Documente Academic

Documente Profesional

Documente Cultură

WMS Summary English

Încărcat de

Karthik babuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WMS Summary English

Încărcat de

Karthik babuDrepturi de autor:

Formate disponibile

WMS Summary

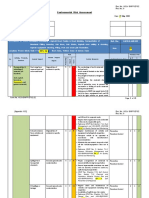

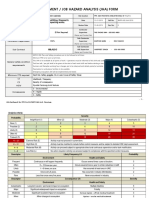

■ Activity : CONSTRUCTION OF G-FORCE POST and BEAM PILE FOUNDATION

■ JHA. No. : xxxx ■ JHA Rev. No. : 0

■ Sub-contractor : xxxxx ■ Site Location :xxxx

Activity Description of Works

1. Loading and unloading of equipments from Low Equipments on the loading body must be secured by chain cargo lashes.

bed/trailer with unsecured equipments. Loading and unloading area must be barricaded and place adequate warning

signages to prevent unauthorized entry.

P-43-Plant&Equipment.

P-56- Road and Traffic safety.

2. Surface preparation (Cutting ,Filling, Drilling & Updated drawings with existing facilities marked must be available prior to start

the activity.

Leveling) on existing contruction area.

Close supervision must be done by competent supervisor.

All the existing live utilities must be clearly marked and information must be

passed to the operators.

Pre-job meeting to be conducted prior to start the activity.

All the lifting beams must be third party certified and color coded as per the BNPP

3. .Installation of pretied reinforcement bars by using

procedure.

spreder beam/lifting beam. Store and handle lifting beam correctly.

Include the self-weight of the beam and attachments when calculating the load

imposed on the crane hook.

Ensure the load will remain stable when lifted.

Ensure no single lifting point becomes overloaded by the slinging or handling

methods.

Pre-job meeting to be conducted to the operators& workers prior to start the

activity by immediate supervisor.

Ensure that the pile case vibro hammer head is properly aligned on top of the steel

4. Pile case driving by using vibro hammer

case.

The area must be barricaded and adequate warning signages to be placed.

Ensure strict compliance of safe buffer zones along the perimeter of piling

operations.

Prohibit entry of other personnel not involve in the task.

Compliance with PPE requirements use eye/face protection, hand gloves,

helmets and safety shoes.

5.Steel Casing Lifting When casing not in use, the casing is to be parked into the ground in a way that a

third of its length is inserted into the ground.

Proper checking and installing of casing pin to connect the casing with the rig turn

table. Rigger to install the pin at the high level or remove it when required using man

basket or man lift vehicle. If area is too narrow to occupy the rig along with a crane for

man basket or man lift so rigger is to mount the rig using the rig winch rope and safety

harness.

Rig casing and all attachments to be checked regularly.

All the crew must be provided mandatory PPE & worn all the time.

Ensure close and competent supervision.

Associated risk & control shall be communicated to crew.

Sub Contractor HSJV

Page 1 of 1

S-ar putea să vă placă și

- SAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEDe la EverandSAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEÎncă nu există evaluări

- Sunmow Jha 001Document3 paginiSunmow Jha 001Douglas DellyÎncă nu există evaluări

- SWP 02 - Use of Mobile ScaffoldDocument4 paginiSWP 02 - Use of Mobile ScaffoldGerald Wong NttÎncă nu există evaluări

- C063 JSA For Installaiton of I Beam at Laundry AreaDocument7 paginiC063 JSA For Installaiton of I Beam at Laundry Areaiftikhar ahmadÎncă nu există evaluări

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 paginiJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyÎncă nu există evaluări

- JSA For Road BarrierDocument3 paginiJSA For Road BarrierMohammed MinhajÎncă nu există evaluări

- Sunmow Jha 002Document3 paginiSunmow Jha 002Douglas DellyÎncă nu există evaluări

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 paginiJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- Job Safety Analysis (Jsa) FormDocument4 paginiJob Safety Analysis (Jsa) FormNaukhez A. KashifÎncă nu există evaluări

- PCW Pipe Installation JhaDocument2 paginiPCW Pipe Installation Jhafatimah100% (1)

- New Job Hazard Analysis (JHA) Hot Water Geyser InstallationDocument2 paginiNew Job Hazard Analysis (JHA) Hot Water Geyser Installationwaqar naeemÎncă nu există evaluări

- Ahu Unit Install JhaDocument3 paginiAhu Unit Install JhafatimahÎncă nu există evaluări

- JSA For Material ShiftingDocument3 paginiJSA For Material ShiftingMohammed Minhaj100% (1)

- 4.assembly & Erection of StructureDocument3 pagini4.assembly & Erection of StructureFrancis Vinoj100% (1)

- JSA For SURGE VESSEL WorkDocument6 paginiJSA For SURGE VESSEL Workathul subashÎncă nu există evaluări

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 paginiJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing Spoolsm.rehanhseÎncă nu există evaluări

- X.9.b Job Hazard AnalysisDocument8 paginiX.9.b Job Hazard AnalysisChris Kenneth ManansalaÎncă nu există evaluări

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 paginiJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreamarvinÎncă nu există evaluări

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 paginiJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaMohammed MinhajÎncă nu există evaluări

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit AreaDocument8 paginiJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit Areanoahlungu96Încă nu există evaluări

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- Jsa (Ercction of Tower Crane) G-11Document4 paginiJsa (Ercction of Tower Crane) G-11khurram shahzadÎncă nu există evaluări

- Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedDocument3 paginiScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedkrishnakumarÎncă nu există evaluări

- Fill-Up This Card Before Commencement of Critical WorksDocument4 paginiFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyÎncă nu există evaluări

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 paginiJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JHA - LiftingDocument3 paginiJHA - Liftingmark jayson yabesÎncă nu există evaluări

- Job Hazard Analysis For Crane DismantlingDocument2 paginiJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 paginiJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- SWP 03 - Hacking WorksDocument3 paginiSWP 03 - Hacking WorksGerald Wong NttÎncă nu există evaluări

- C-41 Aramco Man-Riding OperationsDocument3 paginiC-41 Aramco Man-Riding Operationsreda mesbahÎncă nu există evaluări

- Steel Erection JSADocument5 paginiSteel Erection JSASalah Abd Eldayem100% (1)

- Job Safety Analysis - Cone ErectionDocument7 paginiJob Safety Analysis - Cone ErectionMohammed MinhajÎncă nu există evaluări

- 2..loading Unloading and Installation of PipingDocument3 pagini2..loading Unloading and Installation of PipingFrancis VinojÎncă nu există evaluări

- Job Safety AnalysisDocument3 paginiJob Safety AnalysisMuhammad KaleemÎncă nu există evaluări

- Tower CarneDocument2 paginiTower CarnenabeelÎncă nu există evaluări

- JSA For Piping-Hydro TestDocument10 paginiJSA For Piping-Hydro TestMuthu AlaguRajÎncă nu există evaluări

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 paginiJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- JHA Metrology InstallDocument6 paginiJHA Metrology InstallfatimahÎncă nu există evaluări

- Job Safety Analysis - Cone ErectionDocument6 paginiJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatÎncă nu există evaluări

- Risk Assessment and Method StatementDocument18 paginiRisk Assessment and Method StatementTijana LalovićÎncă nu există evaluări

- JSA For Pressure Test 2ND REVISIONDocument10 paginiJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 paginiHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiÎncă nu există evaluări

- Safety Procedure For Pile TestDocument2 paginiSafety Procedure For Pile TestIsna MuthoharohÎncă nu există evaluări

- RA-for Glass Installation 30-04-2022Document6 paginiRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Jsa For Plaster WorkDocument4 paginiJsa For Plaster Workumar KhitabÎncă nu există evaluări

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 paginiHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟Încă nu există evaluări

- Hazard & Risk Assessment - HIAB VLCDocument6 paginiHazard & Risk Assessment - HIAB VLCDilzar AliÎncă nu există evaluări

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 paginiRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleÎncă nu există evaluări

- 12 - Method Statement For Steel Structure ErectionDocument5 pagini12 - Method Statement For Steel Structure ErectionidzwanÎncă nu există evaluări

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pagini5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisÎncă nu există evaluări

- CTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedDocument7 paginiCTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedMohamed RizwanÎncă nu există evaluări

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 paginiHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithÎncă nu există evaluări

- JSA For Suspended CielingDocument4 paginiJSA For Suspended Cielingumar KhitabÎncă nu există evaluări

- 2 Safe Lifting OperationsDocument2 pagini2 Safe Lifting OperationsSiewkuan LeeÎncă nu există evaluări

- Work Method Statement: Wms Rev. NoDocument5 paginiWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Work Method Statement: Wms Rev. NoDocument5 paginiWork Method Statement: Wms Rev. NoKarthik babuÎncă nu există evaluări

- Jsa For Drilling WellDocument5 paginiJsa For Drilling WellAnna JisabaÎncă nu există evaluări

- Job Hazard Analysis of Site SURVEYINGDocument1 paginăJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- JSA Hot Work and ModificationDocument19 paginiJSA Hot Work and ModificationBrings MotoVlogÎncă nu există evaluări

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 paginiNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuÎncă nu există evaluări

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 paginiWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuÎncă nu există evaluări

- Work Method Statement: Wms Rev. NoDocument5 paginiWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- WMS - Pipe Civil Works-OCADocument6 paginiWMS - Pipe Civil Works-OCAKarthik babuÎncă nu există evaluări

- ERA Rev 03 - Road Works (582018)Document21 paginiERA Rev 03 - Road Works (582018)Karthik babuÎncă nu există evaluări

- Work Flow Chart-ReinforcementDocument2 paginiWork Flow Chart-ReinforcementKarthik babuÎncă nu există evaluări

- Water Supply System For WR #44 & Wr#45: Review Comment SheetDocument1 paginăWater Supply System For WR #44 & Wr#45: Review Comment SheetKarthik babuÎncă nu există evaluări

- BS 7121 Part 5 (97) Tower CraneDocument24 paginiBS 7121 Part 5 (97) Tower CraneKarthik babu100% (1)

- Work Method Statement: Wms Rev. NoDocument5 paginiWork Method Statement: Wms Rev. NoKarthik babuÎncă nu există evaluări

- NEW Form JHA-Road Works (27-03-2018) FinalDocument34 paginiNEW Form JHA-Road Works (27-03-2018) FinalKarthik babu100% (3)

- Work Method Statement: Confined SpaceDocument3 paginiWork Method Statement: Confined SpaceKarthik babu0% (1)

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pagini1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Class 12 Psychology PDFDocument209 paginiClass 12 Psychology PDFSoumyashis Bhattacharya0% (1)

- Chm130 Test Batch-2Document3 paginiChm130 Test Batch-2misakisuki7Încă nu există evaluări

- Lesson Plan 3Document3 paginiLesson Plan 3api-547884261Încă nu există evaluări

- CT PhysicsDocument117 paginiCT PhysicsGarima Bharti100% (2)

- HOconsDocument14 paginiHOconsMax PradoÎncă nu există evaluări

- SWOT Analysis Textile IndustryDocument23 paginiSWOT Analysis Textile Industrydumitrescu viorelÎncă nu există evaluări

- Agriculture Budget 2013-14Document33 paginiAgriculture Budget 2013-14Ajay LimbasiyaÎncă nu există evaluări

- 2021 Lifting Points Main Catalogue V1 - V - RUDDocument120 pagini2021 Lifting Points Main Catalogue V1 - V - RUDmengyu hanÎncă nu există evaluări

- Freedom As A Foundation of EthicsDocument3 paginiFreedom As A Foundation of EthicsGrant Jomar SiadorÎncă nu există evaluări

- 03-CircO2 Previous Control Nitric OxideDocument17 pagini03-CircO2 Previous Control Nitric OxideVic SpeaksÎncă nu există evaluări

- Q4 Lesson 3 Hinge Theorem and Its ConverseDocument36 paginiQ4 Lesson 3 Hinge Theorem and Its ConverseZenn Tee100% (1)

- SLC Past and Future Hustrulid KvapilDocument26 paginiSLC Past and Future Hustrulid KvapilkinsaeyaÎncă nu există evaluări

- NSC Solution F2 enDocument8 paginiNSC Solution F2 ensaeidÎncă nu există evaluări

- Comprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationDocument66 paginiComprensión Lectora en Inglés Clecv Plus 3: Unit 11: The Natural World Unit 12: Music: Influence and InnovationJorge Talavera AnayaÎncă nu există evaluări

- LEC - 19 - Task of Bitcoin MinersDocument36 paginiLEC - 19 - Task of Bitcoin MinersKarunesh AnandÎncă nu există evaluări

- Formula 1638 Collagen Eye CreamDocument2 paginiFormula 1638 Collagen Eye CreamLinh Sa LaÎncă nu există evaluări

- Kantha Embroidery by Nanduri Asha, Shreya Gulati, Saloni PriyaDocument17 paginiKantha Embroidery by Nanduri Asha, Shreya Gulati, Saloni PriyaShreyaa Gulati100% (3)

- Astm E1975 - 1 (En)Document17 paginiAstm E1975 - 1 (En)Dinesh Sai100% (1)

- Hydrostatics-Assignment 3: MPI td9Document2 paginiHydrostatics-Assignment 3: MPI td9whoeverÎncă nu există evaluări

- 09.3090 USTR2433b T Series Cassettes Omega IFU enDocument51 pagini09.3090 USTR2433b T Series Cassettes Omega IFU enAdi SaputraÎncă nu există evaluări

- CERN Courier - Digital EditionDocument33 paginiCERN Courier - Digital EditionFeriferi FerencÎncă nu există evaluări

- Roger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Document2.035 paginiRoger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Jaime Andres Cerda Garrido100% (1)

- MKRS Training ProfileDocument10 paginiMKRS Training ProfileZafri MKRS100% (1)

- Food and Beverages Sample Script For NCADocument11 paginiFood and Beverages Sample Script For NCAHONEY ROSE NAKILAÎncă nu există evaluări

- Deep Carbon ObservatoryDocument90 paginiDeep Carbon ObservatorygoblinÎncă nu există evaluări

- CPower Product Training.09.2016.EnDocument70 paginiCPower Product Training.09.2016.Enerdinc100% (1)

- Sea Shanty PrintDocument3 paginiSea Shanty PrintDiego DracvsÎncă nu există evaluări

- ISO 13920 - Tolerâncias para Juntas SoldadasDocument7 paginiISO 13920 - Tolerâncias para Juntas SoldadasRicardo RicardoÎncă nu există evaluări

- User'S Design Requirements For Single Chamber Pressure VesselsDocument8 paginiUser'S Design Requirements For Single Chamber Pressure VesselspjsanchezmÎncă nu există evaluări

- CE-401CE 2.0 Network Diagrams 2015Document83 paginiCE-401CE 2.0 Network Diagrams 2015Shubham BansalÎncă nu există evaluări