Documente Academic

Documente Profesional

Documente Cultură

Operations Mangement Paper

Încărcat de

Chioma Nwokedi Momah0 evaluări0% au considerat acest document util (0 voturi)

83 vizualizări11 paginiOperations Management In January 2010, I took over the management of my recently deceased mother’s integrated farm, with no prior experience in farming. Koncious Farms Nigeria Limited (“Koncious Farms”) was set up a few years ago. It is located in a remote village in northern Nigeria with no electricity, running water or good roads. Currently, Koncious Farms has six full time staff, and several others who work part-time. We rear broilers (chicken), turkeys, catfish and sheep, and are about to go

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

TXT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentOperations Management In January 2010, I took over the management of my recently deceased mother’s integrated farm, with no prior experience in farming. Koncious Farms Nigeria Limited (“Koncious Farms”) was set up a few years ago. It is located in a remote village in northern Nigeria with no electricity, running water or good roads. Currently, Koncious Farms has six full time staff, and several others who work part-time. We rear broilers (chicken), turkeys, catfish and sheep, and are about to go

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

83 vizualizări11 paginiOperations Mangement Paper

Încărcat de

Chioma Nwokedi MomahOperations Management In January 2010, I took over the management of my recently deceased mother’s integrated farm, with no prior experience in farming. Koncious Farms Nigeria Limited (“Koncious Farms”) was set up a few years ago. It is located in a remote village in northern Nigeria with no electricity, running water or good roads. Currently, Koncious Farms has six full time staff, and several others who work part-time. We rear broilers (chicken), turkeys, catfish and sheep, and are about to go

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

Operations Management

In January 2010, I took over the

management

of my recently deceased mother’s integrated farm, with no prior

experience

in farming. Koncious Farms Nigeria Limited (“Koncious Farms”) was set

up a

few years ago. It is located in a remote village in northern Nigeria

with

no electricity, running water or good roads. Currently, Koncious Farms

has

six full time staff, and several others who work part-time. We rear

broilers (chicken), turkeys, catfish and sheep, and are about to go

into

egg production. We also farm crops such as maize, groundnuts and

tomatoes.

Our major clientele are in the hospitality industry (e.g. hotels,

restaurants and supermarkets) and rely on prompt delivery to meet their

guests’ needs. Since taking over management of the farm, I have had to

learn that running a business requires not only careful

account-keeping,

but careful planning. Most importantly, like any other organization,

the

efficiency of our operations is crucial to the business. When the farm

was

first established, we had the problem of over or under production,

leading

to either inability to meet our customers’ targets, or being left with

a

surplus. Incidents like these have led to our external customers having

to

rely on other suppliers when we either fail to supply them or supply

them

with chicken that does not meet their requirements. This of course has

led

to some of our customers permanently shifting their loyalties to other

producers, resulting in large losses in our revenue. After assessing

the

situation, I discovered that the major reason for our inability to

satisfy

our clientele had to do with delays along our supply chain. Many times,

our

suppliers of day-old chicks failed to supply us our chicks when due or

have

even supplied poor quality chicks, thus leading to us having

insufficient

chickens to supply our customers, or having to supply customers with

low-weight chickens; which they usually reject. Generally, we have

often

had to disappoint customers. Thus, the operational issue I will address

in

this assignment is the supply chain management in Koncious Farms.

Supply

Chain Management in Koncious Farms: An Overview Supply chain

management,

according to Slack et al (2007), is a broad concept which includes the

management of the entire supply chain, from the supplier of raw

material to

the end customer. It involves making sure that the interconnections

between

organizations that lead to the provision of goods and services to the

end

consumer are well managed. A faulty supply chain means that the goods

may

not reach the end user in the best possible way. Professor Marshall

Fisher

of Wharton Business School noted that there are two major distinctions

between supply chains: the efficient supply chain, which is needed in a

functional market, and on the other hand the responsive supply chains,

which are required by innovative markets. Functional markets are more

predictable, which makes planning of the supply chain easier. Koncious

Farms operates a functional market - the demand for our products is

generally stable year round, with fluctuations during festive seasons.

For

our chickens and eggs, there is a high demand year-round. For our sheep

and

goats, the demand is also relatively stable year-round, but spikes

during

Islamic festivities, as these animals are used for religious

ceremonies. A

notable exception is that we sell turkeys mainly during festive periods

such as Easter and Christmas, when the demand is high. Therefore we buy

turkey chicks over summer, so as to ensure that they are ready for

Christmas. To ensure that we satisfy our end users, we need an

efficient

supply chain, one which anticipates our needs as well as those of our

customers. An efficient supply chain runs smoothly from supplier down

to

the end customer. The major objective of any supply chain should be to

make

sure the end customer is satisfied with the goods or services received.

According to Slack et al (2007), to achieve this, the following

performance

objectives must be met: Quality: A supply chain’s performance will

directly

affect the quality of the product that reaches the customer. If there

are

problems along the chain, it will eventually have an adverse affect on

the

quality of the end product or service. In Koncious Farms, this is

clearly

shown in the supply chain of our broiler chickens, as depicted in the

following illustration: the hatchery produces poor quality chicks,

perhaps

due to receiving poor quality parent stock from a chicken breeder.

Without

inspecting the quality of the chicks, the middleman sends them on a

6-hour

journey to our farm, and the chicks therefore arrive exhausted. The

farm

employees further stress the chicks by hurriedly heaping them together

and

sorting them. The generator has no fuel, so the chicks are not able to

feed

properly in a well lit environment, our feed supplier has run out of

feed.

At the end of the day the chickens do not reach their optimum weight

and

the customer is unhappy, and discontinues patronage. It is obvious in

the

above scenario that every action along the supply chain affects the

eventual quality of the chicken reared. Speed: This has to do with the

swiftness with which a consumer receives his product. On our farm, we

have

been able to score above average in this regard. Usually our customers

place orders a day or two in advance, and we are able to slaughter and

process our chicken to meet up with the deadline to supply. In some

instances, we keep some chicken in stock and are able to meet customers

who

place last-minute emergency orders. Dependability: This can also be

referred to as reliability. Customers need to know that they can rely

on us

to supply what they need when they need it. In our farm, our major

challenge has been our inability to depend on our chick supplier to

supply

birds on time. We have had chicks supplied as far as 3 weeks behind

schedule. This sometimes throws the entire supply chain out of sync.

When

we have such issues with undependable supply, we in turn cannot be

depended

on to supply products to our end users. Of recent, we have tried to

shore

up our dependability by buying chickens from other poultry farms and

supplying same to our customers, just to ensure that we maintain the

integrity of our supply chain. Flexibility: This can be referred to as

the

agility of the supply chain. It is the ability of the supply chain to

adjust to small changes which would otherwise adversely affect the end

customer. For example, fuel scarcity and power outages are recurrent

problems in Nigeria. Naturally, this has in no small way affected our

flexibility. A flexible supply chain should be able to meet sudden

fluctuations in supply along the chain. Cost: This is one of the most

important objectives of a supply chain. Even if you meet all other

objectives, a customer will only be willing to pay a certain price for

a

product. It is therefore very important to minimize costs incurred

along

the supply chain, so that they are not passed on to the end customer.

At

Koncious Farms, to ensure that we give our end customer the best price

possible, we constantly negotiate with our suppliers to ensure that we

get

our feed and other raw materials at the best price possible. When we

find a

cheaper, reliable supplier that can offer us good results, we switch

accordingly. As an example, to give an idea of the process our broiler

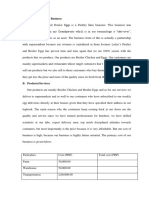

chickens pass through, this is a process map below: Farmers’ market

Supermarket Restaurant End User Koncious Farms Poultry and Fishery

Chick

Hatchery Middle Man (Chick Supplier)Koncious Farms Supply Chain Fuel,

charcoal Feed Seller (A)

Feed Seller (B) One of our problems on the farm stems from the fact

that

when the farm was initially set up, there was no clear-cut plan of how

our

supply chain would work. Originally, suppliers were generally stumbled

upon

by accident. There was lot of trial and error, and when one supplier

failed

we would simply try another. Thus, for the first two years of the

farm’s

operations, the supply chain had knots and disconnections running along

the

chain. Over time, we have discovered the folly in poor planning, and

have

had to go back to the drawing board and plan our supply chain

thoroughly.

For our chicken feed, we currently rely on more than one supplier for

our

feed, i.e. multi-sourcing. This is because we usually purchase our feed

under credit arrangements, and we are wary of heaping too much debt on

a

single supplier. Also, as noted by Russ Banham on Cfo.com many

suppliers

have trouble funding their operations, so we divide the burden of our

feed

orders among two or more suppliers, and are currently on the lookout

for

even more suppliers as our production rate increases. This also ensures

that there is product availability, as sometimes one supplier is not

able

to meet our demands. For our chicks, which are more delicate, it is

safer

to rely on one supplier so as to be sure of the source and quality of

the

chicks supplied. However, because we have only one supplier, our

dependency

on a single source of supply has led to serious problems. Whenever our

supplies are delayed (which of recent has been very often), it affects

our

entire supply chain. A policy of e-procurement would have helped the

flow

of our supply chain, but unfortunately e-procurement is not an option

as

most of our suppliers are not IT compliant due to their location in

rural

areas. However, one area in which we have recorded recent success is in

the

area of partnering with our suppliers, using the principles I have

learnt

while studying operations management. Slack et al (2007 p 447) defines

partnership relationships as:

‘... relatively enduring inter-firm cooperative agreements, involving

flows

and linkages that use resources and/or governance structures from

autonomous organizations, for the joint accomplishment of individual

goals

linked to the corporate mission of each sponsoring firm’. Previously,

our

only criterion for selecting suppliers was that the supplier could give

us

a credit line; however this prevented us from partnering with suppliers

who

could work with us towards the mutual growth and success of our

businesses.

In choosing suppliers, we are currently influenced by the need to find

partners who are able to do the following: give us favorable discounts;

give flexible credit line maintain proximity help us market our

products;

and maintain good links with dependable major suppliers Most

importantly,

we always seek suppliers that we can trust. Trust in the opinion of

Slack

et al (2007) is widely held to be both the key issue in successful

partnerships and is also by far the most difficult element to develop

and

maintain Supply Chain Management Theories as they apply to Koncious

Farms’

Operations I will proceed to assess two major theories in supply chain

management with which we have to deal in order to manage the supply

chain

effectively. Just in Time (JIT).

This is an aspect of lean management, where unnecessary inventory is

avoided. According to Slack et al (2007) JIT can be taken literally:

get

your supplies Just in Time. It means producing goods and services

exactly

when they are needed: not before they are needed so that they wait as

inventory, nor after they are needed so that it is the customers who

have

to wait.

JIT originated in Toyota of Japan, and was created by Taiichi Ohno. The

main goal of JIT is to reduce to the barest minimum, “non value adding

operations and non moving inventories in the production line”

(www.siliconfareast.com). It is sometimes referred to as stockless

operations, as one of its main features is the reduction of inventory

levels. The three main pillars of JIT as stated by Slack et al (2007)

are

eliminating waste, involvement of all staff in operations, and the

adoption

of continuous improvement ideas. The advantages of practising JIT

include:

Less wastage: For us at Koncious Farms, this means that we will engage

in

over-production much less. If we can accurately predict the demand for

our

products for a particular period, we should not over produce, as the

leftovers may be ruined.

Less damage to goods in storage: For example, at Koncious Farms, pests

often break into our storage rooms and destroy our bags of chicken

feed.

Better planning: Implementing JIT forces businesses to engage in

planning

and forecasting. To successfully implement JIT, it is important that

the

organization only has what is needed at every point in time. For

instance,

if a company through forecasting knows that it only needs to supply 200

kg

of chicken per day during the summer months, then JIT advocates that

only

what is needed to produce 200 kg of chicken is kept on the farm. Any

surplus should be avoided. JIT is a “pull” system: in the context of

Koncious Farms’ operations, this means that it is the demand from

external

customers on the supply chain that should determine how many chickens

are

reared at the farm. The practice of storing more raw materials than

needed

should be avoided in order to eliminate wastage, theft, holding costs

and

so on. A good way of achieving this is a system where the needs of the

next

stage in the supply chain modulate the production of the preceding

stage. A

key component of JIT, which aids in its implementation, is the use of

the

Kanban system. The word “kanban” is derived from a Japanese term that

means

card signal or signboard (www.encyclo.co.uk). According to

www.handsongroup.com a kanban system can signal the authorization to

move

material or product from the supplying location to the consuming

location.

It can also be used to signal the authorization to produce additional

product. It is a system that is able to track each stage of production

and

thus limit inventory. If properly used, the workers on the production

line

know when and where materials are needed on the production line. The

kanban

card, which is the major tool of the kanban system, “is both a

transaction

and communication device” Gross, McInnis (2003), which ensures that

components on the production line are delivered ‘Just in Time’. At

Koncious

Farms, our current level of production is still quite low. As such,

kanban

cards are not necessary. However, as we step up production, we will

seek

ways to implement the kanban card system, so as to ensure that the

theory

of JIT is fully adhered to. A good example of how our farm has operated

with respect to JIT is that until recently, we would purchase a tonne

of

feed every week, without studying the consumption rate of the chickens

per

day. Wastage was rife, as the farm staff would over-feed the birds just

because the feed was available. Leftover feed in our storage rooms

would

then be attacked and destroyed by pests. Today, with improved planning

and

input from our staff, we have been able to estimate the average amount

of

feed needed per week, and the amount of feed bought weekly has

significantly dropped. For example, recently, one of the farm staff

noticed

that when the birds ate at night, they would gain more weight. With

this

helpful input, the birds are currently being fed less, but with greater

precision, and are therefore healthier. We are still working on

forecasting

accurately, and with our current progress, we will soon be able to buy

exactly what we need. If we are able to buy only the feed we need from

our

suppliers, we will be able to take less stock on credit, which would

help

us add value to our suppliers’ businesses, thereby partnering more

effectively with them. Another area in which we are attempting to

implement

JIT on Koncious Farms is with respect to our fuel purchases. Currently,

because we have no electricity supply on the farm, we routinely need

petrol

to power our generator. However, it is difficult to stock just enough

fuel

for weekly needs, as our fuel consumption varies from week to week. An

example of this is the need for constant water (which is circulated by

a

generator) during the catfish hatching stage. This does not exist to

the

same degree at other times, and the catfish-hatching stage is not

always

consistently timed. It is therefore clear that due to the limitations

we

face as a growing farm business located in a rural area, implementing

JIT

in its entirety would be difficult, as it is easier to apply the theory

to

systems where production flows are consistent and do not change often,

e.g.

a factory where the same processes are continuously repeated. However,

we

can and have already started implementing some aspects of JIT. With JIT

in

place, we will improve our ability in meeting our end users’ demands

and

operating an effective supply chain. (b) Total Quality Management (TQM)

Another important theory which will affect proper supply chain

management

is Total Quality Management (TQM). This theory was first introduced by

Fegeinbaum, but was made popular and developed further by the legendary

WE

Deming. Others who contributed to the theory are JM Juran, K. Ishikawa,

G.

Taguchi and PB Crosby. TQM,in Fegenbaum’s words,is:

“an effective system for integrating the quality development, quality

maintenance and quality improvement efforts of the various groups in an

organization, so as to enable production and service at the most

economical

levels which allow for full customer satisfaction’.

(Feigenbaum, A.V. 1986) TQM has the customers’ needs at its core. It is

all

about customer satisfaction and ensuring that both internal and

external

customer needs are met. In fact, one of the most powerful aspects to

emerge

from TQM is the concept of the internal customer and internal supplier

(Slack et al (2007) which have been indispensable in supply chain

management. Treating every one along the supply chain as a customer and

conforming to the customers’ needs ensures that quality is upheld. ,

Where

quality is not upheld, the cost of production is ultimately increased.

A

good example of this on Koncious Farms was our maize harvesting

exercise

early this year. The maize was sorted manually after harvesting, and

was

stored in a poorly-ventilated area, without the addition of

preservatives.

As a result, when we eventually sold the maize, it was in such poor

condition that customers offered 30-40% lower than the normal price.

Thus,

we made poor sales and very little profit. If we had stored the maize

properly and bought the chemicals needed to preserve them, we would

have

made significantly more profit. We would also have been able to sell

the

maize faster, as the locals would have spread the word that Koncious

Farms

had good quality maize for sale. Instead, with every subsequent buyer

less

was offered for the poor quality maize. The impact of this will likely

still be felt by the farm in the future, as chances are that when next

we

have maize for sale, potential customers in the area will remember the

poor

quality maize that we sold previously, and may therefore be reluctant

to

return. As stated by Deming in his book “Out of Crisis, “defects are

not

free” (Deming E.W 2000, p 11) For the defects in our maize due to our

carelessness, we “paid” by earning low revenue and even worse, perhaps

a

bad reputation. Like JIT, TQM requires a lot of employee input and a

much

higher standard of management. Its successful implementation must start

from management. John S Oakland stated that in order to achieve quality

throughout an organization, the following questions need to be asked by

the

suppliers: Who are my immediate customers? What are their true

requirements? How do I find out what their requirements are? How can I

measure my ability to meet these requirements Do I have the capability

to

meet the requirements, and if not why? What must we change in order to

meet

them? Do I continually meet these requirements? If not, why not? What

stops

me from doing my job properly? How do I monitor changes in

requirements?

For the customers, Oakland states that the following must be asked Who

are

my immediate suppliers? What are my true requirements? How do I

communicate

my requirements? Do my suppliers have the capacity to measure and meet

my

requirements? How do I inform them of changes in my requirements?

(Oakland

J, Morris P, 1997 p 10) If the above questions can be answered

effectively

by both suppliers and customers, then TQM can be practiced effectively.

Further implications of TQM were revealed by Deming in his

revolutionary

book on crisis, Out of the Crisis, in which he offered 14 key

principles

which would make any business effectively manage its quality practices.

Some of these principles are: Employees in different departments should

work as a team, and be aware of each department’s operations. Training

of

all employees is necessary, especially to instruct them on quality.

Eliminate the need for inspection by ensuring that quality is built

into

the product in the first place. Most importantly, in relation to supply

chain management, minimize total cost by using a single supplier with

which

one would have built a long-term relationship of trust. It is

impossible

for a supply chain to be effectively managed if the elements of TQM are

not

practised. This is because quality is at the core of any serious

organization’s practice. Once a product is known for its quality, then

its

customers remain loyal. On the other hand, where an organization has a

reputation for producing low quality goods, then customers will switch

to a

more reliable service. In fact, as Deming opined, it is impossible to

know

the actual impact of an unhappy customer - not only will such a

customer

not patronize your business, he/she will also discourage others from

using

your services.

There really is not any one way that TQM must be practised. What is

important is that everyone in an organization must practice it

according to

the same set of rules, set by management. As clearly stated in Out of

the

Crisis pg 11, low quality means high costs, and every business aims to

reduce cost and maximize profits. Without quality, this is not

achievable.

From the above, it is obvious that at Koncious Farms, we have

experienced a

sharp decline in customer loyalty as a result of mismanagement of the

supply chain. Recommendations: Some of my recommendations for how

Koncious

Farms’ operations can be improved with respect to supply chain

management

are the following: After carrying out supplier evaluations, we have

decided

that our suppliers should be changed in order to enhance reliability

and

smooth operations along the supply chain. In this spreadsheet (please

see

spreadsheet annex 1) based on a spreadsheet from www.inc.com, I have

been

able to pinpoint and evaluate several areas which are essential to the

smooth running of the farm’s supply chain. Using the results of these

evaluations, the farm will now be able to choose reliable chick and

feed

suppliers and ensure continuous product flow. We will properly partner

with

our suppliers to ensure that we are working together to achieve one

common

goal. This will involve developing customised written policies and

targets

to ensure that our suppliers have a clear reference point with respect

to

the farm’s needs and expectations, and that we at the farm likewise

have a

clear picture of our suppliers’ needs and expectations; Improve on

forecasting and proper planning, so as to accurately anticipate the

farm’s

needs at every point in time and ensure that we carry out lean

operations.

Frank Burrit of Deloitte Consulting has noted that forecasting demand

is

more difficult than ever. In spite of this, it is more important than

ever.

We will make sure we carry out continuous improvements at various

stages of

the farm’s supply chain, such as improving the pesticides and equipment

used on the farm. There are plans to introduce solar panels so as to

reduce

our dependency on electricity. These improvements will be done over

time so

as to be less stressful for the farm, but they will have a lasting and

positive impact on our production. We will make sure that we fully

engage

and involve staff at all stages of operation. Apart from generating

useful

ideas for improvement, this will also increase staff morale and output,

as

they will take greater interest in the process

We will engage in internal and external customer relationship

management

(CRM) .This will help us to anticipate all our customers’ needs and

improve

on the quality of products and services offered by the farm. For

instance,

we will find out from our customers if they require increased

flexibility

with regard to how we supply them with products. If this is required,

we

will ensure that we create this flexibility

Most importantly, we will improve the quality of the end products that

are

sold to customers. When we improve the quality of the final product, we

will lose fewer customers, and will therefore be able to forecast

demand

more effectively. All the above recommendations, when fully implemented

on

an ongoing basis, will lead to a more robust and effective supply chain

at

Koncious Farms.

Reference List Deming W.E (2000), End of Crisis, first MIT press

edition

Feigenbaum, A.V. (1986) Total Quality Control, McGraw-Hill John M

gross,

Kenneth R mcinnis (2003)kanban made simple: demystifying and applying

Toyota s legendary manufacturing process : AMACOM Div American Mgmt

Assn

Oakland J, Morris P(1997) TQM a pictorial guide for managers; pictorial

guides series, illustrated reissue butterworth-heinemann Slack N,

Chambers

S, Johnstone R (2007) Operations Management. Fifth Edition. FT Prentice

Hall http://www.articleplanet.net/negotiation/11660 http://www.cfo.com

http://www.datalliance.com/donovan.pdf

http://www.encyclo.co.uk/define/kanban

http://www.handsongroup.com/lean-articles/taking-the-mystique-out-of-ka

nban

-systems, http://www.inc.com http://www.siliconfareast.com/jit.htm

http://hbr.org/product/...right-supply-chain-for-your-product.../97205-

PDF-

ENG -

S-ar putea să vă placă și

- Operating the Food Truck Business with the Right Ingredients: Food Truck Business and Restaurants, #4De la EverandOperating the Food Truck Business with the Right Ingredients: Food Truck Business and Restaurants, #4Evaluare: 5 din 5 stele5/5 (8)

- Commercial Dairy Farming: From 100 To 500 Cattle HeadsDocument4 paginiCommercial Dairy Farming: From 100 To 500 Cattle HeadsIndra Sarma100% (1)

- SandalwoodDocument20 paginiSandalwoodUj GumilarÎncă nu există evaluări

- A Feasibility Study Business Plan ON Poultry FarmDocument13 paginiA Feasibility Study Business Plan ON Poultry FarmOtobong ukoyoÎncă nu există evaluări

- Ficlau BPDocument13 paginiFiclau BPDocus Natwijuka100% (2)

- Poultry Busines PlanDocument14 paginiPoultry Busines PlanElijah MusawaÎncă nu există evaluări

- Business Plan of Poultry FarmDocument7 paginiBusiness Plan of Poultry FarmTewfic SeidÎncă nu există evaluări

- Business Plan of Poultry FarmDocument20 paginiBusiness Plan of Poultry FarmFiker Er MarkÎncă nu există evaluări

- The Food Service Professional Guide to Controlling Restaurant & Food Service Labor CostsDe la EverandThe Food Service Professional Guide to Controlling Restaurant & Food Service Labor CostsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Business Plan of Poultry FarmDocument10 paginiBusiness Plan of Poultry FarmDiip_Ahsan_791184% (165)

- Flora PoultryDocument20 paginiFlora Poultryflorence elenwa100% (2)

- Session 1 - Getting Started With Operations & Supply ChainDocument25 paginiSession 1 - Getting Started With Operations & Supply ChainChandan Jain100% (5)

- English UPSR Grammar Questions Q16 20Document11 paginiEnglish UPSR Grammar Questions Q16 20Pizza40100% (10)

- Mahuraan Poultry: Business PlanDocument13 paginiMahuraan Poultry: Business Planmustafe omer100% (2)

- Business Plan of Poultry Farm-1Document23 paginiBusiness Plan of Poultry Farm-1Muhammad Riaz100% (1)

- A Manual for Agribusiness Value Chain Analysis in Developing CountriesDe la EverandA Manual for Agribusiness Value Chain Analysis in Developing CountriesÎncă nu există evaluări

- Chapter 1 Discussion Questions: Chapter 1: Understanding The Supply ChainDocument3 paginiChapter 1 Discussion Questions: Chapter 1: Understanding The Supply ChainseifSamhanÎncă nu există evaluări

- Lynn Piggery FinalDocument9 paginiLynn Piggery FinalWana HaglerÎncă nu există evaluări

- Supply Chain of MilkDocument6 paginiSupply Chain of MilkFahad TatlaÎncă nu există evaluări

- Business Proposal For PoultryDocument7 paginiBusiness Proposal For PoultryAbdullahi Musa100% (1)

- Mohammed Oumer Business PlanDocument11 paginiMohammed Oumer Business PlanKaleab Alemayehu100% (1)

- Supply Chain of Pepsi CoDocument19 paginiSupply Chain of Pepsi CoAnkit Sherawat60% (5)

- Business Plan of Tiffin BoxDocument17 paginiBusiness Plan of Tiffin BoxArefin Wisea AblagÎncă nu există evaluări

- Marketing Plan of BiogasDocument14 paginiMarketing Plan of BiogasNasir Naveed67% (3)

- Business ReportDocument7 paginiBusiness ReportFaizan AliÎncă nu există evaluări

- Norton Business ProposalDocument9 paginiNorton Business Proposalkevin gwenhureÎncă nu există evaluări

- Strategic Management (Mba 431) : Bsusiness Plan - Cia 3Document28 paginiStrategic Management (Mba 431) : Bsusiness Plan - Cia 3PrasadÎncă nu există evaluări

- A SUCCESSFUL POULTRY PROJECT: MAKE MONEY OUT OF CHICKENSDe la EverandA SUCCESSFUL POULTRY PROJECT: MAKE MONEY OUT OF CHICKENSÎncă nu există evaluări

- 1588943230marie ME Assignment On AFE 202 PDFDocument13 pagini1588943230marie ME Assignment On AFE 202 PDFDeep & Minimal Tech House Music UnionHouseMusicÎncă nu există evaluări

- RepDocument21 paginiRepMuhammad AshfaqÎncă nu există evaluări

- Poultry FarmDocument4 paginiPoultry FarmClintÎncă nu există evaluări

- Business DescriptionDocument6 paginiBusiness DescriptionTahir MumtazÎncă nu există evaluări

- You Are Given USD 10000 To Start A Business. Explain Any Agricultural Business That You Would Start and Why You Choose That Line of AgribusinessDocument5 paginiYou Are Given USD 10000 To Start A Business. Explain Any Agricultural Business That You Would Start and Why You Choose That Line of AgribusinessLawrence Nyamunderu100% (1)

- Case Analysis - Wegmans Food MarketsDocument4 paginiCase Analysis - Wegmans Food MarketsJoshue Glenn CatubagÎncă nu există evaluări

- Project Management AssignmentDocument14 paginiProject Management Assignmentkelil Gena komichaÎncă nu există evaluări

- Worksheets: Connected StrategyDocument24 paginiWorksheets: Connected Strategyananth080864Încă nu există evaluări

- Business LanDocument55 paginiBusiness LanabukibnakahmedÎncă nu există evaluări

- Infosis Assignment 2Document11 paginiInfosis Assignment 2Lijialin388Încă nu există evaluări

- Access PoultryDocument4 paginiAccess Poultryclark philipÎncă nu există evaluări

- Business ConceptDocument22 paginiBusiness ConceptJossi AbuleÎncă nu există evaluări

- Optimize Food Supply Chain Operation: Source: 8 Simple Lessons About Outsourcing To Grow Your BusinessDocument8 paginiOptimize Food Supply Chain Operation: Source: 8 Simple Lessons About Outsourcing To Grow Your BusinessMOHD FARHAN NAJMIÎncă nu există evaluări

- Executive SummaryDocument5 paginiExecutive Summarymustafe omerÎncă nu există evaluări

- 4 Chicken RunDocument9 pagini4 Chicken RuntrishaweepatsparatatsÎncă nu există evaluări

- Suubi Deborah (Ducks) PoultryDocument3 paginiSuubi Deborah (Ducks) PoultryMukubira John MarkÎncă nu există evaluări

- Group Activity 1Document15 paginiGroup Activity 1TAN JUN HANÎncă nu există evaluări

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument10 paginiName Netid Group Number: Website Link: Tutorial Details Time Spent On Assignmentbraidon_23Încă nu există evaluări

- Fish FarmingDocument29 paginiFish FarmingEdwin Hazard OyaroÎncă nu există evaluări

- Pachawo Kudakwashe S. KAG112-1Document15 paginiPachawo Kudakwashe S. KAG112-1Ashley Tanya GilbertÎncă nu există evaluări

- Case Study: Magnolia Fresh Chicken: SWOT AnalysisDocument5 paginiCase Study: Magnolia Fresh Chicken: SWOT AnalysisAnnamaAnnamaÎncă nu există evaluări

- Nemrod ProjectDocument19 paginiNemrod ProjectCourageÎncă nu există evaluări

- UNIT - II Supply Chain AnalyticsDocument43 paginiUNIT - II Supply Chain Analyticsyash luckyÎncă nu există evaluări

- Daily in The Life Of: Rommel E. Casaba A Sales ManagerDocument7 paginiDaily in The Life Of: Rommel E. Casaba A Sales ManagerMirai KuriyamaÎncă nu există evaluări

- Egg ProductionDocument15 paginiEgg Productionjohnrovietbauat41Încă nu există evaluări

- Answer To The Question No 1: Raw Material SuppliersDocument4 paginiAnswer To The Question No 1: Raw Material SuppliersGadha GadhaÎncă nu există evaluări

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument10 paginiName Netid Group Number: Website Link: Tutorial Details Time Spent On Assignmentbraidon_23Încă nu există evaluări

- DocumentDocument2 paginiDocumenthazel samsonÎncă nu există evaluări

- Bullwhip Effect: Uncertainty CausedDocument25 paginiBullwhip Effect: Uncertainty Causedmohit0503100% (1)

- Chapter IVDocument9 paginiChapter IVMa Kathleen Laude - DuranÎncă nu există evaluări

- Junior BPP DocuDocument7 paginiJunior BPP DocuJohn Louie Sescar CastillonÎncă nu există evaluări

- Broiler Chicken Farming Business Plan 2Document16 paginiBroiler Chicken Farming Business Plan 2kakajumaÎncă nu există evaluări

- Operations and Supply ChainDocument54 paginiOperations and Supply ChainLoan PhạmÎncă nu există evaluări

- Supply - Aug26 - Joel A. Benituasan JRDocument3 paginiSupply - Aug26 - Joel A. Benituasan JRjoel benituasanÎncă nu există evaluări

- The Non-Commercial Food Service Manager's Handbook: A Complete Guide for Hospitals, Nursing Homes, Military, Prisons, Schools, and ChurchesDe la EverandThe Non-Commercial Food Service Manager's Handbook: A Complete Guide for Hospitals, Nursing Homes, Military, Prisons, Schools, and ChurchesÎncă nu există evaluări

- PARCIAL 2 CORTE - PARAGRAPH - Ingles 3Document2 paginiPARCIAL 2 CORTE - PARAGRAPH - Ingles 3wendy castillejoÎncă nu există evaluări

- Best Swedish MeatballsDocument11 paginiBest Swedish MeatballsClaudia GonzalesÎncă nu există evaluări

- A Morga's Sucesos, Chap 8Document114 paginiA Morga's Sucesos, Chap 8Jessi Anne Aligato75% (4)

- Orientation SchduleDocument3 paginiOrientation SchduleSaravana KumarÎncă nu există evaluări

- Jatropha Oil and TermitesDocument8 paginiJatropha Oil and TermitesSanjay AnnaÎncă nu există evaluări

- Soil Conservation PracticesDocument12 paginiSoil Conservation PracticesArchon BanzonÎncă nu există evaluări

- Seetah K. 2006. A Multidisciplinary Approach To Cattle Butchery-LibreDocument8 paginiSeetah K. 2006. A Multidisciplinary Approach To Cattle Butchery-LibreProciuc MarianaÎncă nu există evaluări

- Application of Gis in Precision AgricultureDocument10 paginiApplication of Gis in Precision Agriculturejasmeen kaurÎncă nu există evaluări

- CGDocument63 paginiCGNadya KhanÎncă nu există evaluări

- General Organization Study - Tafe - LTD: Presented by P.VigneshDocument13 paginiGeneral Organization Study - Tafe - LTD: Presented by P.VigneshpvigneshÎncă nu există evaluări

- Kane County Board AgendaDocument138 paginiKane County Board AgendacherylwaityÎncă nu există evaluări

- Inoculating Poultry Manure With Companion Bacteria Influences Growth and Development of Black Soldier Fly (Diptera: Stratiomyidae) LarvaeDocument7 paginiInoculating Poultry Manure With Companion Bacteria Influences Growth and Development of Black Soldier Fly (Diptera: Stratiomyidae) LarvaejocyeoÎncă nu există evaluări

- Dairy-Free and Delicious RecipesDocument4 paginiDairy-Free and Delicious RecipesVegan FutureÎncă nu există evaluări

- Macadamia Nuts-Mango Seed-Oil PreparationDocument3 paginiMacadamia Nuts-Mango Seed-Oil PreparationYogesh DangleÎncă nu există evaluări

- Horticulture Zimbabwe: Updated June 2012Document8 paginiHorticulture Zimbabwe: Updated June 2012Blessmore Andrew ChikwavaÎncă nu există evaluări

- Fertilizers Libro 1 PDFDocument136 paginiFertilizers Libro 1 PDFJose Moctezuma IglesiasÎncă nu există evaluări

- Introduction A Review of The Gilund ExcaDocument6 paginiIntroduction A Review of The Gilund ExcacecilioangelisÎncă nu există evaluări

- Anashwara: A Quality Rice Variety With Multiple Tolerance Released For Kerala, Southern IndiaDocument4 paginiAnashwara: A Quality Rice Variety With Multiple Tolerance Released For Kerala, Southern IndiaGrace CañasÎncă nu există evaluări

- Instant Download Organization Theory and Design 12th Edition Daft Solutions Manual PDF Full ChapterDocument32 paginiInstant Download Organization Theory and Design 12th Edition Daft Solutions Manual PDF Full ChapterTonyaWilliamswejr100% (6)

- Bread Maker AKAIDocument8 paginiBread Maker AKAIIony BijouxÎncă nu există evaluări

- Agricultural Colonization and Immigration in Venezuela, 1810-1860Document9 paginiAgricultural Colonization and Immigration in Venezuela, 1810-1860Giuseppe De CorsoÎncă nu există evaluări

- Don't Starve Crafting Reference Sheet (Full)Document10 paginiDon't Starve Crafting Reference Sheet (Full)Hai ThuongÎncă nu există evaluări

- Kentucky Pest News, September 24, 2013Document3 paginiKentucky Pest News, September 24, 2013awpmaintÎncă nu există evaluări

- Pa Farm Show 2016: ScheduleDocument12 paginiPa Farm Show 2016: ScheduleJewel WickerÎncă nu există evaluări

- Nelumbo NuciferaDocument5 paginiNelumbo Nuciferarita44Încă nu există evaluări

- Agri WarehouseDocument12 paginiAgri WarehouseBoy BearishÎncă nu există evaluări

- Soyoyl Offers High Performance and Versatility: News About Industrial Products Made From SoyDocument3 paginiSoyoyl Offers High Performance and Versatility: News About Industrial Products Made From SoyA MahmoodÎncă nu există evaluări