Documente Academic

Documente Profesional

Documente Cultură

E 106

Încărcat de

Bith SMG0 evaluări0% au considerat acest document util (0 voturi)

89 vizualizări1 paginăDATASHEET HE

Titlu original

E-106

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDATASHEET HE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

89 vizualizări1 paginăE 106

Încărcat de

Bith SMGDATASHEET HE

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

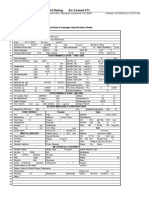

Aspen Exchanger Design and Rating Shell & Tube V10

File: D:\Per Proses\!Rancang Pabrik\Bkup RP\pendingin aldehid.EDR Printed: 08/03/2019 at 22.16.53

TEMA Sheet

Heat Exchanger Specification Sheet

1 Company:

2 Location:

3 Service of Unit: Our Reference:

4 Item No.: E-106 Your Reference:

5 Date: Rev No.: Job No.:

6 Size : 305 - 1828,8 mm Type: BEM Horizontal Connected in: 1 parallel 1 series

7 Surf/unit(eff.) 8,2 m² Shells/unit 1 Surf/shell(eff.) 8,2 m²

8 PERFORMANCE OF ONE UNIT

9 Fluid allocation Shell Side Tube Side

10 Fluid name COOLING WATER BUTYRALDEHYDE TO DISTILLATION

11 Fluid quantity, Total kg/h 16974 21925

12 Vapor (In/Out) kg/h 0 0 0 0

13 Liquid kg/h 16974 16974 21925 21925

14 Noncondensable kg/h 0 0 0 0

15

16 Temperature (In/Out) °C 30 45 92,92 71,99

17 Bubble / Dew point °C / / / /

18 Density Vapor/Liquid kg/m³ / 997,34 / 992,69 / 702,71 / 729,55

19 Viscosity cp / 0,7998 / 0,5981 / 0,2763 / 0,3252

20 Molecular wt, Vap

21 Molecular wt, NC

22 Specific heat kJ/(kg-K) / 4,19 / 4,187 / 2,381 / 2,269

23 Thermal conductivity W/(m-K) / 0,607 / 0,626 / 0,1109 / 0,1176

24 Latent heat kJ/kg

25 Pressure (abs) kPa 100 96,985 1000 978,465

26 Velocity (Mean/Max) m/s 0,25 / 0,27 1,98 / 2,74

27 Pressure drop, allow./calc. kPa 20,684 3,015 55,503 21,535

28 Fouling resistance (min) m²-K/W 2E-05 0,00026 0,00034 Ao based

29 Heat exchanged 296,2 kW MTD (corrected) 43,84 °C

30 Transfer rate, Service 826,9 Dirty 829,7 Clean 1176,7 W/(m²-K)

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Side Tube Side

33 Design/Vacuum/test pressure kPa 344,738 / / 1103,162/ /

34 Design temperature °C 82,22 132,22 T1 S2

35 Number passes per shell 1 4

36 Corrosion allowance mm 1,59 1,59 T2 S1

37 Connections In mm 1 76,2 / - 1 76,2 / -

38 Size/Rating Out 1 76,2 / - 1 76,2 / -

39 Nominal Intermediate 1 / - 1 / -

40 Tube #: 58 OD: 25,4 Tks. Average 2,77 mm Length: 1828,8 mm Pitch: 31,75 mm Tube pattern:30

41 Tube type: Plain Insert:None Fin#: #/m Material:Carbon Steel

42 Shell Carbon Steel ID 307,09 OD 323,85 mm Shell cover -

43 Channel or bonnet Carbon Steel Channel cover -

44 Tubesheet-stationary Carbon Steel - Tubesheet-floating -

45 Floating head cover - Impingement protection None

46 Baffle-cross Carbon Steel Type Single segmental Cut(%d) 37,59 Horizontal

Spacing: c/c 165,1 mm

47 Baffle-long - Seal Type Inlet 304,8 mm

48 Supports-tube U-bend 0 Type

49 Bypass seal Tube-tubesheet joint Expanded only (2 grooves)(App.A 'i')

50 Expansion joint - Type None

51 RhoV2-Inlet nozzle 980 Bundle entrance 68 Bundle exit 68 kg/(m-s²)

52 Gaskets - Shell side - Tube side Flat Metal Jacket Fibe

53 Floating head -

54 Code requirements ASME Code Sec VIII Div 1 TEMA class C - general service

55 Weight/Shell 488,1 Filled with water 627,9 Bundle 217,4 kg

56 Remarks

57

58

S-ar putea să vă placă și

- Gravimetric Determination of Condensable Components: Group StandardDocument6 paginiGravimetric Determination of Condensable Components: Group Standardthiagomcasimiro100% (1)

- Seminar Report On Aircraft Hydraulic SystemDocument37 paginiSeminar Report On Aircraft Hydraulic Systempriya007893878% (18)

- 10 1016@j Jngse 2016 01 016Document37 pagini10 1016@j Jngse 2016 01 016saiful bahriÎncă nu există evaluări

- JEWEL T Hydrocarbon Dew Point ControlDocument2 paginiJEWEL T Hydrocarbon Dew Point ControljojeecaresÎncă nu există evaluări

- (Doru Michael Stefanescu) Science and EngineeringDocument413 pagini(Doru Michael Stefanescu) Science and EngineeringJayant Raj SauravÎncă nu există evaluări

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 paginiAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũÎncă nu există evaluări

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 paginiAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoÎncă nu există evaluări

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 paginiGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongÎncă nu există evaluări

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 paginăC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaÎncă nu există evaluări

- Jet Flood: Kister and Haas CorrelationDocument3 paginiJet Flood: Kister and Haas CorrelationFeni AlvionitaÎncă nu există evaluări

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 paginiMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanÎncă nu există evaluări

- Data Sheet - Gas-Gas Heat ExchangerDocument1 paginăData Sheet - Gas-Gas Heat ExchangerPrabhakarÎncă nu există evaluări

- Castable-Free Fired HeaterDocument4 paginiCastable-Free Fired HeaterchemengseliemÎncă nu există evaluări

- Gas Chiller Datasheet PDFDocument2 paginiGas Chiller Datasheet PDFidilfitriÎncă nu există evaluări

- Mr. C.H.Park / Project Manager 03-May-06Document30 paginiMr. C.H.Park / Project Manager 03-May-06Ali YassineÎncă nu există evaluări

- High Performance TraysDocument4 paginiHigh Performance Traysahmed mohamedÎncă nu există evaluări

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 paginiOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- UOP 3-28-6 - Storage Tanks Low PressureDocument3 paginiUOP 3-28-6 - Storage Tanks Low Pressurejev_vdÎncă nu există evaluări

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 paginiCMPAPPP Separator Vessel and Filter Design GuideJWilson73Încă nu există evaluări

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 paginăTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisÎncă nu există evaluări

- E07 QDocument20 paginiE07 QSoledad Fernández SantosÎncă nu există evaluări

- MP60P70Document28 paginiMP60P70903352Încă nu există evaluări

- Bulletin 71.4MR108 PDFDocument20 paginiBulletin 71.4MR108 PDFBledarÎncă nu există evaluări

- Offsites and UtilitiesDocument70 paginiOffsites and Utilitiesankitalalwani100% (1)

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 paginiCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- Webinar FAQ - Shell and Tube Heat ExchangersDocument8 paginiWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810Încă nu există evaluări

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 paginiR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRAÎncă nu există evaluări

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 paginiShell and Tube Heat Exchanger Design: Fluid AllocationLungeloÎncă nu există evaluări

- NGL SeparationDocument6 paginiNGL SeparationhoustonmathÎncă nu există evaluări

- Thermophysical PropertiesDocument14 paginiThermophysical PropertiesKalinga BalÎncă nu există evaluări

- Guide Document GE P312 4.1.2 I General ConsiderationsDocument31 paginiGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraÎncă nu există evaluări

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocument3 paginiTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasÎncă nu există evaluări

- Equipment DatasheetDocument3 paginiEquipment DatasheetmdgouseahmedÎncă nu există evaluări

- Mole Sieve Dehydration Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument26 paginiMole Sieve Dehydration Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignMariana Michel0% (1)

- EGE13B11Document18 paginiEGE13B11Jhonny Rafael Blanco CauraÎncă nu există evaluări

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocument77 paginiAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- Long Weld Necks 300 PDFDocument1 paginăLong Weld Necks 300 PDFPedro Montes MarinÎncă nu există evaluări

- Practical Aspects of Condenser and Reboiler DesignDocument11 paginiPractical Aspects of Condenser and Reboiler DesignForcus on100% (1)

- CPS6 Choke GAsDocument19 paginiCPS6 Choke GAskarthikÎncă nu există evaluări

- Instrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAIDocument1 paginăInstrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAInastyn-1Încă nu există evaluări

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringDocument5 paginiInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLAÎncă nu există evaluări

- Thermal Degassing Fundamentals R4i1 enDocument6 paginiThermal Degassing Fundamentals R4i1 enAnonymous v5uipHÎncă nu există evaluări

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocument8 paginiPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimÎncă nu există evaluări

- TN 010-Drip Traps Rev ADocument6 paginiTN 010-Drip Traps Rev AMariusCapraÎncă nu există evaluări

- 09 SpargerDocument17 pagini09 SpargerWeb LogueandoÎncă nu există evaluări

- VGS Vane Separators Are Recommended ForDocument1 paginăVGS Vane Separators Are Recommended ForSanthu PeelaÎncă nu există evaluări

- 08 Subsurface Sucker-Rod Pumps PDFDocument10 pagini08 Subsurface Sucker-Rod Pumps PDFBanda ClaretÎncă nu există evaluări

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocument8 paginiA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Aspen Exchanger Design and Rating Air Cooled V11Document1 paginăAspen Exchanger Design and Rating Air Cooled V11HafidzAliyufaÎncă nu există evaluări

- General Arrangement Drawing: Pump DataDocument1 paginăGeneral Arrangement Drawing: Pump DataJwardÎncă nu există evaluări

- M17Document28 paginiM17Adrian GuzmanÎncă nu există evaluări

- Control Valve Data Sheet Form S20 50 PDFDocument4 paginiControl Valve Data Sheet Form S20 50 PDFPanner2009Încă nu există evaluări

- Dukler Et Al. (1969) CorrelationDocument8 paginiDukler Et Al. (1969) Correlationkhalid alrawiÎncă nu există evaluări

- IPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ADocument9 paginiIPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ANikhil KarkeraÎncă nu există evaluări

- Line ListDocument1 paginăLine Listهيمنت بيلودياÎncă nu există evaluări

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 paginiFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismÎncă nu există evaluări

- Flare Systems Basics Design and Calculations 1678330360Document63 paginiFlare Systems Basics Design and Calculations 1678330360nitinÎncă nu există evaluări

- Introduction For Test Separator: CNPCIC Field ProductionDocument18 paginiIntroduction For Test Separator: CNPCIC Field Productionsalahadine maideÎncă nu există evaluări

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 paginiVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasÎncă nu există evaluări

- Boiler Feedwater Treating Systems: Design PracticesDocument96 paginiBoiler Feedwater Treating Systems: Design PracticesAleem QureshiÎncă nu există evaluări

- Fuel Gas Skid Train PDFDocument1 paginăFuel Gas Skid Train PDFhadÎncă nu există evaluări

- Statistics for Process Control Engineers: A Practical ApproachDe la EverandStatistics for Process Control Engineers: A Practical ApproachÎncă nu există evaluări

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectDe la EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectÎncă nu există evaluări

- A Review On Importance of Artocarpus Heterophyllus L. (Jackfruit)Document11 paginiA Review On Importance of Artocarpus Heterophyllus L. (Jackfruit)Bith SMGÎncă nu există evaluări

- (ITB) Pengumuman Seleksi Assessment & FGD 2018Document3 pagini(ITB) Pengumuman Seleksi Assessment & FGD 2018Bith SMGÎncă nu există evaluări

- 03 - Präsentation - Biogasanlagen - Schöllauf - Engl. (Kompatibilitätsmodus)Document69 pagini03 - Präsentation - Biogasanlagen - Schöllauf - Engl. (Kompatibilitätsmodus)Bith SMGÎncă nu există evaluări

- The Ribbon Advocates A MysticDocument1 paginăThe Ribbon Advocates A MysticBith SMGÎncă nu există evaluări

- Alpha Pinene LibDocument13 paginiAlpha Pinene LibBith SMGÎncă nu există evaluări

- CO20 E On Line Carbon Dioxide MonitorDocument1 paginăCO20 E On Line Carbon Dioxide MonitorBith SMGÎncă nu există evaluări

- Kuliah Pendahuluan Labtek PDFDocument34 paginiKuliah Pendahuluan Labtek PDFBith SMGÎncă nu există evaluări

- GPM Lap 1 - 2 NovDocument2 paginiGPM Lap 1 - 2 NovBith SMGÎncă nu există evaluări

- Green Engineering Chapter 1Document4 paginiGreen Engineering Chapter 1Zward21Încă nu există evaluări

- Masterbatch Processing - PT Kasakata KimiaDocument9 paginiMasterbatch Processing - PT Kasakata KimiaBith SMGÎncă nu există evaluări

- Dictionary For LubricationDocument64 paginiDictionary For LubricationChristine Sta RomanaÎncă nu există evaluări

- Kinetic Theory 1.1.1 Kinetic Theory Solids, Liquids & Gases SolidsDocument58 paginiKinetic Theory 1.1.1 Kinetic Theory Solids, Liquids & Gases SolidsNandni JethwaÎncă nu există evaluări

- L-1.2: Thermal Energy Section A: Choose The Best AnswerDocument17 paginiL-1.2: Thermal Energy Section A: Choose The Best AnswerDani BaderÎncă nu există evaluări

- May 30, 1944. P. C. Dixon 2,349,944: Method of and Means For Separating Liquid and Gas or Gaseous FluidDocument8 paginiMay 30, 1944. P. C. Dixon 2,349,944: Method of and Means For Separating Liquid and Gas or Gaseous FluidsamandondonÎncă nu există evaluări

- Typical PFD For Centrifugal Compressor SystemsDocument2 paginiTypical PFD For Centrifugal Compressor SystemsKmt_Ae0% (1)

- Viscosity & RheologyDocument8 paginiViscosity & RheologySwatsawi SwatÎncă nu există evaluări

- Gear Pump Standard Operating Manual and Instructions PDFDocument35 paginiGear Pump Standard Operating Manual and Instructions PDFdalbaasÎncă nu există evaluări

- Metal Working Fluids and Related Materials: Standard Classification ForDocument2 paginiMetal Working Fluids and Related Materials: Standard Classification ForDennise Chicaiza100% (2)

- Compact, Continuous, Effective: BOLL Automatic FiltersDocument7 paginiCompact, Continuous, Effective: BOLL Automatic FiltersFer SevanÎncă nu există evaluări

- MINERAL OIL EMULSION (USP 23, P.1029, Matindale 29 TH, p.1322)Document3 paginiMINERAL OIL EMULSION (USP 23, P.1029, Matindale 29 TH, p.1322)sanaÎncă nu există evaluări

- Pioro, 2017. Supercritical Power Generation PDFDocument55 paginiPioro, 2017. Supercritical Power Generation PDFFabian MendozaÎncă nu există evaluări

- Flow Instabilities in A Horizontal Thermosyphon Reboiler LoopDocument22 paginiFlow Instabilities in A Horizontal Thermosyphon Reboiler Loopwylie01Încă nu există evaluări

- Sihi Lem 90 - 125 - 150 DetailsDocument4 paginiSihi Lem 90 - 125 - 150 DetailsElmer RchÎncă nu există evaluări

- 19xl 3pd PDFDocument38 pagini19xl 3pd PDFDione SilvaÎncă nu există evaluări

- 3.2 Pressure in LiquidsDocument15 pagini3.2 Pressure in Liquidssaeed akhtar100% (1)

- Tutorial Sheet 2Document2 paginiTutorial Sheet 2Syed YousufuddinÎncă nu există evaluări

- Salt Fouling FCCDocument6 paginiSalt Fouling FCCVenkatesh Kumar RamanujamÎncă nu există evaluări

- AbsorberDocument22 paginiAbsorberNAGARAJAN A R [CB.EN.U4CHE17035]Încă nu există evaluări

- Physics 2.3 - Thermal Properties and Temperature - 1Document55 paginiPhysics 2.3 - Thermal Properties and Temperature - 1Yu ErinÎncă nu există evaluări

- Lesson 3 Energy and Phase ChangesDocument22 paginiLesson 3 Energy and Phase Changesyour mamaÎncă nu există evaluări

- Redlich-Kister EquationDocument6 paginiRedlich-Kister EquationVatsal ShahÎncă nu există evaluări

- Physical Science: Quarter 1 - Module 3: Intermolecular Forces of AttractionDocument24 paginiPhysical Science: Quarter 1 - Module 3: Intermolecular Forces of AttractionZeporah OrdonÎncă nu există evaluări

- Module Thermodynamics 1-4: Colorado State UniversityDocument28 paginiModule Thermodynamics 1-4: Colorado State UniversityAsyifa Rizqi UtamiÎncă nu există evaluări

- Grade 7 Physics - Worksheet 1 (4th Quarter)Document5 paginiGrade 7 Physics - Worksheet 1 (4th Quarter)Kibrom KirosÎncă nu există evaluări

- Design Consideration PumpsDocument18 paginiDesign Consideration PumpsChandaKundaÎncă nu există evaluări

- Quiz Science HeatDocument3 paginiQuiz Science HeatlinaÎncă nu există evaluări

- 01 - IntroductiontoCrystalGrowthPrinciplesandPractice by HLBhattDocument346 pagini01 - IntroductiontoCrystalGrowthPrinciplesandPractice by HLBhatthariÎncă nu există evaluări