Documente Academic

Documente Profesional

Documente Cultură

A Review On Alccofine A Supplementary Cementitous Material

Încărcat de

Siddhesh Kamat MhamaiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Review On Alccofine A Supplementary Cementitous Material

Încărcat de

Siddhesh Kamat MhamaiDrepturi de autor:

Formate disponibile

A Review on Alccofine : A supplementary cementitous material

Saurabh Gupta1, Dr. Sanjay Sharma2, Er. Devinder Sharma3

1,2,3 Civil Department, Nitttr Chandigarh

Abstract— Supplementary cementitious materials (SCM) are becoming popular in the construction

industry as these materials are bringing technical revolution in the field of civil engineering.

Alccofine is a new generation micro fine concrete material for high Strength Concrete which is

important in respect of workability as well as strength. The aim of this paper is to highlight the

importance of Alccofine as Supplementary cementitrious materials in construction industries. This

can be used as a SCM due to its ultrafine size and high content of calcium oxide (Cao),

Alccofine1203 is essential in terms of reducing heat of hydration and strength at all stages where as

Alccofine 1101 can be used as a grouting purpose.

Keywords— Alccofine, Silica fume, Ultrafine slag, SCM, High strength concrete

I. INTRODUCTION

High strength and high performance concrete are gaining popularity day by day in the construction

industry worldwide. Practically high strength concrete is generally said to be high strength concrete

having high cement content and very low water cement ratio. The concrete prepared in such a

manner suffer from majorly two type of weaknesses. Firstly, it is difficult to achieve workability and

secondly to retain the workability for sufficiently long time with such concrete mixes. To overcome

these weaknesses, it becomes necessary to use high dosage of high range water reducing agents

(HRWR) i.e admixture as cohesive and sticky mixes are equally difficult to place and compact fully

and effectively. So the water to be used in the mix posses to have critical limit below which high

HRWR dosage become undesirable and is harmful from the durability considerations. Mostly SCM

like silica fume etc are proposed against HRWR where high strength of concrete mix, low

permeability are the main consideration for developing high strength concrete mix. But these are

often ineffective by the increased water or admixture dosage for workability of the green concrete.[1]

Table 1. Types of Alccofine

ALCCOFINE SCM LOW CALCIUM

ALCCOFINE-1203 SILICATE

GROUTING HIGH CALCIUM

ALCCOFINE-1101 SILICATE

Alccofine is a new generation, micro fine material of particle size much finer than other hydraulic

materials like cement, fly ash, silica etc. being manufactured in India. Alccofine has unique

characteristics to enhance 'performance of concrete' in fresh and hardened stages due to its optimized

particle size distribution. It can be used as practical substitute for Silica Fume as it has optimum

particle size distribution not too coarse, not too finer either per the results obtained by Counto Micro

fine products Pvt. Ltd [2] ( A joint venture with ambuja cement ltd and alcon developers). It is

manufactured in the controlled conditions with special equipments to produce optimized particle size

distribution which is its unique property.

Alcofine 1203 and Alcofine 1101 are two types of Alccofine with low calcium silicate and high

calcium silicate respectively. Alccofine 1200 series is of 1201, 1202, 1203 which represents fine,

micro fine, ultrafine particle size respectively. Alccofine 1203 is slag based SCM having ultra

fineness with optimized particle size distribution whereas Alcofine 1101 is a micro finer

@IJMTER-2015, All rights Reserved 114

International Journal of Modern Trends in Engineering and Research (IJMTER)

Volume 02, Issue 08, [August– 2015] ISSN (Online):2349–9745 ; ISSN (Print):2393-8161

cementitious grouting material for soil stabilization and rock anchoring. The performance of

Alcofine is superior to all the other admixtures used in India. Due to high Calcium oxide (Cao)

content.

In the concrete mix design of Alccofine 1203 the initial rate of strength is found similar or increased

to that of Silica Fume as it trigger the primary reaction during hydration and Alccofine also

consumes by product calcium hydroxide from the hydration of cement to from additional C-S-H gel

which similar to pozzolans. The computed blain value based on particle size distribution (PSD) is

approximately 12000cm2/gm and is truly ultra fine. Due to its ultra fineness, of Alccofine 1203,it

provides reduced water demand for a given workability, even up to 70% replacement level as per

requirement.

Table 2. Physical parameters of Alccofine 1203

Specific gravity Bulk Density Partical size distribution (µ )

(kg/m3)

d 10 d 50 d90

2.9 600-700 1-2 4-5 8-9

Table 3. Chemical parameters of Alccofine 1203

CaO Al2o3 SIO2 Glass content

31-33 %z 23-25 % 33-35 % >90%

Applications - Alccofine 1101 Micro fine Cement-Grout

• It is used in Tunnels, caverns, mines, etc. as Rock injection:

• It can be used for pre and post excavation injection.

•It can also be used for soil stabilization and sealing of ground water

• Soil injection

• Pre packed injection

• Contact injection

Benefits of Alccofine 1101

• Standard cement injection equipment can be used to perform grouting.

• It has better penetration in tight joints, fissures and pore spaces.

• Greater penetration imparts greater water tightness.

• Its rate of setting is very high.

• Better working environment and no hazardous components

• It is Durable

• It is found to be an economical solution.

Applications of Alccofine 1203

• Bridges

• Roads and air ports

• High rise buildings

Benefits of Alccofine 1203

In Fresh State

• The workability of the mix retention is improved.

• Flow ability of the mix is increased

• Reduction in segregation can be observed in the mix

• Reduction in heat of hydration of the mix

@IJMTER-2015, All rights Reserved 115

International Journal of Modern Trends in Engineering and Research (IJMTER)

Volume 02, Issue 08, [August– 2015] ISSN (Online):2349–9745 ; ISSN (Print):2393-8161

In Hardened state

• Improvement in durability of the mix

• Resistance to AAR is increased

• Strength at all ages is increased

• Resistance to chemical attack / corrosion is improved as ingression becomes difficult

• Lowers permeability of the mix

Recent application of Alccofine in India:

Project first cable stayed bridge at Nagpur

Kochi metro in Kerala Alccofine 1203 is being used.

Project Chennai metro Alccofine 1101 micro fine cement grout is being used.

II. EXPERIMENTAL PROGRAM

For determining the effect of ALCCOFINE 1203 on the workability, water requirement and HRWR

dosages, three trials of concrete mixes were prepared, based on the following mix design

methodology: Results are taken from study carried by Counto Micro fine Products PVT. LTD [2]

(A joint venture with Ambuja cement ltd and alcon developers)

A. Workability: Considering the water/binder ratio, admixture dosage constant and determining the

slump and compressive strength.

B. Water Demand: Considering the admixture quantity constant and varying the water/binder ratio

and determining the slump and compressive strength.

C. Admixture Requirement: Considering the water/binder ratio constant and varying the admixture

content and determining slump and compressive strength.

In these three methodologies binders are OPC – 430 kg, Fly Ash – 80kg and alternately using

ALCCOFINE 1203 – 40kg and Silica Fume – 40kg as total binder content. The amount of total

cementitious content was considered constant at 550 kg/m3. Coarse aggregate used was crushed

basalt rock and fine aggregate used was local river sand . These materials were dried completely

before using. The HRWR used was Polycarboxylate ether. Considering typical mix design, the

further changes were carried out as per the described methodologies.

Table 4. Typical Mix Design Mass of Constituents (kgs)

Materials Reference Mix Silica Fume Sample mix ALCCOFINE

1203

Cement 430 430

Fly Ash 80 80

Silica Fume 40 0

Alccofine1203 0 40

Water 160 160

Admixture 4 4

Table 4 A. Materials Used For Experiment

Material Brand Name Product

Cement ACC 43 Grade OPC

Fly Ash Dirk (I) Pvt. Ltd. P 60

Silica Fume ORkLA (I) Pvt.Ltd. (Formerly known as Elkem India Pvt.Ltd.) 920 D

Admixture Glenium BASF B - 244

@IJMTER-2015, All rights Reserved 116

International Journal of Modern Trends in Engineering and Research (IJMTER)

Volume 02, Issue 08, [August– 2015] ISSN (Online):2349–9745 ; ISSN (Print):2393-8161

Table 5. The Effect of ALCCOFINE1203 addition on compressive strength and workability

of concrete specimen with equal water/binder ratio.

Reference mix silica fume Sample mix ALCCOFINE 1203

Slump (mm)

Initial 180 210

30 min 150 210

60 min 110 150

90 min 90 120

120 min 60 95

Compressive strength (MPa)

1 Day 20.4 20.58

3 Day 38.29 45.11

7 Day 49.83 55.72

28 Day 64.17 67.44

56 Day 68.25 70.42

Table 6. The effect of ALCCOFINE 1203 on the water required to maintain

a constant slump. Assessment of Water Requirement

Materials Reference Mix Silica Fume Sample mix ALCCOFINE

1203

Cement 435 435

Fly Ash 80 80

Silica Fume 40 0

Alccofine1203 0 40

Water 160 155

Admixture 4 4

Table 7: Compressive strength and workability of concrete specimen

with constant binder and HRWR content Slump (mm)

Reference mix Silica Fume Sample mix ALCCOFINE 1203

Initial 190 200

30 min 155 160

60 min 120 130

90 min 95 110

120 min 65 80

Compressive strength(MPa)

1 Day 21.3 23.54

3 Day 38.75 47.2

7 Day 50.02 60.42

28 Day 64.50 70.47

56 Day 68.50 74.44

Table 7. Assessment of HRWR required for a concrete specimen at constant water /binder ratio

Materials Reference Mix Silica Fume Sample mix ALCCOFINE

1203

Cement 430 430

Fly Ash 80 80

Silica Fume 40 0

Alccofine1203 0 40

Water 160 160

Admixture 4 3.00

@IJMTER-2015, All rights Reserved 117

International Journal of Modern Trends in Engineering and Research (IJMTER)

Volume 02, Issue 08, [August– 2015] ISSN (Online):2349–9745 ; ISSN (Print):2393-8161

Note:- Contents in kg/m

Table 8. Workability and compressive strength of concrete specimen

at constant water / binder ratio. Slump (mm)

Reference mix Silica Fume Sample mix ALCCOFINE 1203

Initial 185 195

30 min 150 165

60 min 125 130

90 min 100 115

120 min 60 75

Compressive strength(MPa)

1 Day 20 22.58

3 Day 38.95 46.12

7 Day 49.23 54.72

28 Day 63.57 68.64

56 Day 68.05 72.52

Cost analysis for a standard Mix of M60 with Alccofine 1203 V/s silica fume

Table 9. Cost analysis of Alcco fine concrete

MIX Without MIX With

ALCCOFINE 1203- ALCCOFINE 1203-B

A

Item Rate/kg Cement+ Silica Cost Cement+ALCCOFINE Cost

fume+ FA /Cum 1203+FA per

Cum

Cement 5 430 2150 430 2150

Silica 25 50 1250 0 0

fume

Alccofine 25 0 0 50 1250

Fly ash 15 80 120 80 120

Admixture 130 767 997.1 5.59 726.7

Net savings = 4517.10 – 4246.7 = 270.40 kg

III. CONCLUSION DRAWN

The conclusion from the experiment can be drawn that Alccofine being use as mineral admixture in a

concrete mix increase the initial strength of the concrete than the ordinary concrete. The concrete

posses high workability and retain the workability for sufficient time. Alccofine is easy to use and

can be added directly with cement, ultrafine particle of Alccofine provide better and smooth surface

finish. For high strength concrete the cost of the concrete mix prepared with Alccofine is lesser than

the concrete without Alccofine. It also lower the water/binder ratio.

REFERENCES

[1] Devinder Sharma, Saurabh Gupta, Ashish Kapoor, Anu Sharma “A Review on Alccofine- A New generation Micro

Fine Concrete Material for High Strength Concrete” National Conference on Sustainable Infrastructure

Development, pp. 68-75 , Feb. 2015

[2] “Alccofine” By Counto Micro fine Products Pvt. Ltd. (A joint venture with ambuja cement ltd and alcon developers)

[3] Praveen Nayak S, H. S. Narashimhan and Raghunandan V.Kadaba, “Hardened Properties of Concretes made with

Micro Silica and Alccofine- A Performance Optimization based Comparative Study, International Journal of

Engineering Research and Development e-ISSN: 2278-067X, p-ISSN: 2278-800X, www.ijerd.com Volume 10,

Issue 8 (August 2014), PP.01-09

IS: 456-2000 Code of practice for plain and reinforced concrete (third edition). Bureau of Indian standards, New Delhi,

India

@IJMTER-2015, All rights Reserved 118

S-ar putea să vă placă și

- Porouse Concret 6th Sem Project - AllDocument22 paginiPorouse Concret 6th Sem Project - AllVaibhav 2401Încă nu există evaluări

- Water Supply Rangwala (Contents)Document5 paginiWater Supply Rangwala (Contents)Srishti ShamelÎncă nu există evaluări

- Sika Concrete HandbookDocument151 paginiSika Concrete HandbookFatjon ShahaÎncă nu există evaluări

- Concrete Recycling - Research and PracticeDocument659 paginiConcrete Recycling - Research and Practicekarim hassanÎncă nu există evaluări

- Precast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringDocument12 paginiPrecast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringSoc Rua NguyenÎncă nu există evaluări

- Disaster Resistant ArchitectureDocument78 paginiDisaster Resistant ArchitectureSurbahon Rajkumar100% (1)

- Unit 3 (Sulphur Infiltrated Concrete)Document14 paginiUnit 3 (Sulphur Infiltrated Concrete)flora sharaÎncă nu există evaluări

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDocument5 paginiStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananÎncă nu există evaluări

- DHS Report 1Document16 paginiDHS Report 1PujaÎncă nu există evaluări

- Composition, Properties and Usage of Micro ConcreteDocument5 paginiComposition, Properties and Usage of Micro ConcreteRapolu VyshnaviÎncă nu există evaluări

- EN8592 UNIT 2 Grey Water HarvestingDocument14 paginiEN8592 UNIT 2 Grey Water Harvesting2CIVIL3045 SONIYA AÎncă nu există evaluări

- ContentsDocument12 paginiContentsMoïsës TavarexÎncă nu există evaluări

- Solar Roadways SeminarDocument5 paginiSolar Roadways SeminarNivya Cleetus0% (1)

- A.S Civil Engineering Project Centre: Projects Delivered To All Over Cities in Tamilnadu & India Project TitlesDocument9 paginiA.S Civil Engineering Project Centre: Projects Delivered To All Over Cities in Tamilnadu & India Project TitlesCivil Engineering projectÎncă nu există evaluări

- Group A - Case Study - Building ServicesDocument17 paginiGroup A - Case Study - Building ServicesEmmanuel AndenyangÎncă nu există evaluări

- Planning, Analysis, and Design of Hospital BuildingDocument98 paginiPlanning, Analysis, and Design of Hospital BuildingSri Amarnath BirlaÎncă nu există evaluări

- Component Longevity in Terms of Operation Performance and Resistance To Deleterious ForcesDocument8 paginiComponent Longevity in Terms of Operation Performance and Resistance To Deleterious ForcesPalanisamy RajaÎncă nu există evaluări

- List of Contents. Page No.: ChaptersDocument18 paginiList of Contents. Page No.: Chaptersvaibhavi lakshmiÎncă nu există evaluări

- Academic Site Visit Report On Design of Steel Structures at Kimaya SteelDocument16 paginiAcademic Site Visit Report On Design of Steel Structures at Kimaya SteelKiranMDeoreÎncă nu există evaluări

- Study of Strength Property of Concrete Using Waste Plastics and Steel FiberDocument3 paginiStudy of Strength Property of Concrete Using Waste Plastics and Steel FibertheijesÎncă nu există evaluări

- Civil Mini Project DivyaKamathDocument63 paginiCivil Mini Project DivyaKamathJanaki Vamaraju100% (1)

- Technical Seminar Ashish WanveDocument26 paginiTechnical Seminar Ashish WanvecasaÎncă nu există evaluări

- Airquality StandardsDocument31 paginiAirquality Standardsjanice omadto100% (2)

- A Seminar Report On Self Sustainable BuildingDocument32 paginiA Seminar Report On Self Sustainable BuildingashoknrÎncă nu există evaluări

- GUNITINGDocument11 paginiGUNITINGPavithravasu100% (1)

- Sample Industrial Attachment Report For Diploma in ArchitectureDocument17 paginiSample Industrial Attachment Report For Diploma in ArchitectureSailo'o L. SilasÎncă nu există evaluări

- Mech Control of Corrosion On Underwater PilesDocument14 paginiMech Control of Corrosion On Underwater Pilesraghavendra ragguÎncă nu există evaluări

- Internship ReportDocument20 paginiInternship ReportKarthik Chalageri 7Încă nu există evaluări

- 5.1. 1 Intakes and Inlet StructuresDocument40 pagini5.1. 1 Intakes and Inlet StructuresWonda TayeÎncă nu există evaluări

- Precasting and PrefabricationDocument51 paginiPrecasting and PrefabricationSadia HusainÎncă nu există evaluări

- Seminar Report On Highway Management SystemDocument22 paginiSeminar Report On Highway Management SystemAditya ansuman RoutÎncă nu există evaluări

- KHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFDocument83 paginiKHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFassistant directorÎncă nu există evaluări

- Architectural Style of CHARANJIT SHAHDocument7 paginiArchitectural Style of CHARANJIT SHAHApoorv KalraÎncă nu există evaluări

- Numericals On RCC DESIGNDocument10 paginiNumericals On RCC DESIGNsirfmein50% (2)

- Question Paper Code:: Reg. No.Document2 paginiQuestion Paper Code:: Reg. No.Rajha RajeswaranÎncă nu există evaluări

- Handloom House New DelhiDocument7 paginiHandloom House New DelhiVenkata Vignesh RamÎncă nu există evaluări

- Rehabilitation and Retrofitting of Structures - Unit 1Document14 paginiRehabilitation and Retrofitting of Structures - Unit 1SAKA PREMCHANDÎncă nu există evaluări

- Embodied Energy Computations in BuildingsDocument6 paginiEmbodied Energy Computations in BuildingsVijay KapoorÎncă nu există evaluări

- Nanotechnology in Civil Engineering - SaDocument10 paginiNanotechnology in Civil Engineering - SaAnonymous m6BhZY0czn0% (1)

- Green Buildings Technologies For Affordable Final)Document45 paginiGreen Buildings Technologies For Affordable Final)mikado7Încă nu există evaluări

- Dissertation On Earthquake Resistant DesignDocument22 paginiDissertation On Earthquake Resistant DesignVijay Kumaran100% (2)

- Elective Report GROUP 4 Ashwini SanapDocument23 paginiElective Report GROUP 4 Ashwini SanapAshwini BackupÎncă nu există evaluări

- Prospects of Low Cost Housing in IndiaDocument6 paginiProspects of Low Cost Housing in IndiaRam Prabesh YadavÎncă nu există evaluări

- Kanu PriyaDocument58 paginiKanu PriyaPrdeep SinghÎncă nu există evaluări

- Earthquake Resistant Building Seminar ReportDocument4 paginiEarthquake Resistant Building Seminar ReportRaju KINGÎncă nu există evaluări

- Seminar Report-EARTHQUAKE-RESISTANT-BUILDINGS PDFDocument28 paginiSeminar Report-EARTHQUAKE-RESISTANT-BUILDINGS PDFMeraj aliÎncă nu există evaluări

- CETPDocument20 paginiCETPSourabh RaoraneÎncă nu există evaluări

- Environmental Impact Analysis: A Case Study of Acc Cement Plant AbstractDocument14 paginiEnvironmental Impact Analysis: A Case Study of Acc Cement Plant AbstractMintoo VermaÎncă nu există evaluări

- MWWT Module 1 - NOTESDocument48 paginiMWWT Module 1 - NOTESMonika AcharyaÎncă nu există evaluări

- ATMOSPHERIC WATER GENERATOR Project Report Unais PPDocument27 paginiATMOSPHERIC WATER GENERATOR Project Report Unais PPThe REBELÎncă nu există evaluări

- Project ReportDocument48 paginiProject Reportstars of the nationÎncă nu există evaluări

- ABM Seminar ReportDocument24 paginiABM Seminar Reportmd MuzammilÎncă nu există evaluări

- A Project Report Submited To "QQGPT" in Partial Fulfillment For The Award of The Degree ofDocument52 paginiA Project Report Submited To "QQGPT" in Partial Fulfillment For The Award of The Degree ofSyedAhmed Raza100% (1)

- Electro-Kinetic Road Ramps: Department of Civil EngineeringDocument12 paginiElectro-Kinetic Road Ramps: Department of Civil EngineeringSrinivas JÎncă nu există evaluări

- Disaster ManagementDocument15 paginiDisaster ManagementRahul Paul AbrahamÎncă nu există evaluări

- Waste Water Punjab - 21 March 2019Document48 paginiWaste Water Punjab - 21 March 2019Mohd IshfaqÎncă nu există evaluări

- Final Internship PresentationDocument16 paginiFinal Internship PresentationephÎncă nu există evaluări

- Alccofine 1203 TDSDocument14 paginiAlccofine 1203 TDSpinnacleonline9128100% (1)

- Sulphur Concrete: Modern Concrete Materials and Technology (Cv895)Document26 paginiSulphur Concrete: Modern Concrete Materials and Technology (Cv895)Rachana B HÎncă nu există evaluări

- Alccofine Tech InfoDocument14 paginiAlccofine Tech InfoKamal HamsaÎncă nu există evaluări

- Experimental Studies On M20 Self Compacting Concrete: Reena K, Mallesh MDocument8 paginiExperimental Studies On M20 Self Compacting Concrete: Reena K, Mallesh MPayam ShivaÎncă nu există evaluări

- Presented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversityDocument20 paginiPresented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversitySaurabh AgrawalÎncă nu există evaluări

- Accident ReportingDocument7 paginiAccident ReportingSiddhesh Kamat MhamaiÎncă nu există evaluări

- Emergency Procedure - PlanDocument10 paginiEmergency Procedure - PlanSiddhesh Kamat Mhamai100% (1)

- HSE Company Improvement Plan: Presented by Sanjay NikamDocument25 paginiHSE Company Improvement Plan: Presented by Sanjay NikamSiddhesh Kamat MhamaiÎncă nu există evaluări

- Sieve Analysis ReportDocument4 paginiSieve Analysis ReportSiddhesh Kamat MhamaiÎncă nu există evaluări

- Concrete Family of MixesDocument9 paginiConcrete Family of MixesSiddhesh Kamat MhamaiÎncă nu există evaluări

- Hse Policy: - Get HSE Policy Copies in English and Local Language.Document15 paginiHse Policy: - Get HSE Policy Copies in English and Local Language.Siddhesh Kamat MhamaiÎncă nu există evaluări

- Executive Development Programme (Edp)Document7 paginiExecutive Development Programme (Edp)Siddhesh Kamat MhamaiÎncă nu există evaluări

- Sieve Analysis ReportDocument4 paginiSieve Analysis ReportSiddhesh Kamat MhamaiÎncă nu există evaluări

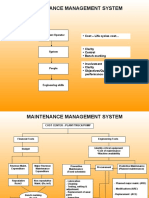

- Maintenance Management System: Cost - Life Cycles CostDocument3 paginiMaintenance Management System: Cost - Life Cycles CostSiddhesh Kamat MhamaiÎncă nu există evaluări

- The Effect of Exposition Conditions On The Durability of Cement Concrete With Dolomite Aggregate Sourced Near Kraków, PolandDocument8 paginiThe Effect of Exposition Conditions On The Durability of Cement Concrete With Dolomite Aggregate Sourced Near Kraków, PolandSiddhesh Kamat MhamaiÎncă nu există evaluări

- Feedback Form: Qcrete Readymix (India) Pvt. Ltd. Introduces Packcrete Shake It, Cut It, Pour It and Cure It!!!!!Document1 paginăFeedback Form: Qcrete Readymix (India) Pvt. Ltd. Introduces Packcrete Shake It, Cut It, Pour It and Cure It!!!!!Siddhesh Kamat MhamaiÎncă nu există evaluări

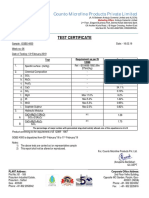

- Test Certificate: Counto Microfine Products Private LimitedDocument1 paginăTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiÎncă nu există evaluări

- Duracrete FichaDocument2 paginiDuracrete FichavankarpÎncă nu există evaluări

- Checklist - Civil WorksDocument25 paginiChecklist - Civil WorksJagoan Neon0% (1)

- Cikomould Pu: Technical Data SheetDocument2 paginiCikomould Pu: Technical Data SheetVaittianathan MahavapillaiÎncă nu există evaluări

- CE645 Term Paper Drilled Shafts PDFDocument22 paginiCE645 Term Paper Drilled Shafts PDFJay PatelÎncă nu există evaluări

- Precast ConcreteDocument6 paginiPrecast ConcreteRaja Sekhar Reddy KasuÎncă nu există evaluări

- Technical PapersDocument778 paginiTechnical PapersANIL KUMARÎncă nu există evaluări

- Structural Design of Load-Bearing Fibre Concrete StructuresDocument43 paginiStructural Design of Load-Bearing Fibre Concrete Structureskongo1984_1Încă nu există evaluări

- Simplified Estimate by Max FajardoDocument300 paginiSimplified Estimate by Max FajardoRyan David MacayanÎncă nu există evaluări

- Colak Foamed GypsumDocument8 paginiColak Foamed GypsumOnyx XynoÎncă nu există evaluări

- Design Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550Document8 paginiDesign Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550nathanÎncă nu există evaluări

- 3.articulated Tower PlatformsDocument2 pagini3.articulated Tower PlatformsAman SinghalÎncă nu există evaluări

- Structural Behavior of Concrete Encased Steel BeamDocument14 paginiStructural Behavior of Concrete Encased Steel BeamJoseph TuzonÎncă nu există evaluări

- Chapter 1 Part 1Document8 paginiChapter 1 Part 1Renderizzah FloraldeÎncă nu există evaluări

- Waterproofing, Construction Chemicals Manufacturers & Suppliers IndiaDocument8 paginiWaterproofing, Construction Chemicals Manufacturers & Suppliers IndiaNagesh ShuklaÎncă nu există evaluări

- जलसंपदा विभागDocument444 paginiजलसंपदा विभागkalpanajadhav11279100% (1)

- MS For Removal and Reinstatement of Wind Dust BarrierDocument7 paginiMS For Removal and Reinstatement of Wind Dust BarrierPartheeban SkpÎncă nu există evaluări

- Design of Hydroelectric Power PlantsDocument54 paginiDesign of Hydroelectric Power Plantsbagus adi saputraÎncă nu există evaluări

- Tracking ListDocument2 paginiTracking ListBaby SinghÎncă nu există evaluări

- Specifications For Covers and Reinforcement in ColumnDocument2 paginiSpecifications For Covers and Reinforcement in ColumnraviciviltÎncă nu există evaluări

- Concrete Block Paving - Book 1 - IntroductionDocument32 paginiConcrete Block Paving - Book 1 - IntroductionTrương Khải100% (1)

- Complet Analyz of Ghori CementDocument3 paginiComplet Analyz of Ghori CementSarbaz BanozaiÎncă nu există evaluări

- Astm c150 PDFDocument4 paginiAstm c150 PDFthaidzungÎncă nu există evaluări

- c4-10 Bored Piling WorksDocument28 paginic4-10 Bored Piling WorksJacky TiongÎncă nu există evaluări

- C09 Fact SheetDocument2 paginiC09 Fact SheetMohammad Ehsan EdalatÎncă nu există evaluări

- WRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Document32 paginiWRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Anup MitraÎncă nu există evaluări

- Harga Bahan 2020Document16 paginiHarga Bahan 2020T Rahmat Putra JauhariÎncă nu există evaluări

- Determination of Size Independent Fracture Energy of Mixes by 2 MethodsDocument7 paginiDetermination of Size Independent Fracture Energy of Mixes by 2 MethodsSai Asrith PylaÎncă nu există evaluări

- Residential Building ReportDocument25 paginiResidential Building ReportKhaleel skmÎncă nu există evaluări