Documente Academic

Documente Profesional

Documente Cultură

Crack Stitching A Solid Wall Using Helibars

Încărcat de

MisterphylTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Crack Stitching A Solid Wall Using Helibars

Încărcat de

MisterphylDrepturi de autor:

Formate disponibile

CS05 Crack Stitching a Solid Wall

using HeliBars

METHOD STATEMENT

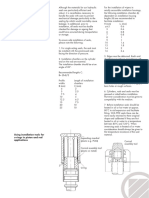

1. Using a twin-bladed, diamond-tipped wall chaser

with vacuum attachment, cut slots into the

horizontal mortar joints to the specified depth and at

the required vertical spacing. Ensure that NO mortar

is left attached to the exposed brick surfaces in order

to provide a good masonry/grout bond.

2. Remove ALL dust and mortar from the slots and

thoroughly flush with water. Where the substrate is

very porous or flushing with water is inappropriate,

use HeliPrimer WB. Ensure the slot is damp or

primed prior to commencing step 5. RECOMMENDED TOOLING

3. Mix HeliBond cementitious grout using a power For cutting slots up to 40mm deep .......................................Twin bladed cutter

mixer and load into the Helifix Pointing Gun CS. with vacuum attachment

4. Fit the appropriate mortar nozzle. For mixing HeliBond................................3-jaw-chuck drill with mixing paddle

For injection of HeliBond into slots ..............................Helifix Pointing Gun CS

5. Inject a bead of HeliBond grout, approx. 15mm with mortar nozzle

deep, into the back of the slot.

For smoothing pointing ...................................................Standard finger trowel

6. Push the 6mm HeliBar into the grout to obtain good

coverage.

7. Inject a second bead of HeliBond grout over the Specification Notes

exposed HeliBar and iron it into the slot using a

finger trowel. Inject additional HeliBond as The following criteria are to be used unless specified otherwise:

necessary, leaving 10-15mm for new pointing. A. Depth of slot into the masonry to be 35mm to 40mm.

8. The crack within the wall should be weather-proofed B. Height of slot to be equal to full mortar joint height, with a minimum of

8mm. For thin mortar joint specifications refer to the Helifix Technical

using an appropriate Helifix bonding agent e.g. Dept.

HeliBond or CrackBond, depending on the width of C. HeliBar to be long enough to extend a minimum of 500mm either side of

the crack and the surface made good or left ready for the crack or 500mm beyond the outer cracks if two or more adjacent cracks

any decoration. are being stitched using one rod.

9. Clean tools with clean, fresh water. D. Normal vertical spacing is 450mm (6 brick courses).

E. Where a crack is less than 500mm from the end of a wall or an opening,

the HeliBar is to be continued for at least 100mm around the corner and

N.B. Pointing may be carried out as soon as is convenient after bonded into the adjoining wall or bent back and fixed into the reveal,

the HeliBond has started to gel. avoiding any DPC.

F. In hot conditions ensure the masonry is well wetted or primed to prevent

premature curing of the HeliBond due to rapid de-watering. Ideally

additional wetting of the slot, or priming with HeliPrimer WB, should be

carried out just prior to injecting the HeliBond grout.

G. Do not use HeliBond when the air temperature is +4°C and falling or apply

over ice. In all instances the slot must be thoroughly damp or primed prior

to injection of the HeliBond grout.

The above specification notes are for general guidance only and Helifix reserves

the right to amend details/notes as necessary.

GENERAL NOTES

If your application differs from this repair detail or you require specific

advice on your particular project, call the Helifix Technical Sales Team on

020 8735 5222. Our Technical Department can provide you with a full

support service including:

● Advice, assistance and recommendations on all structural repair matters

● Devising and preparing complete repair proposals for specific situations

● An insurance-backed warranty via our Approved Installers scheme

HELIFIX MASONRY REPAIR DETAILS © May 2015

S-ar putea să vă placă și

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Helifix Complete Crack Stitching Repair DetailsDocument14 paginiHelifix Complete Crack Stitching Repair DetailsHemendra LalgiÎncă nu există evaluări

- How to Build a Tiny Portable House: With Plans and InstructionsDe la EverandHow to Build a Tiny Portable House: With Plans and InstructionsEvaluare: 4 din 5 stele4/5 (1)

- Helifix Cs03 Crack Stitching Repair DetailsDocument1 paginăHelifix Cs03 Crack Stitching Repair DetailsHemendra LalgiÎncă nu există evaluări

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsDe la EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsÎncă nu există evaluări

- Helifix Cs04 Crack Stitching Repair DetailsDocument1 paginăHelifix Cs04 Crack Stitching Repair DetailsHemendra LalgiÎncă nu există evaluări

- Top 5 Reasons For A Roof Consultant To Conduct Your InspectionDe la EverandTop 5 Reasons For A Roof Consultant To Conduct Your InspectionÎncă nu există evaluări

- Helifix - Dryfix TiesDocument1 paginăHelifix - Dryfix TiesNhuVan NguyenÎncă nu există evaluări

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- Appendix B - Helifix Crack Bar Data SheetDocument3 paginiAppendix B - Helifix Crack Bar Data SheetNiemÎncă nu există evaluări

- Helifix Crack StitchingDocument2 paginiHelifix Crack Stitchingneel12321Încă nu există evaluări

- Helibar: Applications FeaturesDocument2 paginiHelibar: Applications FeaturesRomeu Branco SimõesÎncă nu există evaluări

- Installation InstructionsDocument7 paginiInstallation InstructionsWinland Gdl CapacitacionesÎncă nu există evaluări

- Paper RefrnsDocument2 paginiPaper RefrnsVaibhavBadgujarÎncă nu există evaluări

- MFS Installation Instructions35aDocument12 paginiMFS Installation Instructions35a7bqbrvxk5yÎncă nu există evaluări

- (ID15g) Vivid Skylights Installation GuideDocument13 pagini(ID15g) Vivid Skylights Installation GuideHaisen QinÎncă nu există evaluări

- Mast Installation - Internal MountingDocument2 paginiMast Installation - Internal MountingBilly ChrisÎncă nu există evaluări

- IT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri ArtificialeDocument8 paginiIT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri Artificialeandrew_sfiÎncă nu există evaluări

- Installation HydraulicDocument5 paginiInstallation HydraulicNebojsa JovanovicÎncă nu există evaluări

- Thioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceDocument5 paginiThioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceBahaa MohamedÎncă nu există evaluări

- HR Blowers Uk LTD: Installation & Operating ManualDocument20 paginiHR Blowers Uk LTD: Installation & Operating ManualAditya ShrivastavaÎncă nu există evaluări

- Mould Making Techniques Using Acc Gelflex: Application Sealing MethodDocument2 paginiMould Making Techniques Using Acc Gelflex: Application Sealing MethodTina DomančićÎncă nu există evaluări

- Boyd Storefront Installation InstructionsDocument26 paginiBoyd Storefront Installation InstructionsLamija MuhovićÎncă nu există evaluări

- Flashing Systems 10 Book 0 - 1 CompressedDocument26 paginiFlashing Systems 10 Book 0 - 1 CompressedSam SÎncă nu există evaluări

- 60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Document3 pagini60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Eng Victor FidelisÎncă nu există evaluări

- PDS Thioflex 600 SGDocument5 paginiPDS Thioflex 600 SGAjay PrasadÎncă nu există evaluări

- Renderoc HF Premix Jacketing Application MethodDocument5 paginiRenderoc HF Premix Jacketing Application MethodArief BMÎncă nu există evaluări

- WIP Field GuideDocument28 paginiWIP Field GuideVictor PadillaÎncă nu există evaluări

- Veetagrout V71 Instruction Manual - New Format V 2Document3 paginiVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezÎncă nu există evaluări

- Supreme Wall-Base Adhesive: BasebondDocument2 paginiSupreme Wall-Base Adhesive: BasebondYASHICA VAITTIANATHANÎncă nu există evaluări

- Thioflex 600wP7E PDFDocument52 paginiThioflex 600wP7E PDFAjit Singh Rathore100% (2)

- Manual EVK SealDocument18 paginiManual EVK Sealpanamajack26Încă nu există evaluări

- Tds Thioflex 600 Saudi ArabiaDocument5 paginiTds Thioflex 600 Saudi ArabiaSHAIK ASIMUDDINÎncă nu există evaluări

- Grease Traps: Jeevan Bhar Ka Saath..Document2 paginiGrease Traps: Jeevan Bhar Ka Saath..arjun 11Încă nu există evaluări

- Expanseal 105: Construction ChemistryDocument2 paginiExpanseal 105: Construction Chemistrymuhammad aliÎncă nu există evaluări

- Operation Manual: Storing The Nations GrainDocument20 paginiOperation Manual: Storing The Nations GrainEng Urimubenshi DonatÎncă nu există evaluări

- Technical Manual 2011Document49 paginiTechnical Manual 2011Francisco Castillo100% (1)

- Bulletin Description: Escoweld 7505E/7530 Grout InstallationDocument6 paginiBulletin Description: Escoweld 7505E/7530 Grout InstallationECCÎncă nu există evaluări

- Bedliner Distortion During Hot WeatherDocument2 paginiBedliner Distortion During Hot WeatherDarren AÎncă nu există evaluări

- 365 Data SheetDocument2 pagini365 Data SheetFloorkitÎncă nu există evaluări

- Sunroof Will Not Open at High Temperatures: SubjectDocument3 paginiSunroof Will Not Open at High Temperatures: SubjectPavelÎncă nu există evaluări

- GIB Site Guide 2018 GenInstallDocument26 paginiGIB Site Guide 2018 GenInstallLucas RibeiroÎncă nu există evaluări

- Thioflex 60Document4 paginiThioflex 60Mcr KumaraÎncă nu există evaluări

- 60ac025038d3b8eda22a81c8 - 07 56 00.01 - Fluid-Applied Roofing (Asphalt)Document4 pagini60ac025038d3b8eda22a81c8 - 07 56 00.01 - Fluid-Applied Roofing (Asphalt)Eng Victor FidelisÎncă nu există evaluări

- Method Statement Partition WorksDocument3 paginiMethod Statement Partition WorksDipin NediyaparambathÎncă nu există evaluări

- Expoband H45Document4 paginiExpoband H45shanon33Încă nu există evaluări

- Unit Manual - AHUDocument6 paginiUnit Manual - AHUNADEEM ARÎncă nu există evaluări

- 30 - Ms For ReglazingDocument13 pagini30 - Ms For ReglazingAMG Co.Încă nu există evaluări

- Thioflex 600Document4 paginiThioflex 600wikaÎncă nu există evaluări

- Hilti HIT-RE 500 For "Underwater Fastenings"Document5 paginiHilti HIT-RE 500 For "Underwater Fastenings"nikifÎncă nu există evaluări

- Thioflex 600 - Joint SealantDocument104 paginiThioflex 600 - Joint SealantamirskbkbkÎncă nu există evaluări

- Attachment 8 Facade Technical DetailsDocument28 paginiAttachment 8 Facade Technical DetailsLin DavidÎncă nu există evaluări

- 9 Gerbur Vinyl Click Herringbone BrochureDocument17 pagini9 Gerbur Vinyl Click Herringbone BrochureLeyjan JacobÎncă nu există evaluări

- Pyroplex Fire Rated Foam Datasheet - NWDocument4 paginiPyroplex Fire Rated Foam Datasheet - NWAhmed AssafÎncă nu există evaluări

- Bostik Seal N Flex FC Rev1 PDFDocument3 paginiBostik Seal N Flex FC Rev1 PDFpaolo maliksiÎncă nu există evaluări

- Wykamol Damp Treatment CM8HD-CDM-DataSheetDocument4 paginiWykamol Damp Treatment CM8HD-CDM-DataSheetIan MitchellÎncă nu există evaluări

- Dental Casting DefectsDocument86 paginiDental Casting Defectsdennu101100% (3)

- Sliding Window Lock InstallationDocument2 paginiSliding Window Lock InstallationMathan JeyaramanÎncă nu există evaluări

- TDS Polycoat RBEDocument2 paginiTDS Polycoat RBEMang JoseÎncă nu există evaluări

- Cementitious Fluid Grout 100 - Proposed SpecDocument9 paginiCementitious Fluid Grout 100 - Proposed SpecTausif AhmadÎncă nu există evaluări

- Design of Fibre Reinforced Concrete Beams and SlabsDocument128 paginiDesign of Fibre Reinforced Concrete Beams and SlabsMisterphylÎncă nu există evaluări

- BCA Publication "Making Good & Finishing"Document14 paginiBCA Publication "Making Good & Finishing"MisterphylÎncă nu există evaluări

- ACE Client GuideDocument6 paginiACE Client GuideMisterphylÎncă nu există evaluări

- Basement Waterproofing Site GuideDocument24 paginiBasement Waterproofing Site GuideMisterphyl100% (1)

- Guide To Safety at Sports Grounds - Summary of New GuidanceDocument3 paginiGuide To Safety at Sports Grounds - Summary of New GuidanceMisterphylÎncă nu există evaluări

- Conservation of Historic BuildingsDocument404 paginiConservation of Historic BuildingsMisterphyl100% (2)

- Practical Building ConservationDocument114 paginiPractical Building ConservationMisterphyl80% (5)

- Eco-Friendly Walls: AAC BlocksDocument101 paginiEco-Friendly Walls: AAC Blockspoonam_ceÎncă nu există evaluări

- Nte 030 PeruDocument30 paginiNte 030 Perus_khan1997466Încă nu există evaluări

- 06 13025 - S - Torrance Transit Center - Backcheck 1 - Structural - 2017-04-10 PDFDocument49 pagini06 13025 - S - Torrance Transit Center - Backcheck 1 - Structural - 2017-04-10 PDFAob AprilÎncă nu există evaluări

- Product Description Directions For Use: Surface PreparationDocument1 paginăProduct Description Directions For Use: Surface Preparationrajeshji_000Încă nu există evaluări

- MOSLEY BUNGEY HULSE Reinforced Concrete Design To Eurocode 2 1Document420 paginiMOSLEY BUNGEY HULSE Reinforced Concrete Design To Eurocode 2 1Leonard C. Iancu95% (20)

- PWD SR-16-17Document305 paginiPWD SR-16-17Rural Water Supply, Sub-Divission ByadgiÎncă nu există evaluări

- Building Construction ReviewerDocument23 paginiBuilding Construction ReviewerKarl Alexander CaraanÎncă nu există evaluări

- Productivity RateDocument10 paginiProductivity RateRodelÎncă nu există evaluări

- Is 1649 1962 PDFDocument41 paginiIs 1649 1962 PDFsauravÎncă nu există evaluări

- Termidor EPA LabelDocument15 paginiTermidor EPA LabelEvelyn KlineÎncă nu există evaluări

- Technical Information: Truspread Dry Silo MortarsDocument4 paginiTechnical Information: Truspread Dry Silo MortarsHka IsmailÎncă nu există evaluări

- Technical Specifications For Terminal BuildingDocument42 paginiTechnical Specifications For Terminal BuildingrajeshÎncă nu există evaluări

- B TechDocument83 paginiB TechBharathi RajÎncă nu există evaluări

- Typcal Glass Design GEO.a.kelsonDocument466 paginiTypcal Glass Design GEO.a.kelsonDejin KongÎncă nu există evaluări

- Indian Standard: Brick Works - Code of Practice (First Revision)Document2 paginiIndian Standard: Brick Works - Code of Practice (First Revision)Sathish Elangovan0% (1)

- Productivity RateDocument133 paginiProductivity Ratejucar fernandez100% (1)

- Volume Rumah GensetDocument34 paginiVolume Rumah GensetIbnu SalamÎncă nu există evaluări

- Acad - Pat PatternsDocument15 paginiAcad - Pat PatternspaulixÎncă nu există evaluări

- Instructio NS:: 1 2 3 Your Answer Will Be Valued As A Whole 4 5 6 7Document7 paginiInstructio NS:: 1 2 3 Your Answer Will Be Valued As A Whole 4 5 6 7ikushalpatilÎncă nu există evaluări

- IOE Syllabus (Civil-3rd-Year)Document36 paginiIOE Syllabus (Civil-3rd-Year)SibeshKumarSingh100% (1)

- Bill of Quantity TryDocument14 paginiBill of Quantity TryMuhammad Zulhusni Che RazaliÎncă nu există evaluări

- Method Statement For Civil WorksDocument11 paginiMethod Statement For Civil Workssivanand90% (20)

- RRB Je CBT - Ii: Printable Syllabus For Civil & Allied Engineering Exam Group - JEDocument2 paginiRRB Je CBT - Ii: Printable Syllabus For Civil & Allied Engineering Exam Group - JEShashank Raj OnkarÎncă nu există evaluări

- Cyclopean MasonryDocument11 paginiCyclopean MasonryArash BarbuÎncă nu există evaluări

- Masonry Basics - The Tools You Need and How To Use Them PDFDocument5 paginiMasonry Basics - The Tools You Need and How To Use Them PDFSantosh Upadhyay100% (1)

- BCP 2007Document279 paginiBCP 2007abdul ghafoorÎncă nu există evaluări

- Brick Work PresentationDocument56 paginiBrick Work PresentationAkash YadavÎncă nu există evaluări

- Shree Dumre LSS, PalungtarDocument88 paginiShree Dumre LSS, PalungtarpraveshÎncă nu există evaluări

- Estimate Road Nuwakot 2077 078Document116 paginiEstimate Road Nuwakot 2077 078Rajendra K KarkiÎncă nu există evaluări

- Comparision Between Brick and Stone MansoryDocument1 paginăComparision Between Brick and Stone MansoryAzharÎncă nu există evaluări

- Process Plant Equipment: Operation, Control, and ReliabilityDe la EverandProcess Plant Equipment: Operation, Control, and ReliabilityEvaluare: 5 din 5 stele5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDe la EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersÎncă nu există evaluări

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDe la EverandSodium Bicarbonate: Nature's Unique First Aid RemedyEvaluare: 5 din 5 stele5/5 (21)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDe la EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceEvaluare: 4 din 5 stele4/5 (19)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsDe la EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsEvaluare: 4 din 5 stele4/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Laws of UX: Using Psychology to Design Better Products & ServicesDe la EverandLaws of UX: Using Psychology to Design Better Products & ServicesEvaluare: 5 din 5 stele5/5 (9)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

- Guidelines for Chemical Process Quantitative Risk AnalysisDe la EverandGuidelines for Chemical Process Quantitative Risk AnalysisEvaluare: 5 din 5 stele5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDe la EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookÎncă nu există evaluări

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookDe la EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookÎncă nu există evaluări

- Principles and Case Studies of Simultaneous DesignDe la EverandPrinciples and Case Studies of Simultaneous DesignÎncă nu există evaluări