evaluări

- Blank Freeway Walls Replaced With Local Designs - Press EnterpriseDocument5 paginiBlank Freeway Walls Replaced With Local Designs - Press EnterpriseEmmanuel Cuauhtémoc Ramos BarajasÎncă nu există evaluări

- Grade 8 Least Mastered Competencies Sy 2020-2021: Handicraft Making Dressmaking CarpentryDocument9 paginiGrade 8 Least Mastered Competencies Sy 2020-2021: Handicraft Making Dressmaking CarpentryHJ HJÎncă nu există evaluări

- Laminar Premixed Flames 6Document78 paginiLaminar Premixed Flames 6rcarpiooÎncă nu există evaluări

- Norm ANSI PDFDocument1 paginăNorm ANSI PDFAbdul Quddus Mat IsaÎncă nu există evaluări

- M 995Document43 paginiM 995Hossam AliÎncă nu există evaluări

- Objective-C Succinctly PDFDocument110 paginiObjective-C Succinctly PDFTKKÎncă nu există evaluări

- Second Quarter Lesson 4Document7 paginiSecond Quarter Lesson 4Jomarie PauleÎncă nu există evaluări

- Inglês - Advérbios - Adverbs.Document18 paginiInglês - Advérbios - Adverbs.KhyashiÎncă nu există evaluări

- Decolonization DBQDocument3 paginiDecolonization DBQapi-493862773Încă nu există evaluări

- Solving Systems of Linear Equations in Three Variables: You Should LearnDocument8 paginiSolving Systems of Linear Equations in Three Variables: You Should LearnTheodore JoaquinnÎncă nu există evaluări

- Assignment OSDocument11 paginiAssignment OSJunaidArshadÎncă nu există evaluări

- PresentationDocument6 paginiPresentationVruchali ThakareÎncă nu există evaluări