Documente Academic

Documente Profesional

Documente Cultură

Laboratory Air Flow Controls - AbstractOBRIENATKINS Richert

Încărcat de

gerx11xregDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Laboratory Air Flow Controls - AbstractOBRIENATKINS Richert

Încărcat de

gerx11xregDrepturi de autor:

Formate disponibile

LAB DESIGN SPRING 2010 CONFERENCE

Raleigh, N.C. (Sheraton Raleigh), April 19-21, 2010

Topic: "Laboratory Air Flow Controls – The Past, the Present, the Future"

O’Brien/Atkins Associates, PA, Research Triangle Park, NC (919-941-9000)

G. Edward Richert, PE, LEED AP – erichert@obrienatkins.com

Three primary factors determine chemical laboratory air flow requirements and the associated energy

consumed to meet those requirements. These are fume hood exhaust, equipment heat load, and

ventilation air change rate for dilution. This presentation will review the evolution of air flow control

in the chemical laboratory and discuss the trends in air flow controls that will allow future laboratories

to function with much less energy consumption and therefore with much less operating cost.

The chemical fume hood has long been recognized as a significant consumer of energy in laboratory

buildings. Many strategies to reduce energy consumption by reducing the quantity of fume hoods and

the exhaust flow requirements of fume hoods have been explored over the years.

Since the laboratory chemical fume hood was invented, engineers and scientists have been trying to

improve its performance and reduce its impact on building energy consumption. Throughout the past

five decades there have been two significant surges in the laboratory design industry toward

significant reductions in energy consumption by laboratory buildings. First in the 70’s with the fuel

crisis and then again in the current decade with the drive to energy independence, the goal of reducing

energy consumption in laboratories has led to innovation. Throughout the last five decades, there

have also been steady incremental steps toward the same goal.

In the 30’s fume hoods were fitted with sashes to improve performance and effectively reduce the

open face area and the required exhaust air flow. In the 40’s and 50’s, bypasses were incorporated

into fume hood designs to maintain air balance with sash opening and closing. In the 70’s, it was

recognized that a constant full flow of exhaust from fume hoods consumed an enormous amount of

energy unnecessarily. Throughout the 80’s and 90’s with the advent of direct digital control (DDC)

systems, much work was done to design hoods and HVAC systems that would allow variable air flow

and still assure laboratory containment and temperature control.

Strategies incorporating variable volume supply and exhaust air flow based on hood sash position,

operator occupancy, and time of day schedules are now common place and considered prudent

practice in laboratory HVAC design.

However, with the current trend of laboratory processes becoming smaller, the numbers of fume

hoods and equipment loads in laboratories have seen great reduction thereby pushing ventilation air

change rates to the front of the energy discussion. Ventilation air change rate in laboratories has since

become the subject of much debate as the industry continues to search for ways to improve energy

performance.

Borrowing from the demand controlled ventilation techniques of the recent indoor air quality (IAQ)

initiatives and the past work with safety in motor vehicle ventilation, engineers and scientists are now

developing strategies for controlling laboratory air flow based on the sensed quality of the laboratory

air. While this strategy is fairly straight forward in theory its practical implementation has many

challenges. Notably, a method for economically sensing the laboratory environment has been most

challenging but recent innovation is bringing the industry closer to a solution.

All of these advancements combined with the sophisticated computer control sequences available with

today’s DDC control systems offer the laboratory designer the opportunity to develop systems that

assure the safety of the laboratory environment while minimizing energy consumption.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- SP-PS-312 - Specification For Bonding and Earthing During The Installation of New ConnectionsDocument5 paginiSP-PS-312 - Specification For Bonding and Earthing During The Installation of New ConnectionsShadi AbdelsalamÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Mathematical Model For A Stirred Tank HeaterDocument14 paginiMathematical Model For A Stirred Tank HeaterMfon100% (3)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Multi-Instrument With Control and Protection: TYPE SPG-120/10Document12 paginiMulti-Instrument With Control and Protection: TYPE SPG-120/10Muhammad SulaniÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- RdsoDocument7 paginiRdsoMrinmy ChakrabortyÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Energy: Forms and ChangesDocument43 paginiEnergy: Forms and ChangesDian WestbyÎncă nu există evaluări

- TNB Tech Guidebook For The Connection of Generation To The Distn Network PDFDocument188 paginiTNB Tech Guidebook For The Connection of Generation To The Distn Network PDFckwei0910Încă nu există evaluări

- ABB ABB ABB ABB: Type KD-10 and KD-11 Compensator Distance RelayDocument60 paginiABB ABB ABB ABB: Type KD-10 and KD-11 Compensator Distance RelaybcfochtÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Sankalp Phaseiv El 15 Lecture-14Document5 paginiSankalp Phaseiv El 15 Lecture-14SuyashÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Load ScheduleDocument1 paginăLoad ScheduleAlvin ConcepcionÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Power Flow Analysis Considering Automatic Generation Control For Multi-Area Interconnection Power NetworksDocument9 paginiPower Flow Analysis Considering Automatic Generation Control For Multi-Area Interconnection Power NetworksPoorani MahesÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocument4 paginiNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJohn YangÎncă nu există evaluări

- Cement Kiln Performance CalculationsDocument9 paginiCement Kiln Performance Calculationsvvijaybhan0% (2)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Cheops SPOKE Pt. 2 - Mission GuideDocument412 paginiCheops SPOKE Pt. 2 - Mission Guidetriple7incÎncă nu există evaluări

- Dados Tec - c2500Document5 paginiDados Tec - c2500Sandro MunizÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

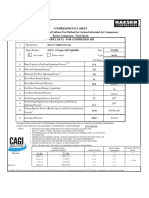

- SM 15-115-125-AC-460V-CAGI-Datasheet - 46-37534Document1 paginăSM 15-115-125-AC-460V-CAGI-Datasheet - 46-37534rigoberto alvaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- 542136insulation Design and Simulation of Pyinmana Substation by Using ATPDocument6 pagini542136insulation Design and Simulation of Pyinmana Substation by Using ATPswarupkumarnayakÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Applied Energy: Jose Pereira Da Cunha, Philip EamesDocument12 paginiApplied Energy: Jose Pereira Da Cunha, Philip EamesJose Luis Sarango DiazÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Experiment 8 Synchronous Generator Line SynchronizationDocument10 paginiExperiment 8 Synchronous Generator Line SynchronizationMd Rodi Bidin100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- MIT6 701S10 Notes by Marc BaldoDocument261 paginiMIT6 701S10 Notes by Marc BaldoAlfredo Rico GuzmánÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Chapter 1Document4 paginiChapter 1OmungÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Coal Vessel Updates As On 18 Mar 20Document15 paginiCoal Vessel Updates As On 18 Mar 20Frianata ZrÎncă nu există evaluări

- Estimating Enthalpy Using Bond EnergyDocument3 paginiEstimating Enthalpy Using Bond EnergyEmille IlmansyahÎncă nu există evaluări

- ABB Protection Application HandbookDocument356 paginiABB Protection Application HandbookUsman Hamid100% (1)

- Meiji With PriceDocument30 paginiMeiji With PriceMarilou BelaraÎncă nu există evaluări

- EV3200 EMERSON Door Control InverterDocument59 paginiEV3200 EMERSON Door Control InverterRebecca DangÎncă nu există evaluări

- THERMODYNAMICS Lesson 1Document27 paginiTHERMODYNAMICS Lesson 1Rijay SarkarÎncă nu există evaluări

- Lucas TVSLimitedChennaiDocument17 paginiLucas TVSLimitedChennaiAnbu LoveÎncă nu există evaluări

- Reciprocating Compressor Seals Partner Savings From Compressor Rod PackingDocument20 paginiReciprocating Compressor Seals Partner Savings From Compressor Rod PackingONURÎncă nu există evaluări

- Lab Design and Simulation of Voltage Source InverterDocument8 paginiLab Design and Simulation of Voltage Source InverterIzzah NadhirahÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Coal Gasification: A PRB: OutlineDocument13 paginiCoal Gasification: A PRB: Outlinetaufany99Încă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)