Documente Academic

Documente Profesional

Documente Cultură

RUN N SEAL Extreme Tds

Încărcat de

Jhun AquinoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RUN N SEAL Extreme Tds

Încărcat de

Jhun AquinoDrepturi de autor:

Formate disponibile

RUN-N-SEAL EXTREME

OILFIELD

METAL-FREE THREAD SEALANT

DESCRIPTION PR ODUCT CHARA

PRODUCT CTERISTICS

CHARACTERISTICS

JET

JET-L -L UBE ® R

-LUBE UN-N-SEAL ® EXTREME is a pat-

RUN-N-SEAL Thickener Complex Soap

ented metal-free, high-pressure sealant alternative for API- Fluid Type Petroleum

MODIFIED. The compound contains graphite and other Dropping Point (ASTM D-2265) 450°f (232°C)

nonmetallic, inorganic, anti-wear additives blended into a Specific Gravity 1.23

state-of-the-art, high-temperature, rust-inhibiting complex

Density (lbs./gal.) 10.25

soap based grease. RUN-N-SEAL EXTREME con-

tains a large volume of solids enhanced by a higher con- Oil Separation <3.0

centration of large-sized particles. The improved distribu- Wt. % Loss @ 212°F (100°C)

OILFIELD

tion of particle sizes and volume of solids provides an ex- Flash Point (ASTM D-92) >450°F (232°C)

cellent seal in large and small diameter, non-shouldered NLGI Grade 1

threads. The complex soap grease provides a high melt- Penetration @ 77°F 325 - 350

ing point, ensures brushability over a wide range of tem- (ASTM D-217)

peratures and has excellent inherent water resistance. It Copper Strip Corrosion 1A

sticks to wet and oily steel, ensuring the compound will not (ASTM D-4048)

wash off threads. 4-Ball Weld Point, kgf 800

RUN-N-SEAL EXTREME has been tested for Cali- (ASTM D2596)

fornia Code of Regulations - Title 22, Chapter 30, Article II

Friction Factor 0.9

and is not classified as a hazardous waste. RUN-N-

SEAL EXTREME is nontoxic, even in a marine envi- (Relative to API-MODIFIED)

ronment, as evidenced by test results on the California

Hazardous Waste Assessment Bioassay and a “D” rating

in the North Sea (OSPAR) Guidelines.

OILFIELD

• Enhanced rust inhibiting properties

• Friction factor of 0.9 (relative to API-MODIFIED)

• Contains additives for protection against rust, corro-

sion, and oxidation PA CKA GING

CKAGING

• Prevents leakage (seals to 10,000 psi) Code No. Container Size Shipping Wt.

• High film strength to protect against wear, galling, and

12223 1 gal. 11 lb.

seizure

• Exceeds all of the performance criteria described in 12212 2 gal. 22 lb.

API spec. 5CT 12215 5 gal. 54 lb.

• Tested in conformance with API RP 5A3

• H2S Inhibited

APPLICATIONS

APPLICATIONS LIMITED WARRANTY

RUN-N-SEAL EXTREME is recommended for use Jet-Lube, Inc. makes the Limited Express Warranty that at the date of

delivery, this product shall be free from defects in Jet-Lube, Inc. materials

on OCTG connections, API connections, and subsurface and workmanship.

production tools. RUN-N-SEAL EXTREME will lu-

OILFIELD

This Limited Express Warranty is expressly in lieu of any other express

bricate, seal, and protect threaded connections of oilfield or implied warranties, including any implied warranty of merchantability or

fitness for a particular purpose, and of any other obligation on the part of

tubular goods on makeup, in service, and in storage. For Jet-Lube, Inc.

premium thread designs, use JET -L

JET-L UBE ® SEAL-

-LUBE The sole remedy for breach of the Limited Express Warranty shall be the

GU ARD TM. For an environmentally friendly premium

GUARD refund of the purchase price. All other liability is negated and disclaimed,

UBE® SEAL-GU ARDTM and Jet-Lube, Inc. shall not be liable for incidental or consequential dam-

thread compound, use JET JET-L -L

-LUBE SEAL-GUARD ages.

ECF.

CORPORATE LOCATIONS

Houston, Texas–World Headquarters

Maidenhead, England Edmonton, Canada

JET-LUBE, INC. WATS: 800-538-5823

OILFIELD

4849 HOMESTEAD RD., PHONE: 713-670-5700

SUITE 232 FAX: 713-678-4604

HOUSTON, TX 77028 sales@jetlube.com

www.jetlube.com

S-ar putea să vă placă și

- kx0804 PDFDocument519 paginikx0804 PDFstefan corjuc100% (7)

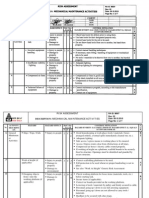

- Tyre Risk AssessmentDocument3 paginiTyre Risk AssessmentJhun Aquino84% (31)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Item Description: From GroundDocument16 paginiItem Description: From GroundJhun Aquino100% (1)

- Roto ZDocument3 paginiRoto Zjayakumar rajanÎncă nu există evaluări

- Mechanical Maintenance ActivitesDocument7 paginiMechanical Maintenance ActivitesJhun Aquino50% (2)

- Atlas Copco GA90Document132 paginiAtlas Copco GA90Jhun Aquino75% (4)

- Saudi Arabian Oil Company: NotesDocument1 paginăSaudi Arabian Oil Company: Noteshany mohamedÎncă nu există evaluări

- Aeroshell Grease 22: Versatile Multi-Purpose GreaseDocument2 paginiAeroshell Grease 22: Versatile Multi-Purpose GreaseNICKYÎncă nu există evaluări

- Deck Cranes PDFDocument7 paginiDeck Cranes PDFIndra Ranu KusumaÎncă nu există evaluări

- Shape Cutting Systems From EsabDocument36 paginiShape Cutting Systems From EsabJhun Aquino100% (1)

- 5456 de Filter PressDocument6 pagini5456 de Filter PressmbhadelÎncă nu există evaluări

- Terex TL310 ManualDocument180 paginiTerex TL310 ManualJhun Aquino100% (1)

- Introduction To MicroWavesDocument5 paginiIntroduction To MicroWavesKrish_666Încă nu există evaluări

- Kamag SPMTDocument3 paginiKamag SPMTJhun AquinoÎncă nu există evaluări

- Module 1 Capital and Cost EstimationDocument39 paginiModule 1 Capital and Cost EstimationYozora夜空Încă nu există evaluări

- DNV Maritime Forecast 2050 2021-WebDocument82 paginiDNV Maritime Forecast 2050 2021-WebДмитрий Ганжа100% (1)

- Atlas Copco Document GA90Document176 paginiAtlas Copco Document GA90Jhun Aquino100% (1)

- Kov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingDocument1 paginăKov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingJeremias UtreraÎncă nu există evaluări

- SealguardDocument1 paginăSealguardJorge ForeroÎncă nu există evaluări

- KOPR KOTE INDUSTRIAL TdsDocument1 paginăKOPR KOTE INDUSTRIAL TdsJeremias UtreraÎncă nu există evaluări

- JET LUBE 21 OILFIELD Tds PDFDocument1 paginăJET LUBE 21 OILFIELD Tds PDFDarshan MakwanaÎncă nu există evaluări

- Kopr Kote Geothermal TdsDocument1 paginăKopr Kote Geothermal Tdsferdy110276Încă nu există evaluări

- Seal-Guard: Environmental Service RatingDocument1 paginăSeal-Guard: Environmental Service RatingEdgarGuillermoÎncă nu există evaluări

- Alcoep 73Document1 paginăAlcoep 73ferdy110276Încă nu există evaluări

- Ficha Técnica Lubricante Omega 73Document12 paginiFicha Técnica Lubricante Omega 73juan felipe diazgranados santosÎncă nu există evaluări

- Seal-Guard+ECF TDS EnglishDocument1 paginăSeal-Guard+ECF TDS Englishabbas ansariÎncă nu există evaluări

- API Modified TdsDocument1 paginăAPI Modified Tdssigit praÎncă nu există evaluări

- Kopr Kote Oilfield TdsDocument1 paginăKopr Kote Oilfield Tdsbob smithÎncă nu există evaluări

- Alco EP 73 Plus - TDS - EnglishDocument1 paginăAlco EP 73 Plus - TDS - EnglishSefa ZumbulÎncă nu există evaluări

- EZY-TURN+#2 TDS EnglishDocument1 paginăEZY-TURN+#2 TDS EnglishKalpana BansalÎncă nu există evaluări

- Jet-Lube Jacking Grease ECF - TDS - EnglishDocument1 paginăJet-Lube Jacking Grease ECF - TDS - EnglishDon HowardÎncă nu există evaluări

- Silicone Compound Dm-2: Moisture Proofing Sealant & LubricantDocument1 paginăSilicone Compound Dm-2: Moisture Proofing Sealant & LubricantvarunchÎncă nu există evaluări

- 21®+oilfield TDS EnglishDocument1 pagină21®+oilfield TDS Englishferdy110276Încă nu există evaluări

- Ficha Técnica - Shell Gadus High Speed Coupling GreaseDocument3 paginiFicha Técnica - Shell Gadus High Speed Coupling Greasejuan felipe diazgranados santosÎncă nu există evaluări

- TDS Drag Cable LubricantDocument2 paginiTDS Drag Cable LubricantDaniel ColinsÎncă nu există evaluări

- Kopr-Kote TDS 2Document1 paginăKopr-Kote TDS 2jesusÎncă nu există evaluări

- Gearmate 1000 ICT TDS 3041Document1 paginăGearmate 1000 ICT TDS 3041Don HowardÎncă nu există evaluări

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 paginăProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzÎncă nu există evaluări

- Product Information Sheet: Description: ApplicationDocument2 paginiProduct Information Sheet: Description: ApplicationgalaxiprinceÎncă nu există evaluări

- Bel-Ray 6 in 1 Multipurpose LubricantDocument2 paginiBel-Ray 6 in 1 Multipurpose LubricantdhowardjÎncă nu există evaluări

- Naturelle S2 Wire Rope Lubricant A TDSDocument2 paginiNaturelle S2 Wire Rope Lubricant A TDSJohn MithuÎncă nu există evaluări

- Jet-Lube JLS - Jet-Lube SpecialDocument1 paginăJet-Lube JLS - Jet-Lube SpecialDon HowardÎncă nu există evaluări

- Jet-Lube 21 Waterwell Drill Rod CompoundDocument1 paginăJet-Lube 21 Waterwell Drill Rod CompoundDon HowardÎncă nu există evaluări

- GPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSDocument2 paginiGPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSSalem IereebiÎncă nu există evaluări

- Jet-Lube 769 Lubricant and PenetrantDocument1 paginăJet-Lube 769 Lubricant and PenetrantDon HowardÎncă nu există evaluări

- Jet-Lube Marine Grade Anti-SeizeDocument1 paginăJet-Lube Marine Grade Anti-SeizeDon HowardÎncă nu există evaluări

- ISO Grade 68: Performance in MotionDocument2 paginiISO Grade 68: Performance in MotionJose Angel GonzalezÎncă nu există evaluări

- Marine Lubricants FlyerDocument4 paginiMarine Lubricants FlyerjjgonzalezquinaÎncă nu există evaluări

- Jet-Lube FMG Grease 2Document1 paginăJet-Lube FMG Grease 2Don HowardÎncă nu există evaluări

- Gadus S3 Wirerope A (en-GB) TDSDocument2 paginiGadus S3 Wirerope A (en-GB) TDSHazel KatipunanÎncă nu există evaluări

- CASTROL BIO TAC OG - Pds - Rev. 17.08.2022Document2 paginiCASTROL BIO TAC OG - Pds - Rev. 17.08.2022Massimiliano VolaÎncă nu există evaluări

- iNVENTA 515UL Material: Properties Values (Metric) Values (English) Test MethodDocument1 paginăiNVENTA 515UL Material: Properties Values (Metric) Values (English) Test Methodsatheez3251Încă nu există evaluări

- 31.royal Enviroguard CurveRail GreaseDocument2 pagini31.royal Enviroguard CurveRail GreaseGerman Gonzales RuizÎncă nu există evaluări

- Technical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantDocument3 paginiTechnical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantSantaj TechnologiesÎncă nu există evaluări

- Envirolube XE Extreme TDS 190828 203810Document1 paginăEnvirolube XE Extreme TDS 190828 203810Don HowardÎncă nu există evaluări

- Mobilgrease XHP 460Document3 paginiMobilgrease XHP 460Jaime Miloz Masle JaksicÎncă nu există evaluări

- 76 Grasa Megaplex XD3Document2 pagini76 Grasa Megaplex XD3Gustavo De Haro GonzálezÎncă nu există evaluări

- Jet-Lube 550 Nonmetallic AntiSeize CompoundDocument1 paginăJet-Lube 550 Nonmetallic AntiSeize CompoundDon HowardÎncă nu există evaluări

- Ficha Tecnica Shell Spirax GSXDocument2 paginiFicha Tecnica Shell Spirax GSXselvinvillatoro9758Încă nu există evaluări

- Roto Z en 2935004221Document2 paginiRoto Z en 2935004221Madjid HernandezÎncă nu există evaluări

- Lubri-Bond 220: Technical Data (Spec Qualified)Document2 paginiLubri-Bond 220: Technical Data (Spec Qualified)Santaj TechnologiesÎncă nu există evaluări

- Shell Gadus S3 Wirerope: Performance, Features & Benefits Main ApplicationsDocument2 paginiShell Gadus S3 Wirerope: Performance, Features & Benefits Main ApplicationsptscmscÎncă nu există evaluări

- Lubricant and Penetrant: Technical Data SheetDocument1 paginăLubricant and Penetrant: Technical Data SheetJeremias UtreraÎncă nu există evaluări

- 369 and VpCI-369 H PDFDocument2 pagini369 and VpCI-369 H PDFOmar MorteoÎncă nu există evaluări

- 21® Oilfield - TDS - EnglishDocument1 pagină21® Oilfield - TDS - Englishferdy110276Încă nu există evaluări

- Shell Gadus S2 OG 85Document2 paginiShell Gadus S2 OG 85Anonymous oAbjbl4HÎncă nu există evaluări

- Roto-Xtend Duty Fluid: Atlas Copco LubricantsDocument2 paginiRoto-Xtend Duty Fluid: Atlas Copco LubricantsJeremias UtreraÎncă nu există evaluări

- Hoja Técnica Roto Xtend Duty Fluid PDFDocument2 paginiHoja Técnica Roto Xtend Duty Fluid PDFFederico Liaudat100% (2)

- Mobilgrease XHP 222Document2 paginiMobilgrease XHP 222Stefan Cel MareÎncă nu există evaluări

- PDS - Mobilgrease XHP 460 SeriesDocument3 paginiPDS - Mobilgrease XHP 460 SeriesJuanSantillanÎncă nu există evaluări

- Molykote D 321R - BrochureDocument2 paginiMolykote D 321R - Brochuretaufik perdanaÎncă nu există evaluări

- Envirolube Xe Extreme: Technical Data SheetDocument1 paginăEnvirolube Xe Extreme: Technical Data SheetDon HowardÎncă nu există evaluări

- 1232 TDB FlyerDocument2 pagini1232 TDB FlyerDeltalube TangerangÎncă nu există evaluări

- Silicone Compound Dm-3: Moisture Proofing Sealant & LubricantDocument1 paginăSilicone Compound Dm-3: Moisture Proofing Sealant & LubricantvarunchÎncă nu există evaluări

- Installation Manual - MC1101S-R56Document12 paginiInstallation Manual - MC1101S-R56Jhun AquinoÎncă nu există evaluări

- Toku AirtoolenDocument9 paginiToku AirtoolenJhun AquinoÎncă nu există evaluări

- The Solid Waste Handbook A Practical GuideDocument4 paginiThe Solid Waste Handbook A Practical GuideJhun AquinoÎncă nu există evaluări

- Item Description Status NO OK N/A: Clamshell Visual Pre Use Checklist (Air / Hydraulic)Document1 paginăItem Description Status NO OK N/A: Clamshell Visual Pre Use Checklist (Air / Hydraulic)Jhun AquinoÎncă nu există evaluări

- Breathing Apparatus ChecklistDocument6 paginiBreathing Apparatus ChecklistJhun AquinoÎncă nu există evaluări

- Data Sheet Traigo 80 4.0-5.0t - EnglishDocument4 paginiData Sheet Traigo 80 4.0-5.0t - EnglishJhun AquinoÎncă nu există evaluări

- Air Die Grinder (22000rpm) GP 824Document1 paginăAir Die Grinder (22000rpm) GP 824Jhun AquinoÎncă nu există evaluări

- Blind Flanges For SpoolsDocument11 paginiBlind Flanges For SpoolsJhun AquinoÎncă nu există evaluări

- Connection DisconnectionDocument4 paginiConnection DisconnectionJhun AquinoÎncă nu există evaluări

- TrolleyDocument1 paginăTrolleyJhun AquinoÎncă nu există evaluări

- THERMOBILEDocument3 paginiTHERMOBILEJhun AquinoÎncă nu există evaluări

- Filters PDFDocument1 paginăFilters PDFJhun AquinoÎncă nu există evaluări

- Clutch PDFDocument1 paginăClutch PDFJhun AquinoÎncă nu există evaluări

- Caliper Brake PDFDocument1 paginăCaliper Brake PDFJhun AquinoÎncă nu există evaluări

- Test Procedure of Crane: Bos Shelf Llc. Work InstructionDocument11 paginiTest Procedure of Crane: Bos Shelf Llc. Work InstructionJhun AquinoÎncă nu există evaluări

- Cooling PDFDocument1 paginăCooling PDFJhun AquinoÎncă nu există evaluări

- Starter PDFDocument1 paginăStarter PDFJhun AquinoÎncă nu există evaluări

- Steering PDFDocument1 paginăSteering PDFJhun AquinoÎncă nu există evaluări

- Illustr. Article Number Description: All ValuesDocument1 paginăIllustr. Article Number Description: All ValuesJhun AquinoÎncă nu există evaluări

- Belts PDFDocument1 paginăBelts PDFJhun AquinoÎncă nu există evaluări

- Brake Disc PDFDocument1 paginăBrake Disc PDFJhun AquinoÎncă nu există evaluări

- KOmatsu OilDocument7 paginiKOmatsu OilJhun AquinoÎncă nu există evaluări

- Dryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersDocument5 paginiDryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersTristan Paul Guerra OrodioÎncă nu există evaluări

- Arc Mercer 2011 Fall NewsletterDocument12 paginiArc Mercer 2011 Fall NewsletterarcmercerÎncă nu există evaluări

- NAKED Singularities - PenroseDocument10 paginiNAKED Singularities - PenroseLeon FosiltÎncă nu există evaluări

- Снимок экрана 2023-03-01 в 09.16.43Document48 paginiСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovÎncă nu există evaluări

- MONTZ Main Cataloque PDFDocument69 paginiMONTZ Main Cataloque PDFswaminathanÎncă nu există evaluări

- Space News - Sukhbir GDocument6 paginiSpace News - Sukhbir Gapi-288584327Încă nu există evaluări

- Water Level Indicator Project PDFDocument7 paginiWater Level Indicator Project PDFSimranÎncă nu există evaluări

- ASTM G128 - Oxygen Awareness Write-Up#1Document26 paginiASTM G128 - Oxygen Awareness Write-Up#1Indrajit SaoÎncă nu există evaluări

- PV Cell CharaDocument40 paginiPV Cell CharaBlessy JoyÎncă nu există evaluări

- MegaFlex - 480V UL UPS Brochure - 041720Document9 paginiMegaFlex - 480V UL UPS Brochure - 041720GeorgeÎncă nu există evaluări

- Parallel Operation of Three-Phase AlternatorsDocument13 paginiParallel Operation of Three-Phase AlternatorsSTUDENTS OF DOE CUSATÎncă nu există evaluări

- Melting Point and Molecular SymmetryDocument8 paginiMelting Point and Molecular SymmetryPriscilla Solera RodriguezÎncă nu există evaluări

- Detailed CalculationsDocument14 paginiDetailed CalculationsrozÎncă nu există evaluări

- SolarPro2 4Document100 paginiSolarPro2 4lgv2Încă nu există evaluări

- Sinusifdv GB V301 R13-A5Document149 paginiSinusifdv GB V301 R13-A5Mr.K chÎncă nu există evaluări

- MA 40 - Premium Quality Stationary Gas Engine OilDocument2 paginiMA 40 - Premium Quality Stationary Gas Engine OilRaden ArdyÎncă nu există evaluări

- Operation of Fresh Water GeneratorDocument3 paginiOperation of Fresh Water GeneratoralexdenychenkoÎncă nu există evaluări

- Human Tissues Structure, Function and LococationDocument4 paginiHuman Tissues Structure, Function and Lococationxuxi dulÎncă nu există evaluări

- Eat That Frog!: A Book Summary OnDocument17 paginiEat That Frog!: A Book Summary OnramranganÎncă nu există evaluări

- CONSERVATION OF PLANTS AND ANIMALS - NotesDocument3 paginiCONSERVATION OF PLANTS AND ANIMALS - NotesNiraj SethiÎncă nu există evaluări

- Microturbine Developments PDFDocument26 paginiMicroturbine Developments PDFsfsagfegfdbfdÎncă nu există evaluări

- Design and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsDocument12 paginiDesign and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsReno ReoÎncă nu există evaluări

- Digital BangladeshDocument5 paginiDigital Bangladeshhimelhimel34Încă nu există evaluări