Documente Academic

Documente Profesional

Documente Cultură

347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)

Încărcat de

Prem NautiyalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)

Încărcat de

Prem NautiyalDrepturi de autor:

Formate disponibile

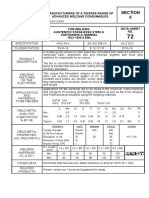

DATA SHEET B-31

METRODE PRODUCTS LTD

HANWORTH LANE, CHERTSEY

SURREY, KT16 9LL

Tel: +44(0)1932 566721

Fax: +44(0)1932 565168 Sales

Fax: +44(0)1932 569449 Technical

Fax: +44(0)1932 566199 Export

347 STAINLESS STEEL Email: info@metrode.com

Internet: http//www.metrode.com

Alloy type Microstructure

347 austenitic stainless steel for joining 321 and 347 Austenite with a controlled level of ferrite, normally in

base materials. the range 3-12FN.

Materials to be welded Welding guidelines

ASTM-ASME BS EN & DIN No preheat, maximum interpass temperature 250C; no

321 1.4541 PWHT required.

347 1.4543/1.4561/1.4550

CF8C (cast) 1.4552 (cast)

Additional information

BS UNS There is a Technical Profile available on sub-arc

321S31 S32100 welding with 347S96. There is also additional

347S31 S34700 information available covering the Supercore flux cored

347C17 (cast) wires.

Applications Related alloy groups

Used to weld titanium and niobium stabilised 18/8 The 308L consumables cover many of the same base

stainless steel types 321 and 347. Also suitable for materials and applications (B-30). For elevated

unstabilised grades such as 304/304L. Service temperature applications 347H consumables should be

temperatures are typically -100C to about 400C. used (C-11).

Applications are similar to 308L (B-30) and include

Products available

food, brewery, pharmaceutical equipment,

architectural and general fabrication, and nuclear Process Product Specification

engineering. MMA Ultramet 347 AWS E347-16

The 347 consumables covered here are generally not Ultramet B347 AWS E347-15

suitable for service in elevated temperature structural TIG/MIG/SAW 347S96 AWS ER347

applications where 0.04-0.08% carbon is specified for SAW flux SS300 BS EN SA AF2

creep resistance, see data sheets C-11 and C-12.

SSB BS EN SA AF2

For cryogenic applications requiring >0.38mm (15mils) FCW Supercore 347 AWS E347T0-1/4

charpy lateral expansion at –196C, use unstabilised

weld metal with low carbon and controlled ferrite (B-

30).

Rev 07 06/09 DS: B-31 (pg 1 of 4)

General Data for all 347 MMA Electrodes

Storage 3 hermetically sealed ring-pull metal tins per carton, with unlimited shelf life. Direct use from tin is satisfactory

for longer than a working shift of 8h. Excessive exposure of electrodes to humid conditions will cause some

moisture pick-up and increase the risk of porosity.

For electrodes that have been exposed:

Redry 200 – 300°C/1-2h to restore to as-packed condition. Maximum 400° C, 3 cycles, 10h total.

Storage of redried electrodes at 50 – 200°C in holding oven or heated quiver: no limit, but maximum 6 weeks

recommended. Recommended ambient storage conditions for opened tins (using plastic lid): < 60% RH, > 18°C.

Fume data Fume composition, wt % typical:

Fe Mn Ni Cr Cu F* OES (mg/m3)

8 5 0.8 5 <0.2 16 1

* F=28% for basic coated Ultramet B347 but this does not affect the OES.

ULTRAMET 347 All-positional rutile MMA electrode for 321/347

Product description MMA rutile flux coated 347 electrode on high purity 304L core wire. Ultramet 347 has all the benefits of an

advanced rutile flux design, including all-positional fixed pipework welding with the 2.5/3.2mm diameter

electrodes.

Recovery is about 110% with respect to core wire, 65% with respect to whole electrode.

Specifications AWS A5.4 E347-16

BS EN 1600 E 19 9 Nb R32

BS 2926 19.9.Nb.R

DIN 8556 E 19 9 Nb R 23

ASME IX Qualification QW432 F-No 5, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo Nb Cu FN

(weld metal wt %) min -- 0.5 -- -- -- 18.0 9.0 -- 10xC -- 4

max 0.04 2.0 0.9 0.025 0.030 21.0 11.0 0.50 1.00 0.50 12

typ 0.02 0.7 0.7 0.01 0.02 19 9.5 0.05 0.4 0.07 6

All-weld mechanical As welded min typical

properties Tensile strength MPa 560 650

0.2% Proof stress MPa 350 500

Elongation on 4d % 30 40

Elongation on 5d % 25 37

Reduction of area % -- 52

Impact energy + 20°C J -- 70

-196°C J -- 20

-196°C J -- 53 (1050°C + WQ)

Operating parameters DC +ve or AC (OCV: 50V min)

ø mm 2.5 3.2 4.0 5.0

min A 60 75 100 130

max A 90 120 155 210

Packaging data ø mm 2.5 3.2 4.0 5.0

length mm 300 350 350 450

kg/carton 11.4 13.5 13.5 16.5

pieces/carton 660 399 261 159

Rev 07 06/09 DS: B-31 (pg 2 of 4)

ULTRAMET B347 Basic pipe-welding electrode for 321/347

Product description MMA electrode with basic carbonate-fluoride flux on high purity 304L core wire. Designed to give good moisture

resistance and hence freedom from weld porosity. The electrode is particularly suited to positional welding of

fixed pipework qualified in the ASME 5G/6G position and is tolerant to adverse wind and draughts under site

conditions. Compared with rutile types, the basic flux gives a more convex fillet bead profile and although the

slag does not self-lift, it is easily removed and gives welds of exceptional appearance and quality.

Recovery is about 110% with respect to core wire, 65% with respect to whole electrode.

Specifications AWS A5.4 E347-15

BS EN 1600 E 19 9 Nb B 42

BS 2926 19.9.Nb.B

DIN 8556 E 19 9 Nb B 20+

ASME IX Qualification QW432 F-No 5, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo Nb Cu FN

(weld metal wt %) min -- 0.5 -- -- -- 18.0 9.0 -- 10xC -- 4

max 0.06 2.0 0.9 0.025 0.030 21.0 11.0 0.50 1.00 0.50 12

typ 0.03 1.2 0.3 0.01 0.02 19 9.5 0.05 0.5 0.07 6

All-weld mechanical As welded min typical

properties Tensile strength MPa 560 650

0.2% Proof stress MPa 350 500

Elongation on 4d % 30 40

Elongation on 5d % 25 37

Reduction of area % -- 52

Impact energy - 50°C J -- 90

Operating parameters DC +ve

ø mm 2.5 3.2 4.0 5.0

min A 60 75 100 130

max A 90 120 155 210

Packaging data ø mm 2.5 3.2 4.0* 5.0

length mm 300 350 350/450 450

kg/carton 12.0 13.5 13.5/17.4 17.4

pieces/carton 669 396 258/267 162

* 350mm is the standard length, 450mm is available to order.

347S96 Solid welding wire for TIG, MIG & SAW of 321/347

Product description Solid wire for TIG, MIG and SAW.

Specifications AWS A5.9 ER347 BS 2901: PT2 347S96

BS EN ISO 14343-A 19 9 Nb

BS EN ISO 14343-B SS347

DIN 8556 (SG X5CrNiNb 19 9 (1.4551))

ASME IX Qualification QW432 F-No 6, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo Nb Cu FN

(wire wt %) min -- 1.0 0.30 -- -- 19.0 9.0 -- 10xC -- 4

max 0.08 2.5 0.65 0.020 0.030 21.0 11.0 0.3 1.0 0.3 12

typ < 0.04 1.5 0.4 0.005 0.02 19.5 9.7 0.2 0.6 0.1 8

All-weld mechanical Typical values as welded TIG

properties Tensile strength MPa 660

0.2% Proof stress MPa 450

Elongation on 4d % 42

Elongation on 5d % 40

Impact energy - 50°C J 150

- 196°C J 35

Hardness cap/mid HV 220/240

Rev 07 06/09 DS: B-31 (pg 3 of 4)

347S96 (continued)

Typical operating TIG MIG SAW

parameters Shielding Argon * Ar+2%O2 ** SS300 or SSB flux

Current DC- DC+ DC+

Diameter 2.4mm 1.2 2.4mm

Parameters 100A, 12V 260A, 26V 350A, 28V

* Also required as a purge for root runs.

** Also proprietary Ar and Ar-He mixtures with <3%CO2.

Packaging data ø mm TIG MIG SAW

1.0 -- 15kg spool --

1.2 -- 15kg spool --

1.6 2.5kg tube -- 25kg coil

2.0 To order -- --

2.4 2.5kg tube -- 25kg coil

3.2 2.5kg tube -- 25kg coil

Fume data MIG fume composition (wt %) (TIG and SAW fume negligible)

Fe Mn Cr3 Ni Mo Cu OES (mg/m3)

32 12 16 8 <0.5 <0.5 3.1

SUPERCORE 347 Downhand rutile flux cored wire for 321/347

Product description Flux cored wire made with an austenitic stainless steel sheath and rutile flux system. Supercore 347 combines easy

operability, high deposit quality and good weld bead appearance for downhand and HV welding. Metal recovery is

about 90% with respect to wire.

Specifications AWS A5.22 E347T0-1/4

BS EN ISO 17633-A T19 9 Nb R C/M 3

BS EN ISO 17633-B TS347-FB0

ASME IX Qualification QW432 F-No 6, QW442 A-No 8

Composition C Mn Si S P Cr Ni Mo Nb Cu FN

(weld metal wt %) min -- 0.5 -- -- -- 18.0 9.0 -- 8xC -- 4

max 0.08 2.0 1.0 0.025 0.030 21.0 11.0 0.3 1.0 0.3 12

typ 0.03 1.2 0.4 0.01 0.02 19 10.5 0.1 0.5 0.1 8

All-weld mechanical As welded min typical

properties Tensile strength MPa 550 600

0.2% Proof stress MPa 350 435

Elongation on 4d % 30 47

Elongation on 5d % 25 42

Reduction of area % -- 50

Impact energy + 20°C J -- 90

Operating parameters Shielding gas: 80%Ar-20%CO2 at 20-25l/min. Proprietary gases may be used but argon should not exceed 85%

argon. The wire is suitable for use on CO2 but with some loss of cosmetic appearance and increased spatter.

Current: DC+ve ranges as below (for 100%CO2 increase voltage by 2-3V):

ø mm amp-volt range typical stickout

1.2 120-280A, 22-34V 180A, 29V 15-20mm

Packaging data Spools vacuum-sealed in barrier foil with cardboard carton: 15kg

The as-packed shelf life is virtually indefinite.

Resistance to moisture absorption is high, but to maintain the high integrity of the wire surface and prevent any

possibility of porosity, it is advised that part-used spools are returned to polythene wrappers.

Where possible, preferred storage conditions are 60% RH max, 18°C min.

Fume data Fume composition (wt %)

Fe Mn Ni Cr3 Cr6 Cu F OES (mg/m3)

17 11 2 4 5 <1 5 1

Rev 07 06/09 DS: B-31 (pg 4 of 4)

S-ar putea să vă placă și

- (RMD™) MIG Welding ProcessDocument5 pagini(RMD™) MIG Welding ProcessPradip GoswamiÎncă nu există evaluări

- ASME IX Interpretation-Part9Document36 paginiASME IX Interpretation-Part9kevin herry100% (1)

- ShipCo Notes - Phase 1 MMDDocument52 paginiShipCo Notes - Phase 1 MMDGurjit Singh100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Superduplex Welding Procedure Specification (WPSDocument4 paginiSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDe la EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsEvaluare: 5 din 5 stele5/5 (2)

- Valve MaterialTypeEquivalent PDFDocument3 paginiValve MaterialTypeEquivalent PDFInaamÎncă nu există evaluări

- TIG Welding Seminar ReportDocument13 paginiTIG Welding Seminar ReportRahul ShawÎncă nu există evaluări

- Stainless Steel Welding by Weld RealityDocument50 paginiStainless Steel Welding by Weld RealitylightwinterdayÎncă nu există evaluări

- Welding GuideDocument48 paginiWelding Guideedu_canete100% (2)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39De la EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Evaluare: 5 din 5 stele5/5 (1)

- Spiral Wound GasketsDocument7 paginiSpiral Wound GasketsPrem NautiyalÎncă nu există evaluări

- Welding of Deepwater Pipelines, Flowlines and Steel Catenary Risers (Amendments and Supplements To API 1104)Document80 paginiWelding of Deepwater Pipelines, Flowlines and Steel Catenary Risers (Amendments and Supplements To API 1104)Jacob PhilipÎncă nu există evaluări

- Welding Consumables For The Offshore IndustryDocument24 paginiWelding Consumables For The Offshore IndustryLuis DuarteÎncă nu există evaluări

- Stainless Steel Grade AISI 321Document2 paginiStainless Steel Grade AISI 321Mitul RawatÎncă nu există evaluări

- Metrode Dissimilar Consumable SelectorDocument7 paginiMetrode Dissimilar Consumable SelectorClaudia MmsÎncă nu există evaluări

- Welding ProcessesDocument189 paginiWelding ProcessesahmadÎncă nu există evaluări

- P 36 Material 15NiCuMoNb5-6-4Document13 paginiP 36 Material 15NiCuMoNb5-6-4Mudassar Iqbal100% (1)

- CF10MC (1.4571)Document3 paginiCF10MC (1.4571)Gilcimar Cavalcante GilcimarÎncă nu există evaluări

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 paginiConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Încă nu există evaluări

- Metrode Cryogenic ER316 B-38Document5 paginiMetrode Cryogenic ER316 B-38Claudia MmsÎncă nu există evaluări

- 309mo Stainless Steels: Data SheetDocument5 pagini309mo Stainless Steels: Data SheetFilipe CordeiroÎncă nu există evaluări

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 paginiA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Încă nu există evaluări

- B-41 Alloy20 Rev02Document2 paginiB-41 Alloy20 Rev02Stephen Rey CaldeaÎncă nu există evaluări

- MMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347Document1 paginăMMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347Gogo PÎncă nu există evaluări

- C 70 SuperthermDocument2 paginiC 70 SuperthermMandeep SinghÎncă nu există evaluări

- 11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data SheetDocument7 pagini11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data Sheetanon_928750560Încă nu există evaluări

- Cryogenic 308LCFDocument5 paginiCryogenic 308LCFslowmosquitoÎncă nu există evaluări

- Metrode Cryogenic 308lcf B-37Document5 paginiMetrode Cryogenic 308lcf B-37Claudia MmsÎncă nu există evaluări

- TNI2TIDocument2 paginiTNI2TIKureiÎncă nu există evaluări

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 pagină3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarÎncă nu există evaluări

- CHM 316LDocument1 paginăCHM 316LImmalatulhusnaÎncă nu există evaluări

- FCAW - Flux Coredpowder Cored WiredDocument40 paginiFCAW - Flux Coredpowder Cored WiredGabor VatoÎncă nu există evaluări

- Afrox 308L (-196) electrode for cryogenic applicationsDocument4 paginiAfrox 308L (-196) electrode for cryogenic applicationsBranko FerenčakÎncă nu există evaluări

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 paginăL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55Încă nu există evaluări

- Data Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless SteelsDocument5 paginiData Sheet for 16.8.2 Welding Consumables for High Temperature 3XXH Stainless Steelsprabu prasadÎncă nu există evaluări

- AFROX Stainless Steel 98Document1 paginăAFROX Stainless Steel 98Branko FerenčakÎncă nu există evaluări

- ER316L Ss en 1Document1 paginăER316L Ss en 1brayanÎncă nu există evaluări

- Stainless Steel Welding Consumable GuideDocument10 paginiStainless Steel Welding Consumable GuideBranko FerenčakÎncă nu există evaluări

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 paginăBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaÎncă nu există evaluări

- KObelco Rods 202-209Document4 paginiKObelco Rods 202-209dedikartiwa_dkÎncă nu există evaluări

- Boehler CM2-UPDocument1 paginăBoehler CM2-UPdiahÎncă nu există evaluări

- Alloy 318Document2 paginiAlloy 318Branko FerenčakÎncă nu există evaluări

- Valve Material Equivalents PDFDocument3 paginiValve Material Equivalents PDFmahdi.guidara100% (1)

- Data Sheet A-10: Alloy TypeDocument3 paginiData Sheet A-10: Alloy Typemohamed AdelÎncă nu există evaluări

- 316 Tubeing TrisDocument1 pagină316 Tubeing Triscenter steel110Încă nu există evaluări

- 78 PDFDocument1 pagină78 PDFGogo PÎncă nu există evaluări

- Er308l PDFDocument1 paginăEr308l PDFnargissuhailÎncă nu există evaluări

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pagini22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptÎncă nu există evaluări

- Section 4: Specification ClassificationDocument1 paginăSection 4: Specification ClassificationTheo AnggaraÎncă nu există evaluări

- Materilas-An Overview: 3.1 Austenitic Stainless Steel 316LDocument13 paginiMaterilas-An Overview: 3.1 Austenitic Stainless Steel 316LRS CreationsÎncă nu există evaluări

- Fox CN 23-12-ADocument1 paginăFox CN 23-12-AVIRPOPÎncă nu există evaluări

- Section 6: Specification ClassificationDocument1 paginăSection 6: Specification ClassificationDimas Wisnu WardanaÎncă nu există evaluări

- Coremax 308LP DataDocument1 paginăCoremax 308LP DataLIM hoon boonÎncă nu există evaluări

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 paginăB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55Încă nu există evaluări

- Ga-24 Aws E7024Document1 paginăGa-24 Aws E7024Bang OchimÎncă nu există evaluări

- Electrodes Hilchrome 308rDocument1 paginăElectrodes Hilchrome 308rManu NistorÎncă nu există evaluări

- 1%Ni Low Alloy Steel for Improved ToughnessDocument4 pagini1%Ni Low Alloy Steel for Improved Toughnessmohamed AdelÎncă nu există evaluări

- KST 309LDocument1 paginăKST 309LTharman SupramaniamÎncă nu există evaluări

- E16 8 2Document4 paginiE16 8 2Branko FerenčakÎncă nu există evaluări

- Bohler AWS ER308LDocument1 paginăBohler AWS ER308LbrayanÎncă nu există evaluări

- Bohler Aws Er308lDocument1 paginăBohler Aws Er308lJuan ShunaÎncă nu există evaluări

- Manual Metal-Arc Welding Product Data SheetDocument2 paginiManual Metal-Arc Welding Product Data SheetC7 TGÎncă nu există evaluări

- C-60 Data Sheet for High Carbon 35Cr-45Ni-1Nb Alloy Welding ProductsDocument2 paginiC-60 Data Sheet for High Carbon 35Cr-45Ni-1Nb Alloy Welding ProductsSaravanan Pitchandi100% (1)

- Stainarc 308L-17 (Rev 1)Document1 paginăStainarc 308L-17 (Rev 1)LIM hoon boonÎncă nu există evaluări

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 paginăSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaÎncă nu există evaluări

- Railrod: Data SheetDocument1 paginăRailrod: Data Sheetmohamed AdelÎncă nu există evaluări

- MARS invoice for technical servicesDocument1 paginăMARS invoice for technical servicesPrem NautiyalÎncă nu există evaluări

- George FischerDocument1 paginăGeorge FischerPrem NautiyalÎncă nu există evaluări

- Frequently Asked Questions About Hardface Welding: Understanding What It Is and How It Is UsedDocument10 paginiFrequently Asked Questions About Hardface Welding: Understanding What It Is and How It Is UsedPrem NautiyalÎncă nu există evaluări

- IGI001-001 28 Jan 2020 PreviewDocument2 paginiIGI001-001 28 Jan 2020 PreviewPrem NautiyalÎncă nu există evaluări

- Advertising Objectives and Models for Defining GoalsDocument50 paginiAdvertising Objectives and Models for Defining GoalsPrem NautiyalÎncă nu există evaluări

- Market Research Applications Lecture 6Document22 paginiMarket Research Applications Lecture 6Prem NautiyalÎncă nu există evaluări

- 4.111 MMM II &IIIDocument18 pagini4.111 MMM II &IIIPrem NautiyalÎncă nu există evaluări

- Advertising Objectives and Models for Defining GoalsDocument50 paginiAdvertising Objectives and Models for Defining GoalsPrem NautiyalÎncă nu există evaluări

- 1Document28 pagini1Prem NautiyalÎncă nu există evaluări

- Iiw-India - Individual Membership Application Form - RevisedDocument3 paginiIiw-India - Individual Membership Application Form - RevisedPrem NautiyalÎncă nu există evaluări

- Consumer Industrial Buyer BehaviourDocument62 paginiConsumer Industrial Buyer BehaviourPrem NautiyalÎncă nu există evaluări

- Social PsychologyDocument33 paginiSocial PsychologyPrem NautiyalÎncă nu există evaluări

- Consumer Industrial Buyer BehaviourDocument62 paginiConsumer Industrial Buyer BehaviourPrem NautiyalÎncă nu există evaluări

- Corrosion ScienceDocument18 paginiCorrosion SciencePrem NautiyalÎncă nu există evaluări

- Competitive Analysis of Godrej With SamsungDocument49 paginiCompetitive Analysis of Godrej With SamsungPrem NautiyalÎncă nu există evaluări

- ShipbuildingDocument13 paginiShipbuildingPrem NautiyalÎncă nu există evaluări

- Companies ActDocument10 paginiCompanies ActPrem NautiyalÎncă nu există evaluări

- Perimeter: - The Sum of All The Sides of A Closed Plane FigureDocument6 paginiPerimeter: - The Sum of All The Sides of A Closed Plane FigureanizazakiÎncă nu există evaluări

- Competitive Analysis of Godrej With SamsungDocument49 paginiCompetitive Analysis of Godrej With SamsungPrem NautiyalÎncă nu există evaluări

- ShipbuildingDocument13 paginiShipbuildingPrem NautiyalÎncă nu există evaluări

- Copper WeldingDocument13 paginiCopper Weldingkatchani123Încă nu există evaluări

- MIG-200L ManualDocument30 paginiMIG-200L ManualV-Man systemÎncă nu există evaluări

- Operation of GTAW - 7 Steps - Metallurgy (1) - OcredDocument17 paginiOperation of GTAW - 7 Steps - Metallurgy (1) - OcredMarceloToccoÎncă nu există evaluări

- Stainless Steel PlateDocument19 paginiStainless Steel PlateHarsh AdvaniÎncă nu există evaluări

- Master Mls Mastertig Mls Mastercool 10 Om enDocument26 paginiMaster Mls Mastertig Mls Mastercool 10 Om enrravibharathÎncă nu există evaluări

- Continuously Evolving TAWERS!Document13 paginiContinuously Evolving TAWERS!ekopujiantoeÎncă nu există evaluări

- Blueshield: Advanced Shielding Gases. When It Matters, BLUESHIELD DeliversDocument6 paginiBlueshield: Advanced Shielding Gases. When It Matters, BLUESHIELD DeliverstdfsksÎncă nu există evaluări

- Essential Variables For All ProcessesDocument4 paginiEssential Variables For All ProcessesRahulÎncă nu există evaluări

- ME 330 Manufacturing Welding Processes OverviewDocument36 paginiME 330 Manufacturing Welding Processes OverviewMayur PatelÎncă nu există evaluări

- Welding Guide: Processes, Safety, and ApplicationsDocument23 paginiWelding Guide: Processes, Safety, and ApplicationsPRATIK PODDARÎncă nu există evaluări

- Practical advice on purging and root backingDocument7 paginiPractical advice on purging and root backingcarlosÎncă nu există evaluări

- Automatic Welding Table ThesisDocument89 paginiAutomatic Welding Table ThesisKhaled Omar0% (2)

- EME Module 2Document31 paginiEME Module 2Yashaswini AnandÎncă nu există evaluări

- 0463 271 001 GBDocument32 pagini0463 271 001 GBIrmad RusdianaÎncă nu există evaluări

- KWT Special Mild and 490MPaDocument24 paginiKWT Special Mild and 490MPaBudy SinagaÎncă nu există evaluări

- Welding ClassificationDocument30 paginiWelding ClassificationSamÎncă nu există evaluări

- Welding Lectures 5-7 PDFDocument83 paginiWelding Lectures 5-7 PDFSwaraj PrakashÎncă nu există evaluări

- WPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticDocument2 paginiWPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticAlex MendozaÎncă nu există evaluări

- Atlas Honda Internship ReportDocument33 paginiAtlas Honda Internship Report3126328310Încă nu există evaluări

- Class 12 GTAWDocument53 paginiClass 12 GTAWSaurabh TripathiÎncă nu există evaluări

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 paginăDoclib 4677 Autocraft 316lsi Datasheetamir moniriÎncă nu există evaluări

- 08 PawDocument30 pagini08 PawAnupam KushwahaÎncă nu există evaluări