Documente Academic

Documente Profesional

Documente Cultură

MODUL PARKIR - Parkson-Sand-Saver PDF

Încărcat de

messy kolloTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MODUL PARKIR - Parkson-Sand-Saver PDF

Încărcat de

messy kolloDrepturi de autor:

Formate disponibile

Parkson Sand Saver

Removes and cleans sand from manure

Designed to help you effectively

manage sand bedding

• Efficiently removes sand from manure

• Provides washed, clean sand for reuse

• Significantly reduces sand replacement costs

• Minimal power and water requirements

• Reduces equipment wear and hauling costs

• Proven, reliable design

A patented, innovative design for effective sand washing

Efficient Operation Fast Return on Investment

Before: Typical sand laden dairy manure slurry The Parkson Sand Saver is uncomplicated and Savings in sand replacement alone equal a very

prior to washing requires minimal operator attention. Its efficient short payback period. With additional savings in

washing operation can reclaim 80%-90% or more lagoon and storage tank cleaning; reduced hauling

of the bedding sand that becomes mixed with and spreading costs and reduced equipment

manure during the normal operation of a dairy wear; the Parkson Sand Saver becomes a real

barn. This washed, reclaimed sand is clean, dry, money saver.

odor free and ready for rebedding. Typically, less

than 1% organics remain in the washed sand. The Parkson Sand Saver is a clean, enclosed

design quality engineered of durable, corrosion-

The Parkson Sand Saver has low wash water and resistant stainless steel. The shaftless spiral is

energy requirements. Wash water can be 100% constructed of heavy-duty carbon steel and there

recycled water. Two low horsepower motors are no submerged bearings.

operate automatically on demand.

After: Recovered sand, washed clean

Simple, Automatic Operation

Sand laden dairy manure enters the Parkson Sand Dirty sand inlet

Saver washing chamber through an opening at

the top of the unit while wash water is introduced

through an opening at the bottom. The descending

sand flows countercurrent to the rising water,

initiating the first stage of sand cleaning.

A lifting device moves slowly through the sand bed

Clean Sand

to loosen and dislodge the organic matter that has

Liquid

been trapped in the sand. The rising flow of water Discharge

moves the organics upward and out the overflow.

The clean sand is removed from the bottom of the

tank by a shaftless spiral. The spiral conveys the

The Parkson Sand Saver

clean sand upward, rotating slowly and intermittently Wash-water

operates automatically

to facilitate drainage before discharge. upon demand.

Sample Configuration

C Parkson Dairy Manure Treatment System

Removes phosphorus, nitrates, solids and BOD

Sand Bedding

Parkson Sand Saver

B using recycled water Biolac® Wastewater Treatment System

Chemical

Clean sand Treatment

reused as bedding Fine screen

A Belt Dewatering Press

Recycled water

Solids

for system

requirements or

Organic Bedding discharge

Fine screen

Solids to composting Solids

or reuse

PSS-2 PSS-5

THERMO-SYSTEM®

Agitator Solar Sludge Dryer

Reuse

Motor 3/4HP 1-1/2 HP or

irrigation

Solids to composting or reuse Class A Biosolids

Spiral Dewatering press

for compost or reuse

Motor 1 HP 2 HP

Height A 91 136

Parkson Corporation can provide complete Dairy Manure Treatment Systems and components

Length B 179 264

that produce recycled water to be used for system requirements, irrigation or discharge. These

Width C 48 65 systems are designed for nutrient removal (Phosphorus, Nitrogen, BOD), liquid/solid separation

Dry Weight 1,850 4,300 and odor control.

Operating

Weight 3,850 12,500

Dimensions in inches and weight in pounds are

approximate

Fort Lauderdale Chicago Montreal Dubai

ISO 9001:2000 Certified www.parkson.com

technology@parkson.com

Quality Management System

AN AXEL JOHNSON INC. COMPANY

1.888.PARKSON

1.954.974.6610 GRMG-MSS020109 ©2009 Parkson Corporation

S-ar putea să vă placă și

- Question 15Document2 paginiQuestion 15Mohammad FarhanÎncă nu există evaluări

- Waterbrane: A New Generation of Filtration Treatment - For Industrial WaterDocument4 paginiWaterbrane: A New Generation of Filtration Treatment - For Industrial WaterGabriel Montoya CorreaÎncă nu există evaluări

- Autorain BroucherDocument6 paginiAutorain BroucherRavi ShankarÎncă nu există evaluări

- Package Treatment Plant: For Potable WaterDocument4 paginiPackage Treatment Plant: For Potable Watermohammed rafi shaikhÎncă nu există evaluări

- Supersand: Continuous Backwash FiltersDocument4 paginiSupersand: Continuous Backwash FiltersCornel NasturasÎncă nu există evaluări

- Dasherkandi Sewerage Treatment Plant Is Located in The Capital City DhakaDocument2 paginiDasherkandi Sewerage Treatment Plant Is Located in The Capital City DhakaMohammad FarhanÎncă nu există evaluări

- Densadeg: Lamellar Settling Sludge ThickeningDocument4 paginiDensadeg: Lamellar Settling Sludge Thickeningzhigang dingÎncă nu există evaluări

- SUB Theme 3 - Full PaperDocument81 paginiSUB Theme 3 - Full PaperDedi ApriadiÎncă nu există evaluări

- Grey WaterDocument3 paginiGrey WaternkhiangteÎncă nu există evaluări

- ReedBedSludgeTreatment 2Document2 paginiReedBedSludgeTreatment 2Luis DavilaÎncă nu există evaluări

- Sand Washing PlantDocument5 paginiSand Washing PlantAfriza NurdiansyahÎncă nu există evaluări

- Plantilla de Infografias en Word 42Document1 paginăPlantilla de Infografias en Word 42Erika JazminÎncă nu există evaluări

- FiltrationDocument42 paginiFiltrationAnonymous ntE0hG2TPÎncă nu există evaluări

- Gravity Filtration Systems - Napier-ReidDocument7 paginiGravity Filtration Systems - Napier-ReidWendyÎncă nu există evaluări

- Treatment Technologies: Presented byDocument32 paginiTreatment Technologies: Presented bySunghava UpadhayaÎncă nu există evaluări

- Portable Water FilterDocument6 paginiPortable Water FilterJeromeÎncă nu există evaluări

- Perfection in Backwashing of Rapid Sand Filter To Augment The Performance of Sand Filter SystemDocument17 paginiPerfection in Backwashing of Rapid Sand Filter To Augment The Performance of Sand Filter Systemsahle mamoÎncă nu există evaluări

- MBR Process: Membrane Bioreactors MBR PlantsDocument1 paginăMBR Process: Membrane Bioreactors MBR Plantsprem_k_sÎncă nu există evaluări

- Dia Via ScadaDocument24 paginiDia Via ScadaShivaniÎncă nu există evaluări

- Components of A Rainwater Harvesting SystemDocument8 paginiComponents of A Rainwater Harvesting SystemZed IdiazÎncă nu există evaluări

- SOP Tertiary Treatment PlantDocument8 paginiSOP Tertiary Treatment PlantAce Dynamics IndiaÎncă nu există evaluări

- Veolia Oil SeparationDocument8 paginiVeolia Oil SeparationbolixinÎncă nu există evaluări

- Overview of Environmental Unit Processes and OperationsDocument26 paginiOverview of Environmental Unit Processes and OperationsDr. Akepati Sivarami ReddyÎncă nu există evaluări

- Topic 5 Principle of Water - Wastewater Treatment Processes-20191008090049 PDFDocument111 paginiTopic 5 Principle of Water - Wastewater Treatment Processes-20191008090049 PDFLipQin YeoÎncă nu există evaluări

- Which filtration solution is right for your applicationDocument2 paginiWhich filtration solution is right for your applicationPower NguyenÎncă nu există evaluări

- Filtration Systems For Chlor-Alkali and Chlorate Plants: Edition 3, Dec 2017Document9 paginiFiltration Systems For Chlor-Alkali and Chlorate Plants: Edition 3, Dec 2017elhamÎncă nu există evaluări

- 10002SYYDocument4 pagini10002SYYleoboyaliÎncă nu există evaluări

- 08 ETP Reject Handling SystemsDocument12 pagini08 ETP Reject Handling SystemsGabriel T. BastosÎncă nu există evaluări

- Asws Reverse Osmosis PlantDocument7 paginiAsws Reverse Osmosis PlantEngenharia MecânicaÎncă nu există evaluări

- Community Wastewater Treatment and DisposalDocument18 paginiCommunity Wastewater Treatment and DisposalJestoni FloresÎncă nu există evaluări

- 3 - SVM Process Flow Chart HACCPDocument3 pagini3 - SVM Process Flow Chart HACCPc.ramÎncă nu există evaluări

- Detergent BuildersDocument2 paginiDetergent Buildersevelyne taruvingaÎncă nu există evaluări

- Ultra Pure WaterDocument6 paginiUltra Pure Watergauravgarg115Încă nu există evaluări

- Textile Filtration SolutionsDocument8 paginiTextile Filtration SolutionsUğurcan KurtÎncă nu există evaluări

- ?filtration ?Document21 pagini?filtration ?Nhật Quang PhạmÎncă nu există evaluări

- dynasand_continuous_sand_filter_e10799Document6 paginidynasand_continuous_sand_filter_e10799lucÎncă nu există evaluări

- Innovative Sludge Drying Bed Design (Presto)Document2 paginiInnovative Sludge Drying Bed Design (Presto)apolo_godÎncă nu există evaluări

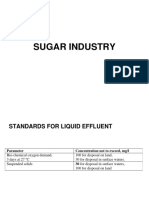

- LIQUID EFFLUENT STANDARDS FOR SUGAR INDUSTRYDocument16 paginiLIQUID EFFLUENT STANDARDS FOR SUGAR INDUSTRYsong1088Încă nu există evaluări

- HUBER Disc Filter RoDisc® Filtration SolutionDocument4 paginiHUBER Disc Filter RoDisc® Filtration SolutionAhmedRamadanÎncă nu există evaluări

- Water TreatmentDocument24 paginiWater Treatmentsiddhant baisla100% (1)

- Design natural water purification rural areasDocument9 paginiDesign natural water purification rural areasAnkit RaiÎncă nu există evaluări

- Wastewater Treatment TechnologiesDocument8 paginiWastewater Treatment Technologiesminhtruong.dtmÎncă nu există evaluări

- Blue Barrel System Manual EnglishDocument12 paginiBlue Barrel System Manual EnglishKennedy NgoseyweÎncă nu există evaluări

- Water MSD 3 PDFDocument32 paginiWater MSD 3 PDFDiyana JefryÎncă nu există evaluări

- Module 2 Public Water SupplyDocument26 paginiModule 2 Public Water Supplyma. rothsheld may bulacanÎncă nu există evaluări

- Waterwastewatertreatment 0Document24 paginiWaterwastewatertreatment 0Azka Januartrika100% (1)

- Cascade Aerator: How It WorksDocument29 paginiCascade Aerator: How It WorksMahaveer ChaudhariÎncă nu există evaluări

- Multiflo 2013 EN PDFDocument8 paginiMultiflo 2013 EN PDFEbaid AbdoÎncă nu există evaluări

- Algas Microfilter BrochureDocument8 paginiAlgas Microfilter BrochureNehal ImtiazÎncă nu există evaluări

- SeWAGE DISPOSALDocument7 paginiSeWAGE DISPOSALLulua MstrÎncă nu există evaluări

- Membrane Bioreactors: State of The Art and Technology ExchangeDocument54 paginiMembrane Bioreactors: State of The Art and Technology ExchangeNermeen ElmelegaeÎncă nu există evaluări

- Caustic Recovery PlantsDocument37 paginiCaustic Recovery PlantsCaustic Recovery PlantsÎncă nu există evaluări

- Sustainable Post-Consumer Diaper Recycling SystemDocument22 paginiSustainable Post-Consumer Diaper Recycling SystemluisÎncă nu există evaluări

- Ce-503 ReportDocument3 paginiCe-503 ReportMelano ArjayÎncă nu există evaluări

- Consep Technology OvivoDocument4 paginiConsep Technology OvivoprakashÎncă nu există evaluări

- UntitledDocument52 paginiUntitledVedranL84Încă nu există evaluări

- Standard O&M MANUAL - BANGANGADocument52 paginiStandard O&M MANUAL - BANGANGASumit RautÎncă nu există evaluări

- Continuous Backwash Filters For Side Stream FiltrationDocument27 paginiContinuous Backwash Filters For Side Stream Filtrationtaenker123Încă nu există evaluări

- Sugar IndustryDocument10 paginiSugar Industryharshu DÎncă nu există evaluări

- Analisys and application of dry cleaning materials on unvarnished pain surfacesDe la EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesÎncă nu există evaluări

- Cover Surat PenawaranDocument1 paginăCover Surat Penawaranmessy kolloÎncă nu există evaluări

- Cover Jaminan PenawaranDocument1 paginăCover Jaminan Penawaranmessy kolloÎncă nu există evaluări

- 06 Daftar Pustaka - 2 PDFDocument1 pagină06 Daftar Pustaka - 2 PDFmessy kolloÎncă nu există evaluări

- Cover Surat PenawaranDocument1 paginăCover Surat Penawaranmessy kolloÎncă nu există evaluări

- Cover MetodeDocument1 paginăCover Metodemessy kolloÎncă nu există evaluări

- Teknologi 2012 9 1 7 Walsen PDFDocument10 paginiTeknologi 2012 9 1 7 Walsen PDFmessy kolloÎncă nu există evaluări

- Cover Pakta IntegritasDocument1 paginăCover Pakta Integritasmessy kolloÎncă nu există evaluări

- 2 Medan Listrik 1 - ORIGINALDocument27 pagini2 Medan Listrik 1 - ORIGINALmessy kolloÎncă nu există evaluări

- Cover SubkonDocument1 paginăCover Subkonmessy kolloÎncă nu există evaluări

- 8 PDFDocument8 pagini8 PDFSed BeelzeÎncă nu există evaluări

- Cover K-3Document1 paginăCover K-3messy kolloÎncă nu există evaluări

- Teknologi 2012 9 1 7 WalsenDocument23 paginiTeknologi 2012 9 1 7 Walsenmessy kolloÎncă nu există evaluări

- Modul Parkir Transportasi - Modelling ParkingDocument29 paginiModul Parkir Transportasi - Modelling Parkingmessy kolloÎncă nu există evaluări

- Rainfall interception analysis of coffee plants in Aceh Tengah DistrictDocument16 paginiRainfall interception analysis of coffee plants in Aceh Tengah DistrictSicca VuÎncă nu există evaluări

- Penampung Air Hujan - RoofrunoffDocument29 paginiPenampung Air Hujan - Roofrunoffmessy kolloÎncă nu există evaluări

- MODUL PARKIR TRANSPORTASI - Leion - Net - Parking - RatesDocument45 paginiMODUL PARKIR TRANSPORTASI - Leion - Net - Parking - Ratesmessy kolloÎncă nu există evaluări

- Identify Drainage Parcels and Stormwater Treatment FacilitiesDocument10 paginiIdentify Drainage Parcels and Stormwater Treatment FacilitieslhyteÎncă nu există evaluări

- MODUL PARKIR TRANSPORTASI - Leion - Net - Parking - RatesDocument45 paginiMODUL PARKIR TRANSPORTASI - Leion - Net - Parking - Ratesmessy kolloÎncă nu există evaluări

- 8 PDFDocument8 pagini8 PDFSed BeelzeÎncă nu există evaluări

- Excel 2D Truss Analysis 2004 (For Distribution - Limited Analysis)Document7 paginiExcel 2D Truss Analysis 2004 (For Distribution - Limited Analysis)Fustos CornelÎncă nu există evaluări

- Ririh Sudirahardjo.Document17 paginiRirih Sudirahardjo.Sudarman DiraksaÎncă nu există evaluări

- PondasiDocument2 paginiPondasimessy kolloÎncă nu există evaluări

- HW 5 Divided HighwaysDocument2 paginiHW 5 Divided Highwaysmessy kolloÎncă nu există evaluări

- JALAN RAYA - Geometric Design - D1 Uploaded (Compatibility Mode)Document62 paginiJALAN RAYA - Geometric Design - D1 Uploaded (Compatibility Mode)messy kolloÎncă nu există evaluări

- Essay About Alaskan Way ViaductDocument2 paginiEssay About Alaskan Way Viaductmessy kolloÎncă nu există evaluări

- Pavement Design Fundamentals CEE 320Document77 paginiPavement Design Fundamentals CEE 320messy kollo100% (1)

- 11company Profile Profil PerusahaanDocument6 pagini11company Profile Profil PerusahaanYogi WibisonoÎncă nu există evaluări

- SR 167 HOT Lanes Tolling Engineer RoleDocument20 paginiSR 167 HOT Lanes Tolling Engineer Rolemessy kolloÎncă nu există evaluări

- Company Profile PT Satyamitra Surya PerkasaDocument107 paginiCompany Profile PT Satyamitra Surya Perkasamessy kolloÎncă nu există evaluări

- Mineral Processing FundamentalsDocument15 paginiMineral Processing FundamentalsReshav ChaurasiaÎncă nu există evaluări

- StandardsDocument23 paginiStandardskrixot33% (3)

- Introduction LetterDocument1 paginăIntroduction LetterShankey JAlanÎncă nu există evaluări

- MSDSDocument4 paginiMSDSayomi karinaÎncă nu există evaluări

- Setting Time For ggbs-2019Document12 paginiSetting Time For ggbs-2019Yara MounaÎncă nu există evaluări

- Modelling The Seismic Response of An Unreinforced Masonry StructureDocument152 paginiModelling The Seismic Response of An Unreinforced Masonry Structurecandsbanda100% (1)

- Frankel1996 Antioxidants in Lipid Foods and Their Impact On Food QualityDocument5 paginiFrankel1996 Antioxidants in Lipid Foods and Their Impact On Food QualityCamilo Eduardo Gutiérrez JaraÎncă nu există evaluări

- Lennox ChartDocument2 paginiLennox ChartkimichaelÎncă nu există evaluări

- High Performance Liquid ChromatographyDocument14 paginiHigh Performance Liquid Chromatographyghaluh parahitaÎncă nu există evaluări

- Acetic AcidDocument10 paginiAcetic AcidwasayÎncă nu există evaluări

- CAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsDocument7 paginiCAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsAgoenk KertawijayaÎncă nu există evaluări

- Afcona 4201Document1 paginăAfcona 4201Mantas GrigonisÎncă nu există evaluări

- Sonatrach Well ControlDocument25 paginiSonatrach Well ControlUsama Bin Sabir50% (2)

- Rashid Petroleum Company Exam With AnswerDocument3 paginiRashid Petroleum Company Exam With AnswerabdelrahmanÎncă nu există evaluări

- Confi-Mul S Product Data SheetDocument1 paginăConfi-Mul S Product Data SheetpaimanÎncă nu există evaluări

- Fluids at A Glance: Typical Properties 2017 Europe, Middle East & Africa PortfolioDocument4 paginiFluids at A Glance: Typical Properties 2017 Europe, Middle East & Africa PortfoliomdshoppÎncă nu există evaluări

- Quick Guide to Operating TA Instruments Discovery DSC 250Document9 paginiQuick Guide to Operating TA Instruments Discovery DSC 250Nguyễn Phương ThoaÎncă nu există evaluări

- NMR in Forensic Science-MainDocument83 paginiNMR in Forensic Science-MainIva ManasiÎncă nu există evaluări

- 29000.ENG - CPI.STD - Paintings and CoatingsDocument62 pagini29000.ENG - CPI.STD - Paintings and CoatingsMatteo100% (1)

- ASME IX OrganizationDocument14 paginiASME IX OrganizationemrullahÎncă nu există evaluări

- Böhler 70t4 enDocument1 paginăBöhler 70t4 enValentin Hernández TrianoÎncă nu există evaluări

- Steels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsDocument2 paginiSteels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsHoangÎncă nu există evaluări

- Draw Chemical Structures with Chemfig LaTeX PackageDocument46 paginiDraw Chemical Structures with Chemfig LaTeX PackageCygnus ConstellationÎncă nu există evaluări

- Cover EssayDocument23 paginiCover EssayAstha MishraÎncă nu există evaluări

- Best Welding Practices (Pernis) : Doel / ScopeDocument91 paginiBest Welding Practices (Pernis) : Doel / Scopechompink6900100% (1)

- Purity of A SubstanceDocument13 paginiPurity of A SubstanceAlly Bin AssadÎncă nu există evaluări

- Feasibility of Baking Soda and Calamansi as a Skin Whitening AgentDocument3 paginiFeasibility of Baking Soda and Calamansi as a Skin Whitening AgentJocelyn GuanzonÎncă nu există evaluări

- BIO Project On PopulationDocument17 paginiBIO Project On PopulationHasinur Rahman40% (5)

- Science Comprehensive Worksheet For Midterm Class 7 Ans KeyDocument8 paginiScience Comprehensive Worksheet For Midterm Class 7 Ans KeyALI ImranÎncă nu există evaluări

- 03.selected Color Plates - Steam, Its Generation & Use, 41 - EdDocument9 pagini03.selected Color Plates - Steam, Its Generation & Use, 41 - EdMayur PatelÎncă nu există evaluări