Documente Academic

Documente Profesional

Documente Cultură

Series: Up To 37gpm (140 L/min)

Încărcat de

yuanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Series: Up To 37gpm (140 L/min)

Încărcat de

yuanDrepturi de autor:

Formate disponibile

D/G-35 Series

Up to 37gpm (140 l/min) D/G-35 Specialized Designs

Hydra-Cell Slurry Duty pumps are

specifically designed for abrasive

slurry applications. See page 80 for

complete specifications.

The D-35 Hydra-Cell can be equipped

with an SAE or ANSI flange pump head

for critical performance applications.

74 United States Instant Information: United Kingdom

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

D/G-35 Series Performance

flow RPM

max 0 200 400 600 800 1000 1200

40.0

1050

max flow input

1160

model gpm l/min rpm 140

D/G-35-X

35.0

D/G-35-X 36.5 138 1050

200 PSI (14 bar)

D/G-35-E 34.5 131 1150 1200 PSI (83 bar)

120

D/G-35-E

30.0

pressure 100

25.0

Gallons per Minute

Liters per Minute

Maximum Inlet Pressure:

80

250 psi (17 bar) 20.0

Pressure Variable To: 15.0

60

1200 psi (83 bar)

10.0 40

5.0 20

0 0

Calculating Required Horsepower (kW)**

100 x rpm gpm x psi

+ = electric motor HP

63,000 1,460

100 x rpm lpm x bar

+ = electric motor kW

84,428 511

**rpm equals pump shaft rpm. HP/kW is required application power. Use

caution when sizing motors with variable speed drives.

United States Instant Information: United Kingdom 75

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

D/G-35 Series Specifications

Max Pressure 1200 psi (83 bar)

Net Positive Suction Head (NPSHr)

Capacity @ Max Pressure

rpm gpm I/min 26

1050

1160

D/G-35-X 1050 36.5 138

D/G-35-E 1150 34.5 131 24

D/G-35-X 7

Delivery @ Max Pressure 22

revs/gal revs/liter D/G-35-E

20 6

D/G-35-X 29 7.7

D/G-35-E 33 8.8 18

NPSHr (meters of water)

Max Inlet Pressure 250 psi (17 bar)

NPSHr (feet of water)

16 5

Max Temperature 250°F (121°C) – Consult factory for correct

14

component selection for temperatures above 4

160°F (71°C) 12

Inlet Port D-35: 2-1/2 inch NPT or 3 inch SAE flange 10 3

G-35: 2-1/2 inch BSPT

8

Discharge Port D-35: 1-1/4 inch NPT or 1-1/4 inch SAE flange

2

G-35: 1-1/4 inch BSPT 6

Shaft Diameter 2 inch 4

Shaft Rotation Bi-directional 1

2

Bearings Tapered roller

Oil Capacity 5 US quarts (4.7 liters), see Accessories 0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

Section for oil selection and specification. RPM

Weight 240 lbs (109 kg)

Dry Lift

6

175

D/G-35-X

D/G-35-E

5 150

4 125

Lift (cm of water)

Lift (feet of water)

100

3

75

2

50

1

25

0

0 200 400 600 800 1000 1200

RPM

Refer to installation guidelines and design considerations

section for additional information.

76 United States Instant Information: United Kingdom

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

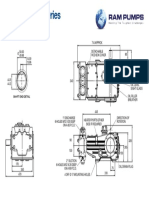

D/G-35 Series Dimensions

D/G-35 Models with NPT/BSPT Inlet/Outlet Ports

6.0 1.2

(152) (30.1) Outlet

D-35: 1.25" NPT

G-35: 1.25" BSPT

Inlet 11.83

D-35: 2.5" NPT (300)

0.50 G-35: 2.5" BSPT dia.

(12.7)

Sq. Key

4.1

(104)

2.00

(50.8)

15.2

(386)

4.1

(104) 7.0

0.9 (178)

(22.9) 0.3

(7.6)

0.66 Slot Width

(16.8) 1.15

7.5 6.5 6.5 0.2 (29.2) 9.9

(191) (165) (165) (5.1) Slot Width (251)

20.7 11.5

(526) (292)

D-35 Models with SAE Flange Inlet/Outlet Ports

6.0 1.2 1.19

Ø1.25 (30.2) 7/16-14 UNC-2B thd.

(152) (30.1)

(31.8)

3.0 outlet

(76.2) 11.83

inlet (300)

0.50 dia.

(12.7) 2.31

Sq. Key (58.7)

4.1

(104)

2.00 2.44

(50.8) (62)

15.2

(386)

4.1

(104) 7.0

0.9 (178)

(22.9) 0.3 5/8-11UNC-2B THD.

(7.6)

0.66 Slot Width 4.19

(16.8) 1.15

(29.2) (106)

7.5 6.5 6.5 0.2 Slot Width 9.9

(191) (165) (165) (5.1) (251)

20.7 11.5

(526) (292)

United States Instant Information: United Kingdom 77

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

D/G-35 Series Options

Materials of Construction

Hydra-Cell pumps are manufactured in a variety of heavy-duty materials to meet specific pumping needs. Refer to the design section for more information on

appropriate material selection and chemical compatibility. Other customized materials are available by special order. Contact factory application engineering

department for further information.

Pumping Head Valves

316 Stainless Steel 17-4 PH Stainless Steel

Brass Ceramic

Ductile Iron, Nickel Plated Hastelloy® C

Nickel Alloy (Hastelloy Nitronic 50

CW12MW) Tungsten Carbide

Diaphragms & O-rings Valve Springs

Buna-N-XS 17-7 PH Stainless Steel

EPDM Elgiloy®

Neoprene Hastelloy® C

Teflon®

Viton®-XT

Valve Seats Valve Spring Retainers

17-4 PH Stainless Steel 17-7 PH Stainless Steel

Ceramic Celcon®

Hastelloy® C Hastelloy® C

Nitronic 50 Kynar®

Tungsten Carbide Nylon (Zytel®)

Polypropylene

D/G-35 Series Accessories

Options, Accessories and Custom Designs ANSI Flange Pump Heads

See the Accessories The D-35 Hydra-Cell can be equipped

Section for complete with ANSI flange pump heads for critical

information on these other performance applications such as oil/

products: gas installations and chemical process

• Valves facilities.

• Baseplates

• Guards Design Features

• 316 stainless steel flanges

• Couplings

• Optional ductile iron pump housing

• Hose Connectors • 2-1/2”x 150# ANSI pipe flange inlet;

• Hydra-Oil 1-1/4” x 600# ANSI pipe flange outlet

• Oil Cooler and Filtering

System

Ordering Information

• Oil Reservoir Contact factory for complete

• Tool Kits specifications and ordering information.

78 United States Instant Information: United Kingdom

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

D/G-35 Series How To Order

A complete model number contains 12 digits of

Ordering Information customer-specified design options: for example D35XKBTHFECA.

1 2 3 4 5 6 7 8 9 10 11 12

Order Order

Digit Code Description Digit Code Description

1-3 Pump Configuration 11 Valve Spring Retainers

D35 Shaft-driven (NPT ports or SAE Flange) C Celcon

G35 Shaft-driven (BSPT ports) H 17-7 PH Stainless Steel

4 Hydraulic End Cam M Kynar®

P Polypropylene

X Max 37 gpm (140 lpm) @ 1050 rpm

T Hastelloy ® C

E Max 35 gpm (132 lpm) @ 1150 rpm

Y Nylon (Zytel)

5 Pump Head Version

12 Hydra-Oil

K Kel-Cell Threaded Ports Version Pump Head

A 10W30 standard duty oil

E Kel-Cell SAE Flange Version Pump Head

B 40-wt for continuous duty (use with 316 SST

6 Pump Head Material or Hastelloy® pump head)

B Brass D 40-wt high-temp EPDM-compatible oil

C Cast Iron (nickel plated) F 40-wt high-temp food-contact oil

S 316 Stainless Steel G 5W30 cold-temp severe duty oil

T Nickel Alloy (Hastelloy® CW12MW)) H 15W50 high-temp severe duty synthetic oil

7 Diaphragm & O-ring Material

E EPDM (requires EPDM-compatible oil –

Digit 12 oil code C or D)

G Viton®-XT

J* Teflon® (available with E cam only;

1050 rpm max)

P Neoprene

T Buna-N-XS

8 Valve Seat Material

C Ceramic

D Tungsten Carbide

H 17-4 PH Stainless Steel

N Nitronic 50 Replacement Hydraulic End Assembly

T Hastelloy® C Complete D/G-35 Hydraulic End Assemblies are available as

replacement items. The Hydraulic End contains all drive end

9 Valve Material

components from the drive shaft up to and including the

C Ceramic

diaphragms. All Hydraulic Ends are factory tested and shipped with

D Tungsten Carbide

oil. To order a Replacement Hydraulic End, specify the desired Cam

F 17-4 PH Stainless Steel – Machined

(Digit 4), the Diaphragm and O-ring Material (Digit 7), and the

N Nitronic 50

Hydra-Oil (Digit 12).

T Hastelloy® C

10 Valve Springs

E Elgiloy® Part Number*

H 17-7 PH Stainless Steel D35 __

4* XX __

7* XXXX 12*

__ G35 __

4* XX __

7* XXXX 12*

__

T Hastelloy® C * Order Code Digits 4, 7 and 12 must be filled in when ordering.

* May require pressurized inlet.

United States Instant Information: United Kingdom 79

(612) 332-5681 Fax (612) 332-6937 www.hydra-cell.com +44 (0) 1252 816847 Fax +44 (0) 1252 629242

S-ar putea să vă placă și

- Installation & Service DG35-991-UK00A1Document23 paginiInstallation & Service DG35-991-UK00A1LakiLakicÎncă nu există evaluări

- OF322 Motor AC (Oil-Less) : E-Mail: Info@jun-Air - DKDocument1 paginăOF322 Motor AC (Oil-Less) : E-Mail: Info@jun-Air - DKEnrique MurgiaÎncă nu există evaluări

- T100 Medium-Pressure DatasheetDocument6 paginiT100 Medium-Pressure DatasheetjuninÎncă nu există evaluări

- CD150MV Wellpoint Pump: FeaturesDocument2 paginiCD150MV Wellpoint Pump: FeaturesAbcehmu EgiÎncă nu există evaluări

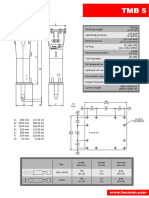

- Tecman TMB5 Web Spec V160921Document1 paginăTecman TMB5 Web Spec V160921thomas.templierÎncă nu există evaluări

- GALAPESCA Firepump Performance CurveDocument1 paginăGALAPESCA Firepump Performance CurveFrancisco AlarconÎncă nu există evaluări

- G35 Series: Versatile, Reliable Pumps For A Wide Range of ApplicationsDocument8 paginiG35 Series: Versatile, Reliable Pumps For A Wide Range of ApplicationsHugo José Abreu de SouzaÎncă nu există evaluări

- Tecman TMB4-V5 Web Spec V160921Document1 paginăTecman TMB4-V5 Web Spec V160921thomas.templierÎncă nu există evaluări

- Hyva Piston Pumps: Bent Axis TypeDocument2 paginiHyva Piston Pumps: Bent Axis TypeJun JunaidiÎncă nu există evaluări

- Operating ParametersDocument1 paginăOperating Parameters陆军Încă nu există evaluări

- Theoretical Working Point Performance Chart: 5150870300-B-18 - TGT/4-400-6/18 BC 0,25KW (230/400V50HZ) IE1 V5Document17 paginiTheoretical Working Point Performance Chart: 5150870300-B-18 - TGT/4-400-6/18 BC 0,25KW (230/400V50HZ) IE1 V5Igor SpirovÎncă nu există evaluări

- VSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedDocument2 paginiVSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedCarlos Andrés CuelloÎncă nu există evaluări

- SG Series: Daejin Battery Co., LTDDocument2 paginiSG Series: Daejin Battery Co., LTDVladimir MelladoÎncă nu există evaluări

- 1.9.4.7 RBT 100 Data Sheet - 2021Document2 pagini1.9.4.7 RBT 100 Data Sheet - 2021CésarÎncă nu există evaluări

- 2PE Salami PDFDocument35 pagini2PE Salami PDFMartin MiaÎncă nu există evaluări

- Fire Pump Systems CatalogDocument12 paginiFire Pump Systems CatalogSijo JoyÎncă nu există evaluări

- Hydraulic Filtration Product GuideDocument320 paginiHydraulic Filtration Product GuideIvan MarijanovićÎncă nu există evaluări

- Hydraulic Filtration Product GuideDocument316 paginiHydraulic Filtration Product GuideAnonymous rGIYBtEeÎncă nu există evaluări

- Chuck Guide Il-2 Cliffs of DoverDocument668 paginiChuck Guide Il-2 Cliffs of DoverStefano SaezÎncă nu există evaluări

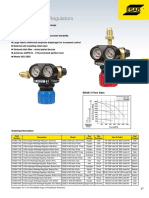

- Regulators Edge 4 Series RegulatorsDocument1 paginăRegulators Edge 4 Series RegulatorsDries VandezandeÎncă nu există evaluări

- CD100MV Dri-Prime Pumps: FeaturesDocument2 paginiCD100MV Dri-Prime Pumps: FeaturesAbcehmu EgiÎncă nu există evaluări

- 4500gpm 135psi Horizontal SplitCase Diesel Fire Pump SpecsDocument13 pagini4500gpm 135psi Horizontal SplitCase Diesel Fire Pump SpecsINGENIERIA8 FYSÎncă nu există evaluări

- Little - Giant LSP-150-C Lawn Sprinkler Pump - OverviewDocument2 paginiLittle - Giant LSP-150-C Lawn Sprinkler Pump - OverviewjuliusttÎncă nu există evaluări

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 paginiMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoÎncă nu există evaluări

- Models: C62/63/64-A/D: Installation & ServiceDocument8 paginiModels: C62/63/64-A/D: Installation & ServiceFelipe LeiteÎncă nu există evaluări

- ESAB ExtractPage25-26cDocument8 paginiESAB ExtractPage25-26cDries VandezandeÎncă nu există evaluări

- Chuck Guide Il 2 Cliffs of Dover He111Document91 paginiChuck Guide Il 2 Cliffs of Dover He111sandyÎncă nu există evaluări

- GH SeriesDocument4 paginiGH Series潘学淼Încă nu există evaluări

- K40plus 01 T ADocument12 paginiK40plus 01 T AromanvauchetskiÎncă nu există evaluări

- BOX RLF 800 T4 11kW: General DataDocument5 paginiBOX RLF 800 T4 11kW: General DataGwenn AsprerÎncă nu există evaluări

- Banco Con Control Electrico Proporcional L218Document60 paginiBanco Con Control Electrico Proporcional L218Agustín TorresÎncă nu există evaluări

- NewCurves LTMDocument5 paginiNewCurves LTMRBS GROUP ENQUIRIESÎncă nu există evaluări

- Hydracell - d15 ManualDocument24 paginiHydracell - d15 ManualElkan Jeveshan NaidooÎncă nu există evaluări

- Chuck Guide Il 2 Cliffs of Dover Bf109Document50 paginiChuck Guide Il 2 Cliffs of Dover Bf109Pro FlexÎncă nu există evaluări

- THGT2-630-627 BLK 11kW (400V50Hz) F400 IE3 V5-471Document3 paginiTHGT2-630-627 BLK 11kW (400V50Hz) F400 IE3 V5-471Goran djukicÎncă nu există evaluări

- Chuck Guide Il 2 Cliffs of Dover Bf110 PDFDocument64 paginiChuck Guide Il 2 Cliffs of Dover Bf110 PDFPaolo FontanazziÎncă nu există evaluări

- Volume Control Damper: VCD ("V" Groove Blade) VCD (Airfoil Shape Blade)Document10 paginiVolume Control Damper: VCD ("V" Groove Blade) VCD (Airfoil Shape Blade)Mahammad GhouseÎncă nu există evaluări

- MMI-50 NT ENG 50HzDocument8 paginiMMI-50 NT ENG 50HzTaimoorÎncă nu există evaluări

- 2ZZ-GE Engine DescriptionDocument9 pagini2ZZ-GE Engine DescriptionJordan DerrickÎncă nu există evaluări

- Dehumidifiers For Radiant Cooling Systems With Heat Recovery: VersionsDocument6 paginiDehumidifiers For Radiant Cooling Systems With Heat Recovery: VersionsNikosÎncă nu există evaluări

- Amos Auto Prime Brochure-AllDocument17 paginiAmos Auto Prime Brochure-AllEsmael BelarminoÎncă nu există evaluări

- Racine and Radial Vane PumpsDocument6 paginiRacine and Radial Vane PumpsVentas Control HidráulicoÎncă nu există evaluări

- Gear Pumps and Motors "B" Series Group 2,5: Technical CatalogueDocument29 paginiGear Pumps and Motors "B" Series Group 2,5: Technical CatalogueLucyan IonescuÎncă nu există evaluări

- Eaton Hydraulics Relief ValvesDocument4 paginiEaton Hydraulics Relief ValvesMAZM17Încă nu există evaluări

- 7660 PULSA Series: Engineered ProductsDocument2 pagini7660 PULSA Series: Engineered ProductsTaQuangDucÎncă nu există evaluări

- Model 183-091-1800-A: Fan Diameter 72 Inches Air Density 0.075 Lbs./cu. Ft. Diffuser Diameter 84.375" Diffuser Length 80"Document1 paginăModel 183-091-1800-A: Fan Diameter 72 Inches Air Density 0.075 Lbs./cu. Ft. Diffuser Diameter 84.375" Diffuser Length 80"Isaías Estrada AlemánÎncă nu există evaluări

- ADC 3010 AC 212 Series RegulatorDocument2 paginiADC 3010 AC 212 Series RegulatorkicsnerÎncă nu există evaluări

- Ficha Tecnica Condensadores Multi-Split G4oc-36hrfn1 y G3od-27hrdn1Document1 paginăFicha Tecnica Condensadores Multi-Split G4oc-36hrfn1 y G3od-27hrdn1Dario ManriquelmeÎncă nu există evaluări

- Diaphragm Drum PumpsDocument29 paginiDiaphragm Drum PumpsLuthfi LegooÎncă nu există evaluări

- HDR 100Document4 paginiHDR 100oscarÎncă nu există evaluări

- Just Right Temperature Control: V SeriesDocument4 paginiJust Right Temperature Control: V SeriesMalek MessaoudÎncă nu există evaluări

- Eaton 421 Pump Sheet Vers-BDocument2 paginiEaton 421 Pump Sheet Vers-Bdzakky syahputraÎncă nu există evaluări

- Frame 616 Ram Whispair & Whispair Gas Pump: 2500 4 Psi 8 Psi 12 PSI 15 PSIDocument2 paginiFrame 616 Ram Whispair & Whispair Gas Pump: 2500 4 Psi 8 Psi 12 PSI 15 PSIPedro Schiavi StoiberÎncă nu există evaluări

- Iam Series H8 Model: Ntermot - Dvanced - OtorsDocument7 paginiIam Series H8 Model: Ntermot - Dvanced - Otorsedgardo roblesÎncă nu există evaluări

- Service Manual: Crawler Dozers PR 711C - 751Document1.079 paginiService Manual: Crawler Dozers PR 711C - 751Ваня Малиш100% (1)

- Database Management Systems: Understanding and Applying Database TechnologyDe la EverandDatabase Management Systems: Understanding and Applying Database TechnologyEvaluare: 4 din 5 stele4/5 (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Ram 50 HCH Dimensional Drawing 223528Document1 paginăRam 50 HCH Dimensional Drawing 223528yuanÎncă nu există evaluări

- Conditions of Sale: Quotation Goods Lost or Damaged in TransitDocument1 paginăConditions of Sale: Quotation Goods Lost or Damaged in TransityuanÎncă nu există evaluări

- Ram 50 HCH Lor 192226Document4 paginiRam 50 HCH Lor 192226sdÎncă nu există evaluări

- T100 - Low IOM PDFDocument32 paginiT100 - Low IOM PDFyuanÎncă nu există evaluări

- Hydra-Cell Industrial & Process Pumps: ® Flow Capacities and Pressure RatingsDocument3 paginiHydra-Cell Industrial & Process Pumps: ® Flow Capacities and Pressure RatingsyuanÎncă nu există evaluări

- T100 - Low IOM PDFDocument32 paginiT100 - Low IOM PDFyuanÎncă nu există evaluări

- Matco Asia Vietnam - Product Summary Overview: KavalDocument3 paginiMatco Asia Vietnam - Product Summary Overview: Kavalyuan100% (1)

- G-35 SD Parts Manual PDFDocument6 paginiG-35 SD Parts Manual PDFyuanÎncă nu există evaluări

- G-35 SD Parts Manual PDFDocument6 paginiG-35 SD Parts Manual PDFyuanÎncă nu există evaluări

- CCS - Catalog PDFDocument4 paginiCCS - Catalog PDFyuanÎncă nu există evaluări

- TC FLS Sihi LPHX 65000 en PDFDocument11 paginiTC FLS Sihi LPHX 65000 en PDFyuanÎncă nu există evaluări

- 2402Document2 pagini2402georgadam1983Încă nu există evaluări

- CCS Indust Flyer PDFDocument3 paginiCCS Indust Flyer PDFyuanÎncă nu există evaluări

- 8430-D35 Iom PDFDocument20 pagini8430-D35 Iom PDFyuanÎncă nu există evaluări

- Models: D35, G35: Installation, Operation & MaintenanceDocument25 paginiModels: D35, G35: Installation, Operation & MaintenanceyuanÎncă nu există evaluări

- Hydra Oil PDFDocument2 paginiHydra Oil PDFyuanÎncă nu există evaluări

- D35 Parts PDFDocument6 paginiD35 Parts PDFyuanÎncă nu există evaluări

- Models: D35, G35: Installation, Operation & MaintenanceDocument25 paginiModels: D35, G35: Installation, Operation & MaintenanceyuanÎncă nu există evaluări

- 8430-D35 Iom PDFDocument20 pagini8430-D35 Iom PDFyuanÎncă nu există evaluări

- Brochure Kcnhiepphuoc 2019Document11 paginiBrochure Kcnhiepphuoc 2019yuanÎncă nu există evaluări

- Hydra Oil PDFDocument2 paginiHydra Oil PDFyuanÎncă nu există evaluări

- D35 Parts PDFDocument6 paginiD35 Parts PDFyuanÎncă nu există evaluări

- Hoang Anh - g10 - DatasheetDocument1 paginăHoang Anh - g10 - DatasheetyuanÎncă nu există evaluări

- Tlglf4b 09 09 MarkedDocument2 paginiTlglf4b 09 09 MarkedyuanÎncă nu există evaluări

- KBL Annual Report 2017-18Document222 paginiKBL Annual Report 2017-18yuanÎncă nu există evaluări

- T100 Low-Pressure DatasheetDocument6 paginiT100 Low-Pressure DatasheetyuanÎncă nu există evaluări

- Rubber Tire - CCSDocument1 paginăRubber Tire - CCSyuanÎncă nu există evaluări

- Letter To EngrDocument5 paginiLetter To EngrMeycauayan DialysisÎncă nu există evaluări

- Flyer: Introducing The World's Most Advanced CH-47 Internally Air Transportable Tactical Utility VehicleDocument2 paginiFlyer: Introducing The World's Most Advanced CH-47 Internally Air Transportable Tactical Utility VehiclevoenpromÎncă nu există evaluări

- Case IH Farmall 110ADocument3 paginiCase IH Farmall 110AVìctorMqzÎncă nu există evaluări

- Shailesh Industries: SINCE 1979Document4 paginiShailesh Industries: SINCE 1979Muhammad RizkiÎncă nu există evaluări

- Isuzu Trooper Workshop ManualDocument3.573 paginiIsuzu Trooper Workshop Manualvit otio89% (19)

- EC240B LC: Volvo ExcavatorDocument12 paginiEC240B LC: Volvo ExcavatorMoncef LazaarÎncă nu există evaluări

- D8K Track Type Tractor Specs PDFDocument6 paginiD8K Track Type Tractor Specs PDFDavid Ramirez100% (2)

- PC400-6 (1.8m3,-20C, Sandy Arrang) ENGDocument11 paginiPC400-6 (1.8m3,-20C, Sandy Arrang) ENGBudi WaskitoÎncă nu există evaluări

- Piston Compressors: Reliable Beyond LimitsDocument8 paginiPiston Compressors: Reliable Beyond LimitsRachid Kerdidi100% (1)

- D14.6L SpecificationsDocument3 paginiD14.6L Specificationstua aggrekoÎncă nu există evaluări

- Plant Visits FinalsDocument224 paginiPlant Visits FinalsKent LabajoÎncă nu există evaluări

- Clg766a - Backhoe LoaderDocument2 paginiClg766a - Backhoe LoaderrandapebriÎncă nu există evaluări

- 252B Series 3Document2 pagini252B Series 3Mostafa SaadÎncă nu există evaluări

- Understanding Power Take-Off SystemsDocument26 paginiUnderstanding Power Take-Off Systemsanibal_rios_rivas100% (2)

- 735 Flex Coil 1720 Air CartDocument9 pagini735 Flex Coil 1720 Air CartTerry BuffaloÎncă nu există evaluări

- HYD01Document6 paginiHYD01scrbdgharaviÎncă nu există evaluări

- Chapter 4 - Part 1-BoilersDocument56 paginiChapter 4 - Part 1-BoilersRaj GandhiÎncă nu există evaluări

- 10017Document2 pagini10017Alex RamirezÎncă nu există evaluări

- Prime Review Online: Boilers Steam Generators)Document13 paginiPrime Review Online: Boilers Steam Generators)Rampage YTÎncă nu există evaluări

- QSK78-G8: Emissions Compliance: EPA Tier 1 at 60 HZDocument2 paginiQSK78-G8: Emissions Compliance: EPA Tier 1 at 60 HZHernan Peñafiel Rea100% (1)

- Vxr300 SpecifiqDocument2 paginiVxr300 SpecifiqAfonso CapandaÎncă nu există evaluări

- PC27MR 3Document8 paginiPC27MR 3LU YO100% (1)

- Illustrated Parts List MFG. ID NO. 96011019305 Customer Catalog No. P11597 PRODUCT NO. 960 11 01-93Document17 paginiIllustrated Parts List MFG. ID NO. 96011019305 Customer Catalog No. P11597 PRODUCT NO. 960 11 01-93Ingar SlangÎncă nu există evaluări

- Gd663a 2 - Cen00472 02Document12 paginiGd663a 2 - Cen00472 02kazemiÎncă nu există evaluări

- CHAPTER 5, Nunbers 1 To 5Document3 paginiCHAPTER 5, Nunbers 1 To 5Shane Buraga67% (3)

- Ashok Leyland ALGP WO4D.E4, ALGPWO4DMK1 - HA4, AL4DTG3 - HA4D, AL4DTIG2 - HA4DT Operator's and Maintenance ManualDocument82 paginiAshok Leyland ALGP WO4D.E4, ALGPWO4DMK1 - HA4, AL4DTG3 - HA4D, AL4DTIG2 - HA4DT Operator's and Maintenance ManualFLORES SANTIAGO CESAR MIGUELÎncă nu există evaluări

- Economy Vacuum Pumps: 3, Hagavish St. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529Document8 paginiEconomy Vacuum Pumps: 3, Hagavish St. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529Ali MustaqimÎncă nu există evaluări

- Appendix 2 - Vehicle Valuation ChecklistDocument5 paginiAppendix 2 - Vehicle Valuation ChecklistRahel SorriÎncă nu există evaluări

- Sumber: Said Firman Furqan (Environment Departement)Document11 paginiSumber: Said Firman Furqan (Environment Departement)sri ramadhaniÎncă nu există evaluări