Documente Academic

Documente Profesional

Documente Cultură

Effect of Wetchemical Substrate Pretreatment On Electronic Interface Properties and Recombination Losses of A Si - H - C Si and A SiNx - H - C Si Heterointerfaces

Încărcat de

Ben Alaya ChaoukiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Effect of Wetchemical Substrate Pretreatment On Electronic Interface Properties and Recombination Losses of A Si - H - C Si and A SiNx - H - C Si Heterointerfaces

Încărcat de

Ben Alaya ChaoukiDrepturi de autor:

Formate disponibile

pss c

solidi

status

physica

Phys. Status Solidi C 8, No. 3, 879 – 882 (2011) / DOI 10.1002/pssc.201000236

www.pss-c.com

current topics in solid state physics

Effect of wet-chemical substrate

pretreatment on electronic interface

properties and recombination losses of a-Si:H/c-Si

and a-SiNx:H/c-Si hetero-interfaces

Heike Angermann*,1, Frank Wünsch2, Marinus Kunst2, Abdelazize Laades3, Uta Stürzebecher3,

Erhard Conrad1, Lars Korte1, and Manfred Schmidt1

1

Helmholtz-Zentrum Berlin für Materialien und Energie GmbH, Institut für Silizium-Photovoltaik, Kekuléstraße 5,

12489 Berlin, Germany

2

Helmholtz-Zentrum Berlin für Materialien und Energie GmbH, Institut Solare Brennstoffe und Energiespeichermaterialien,

Hahn-Meitner-Platz, 14109 Berlin Germany

3

CiS Institut für Mikrosensorik GmbH, SolarZentrum Erfurt, Konrad-Zuse-Str. 14, 99099 Erfurt, Germany

Received 30 April 2010, revised 29 June 2010, accepted 1 July 2010

Published online 16 December 2010

Keywords recombination, passivation, crystalline silicon, hydrogenated amorphous silicon, silicon nitride

* Corresponding author: e-mail angermann@helmholtz-berlin.de, Phone: +49 30 8062 1368, Fax: +49 30 8062 1333

Surface charge, surface state density and interface re- on the rear side, the effect of optimised wet-chemical

combination behavior on polished float zone (FZ) solar pre-treatment can be preserved during the subsequent soft

cell substrates were investigated after various wet- plasma enhanced chemical vapour deposition of a-Si:H

chemical pre-cleaning procedures and deposition of or a-SiNx:H. This leads to hetero-interfaces with low in-

amorphous silicon (a-Si:H) or silicon nitride (a-SiNx:H). terface recombination velocities. These results were

Applying surface photo voltage (SPV), microwave de- compared to previously reported findings, obtained on

tected photo conductance decay (µW-PCD) and transient textured Czochralski (CZ) single crystalline substrates.

microwave conduction (TRMC) measurements, elec- a-SiNx:H is known to result in a field effect passivation.

tronic interface properties were monitored repeatedly Nevertheless a strong influence of wet-chemical treat-

during the preparation processes. As shown for an in- ments on surface charge and recombination losses was

verted a-Si:H/c-Si hetero-junction structure, with front observed on both flat and textured a-SiNx:H/c-Si inter-

side passivation by a-SiNx:H and a p-type a-Si:H emitter faces.

© 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

1 Introduction Crystalline silicon (Si) cells currently based high efficiency Si solar cells hydrogenated amor-

share more than 90% of the worldwide photovoltaic mar- phous silicon (a-Si:H) and silicon nitride (a-SiNx:H) layers

ket [1]. A major advantage of Si is the nearly boundless are utilised to passivate the Si surface and/or to form the

technological availability and the environmental sustain- p/n junction as well as the rear surface field. As is well

ability of this material. However, decisive preconditions to known from the microelectronics and sensor technology,

the development of economically attractive Si solar cells the electronic properties of Si interfaces are strongly influ-

are the development of appropriate interface preparation enced by the chemical integrity and morphological struc-

and passivation methods as well as the application of thin ture of the substrate surface [6]. Therefore, increasing at-

film-technologies in order to reduce material consumption tention should be focused on the monitoring and control of

[2]. The reduction of layer thickness shifts the focus on interface properties after pre-cleaning treatments.

surfaces and interfaces, because the interface takes up a This paper reports on investigations of surface charge,

major part of the device concerned and interface defects surface state density and interface recombination behav-

become increasingly more critical to the solar cell energy iour on wet-chemically treated Si substrates by surface

conversion efficiency, which may be severely reduced due photo voltage (SPV), microwave detected photo conduc-

to large interface recombination losses [3, 4, 5]. In wafer- tance decay (µW-PCD) measurements. The effect of opti-

© 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

pss c

solidi

physica

status

880 H. Angermann et al.: Electronic interface properties of a-Si:H/c-Si and a-SiNx:H/c-Si hetero-interfaces

mised wet-chemical treatment was verified for an inverted mixing SiH4 with H2 diluted B2H6 for p-type doping

a-Si:H/c-Si hetero-junction structure, with front side pas- (2000 ppm B2H6 in SiH4). Microwave power was set to

sivation by a-SiNx:H and a p-type a-Si:H emitter on the 50 W and the process pressure was 0,5 mbar.

rear side [7]. 2.3 a-SiNx:H passivation layers were prepared in a

PECVD reactor (AK 1000 from Roth & Rau AG) operat-

(p)a-Si:H emitter ing with a microwave (MW) excited plasma by means of a

n+-layer linear antenna array at a frequency of 2.45 GHz. The sub-

metalization strate temperature was 380 °C. Film deposition was carried

SiNx out by decomposition of a silane/ammonia gas mixture.

Figure 1 Inverted a-Si:H/c-Si hetero-junction structure, front- 2.4 Inverted a-Si:H/c-Si hetero-junction cell as

side passivation by a-SiNx:H and a-Si:H(p) emitter on the rear- shown in Fig. 1 has advantages over the standard TCO/a-

Si(p)/c-Si(n)/a-Si(n+) heterojuction solar cell with an a-S:H

2 Preparation of Si hetero-interfaces

front emitter layer [11]. These are a higher sensitivity in

2.1 Wet-chemical substrate conditioning In or-

the short wavelength region because of the wider SiN gap

der to analyse the effect of surface conditioning in detail,

and the loss of transparent conductive oxide (TCO) front-

wet-chemical treatments were carried out on polished n-

coverage and the less restrictions of the rear side a-Si:H

type float-zone (FZ) Si(111) substrates (3 Ωcm) under

emitter layer thickness.

cleanroom ambiance as well as on saw damage etched (in

2.5 Interface characterisation The surface photo

KOH solution [8]) n-type high-quality Magnetic Czochral-

voltage technique (SPV) was utilized for contact-less

ski (MCZ) solar substrates (thickness of 270 µm, 2.5 to

measurement of the surface band-bending and the ener-

3.0 Ωcm) under technological conditions. The substrates

getic distribution of the interface state density Dit(E) to es-

were cleaned using the standard process of the Radio Cor-

tablish correlations between the wet-chemical substrate

poration of America (RCA) consisting of RCA I (APM:

preparation, the resulting charge, density and energetic dis-

ammonia / hydrogen peroxide mixture), HF 1% dip and

tribution of rechargeable interface states [10]. A laser di-

RCA II (HPM: hydrochloric acid / hydrogen peroxide mix-

ode (902 nm, 150 ns pulse length) was used as the excita-

tures) [9]. Afterwards, wet-chemically oxidized surfaces

tion light source. The surface photovoltage pulses as

were prepared applying (1) (RCA I), (2) oxidation in de-

shown in Fig. 2a were recorded with a transient recorder

ionized water (DIW) at 80°C (hot water oxidation) [10]

(time resolution 5 ns). From the maximum value of large-

and (3) boiling solution of sulphuric acid and hydrogen

signal photovoltage pulse UPh the surface potential was ob-

peroxide (1:1) for 10 minutes (H2SO4/H2O2). The hydrogen

tained. From a series of photovoltage pulses with different

(H)-termination was completed by removing the so pre-

field voltages UF between a transparent electrode and the

pared wet-chemical oxide in diluted hydrofluoric acid

Si wafer, Dit(E) (Fig. 2b) was determined [12].

(HF 1%) and (4) drying in N2 or (5) rinsing in DIW at

The microwave detected photoconductance decay

room temperature (RT).

(µW-PCD) was used to determine the spatially resolved

2.2 a-Si:H emitter layers - consisting of a stack of

minority charge carrier lifetime [13]. Interface recombina-

~3 nm (i)a-Si:H and ~8 nm (p+)a-Si:H - were deposited by

tion losses were investigated by transient microwave con-

plasma enhanced chemical vapour deposition (PECVD)

duction (TRMC) measurements after excitation by an illu-

and electron cyclotron resonance-CVD (ECR-CVD), re-

mination pulse at a wavelength of λ = 1064 nm [14].

spectively, at about 130 °C in a pure SiH4 process and by

Surface PhotoVoltage decay Interface state density 3 Effect of wet-chemical Si substrate pre-

Uph [V]

14

wet-chemical oxides: 10

treatment on electronic interface properties

Dit [cm eV ]

(1) RCA I

-1

(2) hot water oxidation

(3) H2SO4 / H2O2 wet-chemical oxides (3) 3.1 Charge and Dit(E) on polished substrates

-2

(2)

0,2

H-termination : Wet-chemical cleaning processes for Si wafers can be clas-

(1) (4) HF 1% : 60 s

13

(1) sified according to the final surface condition into two

10

(5) HF 1% + rinsing

groups: the surface passivation by H-termination or by thin

(2)

(3)

wet-chemical oxide layers, resulting in hydrophobic and

0,1

(5) hydrophilic surfaces, respectively.

(4) 12

Surface photovoltage pulses UPh(t) and the calculated

10 H-termination interface state distributions Dit(E) obtained by SPV-

(4)

a b (5) Dit, min measurements on wet-chemically treated polished n-type

0,0

2x10

-5

4x10

-5

-0,4 -0,2 0,0 0,2 0,4 FZ Si are shown in Fig. 2a and b. In order to verify the in-

field voltage UF [V] E-Ei [eV] fluence of surface charge and Dit(E) on recombination

Figure 2 (a) Surface photovoltage pulses and (b) interface state losses of subsequently prepared a-Si:H/c-Si and

distributions Dit(E) obtained on n-type FZ Si after wet-chemical a-SiNx:H/c-Si interfaces, various hydrophilic and hydro-

oxidation in RCA I (curves 1), in hot DIW (curves 2), in phobic processes were applied. The maximal values of UPh

H2SO4/H2O2 (curves 3), and after H-termination by HF (1%) and the time decays of the photo voltage pulse (Fig. 2a) -

(curves 4) and subsequent DIW rinsing at RT (curves 5). which yield information about interface recombination be-

© 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.pss-c.com

Contributed

Article

Phys. Status Solidi C 8, No. 3 (2011) 881

haviour [15] - were found to be strongly influenced by the solar cells largely depends upon on the details of the de-

wet-chemical substrate pre-treatment (Fig. 2a). vice structure and the kind of subsequent layer deposition.

Hydrophilic surfaces arise from H2O2-containing solu- The influence of different wet-chemical treatments on sur-

tions, RCA I (Fig. 2a, curve 1) or H2SO4/H2O2 (Fig. 2a, face photovoltage and interface recombination losses was

curve 3) or hot water oxidation (Fig. 2a, curve 2). After investigated by combined SPV (Figs. 2,3) and TRMC (Fig.

different wet-chemical oxidation procedures characteristic 5) measurements on an inverted a-Si:H(p)/c-Si(n) hetero-

values of surface band bending were obtained, resulting junction structure, with front side passivation by a-SiNx:H

from the interface-trapped charge Qit and different oxide and a-Si:H emitter on the rear side [7] prepared on pol-

charges [10]. Hydrophobic surfaces, mainly covered by ished FZ Si substrates.

Si(−H)x, were prepared by HF 1% (Fig. 2a, curve 4) and In Fig. 3 the maximal values of UPh are given as ob-

HF 1 % followed by rinsing in DIW (Fig. 2a, curve 5). tained (i) after surface pre-treatments: oxidation by RCA I

Significantly slower time decays of UPh were observed (curve 1), hot water (curve 2), and H2SO4/H2O2 (curve 3),

on the HF 1% treated surfaces (Fig. 2a, curves 4,5) as and after H-termination by HF 1 % (curve 4) and HF 1% +

compared to wet-chemical oxides (Fig. 2a, curves 1-3). rinsing (curve 5), (ii) after subsequent front side passiva-

Due to the initial oxidation, DIW rinsing at RT changes the tion by a-SiNx:H, and (iii) after removing wet-chemical

surface charge of the H-terminated surface (Fig. 2a, curve oxides and subsequent deposition of the rear side a-Si:H

4) by appearance of polarized ≡Si−OH (Fig. 2a, curve 5). hetero emitter. Preparation-induced surface charges (Fig

This leads to different surface Fermi level positions and 2a) result in different UPh values on wet-chemically treated

thus changes in band bending, as visible in the difference substrates as shown in Fig. 3 (i). The passivation by a-

of maximal Uph values. SiNx:H is based on the band bending caused by the posi-

The rapid and irregular wet-chemical oxide growth in- tive fixed charge in the a-SiNx:H. Therefore, as expected,

creases the interface micro-roughness [10] and results in no variation of UPh between the different treatments was

high interface state densities Dit(E) ≥ 1013 cm-2eV-1 (Fig. 2b, found after a-SiNx:H deposition, cf. Fig. 3 (ii).

curves 1,3). Significantly lower Dit(E) ≈ 1012 cm-2eV-1 were As demonstrated in Fig. 3 (iii), after subsequent re-

obtained by non-aggressive hot water oxidation (Fig. 2b, moval of wet-chemical oxides and a-Si:H deposition, how-

curve 2) and Dit(E) ≤ 5x1011 cm-2eV-1 on hydrophobic, H- ever, a strong influence of surface treatment on UPh was

terminated surfaces (Fig. 2b, curves 4,5). observed on the rear side a-Si:H/c-Si, as well as on the

3.2 Photovoltage and recombination losses on front side a-SiNx:H/c-Si interface. Highest UPh and best

a-SiNx:H/c-Si and a-Si:H/c-Si interfaces Which sub- energy conversion efficiency η =13.96% [7] were obtained

strate surface conditioning can successfully be applied to for cells with H2SO4/H2O2 treatment (Fig. 3, curve 3).

550

back side

500 Front side: a-SiNx:H passivation

450

400

photovoltage UPh (mV)

(iii) a-Si:H deposition (3)

350

300

(1) (2)

250

(2) (1)

200 (4)

150

(5)

(3)

100

(i) substrate pre-treatment

(5)

x10-6 Time [s]

(4)

50 (ii) SiNx:H deposition Back side: a-Si:H(p) / c-Si(n)

0

-50

front side

-100 (2)

(3)

IW

°C

I

2

2O

/N

2

A

/D

80

RC

4 /H

F

2O

F

2 SO

H

H

(4)

H

(i) front side: Si surface (1)

(ii) front side: c-Si / a-SiNx:H interface (5)

(ii) back side: Si surface after a-SiNx:H deposition

(iii) back side: c-Si / a-Si:H interface (heteroemitter) x10-6 Time [s]

(iii) front side: after back front side a-Si:H deposition

Figure 4 TRMC measurements on inverted a-Si:H/c-Si hetero-

Figure 3 Maximal value of UPh on n-type FZ Si interfaces (i) junction structures, with front side passivation by a-SiNx:H (ii) de-

after surface pre-treatments: oxidation by RCA I (curve 1), hot posited after oxidation by RCA I (curves 1), hot water (curves 2),

water (curve 2), and H2SO4/H2O2 (curve 3), H-termination by H2SO4/H2O2 (curves 3), and H-termination by HF 1% (curves 4)

HF 1 % (curve 4) and HF 1% + DIW rinsing (curve 5), (ii) after and HF 1% + DIW rinsing (curves 5) and on a-Si:H(p) emitter de-

subsequent front side passivation by a-SiNx:H, and (iii) after posited on the rear side (iii) after removing wet-chemical oxides in

subsequent HF 1% and a-Si:H deposition on rear side. HF 1%.

www.pss-c.com © 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

pss c

solidi

physica

status

882 H. Angermann et al.: Electronic interface properties of a-Si:H/c-Si and a-SiNx:H/c-Si hetero-interfaces

Due to the field effect passivation on a-SiNx:H/c-Si, as 500

n-type CZ Silicon (saw damage etched)

passivated by SiNx:H

expected, no relation was obtained between Dit(E) (Fig. 2b) (4)

and interface recombination (Fig. 4). Nevertheless, Fig. 4

demonstrates a strong influence of surface treatments on in- 400 (6)

τeff (µs)

(2)

terface recombination velocities as measured by microwave

detected photo conductance decays on the same inverted 300

a-Si:H/c-Si hetero-junction structures, after front side pas- (1)

sivation by a-SiNx:H (ii) and subsequently removing wet- 200

chemical oxides in HF 1% and depositing an a-Si:H emitter (5)

on the rear side (iii). Lowest interface recombination losses

100 (3)

were achieved on a-SiNx:H/c-Si by H2SO4/H2O2 (Fig. 4 (ii),

curve 3) and on a-Si:H/c-Si by oxidation in H2SO4/H2O2 or

hot water and subsequent HF 1% -dip (Fig. 4 (iii), curves 0

A HF F F

RC DIW +H DIW +H

2,3). On both interfaces rinsing in DIW at RT significantly RC

A+

F +H

ot

otD

IW

F +H

ot

otD

IW

+H +H H

increases the recombination velocities (Fig. 4, curves 5). RC

A+

H

HF

RC

AI +H

F+

A+ AI

3.3 Passivation of saw damage etched solar RC RC

cell substrates by a-SiNx:H µW-PCD measurements Figure 5 Lifetime distribution over the area obtained by µW-PCD

on damage etched n-CZ-Si solar cell substrates after different wet-

[13] were utilized to verify the influence of wet-chemical

chemical treatments and passivation by a-SiNx:H.

treatments on recombination losses on saw damage etched

solar cell substrates [8] under technological conditions. On Acknowledgements The author would like to thank

so prepared a-Si:H/c-Si interfaces also strong correlations Dagmar Patzek for technical support. This work has been par-

were obtained between interface recombination losses and tially funded by the European Commission through the FP7 pro-

wet-chemical conditioning steps (cf. Fig. 5). Thereby gen- ject ”Heterojunction Solar Cells based on a-Si c-Si” (HETSI),

erally lower recombination losses were obtained on hydro- grant no. 211821, and by the Funded by the German Federal Min-

phobic surfaces achieved by final HF 1% steps (Fig. 5 col- istry for the Environment, Nature Conservation and Nuclear

umns 2,4,6). The oxidation in RCA I (Fig. column 5) was Safety (BMU) within the project “TopShot” (FKZ 0325114B).

also found to increase significantly the recombination

losses, whereas previous hot DIW oxidation steps (Fig. 5 References

columns 4,6) markedly reduce recombination losses due to

[1] Photon International, April 2008 and April 2009.

wet-chemical smoothing of the microscopically rough saw [2] H. Tributsch, Die Solarzelle – Schlüsselelement für die Wirt

damage etched surface [10]. Best results were achieved by schaftlichkeit des Wasserstoffs, in: H. Scheer, ed., Die ge-

hot DIW oxidation + HF 1% subsequent to RCA cleaning speicherte Sonne (Piper, München, 1987), pp.119–155.

(Fig. 5 column 4). [3] D. Munoz, P. Carreras, J. Escarre, D. Ibarz, S. Martin de Ni-

colas, C. Voz, J. M. Asensi, and J. Bertomeu, Thin Solid

4 Conclusion There are various effects of wet- Films 517, 3578 (2009).

chemical substrate surface conditioning which influence [4] S. de Wolf and M. Kondo, J. Appl. Phys. 105, 103707 (2009).

the recombination losses on a-SiNx:H/ c-Si and a -Si:H/c- [5] S. Olibt, E. Vallat-Sauvian, L. Fesquet, C. Monachon, A.

Si interfaces. Further investigations are necessary to under- Hessler-Wyser, J. Damon-Lacoste, S. De Wolf, and C. Ballif,

stand the effectiveness of wet-chemical processes on elec- Phys. Status Solidi A 207, 651-656 (2010).

[6] T. Hattori, Crit. Rev. Solid State Mater. Sci. 20, 339 (1995).

tronic properties of different hetero-interfaces in detail. For

[7] F. Wünsch, G. Citarella, O. Abdallah, and M. Kunst, J. Non-

the a-Si:H/c-Si system, passivation occurs mainly due to Cryst. Solids 352, 1962 (2006).

saturation of dangling bond defects. Thus, the recombina- [8] A. Laades, J. Brauer, U. Stürzebecher, K. Neckermann, K.

tion properties can be directly influenced by preparation- Klimm, M. Blech, K. Lauer, A. Lawerenz, and H. Anger-

induced surface charges and rechargeable interface states. mann, 24th European Solar Conference (Hamburg, Germany,

The preparation induced surface micro-roughness and sur- 2009) 2CV.2.61.

face coverage can also affect the initial layer growth, the [9] W. Kern, J. Electrochem. Soc. 137, 1987 (1990).

morphology or adhesion of deposited layers. Although the [10] H. Angermann, Appl. Surf. Sci. 254, 8067 (2008).

passivation by a-SiNx:H is based on field effect passivation, [11] M. Schmidt, L. Korte, A. Laades, R. Stangl, Ch. Schubert,

strong influences of wet-chemical treatment on polished as H. Angermann, E. Conrad, and K. v. Maydell, Thin Solid

Films 515, 7475 (2007).

well as on saw damage etched n-type substrates were ob-

[12] K. Heilig, Exp. Tech. d. Phys. 14, 135 (1968).

served. Where as the preparation of a-Si:H definitely re- [13] K. Lauer, A. Laades, H. Übensee, H. Metzner, and A. Law-

quires hydrophobic surfaces, according to our results the erenz, J. Appl. Phys. 104, 104503 (2008).

surface conditioning for a-SiNx:H deposition has to be [14] C. Swiatkowski, A. Sanders, K.-D. Buhre, and M. Kunst, J.

carefully optimized with respect to the kind of substrate Appl. Phys. 78, 1763 (1995).

and deposition process. It was demonstrated that combined [15] A. Laades, Preparation and Characterization of Amor-

SPV and µW-PCD measurements can be used successfully phous/Crystalline Silicon Heterojunctions, PhD Thesis,

for this purpose. Techn. Univ. Berlin, 2005, ISBN 3-86664-078-1.

© 2010 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.pss-c.com

S-ar putea să vă placă și

- The Impact of The Micro Structure Within Passivated Layers On The Performance of The A Si:H/c Si Heterojunction Solar CellsDocument9 paginiThe Impact of The Micro Structure Within Passivated Layers On The Performance of The A Si:H/c Si Heterojunction Solar CellsSaulo RochaÎncă nu există evaluări

- 6 Rosa2011Document7 pagini6 Rosa2011Tech Hut bdÎncă nu există evaluări

- High Efficiency Amorphous and Nanocrystalline Silicon Thin Film Solar Cells On Flexible SubstratesDocument4 paginiHigh Efficiency Amorphous and Nanocrystalline Silicon Thin Film Solar Cells On Flexible SubstratesPRAKASH CHANTIBABU DIDLA PRAKASH CHANTIBABU DIDLAÎncă nu există evaluări

- Simulation9 PDFDocument5 paginiSimulation9 PDFMECHANICS CED ClassicalÎncă nu există evaluări

- Solar Energy Materials & Solar Cells: Martin Bivour, Christian Reichel, Martin Hermle, Stefan W. GlunzDocument6 paginiSolar Energy Materials & Solar Cells: Martin Bivour, Christian Reichel, Martin Hermle, Stefan W. GlunzHoucine NaimÎncă nu există evaluări

- Improving Efficiency of An Amorphous Silicon (P-A-Sic:H/I-A-Si:H/N-A-Si:H) Solar Cell by Affecting Bandgap and Thickness From Numerical AnalysisDocument4 paginiImproving Efficiency of An Amorphous Silicon (P-A-Sic:H/I-A-Si:H/N-A-Si:H) Solar Cell by Affecting Bandgap and Thickness From Numerical AnalysiserpublicationÎncă nu există evaluări

- Effect of Hydrogen Plasma Treatment On The Surface Morphology Microstructure and Electronic Transport Properties of NC SiHDocument7 paginiEffect of Hydrogen Plasma Treatment On The Surface Morphology Microstructure and Electronic Transport Properties of NC SiH林子耀Încă nu există evaluări

- Silicon Surface Passivation by Atomic Layer Deposited Al2O3: Additional Information On J. Appl. PhysDocument13 paginiSilicon Surface Passivation by Atomic Layer Deposited Al2O3: Additional Information On J. Appl. Physahmed abusnoubarÎncă nu există evaluări

- High E Ciency Graphene Solar Cells by Chemical DopingDocument6 paginiHigh E Ciency Graphene Solar Cells by Chemical DopingSnowdenn BreddÎncă nu există evaluări

- Solar Cells IBCDocument6 paginiSolar Cells IBCYaroslav VainshteinÎncă nu există evaluări

- Study On The Deposition of Amorphous Silicon and Ito Thin Filmsfor Heteroiunction Solar Cell ApplicationDocument11 paginiStudy On The Deposition of Amorphous Silicon and Ito Thin Filmsfor Heteroiunction Solar Cell ApplicationYến Nhi Nguyễn HồÎncă nu există evaluări

- Thin Solid FilmsDocument9 paginiThin Solid FilmsBhabani Sankar SwainÎncă nu există evaluări

- Solar Cell TechnologyDocument30 paginiSolar Cell TechnologypatipanÎncă nu există evaluări

- Progress in Photovoltaics - 2021 - Glunz - Silicon Based Passivating Contacts The TOPCon RouteDocument19 paginiProgress in Photovoltaics - 2021 - Glunz - Silicon Based Passivating Contacts The TOPCon RouteRameeja TaÎncă nu există evaluări

- Separating The Two Polarities of The Polo Contacts of An 26.1%-Efficient Ibc Solar CellDocument15 paginiSeparating The Two Polarities of The Polo Contacts of An 26.1%-Efficient Ibc Solar CellEL OUARGUI El MehdiÎncă nu există evaluări

- Effects of High Hydrogen Dilution Ratio On Optical Properties of Hydrogenated Nanocrystalline Silicon Thin FilmsDocument6 paginiEffects of High Hydrogen Dilution Ratio On Optical Properties of Hydrogenated Nanocrystalline Silicon Thin FilmsMark LieÎncă nu există evaluări

- Performance Study of an Interdigitated Back Contact Si Solar CellDocument4 paginiPerformance Study of an Interdigitated Back Contact Si Solar CellMainul HossainÎncă nu există evaluări

- Profilometry of Thin Films On Rough Substrates by Raman SpectrosDocument7 paginiProfilometry of Thin Films On Rough Substrates by Raman SpectrosgjdapromiseÎncă nu există evaluări

- Design of High-Efficiency SiC Betavoltaic Battery Structures With Reduced Impact of Near-Surface Recombination Based On Accurate ModelingDocument6 paginiDesign of High-Efficiency SiC Betavoltaic Battery Structures With Reduced Impact of Near-Surface Recombination Based On Accurate ModelingRakesh JainÎncă nu există evaluări

- Richter 2017Document8 paginiRichter 2017eniÎncă nu există evaluări

- 17.3% Efficient Black Silicon Solar Cell Without Dielectric Antireflection CoatingDocument6 pagini17.3% Efficient Black Silicon Solar Cell Without Dielectric Antireflection CoatingMohsen GoodarziÎncă nu există evaluări

- Solar Energy Materials & Solar CellsDocument5 paginiSolar Energy Materials & Solar CellsEniÎncă nu există evaluări

- Activation of H-BN and Sic Monolayer Sheets Through Foreign Atom Substitution A Comparative Study Based On Ab-Initio MethodDocument9 paginiActivation of H-BN and Sic Monolayer Sheets Through Foreign Atom Substitution A Comparative Study Based On Ab-Initio MethodEngr Mahesh MaheshwariÎncă nu există evaluări

- High Performance Amorphous Silicon Thin Film Solar Cells Prepared at 100 °C: Toward Flexible Building Integrated PhotovoltaicsDocument7 paginiHigh Performance Amorphous Silicon Thin Film Solar Cells Prepared at 100 °C: Toward Flexible Building Integrated PhotovoltaicsYADAV VikasÎncă nu există evaluări

- Pip 3244Document7 paginiPip 3244Riski RamadaniÎncă nu există evaluări

- Lisheng 2011 J. Phys. Conf. Ser. 276 012177Document10 paginiLisheng 2011 J. Phys. Conf. Ser. 276 012177Rama Shankar YadavwÎncă nu există evaluări

- Battaglia Et Al. - 2014 - Silicon Heterojunction Solar Cell With Passivated Hole Selective MoOx ContactDocument6 paginiBattaglia Et Al. - 2014 - Silicon Heterojunction Solar Cell With Passivated Hole Selective MoOx ContactCristian Quiñones AlbertÎncă nu există evaluări

- Energy Tech - 2023 - Sadhukhan - TOPerc Solar Cell An Integral Approach of Tunnel Oxide Passivated Contact TOPCon andDocument10 paginiEnergy Tech - 2023 - Sadhukhan - TOPerc Solar Cell An Integral Approach of Tunnel Oxide Passivated Contact TOPCon andEniÎncă nu există evaluări

- 2) - SS&DD - Journal of Physics and Chemistry of Solids 105 (2017) 90-98Document9 pagini2) - SS&DD - Journal of Physics and Chemistry of Solids 105 (2017) 90-98Subhashis SamantaÎncă nu există evaluări

- 2012 High-Efficiency Silicon Heterojunction Solar Cells - A ReviewDocument18 pagini2012 High-Efficiency Silicon Heterojunction Solar Cells - A ReviewAkash KhanÎncă nu există evaluări

- Investigation of Channel Doping Concentration and Reverse Boron Penetration On P-Type Pi-Gate Poly-SiDocument6 paginiInvestigation of Channel Doping Concentration and Reverse Boron Penetration On P-Type Pi-Gate Poly-SimeghrajpurkayasthaÎncă nu există evaluări

- J Solener 2017 02 018Document6 paginiJ Solener 2017 02 018hakimkorichiÎncă nu există evaluări

- Optical nanowire sensors detect humidity and gasesDocument58 paginiOptical nanowire sensors detect humidity and gasesallUddinÎncă nu există evaluări

- Ini Iya KayaknyaDocument8 paginiIni Iya KayaknyaRiski RamadaniÎncă nu există evaluări

- Brassard 2003Document7 paginiBrassard 2003LUIS FRANCISCO SANCHEZ SOVEROÎncă nu există evaluări

- Properties of Amorphous Boron Nitride Thin Films: R. Zedlitz, M. Heintze M.B. SchubertDocument4 paginiProperties of Amorphous Boron Nitride Thin Films: R. Zedlitz, M. Heintze M.B. Schubertuddeshya shuklaÎncă nu există evaluări

- In Situ Monitoring of pH Stability of Grafted Silicon SurfacesDocument10 paginiIn Situ Monitoring of pH Stability of Grafted Silicon SurfacesCosmina IlieșiuÎncă nu există evaluări

- Hydrogen Induced Martensite TransformationDocument29 paginiHydrogen Induced Martensite TransformationMohamed Ould MoussaÎncă nu există evaluări

- Mathematical Modelling of A Novel Hetero-Junction Dual Sis Zno-Si-Sno Solar CellDocument10 paginiMathematical Modelling of A Novel Hetero-Junction Dual Sis Zno-Si-Sno Solar CellHoucine NaimÎncă nu există evaluări

- PV Labnotes-Lab1Document6 paginiPV Labnotes-Lab1Vendy KristiÎncă nu există evaluări

- Lee 2018Document29 paginiLee 2018Farhan Thursina IIBSÎncă nu există evaluări

- Enhanced 12.5% efficiency aluminum oxide encapsulated graphene-silicon solar cellDocument16 paginiEnhanced 12.5% efficiency aluminum oxide encapsulated graphene-silicon solar cellAli AliÎncă nu există evaluări

- Stable Microcrystalline Silicon Thin-Film Transistors Produced by The Layer-By-Layer TechniqueDocument5 paginiStable Microcrystalline Silicon Thin-Film Transistors Produced by The Layer-By-Layer TechniqueTianyu TangÎncă nu există evaluări

- PaperenglishDocument5 paginiPaperenglishelvaulinaÎncă nu există evaluări

- Applied Surface Science: M. Hassan, A. Qayyum, S. Ahmad, S. Mahmood, M. Shafiq, M. Zakaullah, P. Lee, R.S. RawatDocument9 paginiApplied Surface Science: M. Hassan, A. Qayyum, S. Ahmad, S. Mahmood, M. Shafiq, M. Zakaullah, P. Lee, R.S. RawatnorbertÎncă nu există evaluări

- Equation Relating Voc and JSC - 2Document7 paginiEquation Relating Voc and JSC - 2NILOFARÎncă nu există evaluări

- Characterization and Electrical Transport in A-Sic/C-Si Heterojunction StructureDocument5 paginiCharacterization and Electrical Transport in A-Sic/C-Si Heterojunction StructurekubikÎncă nu există evaluări

- 2 Peng2010Document2 pagini2 Peng2010Tech Hut bdÎncă nu există evaluări

- Controlling The Adhesion Force For Electrostatic Actuation of Microscale Mercury Drop by Physical Surface ModificationDocument4 paginiControlling The Adhesion Force For Electrostatic Actuation of Microscale Mercury Drop by Physical Surface ModificationdenghueiÎncă nu există evaluări

- Enhancement of Dielectric Constant in HfO2 Thin Films by The AdditionDocument4 paginiEnhancement of Dielectric Constant in HfO2 Thin Films by The AdditionIlse ArreolaÎncă nu există evaluări

- Numerical Simulation of Silicon Heterojunction Solar Cells Featuring Metal Oxides As Carrier-Selective ContactsDocument9 paginiNumerical Simulation of Silicon Heterojunction Solar Cells Featuring Metal Oxides As Carrier-Selective ContactsOussama IkhlefÎncă nu există evaluări

- Intechopen 85039Document44 paginiIntechopen 85039EL OUARGUI El MehdiÎncă nu există evaluări

- Threshold Voltage Modeling On Nanocrystalline Silicon Thin Film Transistors Navneet GuptaDocument5 paginiThreshold Voltage Modeling On Nanocrystalline Silicon Thin Film Transistors Navneet Guptanithin s gowdaÎncă nu există evaluări

- Influence of Contact Effect On The Performance of Microcrystalline Silicon Thin-Film TransistorsDocument4 paginiInfluence of Contact Effect On The Performance of Microcrystalline Silicon Thin-Film TransistorsTianyu TangÎncă nu există evaluări

- Zun Nanostencil 2002 ApplPhysLett 81 2202Document3 paginiZun Nanostencil 2002 ApplPhysLett 81 2202Paul SotoÎncă nu există evaluări

- Surface & Coatings TechnologyDocument8 paginiSurface & Coatings TechnologyAlireza BagherpourÎncă nu există evaluări

- Detailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar CellDocument6 paginiDetailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar Cellgxf980518Încă nu există evaluări

- Influence of Doping and Microstructure On Electrical Properties of Doped Silicon Thin FilmsDocument6 paginiInfluence of Doping and Microstructure On Electrical Properties of Doped Silicon Thin Filmsjuan davidÎncă nu există evaluări

- Reviews in Computational ChemistryDe la EverandReviews in Computational ChemistryAbby L. ParrillÎncă nu există evaluări

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášÎncă nu există evaluări

- Ultra Low Power SRAM DesignDocument24 paginiUltra Low Power SRAM DesignAshish KumarÎncă nu există evaluări

- Electronic Devices 9th Edition by FloydDocument117 paginiElectronic Devices 9th Edition by FloydAsad KhalidÎncă nu există evaluări

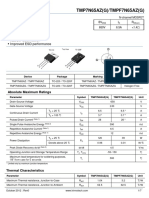

- IRF9540NLDocument10 paginiIRF9540NLMathiasÎncă nu există evaluări

- VLSI M3 Ktunotes - in PDFDocument76 paginiVLSI M3 Ktunotes - in PDFSangeetha SumamÎncă nu există evaluări

- LedDocument20 paginiLedYogesh YadavÎncă nu există evaluări

- Part66 Module4Document2 paginiPart66 Module4K M Mosheur RahmanÎncă nu există evaluări

- Zener Diode Guide: Construction, Working & ApplicationsDocument29 paginiZener Diode Guide: Construction, Working & ApplicationsVarsha PrajapatiÎncă nu există evaluări

- Part 2 - Module 4 - ED - Fundamentals of BJT OperationDocument45 paginiPart 2 - Module 4 - ED - Fundamentals of BJT OperationKRISHNENDU CHAKRABARTYÎncă nu există evaluări

- Led PPT Eng 1st YearDocument12 paginiLed PPT Eng 1st YearsudhaÎncă nu există evaluări

- Nakamura 1991Document4 paginiNakamura 1991fikage2322Încă nu există evaluări

- PNP Epitaxial Silicon TransistorDocument5 paginiPNP Epitaxial Silicon TransistorPedro RodriguezÎncă nu există evaluări

- Direct and Indirect Band GapsDocument5 paginiDirect and Indirect Band GapsSenthil Siva SubramanianÎncă nu există evaluări

- BST Thin Film CapacitorDocument3 paginiBST Thin Film CapacitorKeng Goy PlungpongpanÎncă nu există evaluări

- BJ Transistor Tutorial 2 of 8Document8 paginiBJ Transistor Tutorial 2 of 8haseebiftikharÎncă nu există evaluări

- PHOTOVOLTAICSDocument27 paginiPHOTOVOLTAICSbrian otienoÎncă nu există evaluări

- 03-Lecture-Semiconductor DevicesDocument7 pagini03-Lecture-Semiconductor DevicesAdnan Hyder SoomroÎncă nu există evaluări

- Electron Mobility and Carrier Drift in SemiconductorsDocument17 paginiElectron Mobility and Carrier Drift in SemiconductorsRaja Uzair SaeedÎncă nu există evaluări

- 06 XII Photovoltaic-V2.2plusDocument228 pagini06 XII Photovoltaic-V2.2plusaverdgueÎncă nu există evaluări

- Electronics Lab - Study Devices, Circuits & ExperimentsDocument3 paginiElectronics Lab - Study Devices, Circuits & ExperimentssamactrangÎncă nu există evaluări

- Pmos PDFDocument13 paginiPmos PDF윤진수Încă nu există evaluări

- N-Channel Power MOSFET (2A, 600VoltsDocument8 paginiN-Channel Power MOSFET (2A, 600Voltsserrano.flia.coÎncă nu există evaluări

- Fundamentals of CMOS VLSI QBDocument6 paginiFundamentals of CMOS VLSI QBharshithaÎncă nu există evaluări

- Linear IC Applications - Introduction ClassDocument50 paginiLinear IC Applications - Introduction ClassSudheer BabuÎncă nu există evaluări

- Basic Electronics EngineeringDocument2 paginiBasic Electronics EngineeringsushilÎncă nu există evaluări

- 5 1Document39 pagini5 1santhoshÎncă nu există evaluări

- V. Mosfet PDFDocument33 paginiV. Mosfet PDFleeminho_janxiÎncă nu există evaluări

- N-Channel MOSFET with 650V Breakdown and 6.5A Continuous Drain CurrentDocument7 paginiN-Channel MOSFET with 650V Breakdown and 6.5A Continuous Drain Currentjoswil21Încă nu există evaluări

- Transparent Electronics: An Enabling Display Technology?Document56 paginiTransparent Electronics: An Enabling Display Technology?Shailender ChowdaryÎncă nu există evaluări

- 2sd2061 PDFDocument3 pagini2sd2061 PDFDaniel ParedesÎncă nu există evaluări

- Investigatory ProjectDocument16 paginiInvestigatory ProjectsuhaybÎncă nu există evaluări