Documente Academic

Documente Profesional

Documente Cultură

Details of Residential Scope

Încărcat de

Syed ZamanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Details of Residential Scope

Încărcat de

Syed ZamanDrepturi de autor:

Formate disponibile

No 720

Page 1 of 5

Date 10/20/2010

Technical Bulletin

RESIDENTIAL ROOFING

Typical construction for residential roofing consists of rafters or trusses spaced 16" or 24" on

center and at a pitch, or roof slope, of 3/12 up to 12/12. A plywood, Oriented Strand Board -- OSB

(this product is becoming more common), or wafer board (flake board) is used as a decking on top of

the rafters/trusses. This decking provides two properties - one, it helps brace the framing in a

diaphragm load or "racking" and, secondly, it provides a solid surface to attach the roof covering.

A 30# asphalt impregnated felt paper or any synthetic underlayment is the next item. The

weight, or thickness, is determined by code stipulations. This felt is either tacked in place by staples

or, in some regions of the USA, it is required to be nailed down in a specific pattern with roofing

nails and/or nails with or caps. The Caps are a thin plastic washer, typically quarter sized, and

larger than the nail head; this aids in holding more surface of the felt paper in place.

Once all these items are in place, the roof covering is attached to shed the rain and snow and

to protect the contents of the building from the natural elements and conditions. Various roof

coverings include, but are not limited to: shingles, cement tiles, clay tiles, rubber, asphalt rolls, tar,

wood shakes, slate, and METAL. Zoning and code restrictions must be reviewed to determine what

type of roof coverings are acceptable in neighborhoods, local communities, developments, cities,

counties, state, or regional areas.

When using metal or Grandrib 3, 5V Crimp, , Strongrib (exposed fastener panels) in

particular, certain conditions must be determined and proper application is important. The

construction of rafters/trusses is to be designed and adequate - a house designed to have shingles

(typical weight: 2.5 to 3.4 pounds per square foot) will support Grandrib 3 panels (weight: .8 lbs/sq.

ft.) sufficiently. A minimum 2-1/2" rise in 12" horizontal (2-1/2 / 12 pitch) is required for Grandrib

3 or exposed fastener panels. The decking material may be 7/16” OSB or thicker. When using

OSB, #14 Screws are recommended to obtain the proper pull-out strength.

Grandrib 3 panels are to be applied according to General Installation Instructions. The

application over plywood for residential should include the following changes. A good gun-grade

butyl or sealant tape should be placed along the entire sidelap (see diagram) to ensure a

weatherproof lap.

Screw fastening is recommended because it provides a better sealing quality, better

withdrawal or uplift load resistance, and stays securely fastened in place over the life span of the

roof. Nails tend to back out slightly over years of exposure to the elements which can cause leaks or

extra maintenance to the roof. #14x1" Mill Points or "A" points are to be used for attachment of the

metal to the plywood, or OSB. A #9 Woodgrip screw does not have sufficient thread depth to work

properly into plywood or OSB. The #14 has the larger thread diameter and depth which provides

more withdrawal resistance (see chart) and better installation ease.

M:\Communication (bulletins, monthly emails, etc.)\Bulletins\Engineering\Tech Bulletins for Website\TB720

Residential.doc

No 720

Page 2 of 5

Date 10/20/2010

Technical Bulletin

The application of screws across the width of the profile is of the same pattern as shown in

the General Installation Instructions (see diagram). The spacing of the screws up the slope of the

roof must be determined by the contractor, architect or engineer to meet the code requirements for

wind uplift in the particular geographical region of the application. Roof height, slope, shape, and

location are all taken into account for the uplift design (see chart for uplift resistance vs. screw

spacing).

Besides the main roof area, other roof areas such as the gable, ridge, eave, valley, endlaps,

and hips must be reviewed for extra fastening conditions. These areas are prone to increased uplift

criteria and should be calculated to determine the fastening patterns. For greater fastener resistance

to uplift, furring strips or purlins can be attached on top of the felt paper/plywood/rafters. The

furring strips/purlin thickness is best recommended as a 2" x 4" (allows for 1-1/2" of screw

engagement). Pine or Spruce is the best softwood species. A 1 x 4 or 1 x 6 (only gives 7/8" of

actual wood depth for screw engagement) is a viable option as long as the screw withdrawal strength

is calculated for the reduction in wood thickness penetration.

M:\Communication (bulletins, monthly emails, etc.)\Bulletins\Engineering\Tech Bulletins for Website\TB720

Residential.doc

No 720

Page 3 of 5

Date 10/20/2010

Technical Bulletin

FURRING/PURLINS (see note 3)

The furring or purlins are recommended to be attached with deck or wood screws long

enough to allow for 1” penetration into the rafter. The screws are located at a maximum of 8" o.c.

along the furring, into the plywood and through to the rafters at the 16" rafter spacing. The 30# felt

can be applied to the plywood under the furring/purlin or on top of the furring/purlin. The felt acts

as a vapor barrier to prevent moisture from within the house from reaching the metal roof which

holds a temperature close to the outside temperature. If warm moisture from within is allowed to

reach a cold metal or other roofing products, condensation can occur. If condensation occurs, the

water droplets gather and can leak into the house which gives the owner the perception that the roof

is "leaking." Proper ventilation at the eave soffit and gable/ridge is essential to prevent

condensation.

Flashing and finishing the residential home is done with low profile, smaller accessories than

typical post-frame construction. Fabral provides a number of residential details to satisfy any

builder’s aesthetic and practical needs. Sealing the sidelaps is recommended for extra protection

against moisture or snow/ice from gaining entrance in through the metal roof laps.

Insulation can be used with metal roofing for two purposes. First, it dampens the sound that

rain makes on metal. Insulation is great for reducing the noise in any application, not just metal.

Secondly, it provides condensation protection. Proper insulation design is essential for heating and

cooling protection. A good vapor barrier in conjunction with proper ventilation will provide a dry

area on the inside of the roof structure.

Another form of residential construction, not quite as common, is purlins/furring attached

directly to the rafters/trusses. This form eliminates the structural wood decking. This type of

construction requires more diaphragm evaluation, enhanced bracing and vapor barrier application. If

this construction is applicable (check local codes), the purlins/furring are recommended to be a

minimum 2x4 applied flat over the rafters/trusses and screw attached. For condensation prevention,

a quality vapor barrier should be applied to the warm side or underneath side, of the rafters/trusses.

Insulation can be located between the rafter/trusses running vertically and/or on top of the

purlins under the metal. 1-1/2" or 2" thick, compressible blanket insulation of .6 density is the

maximum thickness that can be applied between the purlins and the metal. Thicker or denser

material will "show through" the metal and be objectionable in appearance. A quarter inch thick or

1/2" thick foil faced, bubble insulation is commonly used in between the metal and the purlins to

provide a vapor barrier and condensation deterrent. The foil insulation provides enough dew point

temperature difference that prevents moisture from forming.

Cathedral type ceilings should be insulated between rafters and a good vapor barrier applied

to the bottom (warm) side of the rafter before drywall or boards are applied. This prevents moisture

from rising up through the ceiling and contacting the cold metal or other roofing material, on top of

M:\Communication (bulletins, monthly emails, etc.)\Bulletins\Engineering\Tech Bulletins for Website\TB720

Residential.doc

No 720

Page 4 of 5

Date 10/20/2010

Technical Bulletin

the roof.

METAL SELECTION

Aluminum is the best metal roofing option as far as longevity is concerned. Acid rain and

corrosive atmospheres (chimney, smoke stacks, etc..) that exist in today's environment can take a toll

on any roof. Grandrib 3 PLUS is the best steel panel to use for an exposed fastener metal roof.

Standing seam metal roofs are more expensive in comparison, but provide a clean, weather tight roof

in either steel or aluminum. Standing seams can be used for roofs that have slopes as low as a 1/12

pitch. Ultimately, the homeowner will decide what price range and what features they want in their

residential metal roof.

NOTES:

1. Refer to Fabral’s Storage and Installation Instructions, F-102 for additional information.

2. Use of furring/purlins - Non-treated lumber should be used for furring/purlins. Treated

lumber can have a variety of harmful substances that are incompatible with metal roofing. If

treated lumber is used, a separation should be provided between the metal and the wood.

This can be plastic sheeting, builders felt or bituminous paint. Please refer to Fabral

Technical Bulletin #803 for additional information on treated lumber.

M:\Communication (bulletins, monthly emails, etc.)\Bulletins\Engineering\Tech Bulletins for Website\TB720

Residential.doc

No 720

Page 5 of 5

Date 10/20/2010

Technical Bulletin

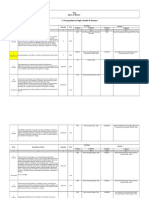

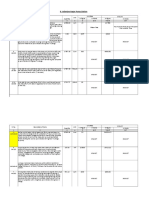

Chart

Typical Wind Speeds and Load ranges:

80 MPH = 14.7 Pounds per Square Foot (psf) to 21.3 psf

90 MPH = 18.7 psf to 27 psf

100 MPH = 23 psf to 33.3 psf

110 MPH = 27.9 psf to 40.3 psf

120 MPH = 33.2 psf to 48 psf

(120 squared X .00256 X .9 or X 1.3)

Grandrib 3 - screws spaced 9" c/c across width (see diagram) X up-slope spacing (see above)

Thickness #14-10

Plywood Up-slope Spacing c/c Design Load

1/2" Nom.. Plywood 12" 113.4 psf

5/8" Nom.. Plywood 12" 138.9 psf

3/4" Nom.. Plywood 12" 197.6 psf

1/2" Nom.. Plywood 18" 71.1 psf

5/8" Nom.. Plywood 18" 92.6 psf

3/4" Nom.. Plywood 18" 131.7 psf

1/2" Nom.. Plywood 24" 53.3 psf

5/8" Nom.. Plywood 24" 69.4 psf

3/4" Nom.. Plywood 24" 98.8 psf

Note: At 24" c/c spacing, Grandrib 3 requires approximately 80 screws per 100 square feet of metal

Diagram

M:\Communication (bulletins, monthly emails, etc.)\Bulletins\Engineering\Tech Bulletins for Website\TB720

Residential.doc

S-ar putea să vă placă și

- The Functions and Classification of RoofsDocument6 paginiThe Functions and Classification of RoofsKevin De Silva86% (7)

- Roofs Building ConstructionDocument38 paginiRoofs Building Constructionisaacwabbi100% (3)

- RPR 0130 00ugx 0 As TB0001 V0001Document10 paginiRPR 0130 00ugx 0 As TB0001 V0001Syed ZamanÎncă nu există evaluări

- Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureDocument36 paginiLoadings - NSCP 2015 - 2 Storey Residential Concrete StructureLimar Setatra100% (1)

- Detail Design Drawings: OCTOBER., 2017 Date Span Carriage WayDocument26 paginiDetail Design Drawings: OCTOBER., 2017 Date Span Carriage WayManvendra NigamÎncă nu există evaluări

- Building Enclosures Exterior Building Materials: Madhav Institute of Technology and Science GwaliorDocument18 paginiBuilding Enclosures Exterior Building Materials: Madhav Institute of Technology and Science Gwalioratharvasaxena93Încă nu există evaluări

- BC CladdingDocument21 paginiBC CladdingGurnoor SinghÎncă nu există evaluări

- Roof CoveringsDocument24 paginiRoof Coveringsdavid adawo100% (1)

- Standard Details For Metal Roofing & Siding: Post Frame and Residential StructuresDocument48 paginiStandard Details For Metal Roofing & Siding: Post Frame and Residential Structurespierre_oosthuizenÎncă nu există evaluări

- Pole Barn Metal DetailsDocument52 paginiPole Barn Metal DetailsKurt Stailey100% (1)

- NAFI Datafile FP1 (2005) - Timber External CladdingDocument18 paginiNAFI Datafile FP1 (2005) - Timber External Claddingsteveh49Încă nu există evaluări

- Framing GuideDocument15 paginiFraming Guidend_prasetya9706Încă nu există evaluări

- Research 1 PDFDocument5 paginiResearch 1 PDFKukishin KrimÎncă nu există evaluări

- Design of Diaphram & Shear WallsDocument36 paginiDesign of Diaphram & Shear WallsChidi HenryÎncă nu există evaluări

- 01 EavesDocument2 pagini01 EavesNatalie WyattÎncă nu există evaluări

- Construction Technology. 4th Sem CivilDocument12 paginiConstruction Technology. 4th Sem CivilZerro erAÎncă nu există evaluări

- Building Construction-V: Types of Metal CladdingDocument6 paginiBuilding Construction-V: Types of Metal CladdingShrish BaglaÎncă nu există evaluări

- VentureDeckingInstallationInstructions LRDocument13 paginiVentureDeckingInstallationInstructions LRGhislainTremblayÎncă nu există evaluări

- HWno.8.4 BSA-1A CORDIALDocument9 paginiHWno.8.4 BSA-1A CORDIALCharles Godwin CordialÎncă nu există evaluări

- Roof and Roofing Materials: Engr. Lito I. MauroDocument32 paginiRoof and Roofing Materials: Engr. Lito I. MauroGerald PrimaveraÎncă nu există evaluări

- Rigid Foam On The Roof and WallsDocument3 paginiRigid Foam On The Roof and WallsMike LojoÎncă nu există evaluări

- Cladding For BuildingsDocument8 paginiCladding For BuildingsCaryl Louise ObcianaÎncă nu există evaluări

- MinimumStandards - (Ext Wall Framing)Document14 paginiMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanÎncă nu există evaluări

- Tata Durashine ManualDocument16 paginiTata Durashine ManualBudha SinghÎncă nu există evaluări

- Assignment EBIM4103Document54 paginiAssignment EBIM4103Helmy SalimÎncă nu există evaluări

- Roof Decks: Santiago, Gian Kennette HDocument21 paginiRoof Decks: Santiago, Gian Kennette HAnonymous pTZCrF7Încă nu există evaluări

- Above Shelter DesignDocument8 paginiAbove Shelter Designwhite171Încă nu există evaluări

- Wall ConstructionDocument22 paginiWall ConstructionJohn Michael CastilloÎncă nu există evaluări

- Exterior FinishDocument5 paginiExterior FinishPAUL DEREK MALANUMÎncă nu există evaluări

- انشاء مباني ٢ 3Document9 paginiانشاء مباني ٢ 3ach.aseelalwakerÎncă nu există evaluări

- Timber Weatherboard InstallationDocument6 paginiTimber Weatherboard InstallationAndrew LeeÎncă nu există evaluări

- Corrugated Sheet Roofing MaterialDocument7 paginiCorrugated Sheet Roofing Materialisland14Încă nu există evaluări

- Guidance RoofingDocument42 paginiGuidance RoofingMujjo SahbÎncă nu există evaluări

- BC CladdingDocument21 paginiBC CladdingEla SharmaÎncă nu există evaluări

- Roofing TerminologyDocument53 paginiRoofing TerminologysoumyasonawaneÎncă nu există evaluări

- Fiber Cement BoardDocument6 paginiFiber Cement BoardFavorSea Industrial Channel Limited, Building Materials DivisionÎncă nu există evaluări

- Flat Roof - WikipediaDocument6 paginiFlat Roof - WikipediaIeeeChannaÎncă nu există evaluări

- Rooftop Pipe Support EBookDocument22 paginiRooftop Pipe Support EBookdhanu_lagwankarÎncă nu există evaluări

- Flat Roof: From Wikipedia, The Free EncyclopediaDocument8 paginiFlat Roof: From Wikipedia, The Free EncyclopediaNorul AindaÎncă nu există evaluări

- BISON PANEL Product GuideDocument24 paginiBISON PANEL Product Guideg_periwal_pune9635Încă nu există evaluări

- Roof Design Principles: GenerallyDocument55 paginiRoof Design Principles: Generallyrcxy98Încă nu există evaluări

- Construction of Linings, Finishes and StairsDocument29 paginiConstruction of Linings, Finishes and StairsAlbert LiuÎncă nu există evaluări

- Roof Coverings: Building MaterialsDocument38 paginiRoof Coverings: Building Materialssoniya bhandariÎncă nu există evaluări

- CW Sheltrh122Document8 paginiCW Sheltrh122warhawkjohnnyÎncă nu există evaluări

- Above Ground Fallout ShelterDocument8 paginiAbove Ground Fallout Shelteragabatti100% (1)

- Building Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory VerandahDocument24 paginiBuilding Weather Cathedral Stadium Dwellings Rain Heat Sunlight Wind Conservatory Verandahdudynayn100% (1)

- Roof - Functional Purpose: BE - 1105 Building Design and Construction Lecture Note - 06Document11 paginiRoof - Functional Purpose: BE - 1105 Building Design and Construction Lecture Note - 06Ken Ingram100% (1)

- Cross-Laminated Timber (CLT)Document16 paginiCross-Laminated Timber (CLT)Sheen GabaisenÎncă nu există evaluări

- Structural Joints in GlulamDocument8 paginiStructural Joints in Glulamziggo88100% (1)

- Know Your Associate 0Document12 paginiKnow Your Associate 0sarveshrathiÎncă nu există evaluări

- CSR Roofing ArchManual S1-S8Document127 paginiCSR Roofing ArchManual S1-S8k2v1n5100% (1)

- Building Your Own Roof Trusses: A B S HDocument3 paginiBuilding Your Own Roof Trusses: A B S HNiroj MaharjanÎncă nu există evaluări

- TB 34 - Steel Building Frames June 2020 EarthingDocument8 paginiTB 34 - Steel Building Frames June 2020 EarthingRethish KochukavilakathÎncă nu există evaluări

- Boism PanelDocument24 paginiBoism PanelhipreyashÎncă nu există evaluări

- Sheetrock Gypsum Sheathing: Submittal Sheet 09250Document2 paginiSheetrock Gypsum Sheathing: Submittal Sheet 09250Henry Valle MolinaÎncă nu există evaluări

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsDe la EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsÎncă nu există evaluări

- Family Handyman Big Book of ProjectsDe la EverandFamily Handyman Big Book of ProjectsFamily HandymanÎncă nu există evaluări

- Copper Flashings And Weatherings - A Practical HandbookDe la EverandCopper Flashings And Weatherings - A Practical HandbookÎncă nu există evaluări

- Practical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesDe la EverandPractical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesÎncă nu există evaluări

- 2017 - 08 - 11 - ТЗ на СМР лот 29 - v2 - engDocument18 pagini2017 - 08 - 11 - ТЗ на СМР лот 29 - v2 - engSyed ZamanÎncă nu există evaluări

- Binding Wire Consumption As Per Is CodeDocument1 paginăBinding Wire Consumption As Per Is CodeSyed ZamanÎncă nu există evaluări

- EXAMPLE - Quatation For Road FancingDocument13 paginiEXAMPLE - Quatation For Road FancingSyed ZamanÎncă nu există evaluări

- Sewerage & Sewage Treatment PlantDocument26 paginiSewerage & Sewage Treatment PlantSyed ZamanÎncă nu există evaluări

- A-Shimrail Pump StationDocument26 paginiA-Shimrail Pump StationSyed ZamanÎncă nu există evaluări

- C-Pumping Plant at Pagla Fatullah ShampurDocument7 paginiC-Pumping Plant at Pagla Fatullah ShampurSyed ZamanÎncă nu există evaluări

- RFQ - Piping & FittingsDocument4 paginiRFQ - Piping & FittingsSyed ZamanÎncă nu există evaluări

- B: Adamjee Nagar Pump Station Part-1: Civil WorksDocument12 paginiB: Adamjee Nagar Pump Station Part-1: Civil WorksSyed ZamanÎncă nu există evaluări

- Rate AnalysisDocument18 paginiRate AnalysisSyed ZamanÎncă nu există evaluări

- Ataur Rahman KhanDocument1 paginăAtaur Rahman KhanSyed ZamanÎncă nu există evaluări

- FFFFFFFFFFFFFDocument9 paginiFFFFFFFFFFFFFSyed ZamanÎncă nu există evaluări

- Extra Cost For Special Quality 1st Class Bricks In/c Sorting Out The BricksDocument2 paginiExtra Cost For Special Quality 1st Class Bricks In/c Sorting Out The BricksSyed ZamanÎncă nu există evaluări

- Home AloneDocument1 paginăHome AloneSyed ZamanÎncă nu există evaluări

- Truss BridgeDocument25 paginiTruss BridgeManoj PradhanÎncă nu există evaluări

- Foc July 2018Document72 paginiFoc July 2018Cesar LaraÎncă nu există evaluări

- Project Management Tracker: Project Start Date Display WeekDocument8 paginiProject Management Tracker: Project Start Date Display Weekmayank pandyaÎncă nu există evaluări

- Sample 2Document1 paginăSample 2Mustapha Rojo Sakali100% (1)

- Seismic DesignDocument27 paginiSeismic Designamachmouchi100% (1)

- Behaivour of Earthquake Resisting Masonry Building As Per Is 4326:1993Document40 paginiBehaivour of Earthquake Resisting Masonry Building As Per Is 4326:1993SaHil ShaRmaÎncă nu există evaluări

- 9Document20 pagini9api-3696315100% (1)

- 30X40 PDFDocument9 pagini30X40 PDFGiri GuruÎncă nu există evaluări

- Blue FairwayDocument15 paginiBlue FairwayIsidro P. BuquironÎncă nu există evaluări

- Additional Works BoQ - Aspex Kumbong 300421Document16 paginiAdditional Works BoQ - Aspex Kumbong 300421My pouÎncă nu există evaluări

- Tech Brochures Truss Facts AusDocument28 paginiTech Brochures Truss Facts AusDee Reyes100% (1)

- Graphical Construction Glossary Roofs and Roofing. Roof Features Parapet GutterDocument25 paginiGraphical Construction Glossary Roofs and Roofing. Roof Features Parapet GutterIeeeChannaÎncă nu există evaluări

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document613 paginiAISC 13ed - LRFD Bolted Moment Connections Post r4jh50000Încă nu există evaluări

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 379Document1 paginăDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 379vivekÎncă nu există evaluări

- Structural Analysis For Two Story Residential BuildingDocument4 paginiStructural Analysis For Two Story Residential BuildingMathan LuceroÎncă nu există evaluări

- Summer: Exploded Conceptual IsometricDocument5 paginiSummer: Exploded Conceptual Isometricanurag bhattacharyaÎncă nu există evaluări

- Types of Frames-1Document23 paginiTypes of Frames-1imaniÎncă nu există evaluări

- StruCalc 60 TutorialDocument21 paginiStruCalc 60 TutorialHoang CongÎncă nu există evaluări

- Wall Anchorage Forces and NotationsDocument2 paginiWall Anchorage Forces and Notationswagipe3094Încă nu există evaluări

- 3-Classroom Block SecondaryDocument14 pagini3-Classroom Block Secondarykwihk100% (2)

- OHT DesignDocument55 paginiOHT Designdheeraj tiwariÎncă nu există evaluări

- Steel Section DesignDocument36 paginiSteel Section DesignMuhammad Wazim AkramÎncă nu există evaluări

- Log Cabin ManualDocument53 paginiLog Cabin ManualJP VersterÎncă nu există evaluări

- Proposed One Bedroom Semi-Dethatch With Boys Quater FOR Abubakar Musibau Oyewumi AT Magiro Area KaiamaDocument7 paginiProposed One Bedroom Semi-Dethatch With Boys Quater FOR Abubakar Musibau Oyewumi AT Magiro Area KaiamaInuwa U UmaruÎncă nu există evaluări

- Timber AssignDocument17 paginiTimber AssignRashid AliÎncă nu există evaluări

- 5-Slender Columns (1604)Document27 pagini5-Slender Columns (1604)Peh Hoong PingÎncă nu există evaluări

- All Sheets ConcreteDocument72 paginiAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- Architectural 1Document1 paginăArchitectural 1Paul Gerard AguilarÎncă nu există evaluări