Documente Academic

Documente Profesional

Documente Cultură

(Lef/ry) 2 (Lef Te) 2

Încărcat de

Vijay KumarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

(Lef/ry) 2 (Lef Te) 2

Încărcat de

Vijay KumarDrepturi de autor:

Formate disponibile

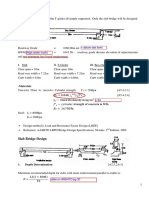

4.4 Permissible bending stress As per IRS.SBC.cl. 3.9.

1(a)

267730 (Lef*te)^2

Cs= (Lef/ry)^ 1+(1/20)

(ry*D)^2

2

Effective length of the compression flange(Leff) = 1.800 m (As per IRS.SBC.Cl.5.4.2.1.a)

Actual thickness of the compression flange(t) = 13.60 mm

Mean thickness of compression flange at point of Max BM = 13.60 mm

Minimum radius of gyration about yy-axis of gross section at point of max bending moment

= 26.10 mm

Ra= Area of both the flanges at point of least bending moment/Area of both the flanges at point of greater bending moment

Ra= 2448 / 2448 = 1.00

K1, corresponding to the value of "Ra" = 1.0 (As per IRS.SBC.Table-V)

Effective thickness of the compression flange(te)=K1 * mean thickness of the compression flange

Effective thickness of the compression flange(te) = 13.60 mm

Lef/ry = 68.98 < 300.00 OK (As per IRS.SBC.Cl.5.3)

D/te = 22.06

As per formula,

267730 (Lef*te)^2

Cs= (Lef/ry)^ 1+(1/20)

(ry*D)^2

2

Calculation of terms:

267730 267730

= = 56.271

(Lef/ry)^2 4757.84

(Lef*te)^2 4757.84

= = 9.778

(ry*D)^2 486.59

(Lef*te)^2

1+(1/20) = 1.220

(ry*D)^2

Cs = 68.662 Kg/mm2

2

"Cs" Calculated above shall be increased by 20% for plate girders = 82.394 Kg/mm

1) te/t is not greater than 2, 1.00 < 2

2) di/t is not greater than 85, 35.89 < 85 (As per IS:2062-2006)

All the stress are increased by 25% for construction condition

Permissible bending compressive stress(σbc) = 18.23 Kg/mm2 (As per IRS.SBC.cl. 3.9.1(a) & Table-VIII)

Permissible bending tensile stress = 17.75 Kg/mm2 (As per IRS.SBC.Table-I & II)

Permissble shear stress = 10.875 Kg/mm2 (As per IRS.SBC.Table-I & II)

4.5 Check

Bending compression/tensile stress 10.3834 < 18.23 OK

Shear stress 2.8325 < 10.88 OK

4.6 Check for deflection

Deflection to be checked for serviceable loads

Maximum load on the beam W = 11.745 t

Deflection WL^3/48EI = 1.1 mm

Allowable deflection l/300 = 6.00 mm -OK-

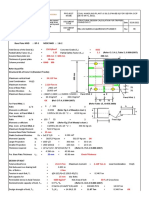

4.7 Connection design of stool & ISMC300 with the trestle

Diameter of the bolt = 20 mm

Daimeter of the hole = 21.5 mm

Thickness of L.65x65x6 = 6.00 mm

Thickness of CC crib member L.65x65x6 = 6.00 mm

All the permissible stress are increased by 25% for erection condition

Permissible stress in shearing of the bolt = 11.75 Kg/mm2 (As per IRS-SBC.table-II)

Permissible stress in bearing of the bolt = 27.50 Kg/mm2 (As per IRS-SBC.table-II)

Permissible stress in bearing of the plate = 23.63 Kg/mm2 (As per IRS-SBC.table-II)

Strength of bolt in single shear = 3691.37 Kg

Strength of bolt in double shear = 7382.74 kg

Strength of bolt/plate in bearing = 3047.63 kg

Bolt value = 3047.63 kg

S-ar putea să vă placă și

- Access Scaffolding CalculationDocument8 paginiAccess Scaffolding CalculationOsama Tahir100% (3)

- Beam Design To ACI 318-14Document10 paginiBeam Design To ACI 318-14dovermanÎncă nu există evaluări

- Stub Cleat Design & DrawingDocument2 paginiStub Cleat Design & DrawingVijay Kumar100% (3)

- Skew Bridge DesignDocument16 paginiSkew Bridge DesignVIGNESH DÎncă nu există evaluări

- Global Transmission Report January 2016 PDFDocument62 paginiGlobal Transmission Report January 2016 PDFVijay KumarÎncă nu există evaluări

- Guy AnchorDocument1 paginăGuy AnchorVijay KumarÎncă nu există evaluări

- Global Transmission Report January 2016 PDFDocument62 paginiGlobal Transmission Report January 2016 PDFVijay KumarÎncă nu există evaluări

- Hard StandDocument10 paginiHard StandYatendra TyagiÎncă nu există evaluări

- Design of Mullion For C W Wall System: Project NameDocument3 paginiDesign of Mullion For C W Wall System: Project NameSales AlufacadesÎncă nu există evaluări

- Perhitungan Balok I GirderDocument19 paginiPerhitungan Balok I GirderArif Rahman Putranto100% (1)

- Example1 1-StraightsupportedDocument7 paginiExample1 1-StraightsupportedOmar BayouÎncă nu există evaluări

- Design of A Slab Bridge On Abeya River A PDFDocument13 paginiDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- 7 Slab Design 1503Document32 pagini7 Slab Design 1503Er Mohd NoshadÎncă nu există evaluări

- Design Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415Document5 paginiDesign Calculation Alternate Staging (Using Mmrda Materials) of Vup at Ch. 16+415swapan.boseÎncă nu există evaluări

- Perhitungan Shaft Pulley ConveyorDocument5 paginiPerhitungan Shaft Pulley ConveyorRiska DamayantiÎncă nu există evaluări

- Compression Design Section2Document10 paginiCompression Design Section2Anonymous sfkedkymÎncă nu există evaluări

- Design of Dogging BeamDocument1 paginăDesign of Dogging BeamSujeet KumarÎncă nu există evaluări

- BS5400 R.C Design With Crack WidthDocument9 paginiBS5400 R.C Design With Crack WidthWangTF100% (4)

- Base Plate BP-3Document3 paginiBase Plate BP-3Anonymous T7v17KhnwcÎncă nu există evaluări

- Project Floor / Slab No. 2 LOCATION Below Platform' WHO-20D' Client BUILDING NAME Production Building, FIT-1Document1 paginăProject Floor / Slab No. 2 LOCATION Below Platform' WHO-20D' Client BUILDING NAME Production Building, FIT-1EakJhuanÎncă nu există evaluări

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 paginiTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11Încă nu există evaluări

- Culvert Design Using Staad As Per IrsDocument171 paginiCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudÎncă nu există evaluări

- Access Scaffolding CalculationDocument8 paginiAccess Scaffolding CalculationSarah HaiderÎncă nu există evaluări

- Bearing DesignDocument24 paginiBearing DesignPrabhakaran KarunanithiÎncă nu există evaluări

- Coba JembatanDocument28 paginiCoba JembatanAbdi Septia PutraÎncă nu există evaluări

- Roof 2 3Document1 paginăRoof 2 3Aek JanÎncă nu există evaluări

- Method of Design Cantilever ErectionDocument62 paginiMethod of Design Cantilever Erectionzieq72Încă nu există evaluări

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 paginiDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaÎncă nu există evaluări

- 1.0 Diesel Tank SupportsDocument3 pagini1.0 Diesel Tank SupportsKushan Dhanushka NanayakkaraÎncă nu există evaluări

- Horizontal Lifting LugDocument1 paginăHorizontal Lifting LugTushar MangratiÎncă nu există evaluări

- Plate GirderDocument13 paginiPlate Girdernurul adilahÎncă nu există evaluări

- Amend Design Stiff CDocument15 paginiAmend Design Stiff Cnurul adilahÎncă nu există evaluări

- Slab CrackwidthDocument15 paginiSlab CrackwidthMohammed Saleem Syed KhaderÎncă nu există evaluări

- 15m Brick Wall Frame 2021-08-21Document21 pagini15m Brick Wall Frame 2021-08-21Jack WenÎncă nu există evaluări

- Project: DLF Club, New DelhiDocument3 paginiProject: DLF Club, New DelhiAniket InarkarÎncă nu există evaluări

- Gable BaseplateDocument2 paginiGable BaseplateSURIYAÎncă nu există evaluări

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pagini1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- Built Up Column - ChannelDocument18 paginiBuilt Up Column - ChannelSambhav PoddarÎncă nu există evaluări

- M019 主機安裝圖HOLDING DOWN BOLTS OF MAIN ENGINE AND LINER ARRANGEMENTDocument6 paginiM019 主機安裝圖HOLDING DOWN BOLTS OF MAIN ENGINE AND LINER ARRANGEMENTabu680530Încă nu există evaluări

- Beam DesignDocument35 paginiBeam DesignAli Aafaaq100% (1)

- Design of Beam (Steel)Document30 paginiDesign of Beam (Steel)jeyavaniÎncă nu există evaluări

- Timber Prop & Beam Side FormworkDocument27 paginiTimber Prop & Beam Side FormworkOng George SammyÎncă nu există evaluări

- Tank Footing Design Based On ACI 318-14: Input DataDocument12 paginiTank Footing Design Based On ACI 318-14: Input DataMaraLeonÎncă nu există evaluări

- Deck Member Design - AshuDocument11 paginiDeck Member Design - Ashurehan7421Încă nu există evaluări

- Shutter DesignDocument28 paginiShutter Designsubhananya50% (4)

- Lifting Lug Calc - VerticalDocument7 paginiLifting Lug Calc - Verticaljahiranazri100% (1)

- Grade Slab CSB BuildingDocument7 paginiGrade Slab CSB BuildingersivarajÎncă nu există evaluări

- REPORT (3) - MergedDocument29 paginiREPORT (3) - MergedMoustafaÎncă nu există evaluări

- Attachment 1 - Bi-Axial Bending CheckDocument2 paginiAttachment 1 - Bi-Axial Bending CheckYang W OngÎncă nu există evaluări

- RCC32R Rigorous Ribbed SlabsDocument554 paginiRCC32R Rigorous Ribbed SlabsCioabla Bogdan100% (1)

- DDDDDD DD DDDD DDDD DDD DDDDDocument11 paginiDDDDDD DD DDDD DDDD DDD DDDDkitti kothapalliÎncă nu există evaluări

- Base Plate Design Gangway ColumnDocument2 paginiBase Plate Design Gangway ColumnsandeepÎncă nu există evaluări

- Example 5.1Document6 paginiExample 5.1Aisyah JamalÎncă nu există evaluări

- Bridge PortionDocument16 paginiBridge PortionNagara SelvarajÎncă nu există evaluări

- Gorakhpur Bypass RobDocument9 paginiGorakhpur Bypass RobvivekÎncă nu există evaluări

- Stair Case Design: Schematic PlanDocument6 paginiStair Case Design: Schematic Planthanigai veluÎncă nu există evaluări

- Com Apps Preliminary SizingDocument8 paginiCom Apps Preliminary SizingTom SawyerÎncă nu există evaluări

- Simple End Plate Connection Design (Bolted End Plate Connection)Document6 paginiSimple End Plate Connection Design (Bolted End Plate Connection)Nitesh SinghÎncă nu există evaluări

- PSC Bridge Girder Design To bs5400 by D ChildsDocument321 paginiPSC Bridge Girder Design To bs5400 by D ChildsRABAH MESLOUBÎncă nu există evaluări

- Top Chord (Mo) : KG M M S 1 KN 1000 NDocument11 paginiTop Chord (Mo) : KG M M S 1 KN 1000 Njoe kyleÎncă nu există evaluări

- Design For Steel Circular Columns (R1)Document8 paginiDesign For Steel Circular Columns (R1)rahul1433Încă nu există evaluări

- Materials Science and Technology of Optical FabricationDe la EverandMaterials Science and Technology of Optical FabricationÎncă nu există evaluări

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesDe la Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesÎncă nu există evaluări

- Rock AnchorDocument2 paginiRock AnchorVijay Kumar100% (1)

- No - of Bolts Required 0.66 No.s No - of Bolts Provided No.sDocument1 paginăNo - of Bolts Required 0.66 No.s No - of Bolts Provided No.sVijay KumarÎncă nu există evaluări

- Check For Uplift (Refer Figure - 2)Document1 paginăCheck For Uplift (Refer Figure - 2)Vijay KumarÎncă nu există evaluări

- Input Parameters For Foundation DesignDocument1 paginăInput Parameters For Foundation DesignVijay KumarÎncă nu există evaluări

- Hence The Spcacing Between Rod Is (MM) 105 O.KDocument1 paginăHence The Spcacing Between Rod Is (MM) 105 O.KVijay KumarÎncă nu există evaluări

- Bending Moment About Section Y-YDocument1 paginăBending Moment About Section Y-YVijay KumarÎncă nu există evaluări

- Structural Design of FoundationDocument1 paginăStructural Design of FoundationVijay KumarÎncă nu există evaluări

- Hence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Document1 paginăHence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Vijay KumarÎncă nu există evaluări

- Check For OverturningDocument1 paginăCheck For OverturningVijay KumarÎncă nu există evaluări

- Nanoparticles Advances in Drug Delivery SystemsDocument6 paginiNanoparticles Advances in Drug Delivery SystemsDr-Mohammad Didare Alam MuhsinÎncă nu există evaluări

- Water Shutoff Techniques in Oil WellsDocument15 paginiWater Shutoff Techniques in Oil WellsOmar ZareefÎncă nu există evaluări

- Abandonment of WellsDocument9 paginiAbandonment of Wellskewall lalta RamirezÎncă nu există evaluări

- Welding Complete PPT With QuestionDocument50 paginiWelding Complete PPT With QuestionKBSMANITÎncă nu există evaluări

- QuickGuide CIRA Geocolor 20171019Document2 paginiQuickGuide CIRA Geocolor 20171019Dardo Melgar RocaÎncă nu există evaluări

- The Mathematical Modelling of The Motion of A Horizontal Vibrating Screen Supported by Rosta Oscillating MountingsDocument9 paginiThe Mathematical Modelling of The Motion of A Horizontal Vibrating Screen Supported by Rosta Oscillating MountingsVilayet AlekperovÎncă nu există evaluări

- Efa FitnetDocument20 paginiEfa FitnetQuoc VinhÎncă nu există evaluări

- Syllabus: M. Tech. Energy Management (Regular)Document28 paginiSyllabus: M. Tech. Energy Management (Regular)Digvijay SinghÎncă nu există evaluări

- Products of CombustionDocument27 paginiProducts of CombustionLorlie Bernales Blanca-TanjayÎncă nu există evaluări

- FTN-AV1K, RN-AV1K Catalogue ENDocument4 paginiFTN-AV1K, RN-AV1K Catalogue ENOdumosu SamuelÎncă nu există evaluări

- Synthesis and Characterization of Polyurethane DispersionDocument78 paginiSynthesis and Characterization of Polyurethane Dispersionichsan hakimÎncă nu există evaluări

- Eka Yunita Rahayu Rosselyne Tampubolon Ronaldo Ahmad Sidik Nisrina KorinDocument10 paginiEka Yunita Rahayu Rosselyne Tampubolon Ronaldo Ahmad Sidik Nisrina KorinekaÎncă nu există evaluări

- Gas Gun - BrochureDocument4 paginiGas Gun - BrochureCamilo MartinezÎncă nu există evaluări

- Phase Behavior of Discotic Liquid Crystalline Polymers and Related Model CompoundsDocument5 paginiPhase Behavior of Discotic Liquid Crystalline Polymers and Related Model CompoundsLeoÎncă nu există evaluări

- SP-1176 V4.0Document45 paginiSP-1176 V4.0Ghulam HusainÎncă nu există evaluări

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 paginiChemical Composition: ASTM A36 Mild/Low Carbon SteelBIPIN BALANÎncă nu există evaluări

- Miniaturization of A Microstrip Antenna Using A Compact and Thin Magneto-Dielectric SubstrateDocument3 paginiMiniaturization of A Microstrip Antenna Using A Compact and Thin Magneto-Dielectric SubstrateaparnaÎncă nu există evaluări

- Friction WeldingDocument8 paginiFriction WeldingGopi KrishnaÎncă nu există evaluări

- Acoustic SensorsDocument7 paginiAcoustic SensorsNihal AhmadÎncă nu există evaluări

- Electrostatic AnalyzerDocument6 paginiElectrostatic AnalyzerKcirtap ZkethÎncă nu există evaluări

- W5 Kinetics of Particle Impulse Momentum (Ch15)Document74 paginiW5 Kinetics of Particle Impulse Momentum (Ch15)Shah KhanÎncă nu există evaluări

- SHS Gr.12 Chap 9Document23 paginiSHS Gr.12 Chap 9Cj NacarioÎncă nu există evaluări

- Stiffness Modifiers For Walls ETABSDocument3 paginiStiffness Modifiers For Walls ETABSHiren DesaiÎncă nu există evaluări

- Demand Capacity Ratios Calculations For 3D Frame ElementsDocument2 paginiDemand Capacity Ratios Calculations For 3D Frame ElementsLuis Martins0% (1)

- Indian Association of Chemistry Teachers: National Standard Examination in Chemistry (Nsec) 2018-19Document27 paginiIndian Association of Chemistry Teachers: National Standard Examination in Chemistry (Nsec) 2018-19sankalp somaniÎncă nu există evaluări

- Al Quds University: Dual Study Industrial EngineeringDocument12 paginiAl Quds University: Dual Study Industrial EngineeringHade GhanemÎncă nu există evaluări

- Chapter 11 - HUMAN EYE and COLOURFUL WORLD-1Document23 paginiChapter 11 - HUMAN EYE and COLOURFUL WORLD-1Sriramulu JaichandarÎncă nu există evaluări

- Calculation of Air Duct Pressure Loss (Rectangular)Document15 paginiCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein KyawÎncă nu există evaluări

- Conexion Viga - PilarDocument5 paginiConexion Viga - PilarAlejandro OspinaÎncă nu există evaluări

- Newtons Rings Formal ReportDocument8 paginiNewtons Rings Formal ReportSammy BennettÎncă nu există evaluări