Documente Academic

Documente Profesional

Documente Cultură

JD250

Încărcat de

Shahzad AliDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JD250

Încărcat de

Shahzad AliDrepturi de autor:

Formate disponibile

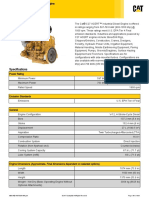

STANDARD SPECIFICATIONS ENGINE / TECHNICAL DATA

250KVA

1. ENGINE

John Deere four stroke heavy duty high Engine Make John Deere

performance industrial type diesel Engine Model 6068HFU55

engine.

Governing class ISO 8528-G2

2. ENGINE FILTRATION SYSTEM Number of Cylinders 6

Cylinder Arrangement Vertical in line

• Cartridge type dry air filters.

Bore and Stroke mm 106 x 127

• Cartridge type fuel filters. POWERED BY:

• Full flow lube oil filters. Displacement / Cubic Capacity litres 6.8

All filters have replaceable Induction System Naturally Aspirated

elements.

Cycle 4 stroke

3. COOLING RADIATOR Combustion System Direct Injection

Radiator and cooling fan, complete with safety Compression Ratio 17:2:1

guards, designed to cool the engine at high Rotation

ambient temperatures (consult your dealer for

Anti-clockwise, viewed on flywheel

de-ration factors). Cooling System Water - cooled

Frequency and Engine Speed 50Hz & 1500rpm

4. EXHAUST SYSTEM Prime Standby

Silencer noise reduction level 12 (dB) Gross Engine Power kW (hp) 227(304) 250 (335)

Maximum allowable back pressure 10.0 (kPa) Fuel Consumption@ 50% load L/hr - 35.9

(kPa)

@ 75% load L/hr - 52.25

5. CIRCUIT BREAKER TYPE

3 pole MCB / MCCB (supplied disconnected @ 100% load L/hr 62.65 68.07

and without cables) Total Lubrication System Capacity litres - -

CONTROL PANEL Total Coolant Capacity (inc. radiator)litres 12.7 -

Exhaust Temperature:°C 523 -

Make Deep Sea - -

Radiator Cooling Air Flow (Min): m 3 /sec

Model DSE6110/20 Combustion Air Flow: m3/min 14.5 -

Exhaust Gas Flow:m3/min 37.3 -

The DSE6110 i s an Auto Start Control Module Fuel Tank Capacity:litres 385 385

and The DSE6120 is an auto mains(utility)

Failure Control Module for single gen-set applications.

Both modules have been designed to work with

electronic engines providing advance engine ALTERNATOR DATA

monitoringand protection features.

Make Marelli / Stamford

• Transfer between mains(utility) and DIMENSIONS AND WEIGHT*

Model MJB 250 LB4 / UCDI274K

generator power(DSE6120 only)

Lengthmm Widthmm Heightmm Weight* kg (wet) KVA 240 / 250

• Generator frequency

3000 1100 1550 2252 KW 192 / 200

• Underspeed, Overspeed

* For skid mounted genset without enclosure wet weight = with lube oil and coolant No. of bearings 1

• Generator volts (L-L, L-N)

• Generator current Insulation class H

• Engine oil pressure Total Harmonic Content at no load <2% at no load <3% - on load <2%

Winding Leads 12

• Engine coolant temperature

Ingress Protection IP23

• Fuel level (Warning or shutdown) Output Ratings Prime Standby

Excitation System SHUNT

• Hours run counter

380-415 V, 3 ph, 50 Hz, 1500 rpm 250 KVA 275 KVA Winding Pitch 2/3 (wdg M0) / 2/3

• Battery volts

AVR Model Mark V / SX460

• Fail to start/stop 200 KW 220 KW

Overspeed 2250 mn-1

• Emergency stop

Applicable Voltages: 220/127 V at 60 Hz only (Consult your dealer for more details) Voltage Regulation ± 1.0 % in steady state condition

• Failed to reach loading voltage/frequency

Short Circuit Capacity -

• Charge fail Ratings at 0.8 Power Factor

• Loss of magnetic pick-up signal

• Low DC voltage

• CAN diagnostics and CAN fail/error

STANDARD SPECIFICATIONS

6. FUEL SYSTEM AVAILABLE OPTIONS & ACCESSORIES

RATINGS DEFINITION

On Generating Sets up to 2000 KVA, the We offer a range of optional features and accessories to tailor our

base frame design can be incorporated with Prime Power generating sets to meet your power needs.

an integral fuel tankwith a capacity of

approx. 8 hours running at Full Load. The These ratings are applicable for supplying continuous electrical

tank is supplied complete with fill cap

power (at variable load) in lieu of 3900.0 1400.0

breather fuel feed and return lines to the

Engine and drain plug. commercially purchased power. 10% overload power is available

for 1 hour in 12 hours continuous

7. ALTERNATOR operation.

7.1 INSULATION SYSTEM

Standby Power

• The insulation system is Class H. 2125.0

• All windings are impregnated in either a triple These ratings are applicable for supplying continuous electrical

dipthermosetting liquid, oil and acid resisting

polyester varnish or vacuum pressure

power (at variable load) in the event of a

impregnated with a special utility power failure. No overload is permitted on these ratings.

polyester resin.

STANDARD REFERENCE CONDITIONS

• Heavy coat of antitracking varnish additional

protection against moisture. Output ratings are presented at 25°C air inlet temperature,

barometric pressure 100 kPa, relative humidity 30%. This

7.2 AUTOMATIC VOLTAGE REGULATOR (AVR)

generating set is designed to operate at high ambient

The fully sealed Automatic Voltage Regulator

maintains the Voltage Regulation at ±0.5%. temperatures (up to 55°C), humidity (up to 99%) and 3000

Nominal adjustment by means of a trim pot altitudes. De-ration may apply,please consult your dealer for

incorporated on the AVR. specific site ratings.

7.3 MOTOR STARTING an overload capacity

STAUNCH Generators are assembled Some of the

equivalent to 300% of the Full Load impedance at

zero Power Factor can be sustained for 10 specifications are not standard on all Genset models. in

seconds. facilities certified to ISO 9001 All information in this 1550

document is substantially correct at time of printing and

8. MOUNTING ARRANGEMENT may be altered subsequently.

8.1 BASE FRAME Generating Set pictured may include optional accessories.

The complete Generating Set is mounted as a

whole on a heavy duty fabricated steel

STAUNCH

Baseframe. 11. DOCUMENTATIONS a set of Operation & Maintenance 1100

manual, Circuit wiring diagrams and Commissioning / Fault

8.2 COUPLINGThe Engine and Alternator are Finding instruction leaflets accompany the Generator.

directly coupled by means of an SAE flange. The

Engine flywheel is flexibly coupled to the 12. QUALITY STANDARDS The equipment meets the

ACCESSORIES

Alternator rotor.

following standards: BS4999, BS5000, BS5514 IEC 60034,

8.3 ANTI-VIBRATION MOUNTING PADS anti- VDE0530, NEMA MG 1.22 and ISO 8528. • switches

Vibration pads are affixed between the Engine / • Load banks

Alternator feet and the Baseframe thus ensuring 13. WARRANTY All of the Generating Sets are covered • Auxiliary fuel tanks

complete vibration isolation of the rotating under a warranty policy for a period of 12 months. Warranty

assembly.The Fan & Fan Drive along with the of the equipment is in line with manufacturers warranty

• Manual & automatic

Battery Charging

terms & conditions. • Genuine spare partstransfer

8.4 SAFETY GUARDS The Fan & Fan Drive along

with the Battery Charging Alternator are Safety (check warranty statement for more details, as it may vary

Guard protected for personal protection. for different countries)In line with continuous product OPTIONS

development, we reserve the right to change specifications

9. FACTORY TESTS without notice. • Water jacket heater

• The Generating set is load tested before • A variety of generating set

dispatch • Additional protection alarms

• All protective devices control functions and site For further information on all of the standard

load conditions are simulated. The generator and and optional features accompanying this • Water fuel seperator control and synchronizing and

it’s systems are checked before dispatch. product please contact your local dealer or visit: shutdowns

10.EQUIPMENT FINISHING all mild steel

• panels

WWW.STAUNCHMACHINERY.COM

components are fully degreased and painted with • Battery charger

powder coated paint to ensure maximum scuff

resistance and durability.

S-ar putea să vă placă și

- STG FPT 65kvaDocument2 paginiSTG FPT 65kvamohamadÎncă nu există evaluări

- STG Perkins 135kvaDocument2 paginiSTG Perkins 135kvaromeo ramirez100% (1)

- Lehe20255 02Document4 paginiLehe20255 02Brian RomanoÎncă nu există evaluări

- VTA28G6Document3 paginiVTA28G6chanchan100% (1)

- Fuel Optimized: Specification SheetDocument3 paginiFuel Optimized: Specification SheetTesla GeneradoresÎncă nu există evaluări

- 4BTAA3.3-G12: EPA Tier 3 CertifiedDocument3 pagini4BTAA3.3-G12: EPA Tier 3 CertifiedLawternay Stevaneli BritoÎncă nu există evaluări

- De1250 GCDocument4 paginiDe1250 GCgjgwrjf78cÎncă nu există evaluări

- EMERD-5935-EN Model Data SheetDocument3 paginiEMERD-5935-EN Model Data SheetmnezamiÎncă nu există evaluări

- DC-850 60hzDocument2 paginiDC-850 60hzJunnie Alvin AgravanteÎncă nu există evaluări

- Fuel Optimized: Specification SheetDocument3 paginiFuel Optimized: Specification SheetArslan AnnaÎncă nu există evaluări

- CatalogueDocument4 paginiCatalogueRakeshÎncă nu există evaluări

- Marine Spec S60 3C3D 1Document2 paginiMarine Spec S60 3C3D 1Amin GuiÎncă nu există evaluări

- WPG344Document4 paginiWPG344Kevin AndrianÎncă nu există evaluări

- VTA28-G5: Fuel OptimizedDocument3 paginiVTA28-G5: Fuel OptimizedIslam HemdanÎncă nu există evaluări

- SPG44BDDocument4 paginiSPG44BDFatima HamdiÎncă nu există evaluări

- 62 5 Kva Silent DG SetDocument3 pagini62 5 Kva Silent DG SetArjun GhoshÎncă nu există evaluări

- Fawde Gs33fld Spec - Faw - 26 KWDocument2 paginiFawde Gs33fld Spec - Faw - 26 KWPaul Cabello SalazarÎncă nu există evaluări

- Cat DE1100 GC: ® Diesel Generator SetsDocument4 paginiCat DE1100 GC: ® Diesel Generator SetsJustUhhIDK2Încă nu există evaluări

- DS C15 D5 PDFDocument3 paginiDS C15 D5 PDFMR BEA100% (1)

- c4.4 Marine Genset SpecsheetDocument4 paginic4.4 Marine Genset SpecsheetBilel Ben SlamaÎncă nu există evaluări

- SC315 60HZ Cummins Generator STAMFORDDocument4 paginiSC315 60HZ Cummins Generator STAMFORDChen CarolineÎncă nu există evaluări

- SC88 Cummins GeneratorDocument4 paginiSC88 Cummins GeneratorChen CarolineÎncă nu există evaluări

- QSG12-G2: Specification SheetDocument3 paginiQSG12-G2: Specification SheetAlejandro Dominado100% (1)

- Generator Set Data Sheet: Our Energy Working For You.™Document3 paginiGenerator Set Data Sheet: Our Energy Working For You.™MR BEAÎncă nu există evaluări

- 4btaa3 3G14Document3 pagini4btaa3 3G14Dieselmotors ManÎncă nu există evaluări

- C2.2NA Fire Pump HX 2022Document6 paginiC2.2NA Fire Pump HX 2022dfheardÎncă nu există evaluări

- Catalogo Planta Fawde Accc-Af25 0Document4 paginiCatalogo Planta Fawde Accc-Af25 0Jackson QuintinoÎncă nu există evaluări

- SS-8003897-1000006023-001 SS Page 1 of 6Document6 paginiSS-8003897-1000006023-001 SS Page 1 of 6Emanuel CondeÎncă nu există evaluări

- KTA38-G9: Fuel OptimizedDocument3 paginiKTA38-G9: Fuel OptimizeddennysÎncă nu există evaluări

- Depco Power Generator: Standard SpecificationsDocument2 paginiDepco Power Generator: Standard SpecificationsRichard De La PeñaÎncă nu există evaluări

- SS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFDocument5 paginiSS-11279002-18375269-002 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18375269-014 PDFANDRES CASASÎncă nu există evaluări

- DS338-CPGK Data SheetDocument3 paginiDS338-CPGK Data SheetMoh NezÎncă nu există evaluări

- FGW9 Weichai Genset 12M26 Series 60HZ 700 1000kwe LTPDocument5 paginiFGW9 Weichai Genset 12M26 Series 60HZ 700 1000kwe LTPeichermguptaÎncă nu există evaluări

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 paginiQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- DC-35 1800RPMDocument2 paginiDC-35 1800RPMJunnie Alvin AgravanteÎncă nu există evaluări

- Kta 38 G7Document3 paginiKta 38 G7ophar100% (1)

- Kta50 GS8Document3 paginiKta50 GS8Mohiuddin totulÎncă nu există evaluări

- Edg Kta50-Gs8Document3 paginiEdg Kta50-Gs8ENGINEER MONIRUJJAMANÎncă nu există evaluări

- Kta50 GS8Document3 paginiKta50 GS8Zaid M. AliÎncă nu există evaluări

- GMP30PXS 1000020483 SpecificationDocument8 paginiGMP30PXS 1000020483 Specificationjorge espinozaÎncă nu există evaluări

- DEPCO DC-501 1800rpm - 1622605917Document2 paginiDEPCO DC-501 1800rpm - 1622605917Gab MercadoÎncă nu există evaluări

- SD46.5 50HZ Deutz GeneratorDocument4 paginiSD46.5 50HZ Deutz GeneratorsunshinemachineryÎncă nu există evaluări

- SD88 50HZ Deutz GeneratorDocument4 paginiSD88 50HZ Deutz GeneratorsunshinemachineryÎncă nu există evaluări

- SS 10278979 1000028914 155Document12 paginiSS 10278979 1000028914 155Mohit electricalsÎncă nu există evaluări

- Diesel Generator Set C600D6: 750 kVA Standby - 60HzDocument4 paginiDiesel Generator Set C600D6: 750 kVA Standby - 60HzIgorÎncă nu există evaluări

- CM20200320 39552 31fa9Document4 paginiCM20200320 39552 31fa9johnward19951995Încă nu există evaluări

- MSS Ind 18375269 009Document3 paginiMSS Ind 18375269 009Abaidi RabieÎncă nu există evaluări

- Gta38gce en 2 (8c1)Document2 paginiGta38gce en 2 (8c1)Oscar BarraganÎncă nu există evaluări

- Gen Set Cat 1056 KWDocument9 paginiGen Set Cat 1056 KWRicardoÎncă nu există evaluări

- 6BTA5.9-G6: Fuel OptimizedDocument3 pagini6BTA5.9-G6: Fuel OptimizedFrank Joel Herrera ApaesteguiÎncă nu există evaluări

- 500 KW Perkins Diesel Generator - Epa - TP p500 t3 UlDocument4 pagini500 KW Perkins Diesel Generator - Epa - TP p500 t3 UlbillyfrancomaciasÎncă nu există evaluări

- Lehw0124 01Document6 paginiLehw0124 01Hosam HamdyÎncă nu există evaluări

- Diesel Generator Sets: Cat Diesel Engine GCCP Control PanelsDocument4 paginiDiesel Generator Sets: Cat Diesel Engine GCCP Control PanelsnoorÎncă nu există evaluări

- Dynamometer: Theory and Application to Engine TestingDe la EverandDynamometer: Theory and Application to Engine TestingÎncă nu există evaluări

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsDe la EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsEvaluare: 3 din 5 stele3/5 (5)

- Digital Power Electronics and ApplicationsDe la EverandDigital Power Electronics and ApplicationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantDe la EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantÎncă nu există evaluări

- Wheel Loader wl56Document6 paginiWheel Loader wl56Shahzad AliÎncă nu există evaluări

- Sharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillDocument1 paginăSharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillShahzad AliÎncă nu există evaluări

- Corporate Office: Lahore Office: Islamabad Office: Faisalabad Office: Multan Office: Hyderabad OfficeDocument1 paginăCorporate Office: Lahore Office: Islamabad Office: Faisalabad Office: Multan Office: Hyderabad OfficeShahzad AliÎncă nu există evaluări

- JDW Sugar Mill Quotation .Document1 paginăJDW Sugar Mill Quotation .Shahzad AliÎncă nu există evaluări

- S284 Oil Level Switch - Capacitance Type: Technical DataDocument1 paginăS284 Oil Level Switch - Capacitance Type: Technical DataShahzad AliÎncă nu există evaluări

- Sharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillDocument1 paginăSharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillShahzad AliÎncă nu există evaluări

- J66KDocument5 paginiJ66KShahzad AliÎncă nu există evaluări

- Volvo Tad 1241 Ge Workshop and Repair ManualDocument38 paginiVolvo Tad 1241 Ge Workshop and Repair Manualahmedalgalo80% (20)

- Sharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillDocument1 paginăSharif S/O Barkat Ali Old Khana 6277 Khana: Web Generated BillShahzad AliÎncă nu există evaluări

- Ammar Medical ComplexDocument1 paginăAmmar Medical ComplexShahzad AliÎncă nu există evaluări

- Department of Molecular Virology: COVID-19 (Corona) VirusDocument1 paginăDepartment of Molecular Virology: COVID-19 (Corona) VirusShahzad Ali100% (1)

- 6081HF001 EngineDocument2 pagini6081HF001 EngineShahzad Ali100% (1)

- Department of Molecular Virology: COVID-19 (Corona) VirusDocument1 paginăDepartment of Molecular Virology: COVID-19 (Corona) VirusShahzad Ali100% (1)

- 1000kW User ManualDocument28 pagini1000kW User ManualShahzad AliÎncă nu există evaluări

- At-Tahur Farm HouseDocument1 paginăAt-Tahur Farm HouseShahzad AliÎncă nu există evaluări

- Genset Test ReportDocument3 paginiGenset Test ReportShahzad AliÎncă nu există evaluări

- Solar Combiner Box Pakistan - Google SearchDocument6 paginiSolar Combiner Box Pakistan - Google SearchShahzad Ali0% (1)

- DC Energy Analyzer: DescriptionDocument2 paginiDC Energy Analyzer: DescriptionShahzad AliÎncă nu există evaluări

- ScaniaPartsSolutions2017Brochure FINAL WEBDocument32 paginiScaniaPartsSolutions2017Brochure FINAL WEBShahzad AliÎncă nu există evaluări

- Battery Charger Service ReportDocument1 paginăBattery Charger Service ReportShahzad AliÎncă nu există evaluări

- Fault CodesDocument28 paginiFault CodesShahzad AliÎncă nu există evaluări

- AG16Document29 paginiAG16Shahzad AliÎncă nu există evaluări

- Model:: 190 - 600 V GasDocument4 paginiModel:: 190 - 600 V GasShahzad AliÎncă nu există evaluări

- Psi8.8l PL 2Document41 paginiPsi8.8l PL 2Shahzad AliÎncă nu există evaluări

- 2000reozm4 10aDocument4 pagini2000reozm4 10aShahzad AliÎncă nu există evaluări

- Ecu CPP User ManualDocument28 paginiEcu CPP User ManualShahzad Ali0% (1)

- C13 Ca PDFDocument6 paginiC13 Ca PDFShahzad AliÎncă nu există evaluări

- 2206c-E13tag2 Electropak Pn1884Document2 pagini2206c-E13tag2 Electropak Pn1884gmuitaÎncă nu există evaluări

- Attester FormDocument1 paginăAttester FormShahzad AliÎncă nu există evaluări

- Centrifugal PumpsDocument6 paginiCentrifugal Pumpsjerome fajardoÎncă nu există evaluări

- 1233 Pid 03Document11 pagini1233 Pid 03Reza AranÎncă nu există evaluări

- MB Biostar P4SDP 3 PDFDocument12 paginiMB Biostar P4SDP 3 PDFEustahije BrzicÎncă nu există evaluări

- Listprice 07 11Document1.797 paginiListprice 07 11Tejano RockÎncă nu există evaluări

- Falcon DEMCO Fire Alarm Bell (Weatherproof Type)Document1 paginăFalcon DEMCO Fire Alarm Bell (Weatherproof Type)LaMinn PaingÎncă nu există evaluări

- Hiab Knuckle Boom Articulating Cranes Spec 54f3f3Document5 paginiHiab Knuckle Boom Articulating Cranes Spec 54f3f3Quỳnh Như Nguyễn ThịÎncă nu există evaluări

- Free Gear Calculator - KHK GearsDocument5 paginiFree Gear Calculator - KHK GearslawlawÎncă nu există evaluări

- Structural MembersDocument37 paginiStructural Membersmario gadianoÎncă nu există evaluări

- RHS Columnuns Embedded in RC ResearchDocument29 paginiRHS Columnuns Embedded in RC ResearchErnie Ernie100% (1)

- Joraform JK Series Operating PrinciplesDocument6 paginiJoraform JK Series Operating Principlesapi-236782993Încă nu există evaluări

- 2014 - Solved Problems in Facility PlanningDocument135 pagini2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- Qualcomm Extensible Diagnostic MonitorDocument2 paginiQualcomm Extensible Diagnostic MonitorGuilherme Pereira0% (1)

- Item 103 Structure ExcavationDocument3 paginiItem 103 Structure ExcavationGerry Velicaria100% (1)

- Crow Proximity Reader ManualDocument8 paginiCrow Proximity Reader ManualMichael GiannakÎncă nu există evaluări

- TXL 025 12s Datasheet 1 en PDFDocument11 paginiTXL 025 12s Datasheet 1 en PDFJulianCitoÎncă nu există evaluări

- ASWipLL HW Installation Guide-V07-460Document322 paginiASWipLL HW Installation Guide-V07-460Fernando MartinÎncă nu există evaluări

- Wave Load Calculation in Transitional Water (Prototype)Document1 paginăWave Load Calculation in Transitional Water (Prototype)pradewoÎncă nu există evaluări

- Examen MesaDocument14 paginiExamen MesaFernando QuirogaÎncă nu există evaluări

- Hanro Tools Incorporation Delhi IndiaDocument10 paginiHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationÎncă nu există evaluări

- DS Mod4Document32 paginiDS Mod4Nikhitha HBÎncă nu există evaluări

- Understand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaDocument168 paginiUnderstand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaChiTownITÎncă nu există evaluări

- Conveyor Belt: Heavy Duty RubberDocument5 paginiConveyor Belt: Heavy Duty RubberHeidrahÎncă nu există evaluări

- GU Pipette Quick Check ENDocument20 paginiGU Pipette Quick Check ENCeren Alim DavutluoğluÎncă nu există evaluări

- Urethane UB-7 Catalog 2013Document32 paginiUrethane UB-7 Catalog 2013yfontalvÎncă nu există evaluări

- Torre Sauter 0 - 5 - 320 - 025 - 4 PDFDocument27 paginiTorre Sauter 0 - 5 - 320 - 025 - 4 PDFGuiÎncă nu există evaluări

- Auto Plin Schema Zapojeni Prepinace Autronic As 101Document28 paginiAuto Plin Schema Zapojeni Prepinace Autronic As 101Tom TalicniÎncă nu există evaluări

- Grinding Polishing: Kiesow Dr. BrinkmannDocument36 paginiGrinding Polishing: Kiesow Dr. BrinkmannChoice OrganoÎncă nu există evaluări

- Butterworth Filter Design With A Low Pass ButterworthDocument8 paginiButterworth Filter Design With A Low Pass ButterworthashishkkrÎncă nu există evaluări

- Technical Reference Options and Adapters Volume 1 Apr84Document501 paginiTechnical Reference Options and Adapters Volume 1 Apr84kgrhoadsÎncă nu există evaluări

- gp30mpc 150Document27 paginigp30mpc 150locomotoras.slpÎncă nu există evaluări