Documente Academic

Documente Profesional

Documente Cultură

Basics of Aggregate

Încărcat de

vrb126Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basics of Aggregate

Încărcat de

vrb126Drepturi de autor:

Formate disponibile

BASICS OF AGGREGATES

Aggregate Quality Monitoring Program

Tex-499-A

Michael Dawidczik, P.G.

Construction Division/Materials & Pavements Section

Geotechnical, Soils, & Aggregates Branch

October 11, 2017

2017 Transportation Short Course October 11, 2017

Table of contents

1 Aggregate Quality Monitoring Program (AQMP) 3-6

2 Purpose & Responsibilities of AQMP 7-15

3 Products & Laboratory Tests of AQMP 16-19

4 Laboratory Tests of AQMP in Detail 20-32

5 Process of Adding & Removing Sources from AQMP 33-40

6 Questions 41

2017 Transportation Short Course October 11, 2017 2

Aggregate Quality Monitoring Program

Aggregate Quality Monitoring Program (AQMP) managed by the Geotechnical,

Soils and Aggregates Branch within TxDOT’s Construction Division/Materials

& Pavements Section (CST/M&P)

Monitors the quality of aggregate products supplied to TxDOT projects

Single sources are included based on the testing history of aggregate

products used for TxDOT construction projects

– Bituminous coarse aggregate

– Concrete fine aggregate

– Concrete coarse aggregate

– Micro-surfacing aggregate

2017 Transportation Short Course October 11, 2017 3

Aggregate Quality Monitoring Program

Durability laboratory tests performed biannually for each source:

• L.A. Abrasion

• Magnesium Sulfate Soundness

• Micro-Deval

• Acid Insoluble

• Coefficient of Thermal Expansion (CoTE)

Statistical evaluation of recent testing history

– Rated values produced and published online & reported in Site Manager

– Bituminous Rated Source Quality Catalog (BRSQC)

– Concrete Rated Source Quality Catalog (CRSQC)

2017 Transportation Short Course October 11, 2017 4

What is the AQMP?

Sources currently in the program are located in:

– Texas

– New Mexico

– Oklahoma

– Arkansas

– Louisiana

– Mexico.

97 sources on the BRSQC

168 sources on the CRSQC

61 sources on both catalogs

2017 Transportation Short Course October 11, 2017 5

Aggregate Sources on the BRSQC and CRSQC

2017 Transportation Short Course October 11, 2017 6

The Purpose of the AQMP

Provides requirements & procedures for CST/M&P to monitor aggregate

products demonstrating continuous quality and uniformity

Allows TxDOT Districts to use the rated values from sources on the AQMP

without project specific testing

– Districts do not have to perform laboratory tests on AQMP

– Expedites acceptance of aggregate meeting specification requirements

Provides continuous quality assurance of aggregate products

2017 Transportation Short Course October 11, 2017 7

Polling Question #1

Which District has the most sources

listed on the AQMP?

2017 Transportation Short Course October 11, 2017 8

2017 Transportation Short Course October 11, 2017 9

Responsibilities

CST/M&P

TxDOT Districts

Aggregate Producers

2017 Transportation Short Course October 11, 2017 10

Responsibilities

CST/M&P

Requesting Quality Monitoring (QM) samples biannually

Laboratory testing of QM, project & informational samples for

properties listed on AQMP

Performing & reporting test results

Maintaining the BRSQC and CRSQC

Notifying Districts & aggregate producer of any quality concerns

Evaluation of source’s quality control plan and test results

Did you know?

Over the last 10 years, CST/M&P - Aggregates Lab on average has completed the

testing of 1650 samples annually.

2017 Transportation Short Course October 11, 2017 11

Responsibilities

TxDOT Districts

Sampling QM & project samples and providing documentation

Shipping or delivering samples to CST/M&P

Offering split samples at the time of sampling with aggregate producer

Job control (project level) testing

Final acceptance of aggregate

Submitting a QM sample from project when material has questionable

quality

Safety - Signing in/out at the quarry & following site specific safety

procedures

Did you know?

The San Antonio District has the most sources on the AQMP and the Tyler District

has the least.

2017 Transportation Short Course October 11, 2017 12

Responsibilities

Aggregate Producers

Notifying CST/M&P of changes in ownership and maintaining current

contact information

Submitting a mining & quality control plan, GPS data and requested

documents

Submitting driving directions to the source from District Lab

Maintaining identification of stockpiles at the quarry at all times

Notifying CST/M&P and the District if split samples are desired

Did you know?

Since 2000, the Aggregates Lab has tested aggregate from over 450 sources.

2017 Transportation Short Course October 11, 2017 13

Polling Question #2

How often are the aggregate MPLs

updated within a year?

2017 Transportation Short Course October 11, 2017 14

2017 Transportation Short Course October 11, 2017 15

Products and Tests Covered in AQMP

Laboratory Tests

Aggregate Products L.A. MgSO4 Acid Insoluble

Micro-Deval CoTE

Abrasion Soundness Residue

(Tex-461-A) (Tex-428-A)

(Tex-410-A) (Tex-411-A) (Tex-612-J)

Concrete Fine Aggregate

Concrete Coarse Aggregate

Bituminous Coarse Aggregate

Micro-Surfacing Aggregate

2017 Transportation Short Course October 11, 2017 16

Products and Tests Covered in AQMP

SAC A SAC B SAC C

Magnesium Sulfate Soundness

(Tex-411-A) 25 30 35

Maximum value

Acid Insoluble Residue

(Tex-612-J) 55 -- --

Minimum value

Crushed Face Count

(Tex-460-A) 85 85 85

Minimum value

Surface Aggregate Classification (SAC)

As determined in Tex-499-A, Table 1

2017 Transportation Short Course October 11, 2017 17

Polling Question #3

How many project samples are

necessary to complete before the rated

values can be calculated?

2017 Transportation Short Course October 11, 2017 18

2017 Transportation Short Course October 11, 2017 19

AQMP Tests

L.A. Abrasion

Performed in accordance to Tex-410-A (ASTM C131)

Resistance to degradation by impact and abrasion forces

Test samples of different gradations A, B, C, and D

500 revolutions at 33 rpms

Steel spheres with a diameter of ~2 inches and weight of ~1 lb

Loss determined by material passing the #12 sieve

Specification limits vary

2017 Transportation Short Course October 11, 2017 20

L.A. Abrasion (Tex-410-A)

2017 Transportation Short Course October 11, 2017 21

L.A. Abrasion

Specification Limits

Item 330,

340, 341, Limestone Rock Asphalt (LRA), Dense-Graded HMA, Concrete 40%

421

Item 302, Seal Coat & Superpave HMA 35%

344

Item 342, Permeable Friction Course (PFC), Stone Matrix

346, 347, Asphalt (SMA), Thin Overlay Mixtures (TOM), & 30%

348 Thin Bonded Friction Courses

0 5 10 15 20 25 30 35 40 45%

2017 Transportation Short Course October 11, 2017 22

AQMP Tests

Magnesium Sulfate Soundness

Performed in accordance to Tex-411-A

Resistance to degradation/disintegration by wetting and drying cycles

Wetting duration of 16-18 hours submerged in magnesium sulfate solution

Drying duration of 4-6 hours in 230°F oven

Rinse cycle in 110°F water until samples completely free of salt

Magnesium Sulfate soundness solution temperature and specific gravity

controls

Loss determined by normalized gradation specific to product type

Specification limits vary

2017 Transportation Short Course October 11, 2017 23

Magnesium Sulfate Soundness (Tex-411-A)

2017 Transportation Short Course October 11, 2017 24

Magnesium Sulfate Soundness (Tex-411-A)

2017 Transportation Short Course October 11, 2017 25

Magnesium Sulfate Soundness

Specification Limits

Item 330,

340, 341, Limestone Rock Asphalt (LRA), Dense-Graded HMA, Concrete 30%

421

Item 302, Seal Coat & Superpave HMA, Microsurfacing

344, 350 25%

Item 342,

346, 347, PFC, SMA, TOM, & Thin Bonded Friction Courses 20%

348

0 5 10 15 20 25 30 35%

2017 Transportation Short Course October 11, 2017 26

AQMP Tests

Micro-Deval

Performed in accordance to Tex-461-A

Resistance to degradation by abrasion forces

Aggregate added to 3/8” diameter steel spheres and water for test

Tested at 100 rpms for 120, 105, 95 or 15 minutes depending on gradation

Rinsed over stacked sieves and oven dried to determine the loss

No specification limit, used as quality control test

2017 Transportation Short Course October 11, 2017 27

Micro-Deval (Tex-461-A)

2017 Transportation Short Course October 11, 2017 28

AQMP Tests

Acid Insoluble Residue

Performed in accordance to Tex-612-J

Resistance to dissolution by Hydrochloric (HCl) acid

Test sample consists of 25 grams

HCl acid added to sample until reaction is complete

Sample rinsed with distilled or deionized water

Specification limits for concrete fine aggregate and bituminous coarse

aggregate to determine SAC

2017 Transportation Short Course October 11, 2017 29

Acid Insoluble Residue

Specification Limits

Item 421

Fine Hydraulic Cement Concrete 60%

Aggregate

SAC A Hot-Mix Asphalt & Seal Coats 55%

SAC B & C No Requirement

0 10 20 30 40 50 60 70%

2017 Transportation Short Course October 11, 2017 30

AQMP Tests

Coefficient of Thermal Expansion (CoTE)

Performed in accordance to Tex-428-A

Determine the thermal expansion of aggregate in concrete

Standard mix design

Test cylinders are cured for 28 days before testing

Temperature cycling from 50°F to 120°F and reduced to 50°F

3 cycles and continuous data collection

Specification limit of 5.5 µstrains/°F for Item 360

No project level testing for a source which has a rated value on the CRSQC

2017 Transportation Short Course October 11, 2017 31

Coefficient of Thermal Expansion (Tex-428-A)

2017 Transportation Short Course October 11, 2017 32

Polling Question #4

Does a source have to be on the AQMP

in order to supply aggregate to a TxDOT

project?

2017 Transportation Short Course October 11, 2017 33

2017 Transportation Short Course October 11, 2017 34

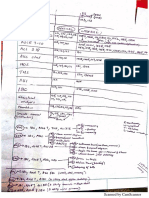

AQMP Process of Adding Sources

Provide Supply

Informational Producer – Aggregate

Quarry Catalogs Updated

Sample Product to

Information TxDOT Project Testing &

Approval of

Project

Aggregate Samples

Producer

and District

Informed

Mining Plan

Submitted

Site

Manager Ratings

Updated Developed for

Aggregate

Product

2017 Transportation Short Course October 11, 2017 35

AQMP Process of Adding Sources

Provide

Informational Producer –

Sample Quarry

Information

One informational sample can be sampled and tested from final product

stockpiles for each aggregate product per aggregate source

Raw uncrushed/unprocessed rock will not be tested

The results from the informational sample can be used to solicit material to

contractors for potential use for TxDOT projects

The informational sample does not count towards the AQMP and does not

pre-approve a stockpile or source

Owner of aggregate source completes Producer-Quarry Information form

Ship samples to CST/M&P at Cedar Park Campus in Austin

2017 Transportation Short Course October 11, 2017 36

AQMP Process of Adding Sources

Supply

Aggregate

Product to

TxDOT Project Testing &

Approval of

Project

Samples

Once the aggregate product from a source is being supplied to a TxDOT

project(s), the aggregate producer will coordinate with the TxDOT District

to begin sampling the stockpiles designated for the project

Stockpile approval is on a stockpile by stockpile basis

CST/M&P performs durability testing as testing lab for TxDOT Districts

2017 Transportation Short Course October 11, 2017 37

AQMP Process of Adding Sources

The aggregate producer is responsible for furnishing the mining

plan and quality control testing of their aggregate

Mining plan - a topographical or aerial map showing the

property lines and shaded areas of current and future Mining Plan

Submitted

production

Flow chart - description of the production of the aggregate

from the ground to the final product in stockpiles

Aggregate supplier’s quality control testing plan and testing

frequency

Driving directions to pit or quarry

2017 Transportation Short Course October 11, 2017 38

AQMP Process of Adding Sources

Five project samples per aggregate product conforming to the items

found in Section 4 of Tex-499-A are used to develop the rated value

One month between each project sample

Test results meet all the standard specification quality

requirements

Statistical ratings of the test results meet the standard

specification requirements

The results of the aggregate product are reviewed prior to being

approved for addition to the AQMP

Site

Site Manager updated for District use Manager

Updated

Ratings

Developed for

Aggregate

Product

2017 Transportation Short Course October 11, 2017 39

AQMP Process of Adding Sources

Catalogs Updated

Aggregate The aggregate producer and the TxDOT District will be

Producer

and District

notified via e-mail of the source’s addition to the AQMP

Informed

The e-mail will contain the rated values, the AQMP

producer code and the Site Manager producer code

The online catalog will be updated accordingly with the

next scheduled update

For out of state/country sources, TxDOT must have

access to aggregate stockpile(s) within Texas to

sample for the AQMP to check for routine compliance

and material consistency

2017 Transportation Short Course October 11, 2017 40

Basics of Aggregates

Questions?

2017 Transportation Short Course October 11, 2017 41

S-ar putea să vă placă și

- Brandin LeBlanc - Revised PDFDocument3 paginiBrandin LeBlanc - Revised PDFvrb1260% (3)

- Equipment Pre Mobilization ChecklistDocument26 paginiEquipment Pre Mobilization ChecklistCendi Grab100% (2)

- Fyp PresentationDocument31 paginiFyp PresentationValiant ParaPluieÎncă nu există evaluări

- Steam TurbineDocument28 paginiSteam Turbineakusuper88% (8)

- FEBRUARY, 2021 G.C Bahir Dar, EthiopiaDocument31 paginiFEBRUARY, 2021 G.C Bahir Dar, EthiopiaAlebachewÎncă nu există evaluări

- 2022.08.08-JAEQR CON 2022533 (DR 2740 - Package IV & V TEST Reports of The Aggregate)Document87 pagini2022.08.08-JAEQR CON 2022533 (DR 2740 - Package IV & V TEST Reports of The Aggregate)Ruwan Sampath WickramathilakaÎncă nu există evaluări

- The Mechanical Properties of Asphalt Mixtures WithDocument7 paginiThe Mechanical Properties of Asphalt Mixtures WithAyesahÎncă nu există evaluări

- The Mechanical Properties of Asphalt Mixtures With PDFDocument7 paginiThe Mechanical Properties of Asphalt Mixtures With PDFAyesahÎncă nu există evaluări

- Polymer Modified Asphalt EmulsionsDocument26 paginiPolymer Modified Asphalt EmulsionsdodifaisholÎncă nu există evaluări

- R K JAIN Concrete Options IRC 2019 PDFDocument134 paginiR K JAIN Concrete Options IRC 2019 PDFVikas ThakarÎncă nu există evaluări

- Development of A Universal Accelerated Test For Alkali-Silica and Alkali-Carbonate Reactivity of Concrete AggregatesDocument13 paginiDevelopment of A Universal Accelerated Test For Alkali-Silica and Alkali-Carbonate Reactivity of Concrete AggregatesВладиславÎncă nu există evaluări

- Bahia Wisconsin UpdateDocument19 paginiBahia Wisconsin UpdateMehdi FarrokhiÎncă nu există evaluări

- Romel GeorgeesDocument11 paginiRomel GeorgeesGregorioÎncă nu există evaluări

- Recycling PS in MortarDocument17 paginiRecycling PS in MortarPrashanth PrabhakarÎncă nu există evaluări

- Carbonation Resistance and Microstructural Analysis of Low and High Volume Fly Ash Self Compacting Concrete Containing Recycled Concrete AggregatesDocument15 paginiCarbonation Resistance and Microstructural Analysis of Low and High Volume Fly Ash Self Compacting Concrete Containing Recycled Concrete AggregatesPurandhar ReddiÎncă nu există evaluări

- A Review in High Early Strength Concrete and Local PDFDocument10 paginiA Review in High Early Strength Concrete and Local PDFAgikx ChabeÎncă nu există evaluări

- Transport and Main Roads Specifications MRTS46 Skid Resistant Friction Coating For Steel Road PlatesDocument7 paginiTransport and Main Roads Specifications MRTS46 Skid Resistant Friction Coating For Steel Road PlatesJose SahuquillozÎncă nu există evaluări

- Air-Cured Alkali Activated Binders For Concrete PavementsDocument7 paginiAir-Cured Alkali Activated Binders For Concrete PavementsAbd El Nour KahlochÎncă nu există evaluări

- Assessment of Printed Circuit Board SolderabilityDocument4 paginiAssessment of Printed Circuit Board SolderabilitysmtdrkdÎncă nu există evaluări

- Sustainable Cities and Society: Alireza Mohammadinia, Arul Arulrajah, Hamed Haghighi, Suksun HorpibulsukDocument8 paginiSustainable Cities and Society: Alireza Mohammadinia, Arul Arulrajah, Hamed Haghighi, Suksun Horpibulsukvaishnavi endluruÎncă nu există evaluări

- Coating ProcedureDocument11 paginiCoating Procedureyoussef gaafarÎncă nu există evaluări

- Carbon Nano-Concrete Paper - 2Document6 paginiCarbon Nano-Concrete Paper - 2Mainak GhosalÎncă nu există evaluări

- Development of High Early-Strength Concrete For Accelerated Bridge Construction Closure Pour ConnectionsDocument12 paginiDevelopment of High Early-Strength Concrete For Accelerated Bridge Construction Closure Pour ConnectionsSatyabrata MishraÎncă nu există evaluări

- 15 Durability - Petkovic - Recycled Concrete Aggregate Durability AspectsDocument10 pagini15 Durability - Petkovic - Recycled Concrete Aggregate Durability AspectsIulia AlmasÎncă nu există evaluări

- Rohs Implementation: OutlineDocument16 paginiRohs Implementation: Outlineradule021Încă nu există evaluări

- A86636-2 Condition 22 - Pressure Test Plan - A5V2R7Document20 paginiA86636-2 Condition 22 - Pressure Test Plan - A5V2R7davis_gpr21Încă nu există evaluări

- Evaluation Test of Applicability of Fire Extinguishing System inDocument21 paginiEvaluation Test of Applicability of Fire Extinguishing System inK.SivanathanÎncă nu există evaluări

- Scale Up ARDDocument71 paginiScale Up ARDFernandoÎncă nu există evaluări

- Mixture Design Consideration For Foamed Asphalt UsDocument9 paginiMixture Design Consideration For Foamed Asphalt UsBurak BulutÎncă nu există evaluări

- Aberdeen Branch: Corrosion Under InsulationDocument2 paginiAberdeen Branch: Corrosion Under InsulationMohan RajÎncă nu există evaluări

- EIA NMDC Pellet PlantDocument437 paginiEIA NMDC Pellet Plantkselvan_1Încă nu există evaluări

- New Recommendations ASR Mitigation USBRDocument24 paginiNew Recommendations ASR Mitigation USBRfdelfinÎncă nu există evaluări

- Mek6222310 - 1Document14 paginiMek6222310 - 1Srinivas KosuriÎncă nu există evaluări

- Carbon Dioxide Utilization in Ready-Mixed Concrete ProductionDocument24 paginiCarbon Dioxide Utilization in Ready-Mixed Concrete Productionjack21ab100% (1)

- Roads 08 Spray Sealing TDO 04oct2022Document31 paginiRoads 08 Spray Sealing TDO 04oct2022FehkalÎncă nu există evaluări

- Al-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Document10 paginiAl-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Saif LlÎncă nu există evaluări

- Zofka CBM 2012Document11 paginiZofka CBM 2012Gesese GankaÎncă nu există evaluări

- BANPDCDocument10 paginiBANPDCRahul KumarÎncă nu există evaluări

- Study of Sustainable High Performance Bituminous MixturesDocument9 paginiStudy of Sustainable High Performance Bituminous Mixturessomesh2727Încă nu există evaluări

- Nepcoat 2022Document7 paginiNepcoat 2022jennifergiannouÎncă nu există evaluări

- UWI Lecture 2024 - Stabilised Aggregates Bases - Subbases in Road Construction and RehabilitationDocument52 paginiUWI Lecture 2024 - Stabilised Aggregates Bases - Subbases in Road Construction and RehabilitationJumaane ShakespeareÎncă nu există evaluări

- Challenges in Life Cycle Assessment (LCA) of Stabilised Clay-Based Construction MaterialsDocument10 paginiChallenges in Life Cycle Assessment (LCA) of Stabilised Clay-Based Construction MaterialsNovita Hillary Christy DamanikÎncă nu există evaluări

- Presentacion - WinPAS - AASHTO 93Document9 paginiPresentacion - WinPAS - AASHTO 93Fabricio OrtegaÎncă nu există evaluări

- ASR MitigationDocument24 paginiASR Mitigationcamilorios11Încă nu există evaluări

- 1 s2.0 S2214509522008488 MainDocument13 pagini1 s2.0 S2214509522008488 MainZrar IsqeliÎncă nu există evaluări

- Enhancing Pipeline Integrity Using ECDA: July 2018Document5 paginiEnhancing Pipeline Integrity Using ECDA: July 2018Tania NoorÎncă nu există evaluări

- 17 Memorandums - Materials & Research Memorandums PDFDocument24 pagini17 Memorandums - Materials & Research Memorandums PDFFaruk AtalarÎncă nu există evaluări

- Chemilink Intoduction Aug 2018Document52 paginiChemilink Intoduction Aug 2018Mohd NasharuddinÎncă nu există evaluări

- Evaluation of Recycled Concrete As Aggregates in New Concrete PavementsDocument7 paginiEvaluation of Recycled Concrete As Aggregates in New Concrete PavementsAHMED ABDEINÎncă nu există evaluări

- Article For Greenhighway 1-2-08Document6 paginiArticle For Greenhighway 1-2-08Brhane W YgzawÎncă nu există evaluări

- Nadcap Scope 189936Document2 paginiNadcap Scope 189936amirkhakzad498Încă nu există evaluări

- McKinney Et Al, - SPE-109861-MSDocument16 paginiMcKinney Et Al, - SPE-109861-MSLecturer Hussein AliwiÎncă nu există evaluări

- Project Report R141898Document23 paginiProject Report R141898KAushik KaRavadiÎncă nu există evaluări

- Performance Assessment of Natural Pozzolan Roller Compacted Concrete PavementsDocument9 paginiPerformance Assessment of Natural Pozzolan Roller Compacted Concrete PavementsMarinaÎncă nu există evaluări

- First-Year Field Performance of Epoxy-Modified AsphaltDocument13 paginiFirst-Year Field Performance of Epoxy-Modified AsphaltAKINMADE OLUWATOSINÎncă nu există evaluări

- Wood Ash 17Document44 paginiWood Ash 17r;rÎncă nu există evaluări

- BFC 31802 Chapter 3b-1Document15 paginiBFC 31802 Chapter 3b-1Muhammad HafizÎncă nu există evaluări

- KJCEpaper PublishedpaperDocument15 paginiKJCEpaper PublishedpaperSiddharthBhasneyÎncă nu există evaluări

- 1 Sustainable Asphalt Intro WebDocument31 pagini1 Sustainable Asphalt Intro WebNasrulÎncă nu există evaluări

- Prof. Yang - Sustainability in Road Infrastructure in TaiwanDocument27 paginiProf. Yang - Sustainability in Road Infrastructure in TaiwanYasruddin MtÎncă nu există evaluări

- Le GroupDocument10 paginiLe Groupabhishek negiÎncă nu există evaluări

- Sustainable Winter Road OperationsDe la EverandSustainable Winter Road OperationsXianming ShiÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemÎncă nu există evaluări

- GDNA-CXM Managers Guide v.1.1Document70 paginiGDNA-CXM Managers Guide v.1.1vrb126Încă nu există evaluări

- University Curriculum Committee: Course ManagementDocument2 paginiUniversity Curriculum Committee: Course Managementvrb126Încă nu există evaluări

- Foundations of Division Using Area Models: Follow Along With The Video and Take NotesDocument2 paginiFoundations of Division Using Area Models: Follow Along With The Video and Take Notesvrb126Încă nu există evaluări

- Weight Lifting Complete Guide (ENG) PDFDocument36 paginiWeight Lifting Complete Guide (ENG) PDFvrb126Încă nu există evaluări

- Sunday School LyricsDocument4 paginiSunday School Lyricsvrb126Încă nu există evaluări

- 4 University Curriculum Committee ChargeDocument1 pagină4 University Curriculum Committee Chargevrb126Încă nu există evaluări

- 8 Ucc Sacscoc FR 10 7 Credit HoursDocument1 pagină8 Ucc Sacscoc FR 10 7 Credit Hoursvrb126Încă nu există evaluări

- AppMech ActiveWorkbook-KEYDocument6 paginiAppMech ActiveWorkbook-KEYvrb126Încă nu există evaluări

- AppMech Active-WorkbookDocument6 paginiAppMech Active-Workbookvrb126Încă nu există evaluări

- Applied Mechanics: Learn MoreDocument42 paginiApplied Mechanics: Learn Morevrb126Încă nu există evaluări

- Research Project Statement 20-247 FY 2020 Annual Program: Title: The ProblemDocument1 paginăResearch Project Statement 20-247 FY 2020 Annual Program: Title: The Problemvrb126Încă nu există evaluări

- PmcinemaDocument3 paginiPmcinemavrb126Încă nu există evaluări

- 6 Ucc Program Management ChecklistDocument1 pagină6 Ucc Program Management Checklistvrb126Încă nu există evaluări

- Lambda Moodle Installation Setup Guide PDFDocument15 paginiLambda Moodle Installation Setup Guide PDFvrb126Încă nu există evaluări

- Cee 316 Geosurveying Homework 5 Horizontal and Vertical CurvesDocument1 paginăCee 316 Geosurveying Homework 5 Horizontal and Vertical Curvesvrb126Încă nu există evaluări

- Required Courses For All Geoscience Degrees: Choose Three of The Following: 9-11Document1 paginăRequired Courses For All Geoscience Degrees: Choose Three of The Following: 9-11vrb126Încă nu există evaluări

- Applying The QM Rubric: Syllabus: DescriptionDocument3 paginiApplying The QM Rubric: Syllabus: Descriptionvrb126Încă nu există evaluări

- Research Project Statement 20-211 FY 2020 Annual Program: Title: The ProblemDocument2 paginiResearch Project Statement 20-211 FY 2020 Annual Program: Title: The Problemvrb126Încă nu există evaluări

- RFP 19-Ltap: Local Technical Assistance Program (Ltap)Document11 paginiRFP 19-Ltap: Local Technical Assistance Program (Ltap)vrb126Încă nu există evaluări

- Cven 2235 - Assignment 2 Assignment Submission InstructionsDocument6 paginiCven 2235 - Assignment 2 Assignment Submission Instructionsvrb126Încă nu există evaluări

- Research Project Statement 20-075 FY 2020 Annual Program: Title: The ProblemDocument1 paginăResearch Project Statement 20-075 FY 2020 Annual Program: Title: The Problemvrb126Încă nu există evaluări

- Civic Engagement Workshop - Final With ReferencesDocument17 paginiCivic Engagement Workshop - Final With Referencesvrb126Încă nu există evaluări

- Research Project Statement 20-008 FY 2020 Annual Program: Title: The ProblemDocument1 paginăResearch Project Statement 20-008 FY 2020 Annual Program: Title: The Problemvrb126Încă nu există evaluări

- 2013 LCCA Procedures ManualDocument2 pagini2013 LCCA Procedures Manualvrb126Încă nu există evaluări

- FUTURE STRUCTURAL ENGINEER - Where Will We Be in 10 Years - Structural Engineering Art and ApproximationDocument11 paginiFUTURE STRUCTURAL ENGINEER - Where Will We Be in 10 Years - Structural Engineering Art and Approximationvrb126Încă nu există evaluări

- Homework 7Document1 paginăHomework 7vrb126Încă nu există evaluări

- Application of Time Series Analysis For Bridge Monitoring: ArticleDocument26 paginiApplication of Time Series Analysis For Bridge Monitoring: Articlevrb126Încă nu există evaluări

- Question DistributionDocument1 paginăQuestion Distributionvrb126Încă nu există evaluări

- En1992 ManualDocument80 paginiEn1992 ManualLuana PamelaÎncă nu există evaluări

- Fiberbond Fiberglass Piping Systems Series 110FW: DescriptionDocument2 paginiFiberbond Fiberglass Piping Systems Series 110FW: DescriptionIbhar Santos MumentheyÎncă nu există evaluări

- KPS Inst Manual Ver 6 (1) .1 EngDocument56 paginiKPS Inst Manual Ver 6 (1) .1 EngMiroslav RakicÎncă nu există evaluări

- P20 Tool Steel DescriptionDocument5 paginiP20 Tool Steel DescriptionJAFFERÎncă nu există evaluări

- RD2.0E To RD200E: Zener DiodesDocument12 paginiRD2.0E To RD200E: Zener DiodesДрагиша Небитни ТрифуновићÎncă nu există evaluări

- Solution3 HIT Optical FiberDocument10 paginiSolution3 HIT Optical FiberMichael NaymarkÎncă nu există evaluări

- Tapas Question Paper 2017 PDFDocument20 paginiTapas Question Paper 2017 PDFRamesh G100% (1)

- Effect of Thermal Stress On Creep Lifetime For A Gas Turbine Combustion LinerDocument7 paginiEffect of Thermal Stress On Creep Lifetime For A Gas Turbine Combustion LinerSriram GanesanÎncă nu există evaluări

- 3.2 Question Bank MCQ OpticsDocument5 pagini3.2 Question Bank MCQ OpticsPrathamesh Nawale100% (1)

- Lecture 1: Fundamentals 1/3: Discretization Of: Convection-Diffusion Equation by Finite Difference MethodDocument27 paginiLecture 1: Fundamentals 1/3: Discretization Of: Convection-Diffusion Equation by Finite Difference MethodJulio Santos100% (1)

- Quantum Dots - A Variety of New ApplicationsDocument290 paginiQuantum Dots - A Variety of New ApplicationsJosé RamírezÎncă nu există evaluări

- 3rd ICAMPN Circular Rev 1Document10 pagini3rd ICAMPN Circular Rev 1Nashrullah Fathullah PrawiraWinataÎncă nu există evaluări

- 1-Intro and First UnitDocument39 pagini1-Intro and First Unitsahale sheraÎncă nu există evaluări

- Introduction To Weibull Analysis Ver4Document113 paginiIntroduction To Weibull Analysis Ver4arkcool100% (2)

- Materials 99 Magnetic Materials PDFDocument57 paginiMaterials 99 Magnetic Materials PDFNur Aini HaryatiÎncă nu există evaluări

- Modeling Blue Shift in Moonlit Scenes by Rod Cone InteractionDocument5 paginiModeling Blue Shift in Moonlit Scenes by Rod Cone InteractionNASAdocumentsÎncă nu există evaluări

- Dynamics Homework 2Document3 paginiDynamics Homework 2Ayrton Medina PanezÎncă nu există evaluări

- 3850 Certificate in Mathematics - Sample Paper Stage 3: Candidate Name (First, Middle, Last)Document20 pagini3850 Certificate in Mathematics - Sample Paper Stage 3: Candidate Name (First, Middle, Last)shan100% (1)

- Trigonometry 02 - Class Notes - Trigonometry-2Document34 paginiTrigonometry 02 - Class Notes - Trigonometry-2Himanshu SinghÎncă nu există evaluări

- 9 - Footings Footings: Footings Definition Footings DefinitionDocument25 pagini9 - Footings Footings: Footings Definition Footings DefinitionMotamed Ben TaherÎncă nu există evaluări

- Investigation of Chloro Pentaammine Cobalt (III) Chloride - Polyvinyl Alcohol CompositesDocument5 paginiInvestigation of Chloro Pentaammine Cobalt (III) Chloride - Polyvinyl Alcohol CompositesAlexander DeckerÎncă nu există evaluări

- Exam in Pre-CalculusDocument1 paginăExam in Pre-CalculusmarkÎncă nu există evaluări

- EEM Unit 2Document20 paginiEEM Unit 2Bhavesh BodkeÎncă nu există evaluări

- Steel Castings HandbookDocument58 paginiSteel Castings Handbookgalici2002100% (3)

- Q. 1-Q.30 Carry One Mark Each: India's No.1 Institute For GATE Chemical Engineering CH-1Document29 paginiQ. 1-Q.30 Carry One Mark Each: India's No.1 Institute For GATE Chemical Engineering CH-1PANKAJ AGRAHARIÎncă nu există evaluări

- STK673-010 3-Phase Stepping Motor Driver (Sine Wave Drive) Output Current 2.4ADocument16 paginiSTK673-010 3-Phase Stepping Motor Driver (Sine Wave Drive) Output Current 2.4AMzsenna Opcional MzsennaÎncă nu există evaluări

- NSC 200-250/D271DC4-ADV: Technical DataDocument3 paginiNSC 200-250/D271DC4-ADV: Technical DatajtorerocÎncă nu există evaluări