Documente Academic

Documente Profesional

Documente Cultură

Di-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak Power

Încărcat de

Jose BenavidesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Di-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak Power

Încărcat de

Jose BenavidesDrepturi de autor:

Formate disponibile

DI-143 Design Idea

TOPSwitch-HX ®

High Efficiency Inkjet Power Supply Provides up to 80 Watts of Peak Power

Application Device Power Output Input Voltage Output Voltage Topology

Inkjet Printer TOP258MN 20 W cont, 80 W pk 90 – 264 VAC 32 V Flyback

Design Highlights typically have peak load requirements applied for very short

• Low component count, high efficiency periods.

• Meets CEC/ENERGY STAR 2008 requirements

• Delivers 20 W continuous and 80 W of peak power The TOP258MN regulates the output by adjusting the duty cycle

• Very high efficiency in standby and sleep modes of the internal MOSFET in proportion to the current fed into the

• Enables more than 0.6 W output power for 1 W input power at CONTROL pin. The feedback signal is provided from the second-

240 VAC input ary via a simple low cost Zener diode (VR3) and optocoupler (U2)

• Enables more than 2.3 W output power for <3 W input power

at 240 VAC input The EcoSmart® multimode control feature of TOPSwitch-HX

• Very low no-load input power <300 mW at 240 VAC provides a virtually constant efficiency over the entire load range.

• Time-triggered overvoltage protection (OVP)

• Latching fault protection and fast AC reset To provide a constant output power with line voltage, R11, R14

• Meets EN55022 and CISPR-22 Class B conducted EMI with and R12 linearly reduce the internal current limit of U4 as the line

>10 dBμV margin voltage increases. This allows the supply to limit the output power

• Limited Power Source (LPS) with maximum apparent power not to <100 VA at high line while still delivering the rated output power

exceeding 100 VA in fault conditions at low line.

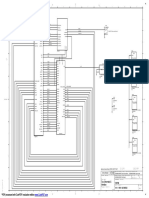

Operation The power supply has time-triggered overload protection sensed

The isolated flyback converter shown in Figure 1 is designed from the primary side bias winding. During overload, the voltage

around the TOPSwitch-HX IC family, the part used is TOP258MN across C13 rises. Once this exceeds 20 V (VR5), the latching

(U4). The power supply operates from a universal input voltage shutdown feature of the VOLTAGE MONITOR (V) pin is triggered.

range and is designed to provide a 32 V output delivering 20 W The values of C9, R20 and R22 determine the delay before

continuous with 80 W peak. The M package (10-pin DIP) allows triggering the OV latch. Once in latching shutdown, the V pin

simultaneous use of current limit programming, line sense and

C8

OVP functions. Ideal applications include inkjet printers, which 1 nF R19 C26

68 7 100 pF

250 VAC

0.5 W 1 kV

C20 C31 32 V

330 MF 22 MF 625 mA, 2.5 APK

50 V L2 50 V L3

1 10

3.3 MH

2 D6-D7

D8 D9 VR7 STPS3150 RTN

R25 9

1N4007 1N4007 BZY97C150 47 MH

C3 100 7

120 MF 150 V C29

o 400 V 5

t 3 C13 220 nF

R1 R11 NC 10 MF C10 50 V

RT1 2 M7 3.6 M7 R17 C5 50 V

D11 D10 1 nF

1N4007 1N4007 10 7 1 k7 10 nF 4 250 VAC

0.5 W 1 kV

T1 D5

EF25 LL4148 R10

56 7 R8

L1 1.5 k7

5.3 mH D2

R2 R14 1N4007GP C28

D13 2 M7 3.6 M7 330 nF

1N4007 50 V

R23 R24 VR3

1N5255B

1 M7 1 M7 28 V

U2A

VR5 R20 PC817D

R3 1N5250B C9

R22 1 MF 130 k7

2 M7 20 V

C1 D V 2 M7 100 V

F1 R21

220 nF 3.15 A CONTROL R9

275 VAC 1 M7 2 k7

R4 0.125 W

2 M7

C

90 - 264 PI-4793-102307

VAC S X

R15

1 k7 R6

R12 TOPSwitch-HX 6.8 7

Q1 C6

7.5 k7 U4 100 nF

C30 2N3904 1% TOP258MN 50 V

100 nF

400 V Q2

Q3 C7

2N3904

2N3904 47 MF

R26 16 V

68 k7 R18

39 k7

Figure 1. Universal input, 20 W Continuous, 80 W Peak Power Inkjet Printer Power Supply Using TOP258MN.

www.powerint.com October 2007

needs to discharge below a fixed threshold before switching can 80

PI-4794-102307

be reinitiated. This is accomplished by a fast AC reset circuit. On

70

loss of AC, Q3 turns off, turning on Q1 and pulling the V pin low to

QP

reset the OVP latch. 60

AV

Key Design Points 50

• For printers the voltage regulation requirement (±7%) allows a

40

simple low cost Zener VR3 to be used to set the output voltage.

dBMV

For tighter voltage tolerances, a shunt regulator like a TL431 30

may be used. 20

• The primary clamp circuit (D2, VR7, R17, C5 and R25) provides

very high light-load efficiency. Zener VR7 and R17 discharge 10

capacitor C5 every cycle and limit to an average clamping 0

voltage. During lower switching frequency operation, the

capacitor cannot discharge below the rated voltage of VR7, -10

which improves light load efficiency. -20

• Selecting D2 as a slow diode (≤2 μs recovery) allows for some 0.15 1.0 10.0 100.0

of the leakage energy to be recycled into the load. If glass MHz

passivated 1N4007 is not available, the plastic FR106 may be Figure 2. Worst Case Conducted EMI (230 VAC with Output Grounded).

substituted.

• Within the normal operating range, Q3 turns on, thereby turning

off Q1. Resistors R1 and R2 can thus inject current into the Transformer Parameters

V pin of U4 and provide line undervoltage detection. Once the EF25 NC-2H or equivalent,

Core Material

current into the V pin exceeds 25 μA, switching is enabled. gapped for ALG of 70 nH/t²

• At very low input voltages, transistor Q2 turns off, thus leaving Bobbin BEF25, 10 pin, Horizontal

the X pin floating. This in turn inhibits switching of U4, and the

3mm margins on primary side of bobbin to meet

power supply turns off.

safety

• Capacitors C1, C3, C8, C10 and common-mode chokes L1 Primary: 48T x 2, AWG31, tape

and L3 provide common mode filtering. Winding Details Bias: 9T x 4, AWG29, 3 layers, tape

• Phase boost network R10 and C28 provides high frequency 32 V: 24T x 2, AWG28, TIW, 3 layers tape

gain and increased phase margin. Shield: 10T x 4, AWG30, tape

Primary: 48T x 2, AWG31, tape

Primary(3 – 2), Bias(5 – 4), 32 V(10 – 9)

Winding Order

Shield(NC – 1), Primary(2 – 1)

Primary Inductance 648 μH, ±20%

Primary Resonant 1000 kHz (minimum)

Frequency

Leakage 16 μH (maximum)

Inductance

Table 1. Transformer Parameters. (NC = No Connection, TIW = Triple Insulated Wire).

Power Integrations Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power

5245 Hellyer Avenue Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS

San Jose, CA 95138, USA. MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED

Main: +1 408-414-9200 WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

Customer Service The products and applications illustrated herein (transformer construction and circuits external to the products) may be covered by

Phone: +1-408-414-9665 one or more U.S. and foreign patents or potentially by pending U.S. and foreign patent applications assigned to Power Integrations.

Fax: +1-408-414-9765 A complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants

Email: usasales@powerint.com its customers a license under certain patent rights as set forth at http://www.powerint.com/ip.htm.

The PI logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, EcoSmart, Clampless, E-Shield, Filterfuse, StackFET,

On the Web PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies.

www.powerint.com ©2007, Power Integrations, Inc.

B

10/07 DI-143

S-ar putea să vă placă și

- Di-187 Design Idea Topswitch-Hx: 35 W LCD MonitorDocument2 paginiDi-187 Design Idea Topswitch-Hx: 35 W LCD MonitorIvanê FonsecaÎncă nu există evaluări

- Di146 0Document2 paginiDi146 0amitÎncă nu există evaluări

- 1676f PDFDocument16 pagini1676f PDFSIVARAMANJAGANATHANÎncă nu există evaluări

- Aif - PFC TRN Rev12 1484268447 TechrefDocument40 paginiAif - PFC TRN Rev12 1484268447 TechrefmigsantÎncă nu există evaluări

- GE Fanuc IC694MDL940: Output Module, Relay 2 Amp 16 Point, Non Isolated. IC694M IC694MD IC694MDLDocument4 paginiGE Fanuc IC694MDL940: Output Module, Relay 2 Amp 16 Point, Non Isolated. IC694M IC694MD IC694MDLomarlgonzÎncă nu există evaluări

- 3798 FaDocument20 pagini3798 FaFavio IousÎncă nu există evaluări

- SCT9320Document20 paginiSCT9320Charith PereraÎncă nu există evaluări

- Datasheet STS Huawei 6000K-H1 For 200-215KTLDocument2 paginiDatasheet STS Huawei 6000K-H1 For 200-215KTLTitoÎncă nu există evaluări

- User's Guide: UCC2541 72-W Synchronous Buck ConverterDocument22 paginiUser's Guide: UCC2541 72-W Synchronous Buck ConverterNeslyn BocioÎncă nu există evaluări

- Datasheet TSI BravoDocument2 paginiDatasheet TSI BravoMax TapiaÎncă nu există evaluări

- MultiPlus-II-GX Inverte Charger DatasheetDocument2 paginiMultiPlus-II-GX Inverte Charger DatasheetWinSajeewaÎncă nu există evaluări

- Reference Design: PR883: A 300-W, Universal Input, Isolated PFC Power Supply For LCD TV ApplicationsDocument23 paginiReference Design: PR883: A 300-W, Universal Input, Isolated PFC Power Supply For LCD TV Applicationsgolu201Încă nu există evaluări

- WLC550 Industrial: Electrical SpecificationsDocument8 paginiWLC550 Industrial: Electrical SpecificationsNigel DsouzaÎncă nu există evaluări

- 15W Universal ChargerDocument11 pagini15W Universal Chargermas udinÎncă nu există evaluări

- Preliminary Data Sheet IXDD404PI / 404SI / 404SIA / 404SI-16Document10 paginiPreliminary Data Sheet IXDD404PI / 404SI / 404SIA / 404SI-16Teles SilvaÎncă nu există evaluări

- STS-3000K-H1: Simple EfficiencyDocument2 paginiSTS-3000K-H1: Simple EfficiencyNatalia AndreaÎncă nu există evaluări

- Charge Pump DC-to-DC Voltage Converter: Features Package TypesDocument20 paginiCharge Pump DC-to-DC Voltage Converter: Features Package TypesTomás CuetoÎncă nu există evaluări

- DatasheetDocument20 paginiDatasheetمحمد محمدÎncă nu există evaluări

- NCP 1055 ST 100Document26 paginiNCP 1055 ST 100NacerÎncă nu există evaluări

- IC694MDL930 RX3i RelayOutputDocument5 paginiIC694MDL930 RX3i RelayOutputFelix BlancoÎncă nu există evaluări

- 00 Datasheet of STS For 200 - 215KTL - Others - 20210928Document4 pagini00 Datasheet of STS For 200 - 215KTL - Others - 20210928Antonio CanalesÎncă nu există evaluări

- 00 Datasheet STS 6000h-H1Document4 pagini00 Datasheet STS 6000h-H1Andres Fabian Torres RicaurteÎncă nu există evaluări

- Ds Bps 350inv60 120 240 9g SeriesDocument10 paginiDs Bps 350inv60 120 240 9g Seriesricardogaravito3353Încă nu există evaluări

- SWT3000 Product Brochure Data 0514 PDFDocument8 paginiSWT3000 Product Brochure Data 0514 PDFJefferson Huerta OlivaresÎncă nu există evaluări

- 45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteDocument9 pagini45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteGrzegorz WegnerÎncă nu există evaluări

- LM5164 100-V Input, 1-A Synchronous Buck DC/DC Converter With Ultra-Low IDocument35 paginiLM5164 100-V Input, 1-A Synchronous Buck DC/DC Converter With Ultra-Low IfagundesbrÎncă nu există evaluări

- Datasheet Certaflux DL S 2000lmDocument5 paginiDatasheet Certaflux DL S 2000lmAth AimanÎncă nu există evaluări

- Efficient and Reliable Smart Transformer StationDocument2 paginiEfficient and Reliable Smart Transformer StationLindy PortsuÎncă nu există evaluări

- VI-200 / VI-J00 Family: Design Guide & Applications ManualDocument97 paginiVI-200 / VI-J00 Family: Design Guide & Applications ManualcurzÎncă nu există evaluări

- Di-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating ControlDocument2 paginiDi-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating Controlahmed chaouki ChamiÎncă nu există evaluări

- EM5106 3A LDO Regulator Technical OverviewDocument10 paginiEM5106 3A LDO Regulator Technical OverviewSib Repair CenterÎncă nu există evaluări

- Linkswitch-Tn: FamilyDocument16 paginiLinkswitch-Tn: FamilyJulián Peláez RestrepoÎncă nu există evaluări

- L 6928D - ReguladorDocument9 paginiL 6928D - ReguladorTiago LeonhardtÎncă nu există evaluări

- L4970ADocument21 paginiL4970ASURESH CHANDRA ROUTÎncă nu există evaluări

- 2059771linksw ln306gnDocument18 pagini2059771linksw ln306gnRegulo GomezÎncă nu există evaluări

- NCP1117, NCV1117Document17 paginiNCP1117, NCV1117kalimbaloÎncă nu există evaluări

- Solar Inverter pvs300 Flyer PDFDocument4 paginiSolar Inverter pvs300 Flyer PDFmile1966Încă nu există evaluări

- Load Detecting Power Supply: 1.0 Design SpecificationsDocument17 paginiLoad Detecting Power Supply: 1.0 Design SpecificationsLucre SandovalÎncă nu există evaluări

- LNK305Document19 paginiLNK305PippoÎncă nu există evaluări

- Contax ContactorDocument4 paginiContax Contactorheri fauziÎncă nu există evaluări

- Lyt0002/0004-0006 Lytswitch-0 Off-Line Low Power Led Driver Ic FamilyDocument18 paginiLyt0002/0004-0006 Lytswitch-0 Off-Line Low Power Led Driver Ic Familyzuffflor_925748656Încă nu există evaluări

- Datasheet of STS-3000K-H1 and SUN2000-185KTL-H1 20200706Document2 paginiDatasheet of STS-3000K-H1 and SUN2000-185KTL-H1 20200706Sav SashaÎncă nu există evaluări

- STR-A6100: SeriesDocument2 paginiSTR-A6100: SeriesY. Leonel MolinaÎncă nu există evaluări

- LM 5163Document36 paginiLM 5163m3rishorÎncă nu există evaluări

- Topswitch - GX: Flyback Quick Selection CurvesDocument12 paginiTopswitch - GX: Flyback Quick Selection Curvessteviej85Încă nu există evaluări

- CET Modular UPS Datasheet Flexa Subrack System en v1.3Document2 paginiCET Modular UPS Datasheet Flexa Subrack System en v1.3dfghjkÎncă nu există evaluări

- Protected Quad Power Driver: Description Features and BenefitsDocument8 paginiProtected Quad Power Driver: Description Features and BenefitsAnkitÎncă nu există evaluări

- ABB Utility Automation: ApplicationDocument4 paginiABB Utility Automation: ApplicationCyrille Max AKEÎncă nu există evaluări

- V048F015T100 V048F015M100: Product Description Absolute Maximum RatingsDocument21 paginiV048F015T100 V048F015M100: Product Description Absolute Maximum Ratingsalllim88Încă nu există evaluări

- Model TransformatorDocument2 paginiModel TransformatorAndrei TaranuÎncă nu există evaluări

- 28V 3A Step-Down Switching Regulator: Power Management Features DescriptionDocument19 pagini28V 3A Step-Down Switching Regulator: Power Management Features Descriptionteban09Încă nu există evaluări

- TPS51123 DatasheetDocument38 paginiTPS51123 DatasheetEduard Vega AyalaÎncă nu există evaluări

- Tps 51123Document37 paginiTps 51123Krista TranÎncă nu există evaluări

- Sboa 290 CSHXGHDCXCFXDDCGDocument6 paginiSboa 290 CSHXGHDCXCFXDDCGKarthik SuryaÎncă nu există evaluări

- ABB String Inverters: UNO-2.0/3.0/3.6/4.2-TL-OUTD 2 To 4.2 KWDocument4 paginiABB String Inverters: UNO-2.0/3.0/3.6/4.2-TL-OUTD 2 To 4.2 KWCristian Rosales RomaoÎncă nu există evaluări

- Uno2 0-3 0-3 6-4 2Document4 paginiUno2 0-3 0-3 6-4 2Cristian Rosales RomaoÎncă nu există evaluări

- VKP 60 LT 515 CDocument8 paginiVKP 60 LT 515 CBadar DayanÎncă nu există evaluări

- DC-AC Inverter: 2 Year WarrantyDocument1 paginăDC-AC Inverter: 2 Year WarrantySaleem MuhammadÎncă nu există evaluări

- SWT300Document8 paginiSWT300yasirÎncă nu există evaluări

- Induction Cooktop: Cooking PerformanceDocument2 paginiInduction Cooktop: Cooking PerformanceJose BenavidesÎncă nu există evaluări

- Pioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Document6 paginiPioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Daniboy1994Încă nu există evaluări

- Design Example Report: TitleDocument19 paginiDesign Example Report: TitleJose BenavidesÎncă nu există evaluări

- TNY268PNDocument2 paginiTNY268PNJose BenavidesÎncă nu există evaluări

- Bluetooth antenna connector padsDocument1 paginăBluetooth antenna connector padsJose BenavidesÎncă nu există evaluări

- TNY278PNDocument4 paginiTNY278PNJose BenavidesÎncă nu există evaluări

- Printed circuit boards main/crt componentsDocument1 paginăPrinted circuit boards main/crt componentsJose BenavidesÎncă nu există evaluări

- NT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListDocument22 paginiNT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListJose BenavidesÎncă nu există evaluări

- How to print large block diagrams in sectionsDocument2 paginiHow to print large block diagrams in sectionsJose BenavidesÎncă nu există evaluări

- The Ultimate DVD Region Hack Guide Book LIBROS de DVDDocument143 paginiThe Ultimate DVD Region Hack Guide Book LIBROS de DVDlondon335Încă nu există evaluări

- TNY264PNDocument6 paginiTNY264PNJose Benavides100% (1)

- Di-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionDocument8 paginiDi-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionJose BenavidesÎncă nu există evaluări

- Sony Play Station 2 Laser Calibration Using OscilloscopeDocument10 paginiSony Play Station 2 Laser Calibration Using OscilloscopeH3liax100% (1)

- TNY277PNDocument2 paginiTNY277PNJose BenavidesÎncă nu există evaluări

- LNK362 PDFDocument16 paginiLNK362 PDFJose BenavidesÎncă nu există evaluări

- Di-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterDocument4 paginiDi-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterJose Benavides100% (1)

- LNK302P Der-92Document14 paginiLNK302P Der-92Jose BenavidesÎncă nu există evaluări

- LNK364PNDocument2 paginiLNK364PNJose Benavides100% (2)

- TOP261LNDocument50 paginiTOP261LNJose BenavidesÎncă nu există evaluări

- China 17-Lcd-power-Inverter Oz9938 Top245 SCHDocument2 paginiChina 17-Lcd-power-Inverter Oz9938 Top245 SCHRicardo Chaman ChavezÎncă nu există evaluări

- TOP233YDocument24 paginiTOP233YJose BenavidesÎncă nu există evaluări

- Design Example Report: TitleDocument63 paginiDesign Example Report: TitleJose BenavidesÎncă nu există evaluări

- TOP250YNDocument38 paginiTOP250YNJose BenavidesÎncă nu există evaluări

- TOP258PNDocument46 paginiTOP258PNJose BenavidesÎncă nu există evaluări

- Design Example Report: Title Specification Application Author Document Number Date RevisionDocument40 paginiDesign Example Report: Title Specification Application Author Document Number Date RevisionJose Benavides100% (1)

- Datasheet B985Document4 paginiDatasheet B985Jose BenavidesÎncă nu există evaluări

- TOP244PDocument112 paginiTOP244PJose BenavidesÎncă nu există evaluări

- TOP257ENDocument34 paginiTOP257ENJose BenavidesÎncă nu există evaluări

- Top259en PDFDocument2 paginiTop259en PDFJose BenavidesÎncă nu există evaluări

- Ug471 7series SelectIO PDFDocument188 paginiUg471 7series SelectIO PDFDlishaÎncă nu există evaluări

- Digital Simulation of 48 Pulse GTO Based Statcom and Reactive Power CompensationDocument4 paginiDigital Simulation of 48 Pulse GTO Based Statcom and Reactive Power CompensationEditor IJRITCCÎncă nu există evaluări

- Transistor TestingDocument2 paginiTransistor TestingKannan AlagumuthiahÎncă nu există evaluări

- Lab # 8 SolvedDocument10 paginiLab # 8 SolvedZabeehullahmiakhailÎncă nu există evaluări

- RVV2NPX310 211RDocument4 paginiRVV2NPX310 211RElego13thÎncă nu există evaluări

- An Introduction To Software Defined Radio: November 2015Document5 paginiAn Introduction To Software Defined Radio: November 2015MarcosZelayaÎncă nu există evaluări

- Experiment No 6 Ce NPNDocument4 paginiExperiment No 6 Ce NPNEugene Christina EuniceÎncă nu există evaluări

- 300+ Top Microprocessors Questions and Answers PDF: Prisma™ Cloud SecurityDocument14 pagini300+ Top Microprocessors Questions and Answers PDF: Prisma™ Cloud SecurityAawez AkhterÎncă nu există evaluări

- Circuits 2 Quiz 3Document2 paginiCircuits 2 Quiz 3John Lenard SanchezÎncă nu există evaluări

- SW-TM4C-RLN-2 1 0 12573Document36 paginiSW-TM4C-RLN-2 1 0 12573trungkiena6Încă nu există evaluări

- Operation: USB Interface U1, U2, U3 and U4Document5 paginiOperation: USB Interface U1, U2, U3 and U4Mohammed MostefaiÎncă nu există evaluări

- 16FF TSMCDocument17 pagini16FF TSMCPraful GaikwadÎncă nu există evaluări

- KRC4-Optional Interfaces enDocument99 paginiKRC4-Optional Interfaces encabecavil100% (2)

- AURETR007 KnowledgeAssessmentDocument18 paginiAURETR007 KnowledgeAssessmentMuhammad IrfanÎncă nu există evaluări

- 3500 22m Transient Data Interface Manual 161580-01 PDFDocument82 pagini3500 22m Transient Data Interface Manual 161580-01 PDFkatja kafka100% (1)

- A Typical PC (Escuela TIC Inglés I)Document3 paginiA Typical PC (Escuela TIC Inglés I)Angelita Beatriz Celis AlcainoÎncă nu există evaluări

- Forum - (HELP) STM32F4 Generate PWM 3 Cha... - STMicroelectronicsDocument6 paginiForum - (HELP) STM32F4 Generate PWM 3 Cha... - STMicroelectronicsAziz AminullahÎncă nu există evaluări

- TN 21Document4 paginiTN 21polanco999Încă nu există evaluări

- Applications of GSM Module in Wireless ECGDocument7 paginiApplications of GSM Module in Wireless ECGAbd TashÎncă nu există evaluări

- WPA-80090/8CF - : Mechanical SpecificationsDocument1 paginăWPA-80090/8CF - : Mechanical Specificationsmiguelona1304Încă nu există evaluări

- Products t1 Brochure TrioDocument8 paginiProducts t1 Brochure TrioAhmed El-ShafeiÎncă nu există evaluări

- IRQ NumbersDocument1 paginăIRQ NumbersGuna ShekarÎncă nu există evaluări

- Analog Electronics Viva & Interview Questions: by Prof. Hitesh Dholakiya Engineering Funda Youtube ChannelDocument45 paginiAnalog Electronics Viva & Interview Questions: by Prof. Hitesh Dholakiya Engineering Funda Youtube ChannelMy WritingsÎncă nu există evaluări

- Paravicini 312 Control Centre Large MemoryDocument2 paginiParavicini 312 Control Centre Large Memoryapi-3833673Încă nu există evaluări

- 5100333-00 - Salwico Cruise - Installation Manual - M - EN - 2015 - MDocument104 pagini5100333-00 - Salwico Cruise - Installation Manual - M - EN - 2015 - MMarco Pastori100% (1)

- EC6502 Principles of Digital Signal ProcessingDocument320 paginiEC6502 Principles of Digital Signal ProcessinglazezijoÎncă nu există evaluări

- State Forest Service Exam Electronics KeyDocument83 paginiState Forest Service Exam Electronics KeyDeepak YugaÎncă nu există evaluări

- ELECTRICAL Sample QuestionDocument17 paginiELECTRICAL Sample QuestionSambit MohapatraÎncă nu există evaluări

- The University of Lahore, Islamabad Campus Course: Power System Protection Lab Work Sheet 4Document8 paginiThe University of Lahore, Islamabad Campus Course: Power System Protection Lab Work Sheet 4Hayat AnsariÎncă nu există evaluări