Documente Academic

Documente Profesional

Documente Cultură

QT 16Cr PDF

Încărcat de

Yaroslav RuizDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QT 16Cr PDF

Încărcat de

Yaroslav RuizDrepturi de autor:

Formate disponibile

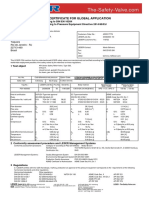

QT-16Cr Technical Data Sheet

As supplied, QT-16Cr may contain tube-to-tube welds. This material is not supplied as Flash-Free or

TRUE-TAPER.

Elemental Composition Mechanical Properties

Carbon (C) 0.03 max Nitrogen (N) 0.15 – 0.30 Minimum Yield Strength, psi (MPa) 90,000 (621)

Manganese (Mn) 7.0 – 9.0 Nickel (Ni) 1.5 – 3.0 Minimum Tensile Strength, psi (MPa) 110,000 (758)

Chromium (Cr) 15.0 – 17.0 Minimum Elongation 35%

Maximum Hardness 38 HRC

Technical Data

Specified

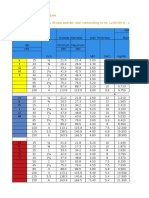

Outside Wall Calculated Inside Plain End Mass, Pipe Metal Cross Pipe Body Yield Internal Yield Hydro Test Torsional

Tensile Load, LT

Diameter, D Thickness, t Diameter, d Mpe Sectional Area, A Load, Ly Pressure, Pr Pressure, P T Yield Strength, Tf

in mm in mm in mm lb/ft kg/m in2 mm2 lb kg lb kg psi MPa psi MPa lb/ft kg/m

1 25.4 0.095 2.4 0.810 20.6 0.919 1.368 0.270 174 0.270 11,030 29,710 13,480 16,200 111 13,000 89 480 650

0.109 2.8 0.782 19.9 1.038 1.545 0.305 196 0.305 12,460 33,560 15,220 18,720 129 15,000 103 530 720

1 1/4 31.8 0.095 2.4 1.060 26.9 1.173 1.746 0.345 222 0.345 14,070 37,920 17,200 12,960 89 10,000 68 800 1,080

0.109 2.8 1.032 26.2 1.330 1.979 0.391 252 0.391 15,950 42,980 19,500 14,980 103 12,000 82 890 1,210

0.134 3.4 0.982 24.9 1.599 2.379 0.470 303 0.470 19,180 51,680 23,440 18,580 128 5,000* 34* 1,030 1,400

0.156 4.0 0.938 23.8 1.824 2.715 0.536 345 0.536 21,890 58,980 26,750 21,740 149 5,000* 34* 1,130 1,530

1 1/2 38.1 0.095 2.4 1.310 33.3 1.427 2.124 0.419 270 0.419 17,120 46,130 20,920 10,800 74 5,000* 34* 1,200 1,630

0.109 2.8 1.282 32.6 1.621 2.412 0.476 307 0.476 19,450 52,400 23,770 12,480 86 8,500 58 1,340 1,820

0.134 3.4 1.232 31.3 1.957 2.912 0.575 371 0.575 23,470 63,260 28,690 15,480 106 5,000* 34* 1,560 2,120

0.156 4.0 1.188 30.2 2.241 3.336 0.659 425 0.659 26,890 72,450 32,860 18,120 124 5,000* 34* 1,740 2,360

0.175 4.4 1.150 29.2 2.479 3.689 0.728 470 0.728 29,740 80,130 36,350 20,400 140 5,000* 34* 1,880 2,550

1 3/4 44.5 0.109 2.8 1.532 38.9 1.912 2.846 0.562 362 0.562 22,940 61,810 28,040 10,700 73 8,000 55 1,880 2,550

0.134 3.4 1.482 37.6 2.315 3.445 0.680 438 0.680 27,770 74,830 33,940 13,270 91 8,500 58 2,210 3,000

0.156 4.0 1.438 36.5 2.658 3.956 0.781 504 0.781 31,890 85,930 38,980 15,530 107 9,000 62 2,480 3,360

0.175 4.4 1.400 35.6 2.946 4.385 0.866 558 0.866 35,350 95,250 43,200 17,490 120 5,000* 34* 2,690 3,650

0.188 4.8 1.374 34.9 3.139 4.672 0.923 595 0.923 37,660 101,480 46,030 18,820 129 5,000* 34* 2,820 3,820

2 50.8 0.134 3.4 1.732 44.0 2.673 3.978 0.786 506 0.786 32,070 86,410 39,190 11,610 80 7,500 51 2,980 4,040

0.156 4.0 1.688 42.9 3.075 4.577 0.904 583 0.904 36,900 99,410 45,090 13,590 93 8,000 55 3,350 4,540

0.175 4.4 1.650 41.9 3.414 5.081 1.003 647 1.003 40,960 110,370 50,060 15,300 105 5,000* 34* 3,650 4,950

0.188 4.8 1.624 41.2 3.642 5.420 1.070 690 1.070 43,690 117,720 53,400 16,470 113 8,500 58 3,840 5,210

2 3/8 60.3 0.134 3.4 2.107 53.5 3.210 4.778 0.943 608 0.943 38,510 103,770 47,070 9,780 67 5,000* 34* 4,330 5,870

0.156 4.0 2.063 52.4 3.700 5.508 1.088 701 1.088 44,400 119,630 54,260 11,440 78 6,000 41 4,910 6,660

0.175 4.4 2.025 51.4 4.116 6.126 1.210 780 1.210 49,380 133,050 60,350 12,880 88 6,500 44 5,370 7,280

0.188 4.8 1.999 50.8 4.395 6.542 1.292 833 1.292 52,730 142,090 64,450 13,870 95 5,000* 34* 5,670 7,690

2 7/8 73.0 0.156 4.0 2.563 65.1 4.534 6.749 1.333 859 1.333 54,400 146,580 66,490 9,450 65 5,000* 34* 7,440 10,090

0.175 4.4 2.525 64.1 5.051 7.518 1.484 957 1.484 60,600 163,280 74,060 10,640 73 6,000 41 8,180 11,090

0.188 4.8 2.499 63.5 5.400 8.037 1.587 1,023 1.587 64,790 174,570 79,180 11,460 79 5,000* 34* 8,670 11,750

A Minimum wall thickness is 0.005” (0.13 mm) less than specified wall thickness. C Maximum hydrostatic test pressure is 15,000 psi (103 MPa).

B Pressures calculated based on t – 0.005” (0.13 mm). D Additional diameters and wall thicknesses may be available upon request.

* See Product Notice August 13, 2008

qualitytubing@nov.com nov.com/qualitytubing

24

S-ar putea să vă placă și

- Carver Hydraulic Press ManualDocument38 paginiCarver Hydraulic Press Manualgotboost777Încă nu există evaluări

- Cameron SSMC WellheadDocument8 paginiCameron SSMC Wellheadtongsabai80% (5)

- 914G Manual Del Estudiante PDFDocument89 pagini914G Manual Del Estudiante PDFRICHARD67% (3)

- Nozzle CatalogueDocument53 paginiNozzle CatalogueMike UpÎncă nu există evaluări

- Jereh Wellhead EquipmentDocument25 paginiJereh Wellhead EquipmentYaroslav RuizÎncă nu există evaluări

- Aisle Master 20 & 44 - Service ManualDocument51 paginiAisle Master 20 & 44 - Service ManualJose Pereira100% (1)

- Split Tee Hot Tap Fitting Spec SheetDocument8 paginiSplit Tee Hot Tap Fitting Spec SheetJesus Alberto Carrasco OrtizÎncă nu există evaluări

- GAS KIT Installation GuideDocument25 paginiGAS KIT Installation Guidealrounder57% (7)

- Brake SystemDocument42 paginiBrake SystemeduamaÎncă nu există evaluări

- PET Bottle TroublesDocument6 paginiPET Bottle Troublesvnbhtpp100% (1)

- NGL PumpsDocument4 paginiNGL Pumpsamol patkiÎncă nu există evaluări

- Gi Pipe Size Is 1239Document4 paginiGi Pipe Size Is 1239sshnvlÎncă nu există evaluări

- S690ql ThyssenkruppDocument7 paginiS690ql ThyssenkruppSivabalan100% (1)

- BASF Oilfield-Solutions DrillingDocument6 paginiBASF Oilfield-Solutions DrillingYaroslav RuizÎncă nu există evaluări

- Tenaris Steel Grades v02 PDFDocument1 paginăTenaris Steel Grades v02 PDFYaroslav RuizÎncă nu există evaluări

- LS Furmanite OyMDocument26 paginiLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- Beyond Heat Checking: Frictional Heating Causes Drillpipe Failure in An Extended-Reach WellDocument4 paginiBeyond Heat Checking: Frictional Heating Causes Drillpipe Failure in An Extended-Reach WellYaroslav Ruiz100% (1)

- Item 13. Codo SCH-80 A234 - 783Document1 paginăItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANÎncă nu există evaluări

- EHB en 9.7 Equivalent MaterialsDocument7 paginiEHB en 9.7 Equivalent MaterialsEzraHasibuanÎncă nu există evaluări

- RH - Em9seDocument6 paginiRH - Em9seJefa DanarÎncă nu există evaluări

- Installation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDocument36 paginiInstallation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDaniel Oscar100% (1)

- SBC (Safety Break-Away Couplings) v140630Document16 paginiSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Bomba Peristalticas ABAQUE PSGDocument49 paginiBomba Peristalticas ABAQUE PSGGabrielÎncă nu există evaluări

- Buesch Xl4 Penstock en 20140905Document2 paginiBuesch Xl4 Penstock en 20140905Ricardo BarrosÎncă nu există evaluări

- Regulador AM 1813CDocument10 paginiRegulador AM 1813CMarceloVelasquezAguirreÎncă nu există evaluări

- Tabla Limite de Retiro EspesoresDocument4 paginiTabla Limite de Retiro EspesoresVicent RojasÎncă nu există evaluări

- Manual Medidor Turbina RMG TRZ 03Document8 paginiManual Medidor Turbina RMG TRZ 03Cleverson BorghezanÎncă nu există evaluări

- Planilla Calculo PSVDocument66 paginiPlanilla Calculo PSVPROCESOS PROCESOSÎncă nu există evaluări

- Engrasadora NEUMATICAFLOWSERVERDocument16 paginiEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarÎncă nu există evaluări

- Split Tee CatalogoDocument3 paginiSplit Tee Catalogobotella berÎncă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 600lbDocument1 paginăANSI-ASME B16.5 Blind Flange 600lbVishal MistryÎncă nu există evaluări

- Fisher Type 667 Diaphragm ActuatorDocument32 paginiFisher Type 667 Diaphragm Actuatorimran khanÎncă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 150lbDocument1 paginăANSI-ASME B16.5 Blind Flange 150lbVishal MistryÎncă nu există evaluări

- Dimensionamento de Válvula de AlívioDocument2 paginiDimensionamento de Válvula de AlívioWanderson WadjôÎncă nu există evaluări

- CRANE-Ficha Tecnica-Valvula CompuertaDocument1 paginăCRANE-Ficha Tecnica-Valvula CompuertaWillyam JiménezÎncă nu există evaluări

- ASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelDocument1 paginăASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelStan HonÎncă nu există evaluări

- ASME B16 48 Dimensions of Spades and Ring Spacers PDFDocument11 paginiASME B16 48 Dimensions of Spades and Ring Spacers PDFpippalla aswiniÎncă nu există evaluări

- Calculo Espesores ASME B31.4Document13 paginiCalculo Espesores ASME B31.4Juan YepesÎncă nu există evaluări

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Document3 paginiButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesÎncă nu există evaluări

- ULMA Flange #150 #300 CatalogDocument3 paginiULMA Flange #150 #300 CatalogEPC Patuha BMJÎncă nu există evaluări

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocument12 paginiData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMÎncă nu există evaluări

- Bolt Torque Chart: ASTM A307Document5 paginiBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- CEPE02100A1 CAG Updated Jan23 14Document60 paginiCEPE02100A1 CAG Updated Jan23 14rudi setiawanÎncă nu există evaluări

- From ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitDocument10 paginiFrom ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitSong TaoÎncă nu există evaluări

- Argus FK76MDocument2 paginiArgus FK76MFelipe Gamboa Gálvez100% (1)

- Hidrante Seco Mod F0733Document1 paginăHidrante Seco Mod F0733Julio FloresÎncă nu există evaluări

- A 447Document27 paginiA 447superman3kÎncă nu există evaluări

- MEDIDAS TURBINA Dresser Imtm MeretDocument3 paginiMEDIDAS TURBINA Dresser Imtm MeretronaldÎncă nu există evaluări

- TEMA FlangesDocument38 paginiTEMA FlangesAshfaq Anwer100% (1)

- Forged Steel Flanges PriceListDocument4 paginiForged Steel Flanges PriceListAdjie HofniÎncă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 300lb PDFDocument1 paginăANSI-ASME B16.5 Blind Flange 300lb PDFVishal MistryÎncă nu există evaluări

- C890 Ceramic Fiber PDFDocument6 paginiC890 Ceramic Fiber PDFKf LiauÎncă nu există evaluări

- PSV 430066 PDFDocument41 paginiPSV 430066 PDFErikikoÎncă nu există evaluări

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 paginăNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefÎncă nu există evaluări

- Spectable Blind Flange 150# Ansi B 16.48Document1 paginăSpectable Blind Flange 150# Ansi B 16.48sanghvi_mukeshÎncă nu există evaluări

- Blind Flanges ANSI B16.5 600lbsDocument1 paginăBlind Flanges ANSI B16.5 600lbsvinonaguÎncă nu există evaluări

- WKM 370d4 Trunnion Mounted Ball Valves Brochure PDFDocument40 paginiWKM 370d4 Trunnion Mounted Ball Valves Brochure PDFAdhie WaelacxhÎncă nu există evaluări

- Practica # 2 PRV2SIZE PDFDocument4 paginiPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaÎncă nu există evaluări

- BPVC Viii-1 Udr-2Document2 paginiBPVC Viii-1 Udr-2asniff08Încă nu există evaluări

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Document3 paginiDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Denso Protal 7200Document2 paginiDenso Protal 7200min_one447065Încă nu există evaluări

- Material 11373Document1 paginăMaterial 11373Deepak MadnaikÎncă nu există evaluări

- Biocleaner - Manual de Operacion y MantenimientoDocument9 paginiBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioÎncă nu există evaluări

- Annex H (Summary API 650) : 1. MaterialDocument6 paginiAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdÎncă nu există evaluări

- C Pi 370Document22 paginiC Pi 370sadeghmsgÎncă nu există evaluări

- ASME ANSI B16.25 Butt Welding EndsDocument4 paginiASME ANSI B16.25 Butt Welding EndsFernandoÎncă nu există evaluări

- Api Spec 6D: API - The American Petroleum InstituteDocument3 paginiApi Spec 6D: API - The American Petroleum Institutenrd9771100% (1)

- B1a1 Pipe ClassDocument1 paginăB1a1 Pipe Classbrujula27Încă nu există evaluări

- Polyken 2036Document2 paginiPolyken 2036nrd9771Încă nu există evaluări

- Ccs SW 6900 GZEDocument35 paginiCcs SW 6900 GZEGabriel MendezÎncă nu există evaluări

- Mechanical Properties: QT-900 Technical Data SheetDocument2 paginiMechanical Properties: QT-900 Technical Data SheetIshmael WoolooÎncă nu există evaluări

- Stranded Overhead Shield Wire (Ground Wire) : Product DescriptionDocument1 paginăStranded Overhead Shield Wire (Ground Wire) : Product DescriptionNguyen KhoaÎncă nu există evaluări

- GT DURACOIL 130 DATASHEET US 3-22 v2Document3 paginiGT DURACOIL 130 DATASHEET US 3-22 v2Ahmed BenayadÎncă nu există evaluări

- TACSRDocument1 paginăTACSRindrawati arsitekturÎncă nu există evaluări

- RPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedDocument31 paginiRPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedSmoking Wheels100% (7)

- NOTES FOR: C-13814/1: Oissco Distribuidor Autorizado de Waukesha para BoliviaDocument48 paginiNOTES FOR: C-13814/1: Oissco Distribuidor Autorizado de Waukesha para BoliviaYaroslav RuizÎncă nu există evaluări

- 6252 5edDocument299 pagini6252 5edYaroslav RuizÎncă nu există evaluări

- Part Number Index Group Number Index Cover Page:) 250) Luvw (GLWLRQDocument2 paginiPart Number Index Group Number Index Cover Page:) 250) Luvw (GLWLRQYaroslav RuizÎncă nu există evaluări

- ColumnsDocument37 paginiColumnsSeventh SkyÎncă nu există evaluări

- Colder Catalog 27-30 PMC ConnectorsDocument4 paginiColder Catalog 27-30 PMC ConnectorsDENNIZÎncă nu există evaluări

- Ppiug 1983Document20 paginiPpiug 1983Anggi Novi AndriÎncă nu există evaluări

- Top and Cabinet Parts: For Model: 3RLSQ8033SW2 (White/Grey)Document13 paginiTop and Cabinet Parts: For Model: 3RLSQ8033SW2 (White/Grey)CristianÎncă nu există evaluări

- JC2 Physics H2 2018 RafflesDocument88 paginiJC2 Physics H2 2018 RafflesVarshLokÎncă nu există evaluări

- Istr Fibo300-Fibo400 GBDocument12 paginiIstr Fibo300-Fibo400 GBFrankie Abdul JimÎncă nu există evaluări

- AC-Report Sport HallDocument5 paginiAC-Report Sport HallMohammad IsmailÎncă nu există evaluări

- Vacuum Breaker Valve: DN50-DN500 PN10-16-25Document2 paginiVacuum Breaker Valve: DN50-DN500 PN10-16-25Cirilo SousaÎncă nu există evaluări

- Pipe Support Trunnion Evaluation For Axial LoadDocument1 paginăPipe Support Trunnion Evaluation For Axial LoadmanojmoryeÎncă nu există evaluări

- Principles of Quantum Mechanics - DiracDocument324 paginiPrinciples of Quantum Mechanics - DiracLuigi RiveraÎncă nu există evaluări

- 6115-Article Text-19834-2-10-20200803 PDFDocument29 pagini6115-Article Text-19834-2-10-20200803 PDFAshaari Cha-eÎncă nu există evaluări

- Theorem of Three Moments - Wikipedia, The Free EncyclopediaDocument3 paginiTheorem of Three Moments - Wikipedia, The Free EncyclopediasoulsellÎncă nu există evaluări

- Course Plan HMTDocument3 paginiCourse Plan HMTparameshÎncă nu există evaluări

- Experiment No: Name of The Experiment: Pressure Process Rig Objective of The ExperimentDocument4 paginiExperiment No: Name of The Experiment: Pressure Process Rig Objective of The ExperimentBhaswati MedhiÎncă nu există evaluări

- LF Student Workbook 05.5Document42 paginiLF Student Workbook 05.5indikumaÎncă nu există evaluări

- Pneumatic Vulcanizing MachineDocument50 paginiPneumatic Vulcanizing MachineANAND KRISHNANÎncă nu există evaluări

- Power System PDFDocument24 paginiPower System PDFlethanhtu0105Încă nu există evaluări

- Compax CL: Operator S ManualDocument114 paginiCompax CL: Operator S ManualPicek30Încă nu există evaluări