Documente Academic

Documente Profesional

Documente Cultură

ESA - ARC-23281 Migmaster 215 and 280 Data Page Email

Încărcat de

Alejandro Pereira BerríosTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ESA - ARC-23281 Migmaster 215 and 280 Data Page Email

Încărcat de

Alejandro Pereira BerríosDrepturi de autor:

Formate disponibile

Migmaster® 215 Pro/280 Pro

Compact strength and mobility.

Equipped with V/A digital meter with hold feature

Creep start – gradual feed of wire for ultimate

starts

Adjustable wire feed speed

Adjustable burnback timer – gives correct stick-out

Spot welding timer

Outstanding welding characteristics – efficient,

high-quality welding

Wide current and voltage range – multi-purpose

applications

Spool gun on-demand

Sturdy, galvanized metal casing with air filter

(optional)

The Migmaster 215 Pro/280 Pro are sturdy and robust Accessories

step-controlled welding power units. They are intended Air filter

for medium (215 Pro) to heavy-duty (280 Pro) MIG/ 215 Pro..................................................................... 0349302599

MAG welding with solid wires of steel, stainless steel, or 280 Pro..................................................................... 0349312810

aluminum, as well as cored-wires with or without shielding Cable and torch holder

gas. ESAB’s proven technology and software provide 215 Pro..................................................................... 0349303362

280 Pro..................................................................... 0349312800

reliability and outstanding welding performance.

MT-250SG spool gun............................................................36779

The units are made with a strong galvanized metal casing ST-23A spool gun (requires 37301 adapter).......................19164

to withstand harsh environments. Large wheels and built- Dual Cylinder Tray Kit

in wire feeder ensure these machines are practical and 215 Pro (208/230v).................................................. 0349309312

mobile solutions. The units are fan-cooled and equipped 280 Pro .................................................................... 0349312760

with thermal overload protection. Feed Rolls

.023 – .030 in. V-HARD............................................ 0367556001

A wide current and voltage range, plus two inductance .030 – .040 in. V-HARD............................................ 0367556002

outlets (280 Pro) make it easy to optimize settings for .040 – .045 in. V-HARD............................................ 0367556003

a variety of filler materials and gases. Migmaster 215 .035 – .045 in. V-HARD*........................................... 0349312497

Pro/280 Pro units are equipped with the potentiometers to .040 – 3/64 in. U-SOFT............................................ 0367556004

set the wire feed speed, spot welding time, and burnback .045 in./.052 – .062 in. VK-G................................... 0367556006

* Note: Included in ready to weld package

time adjustment. Furthermore, Migmaster machines are

equipped with such functions as creep start and inching.

OrderingInformation

Migmaster 215 Pro Package

208/230 V, 15 ft. torch........................................... 0558101322

Migmaster 280 Pro Package

208/230 V, 15 ft. torch........................................... 0558101324

230/460/575 V, 15 ft. torch.................................... 0558101365

Ready to Weld package includes: console with wheel kit installed,

15 ft. (4.5 m) Gunmaster 250 A torch, 10 ft. (3 m) power cord, 10

ft. (3 m) work cable, R-33 FM580 regulator/flowmeter, (1) .035

and .045 contact tip, and 10# spool of

87HP .035

ESAB Welding and Cutting Products Instruction Manual ...................................................... 0349301164

esabna.com / 1.800.ESAB.123 Product Data Page ..................................................... ARC-23281

Migmaster® 215 Pro/280 Pro

Compact strength and mobility.

Specifications

Migmaster 215 Pro Migmaster 280 Pro

Input voltage 208/230 VAC, 1 ph, 60 Hz 208/230 VAC, 1 ph, 60 Hz

230/460/575 VAC, 1 ph, 60 Hz

Primary input current @ 250 A 25% DC 53 A/48 A 74 A/66 A

66 A/34 A/26 A

Permitted load at:

20% duty cycle 250 A/23 V X

40% duty cycle X 300 A/29 V

60% duty cycle 160 A/22 V 250 A/26.5 V

100% duty cycle 110 A/19.5 V 194 A/23.7 V

Setting range (DC) 40 A/16 V–250 A/23 V 40 A/16 V–300 A/29 V

Power factor at maximum current 0.95 0.97

Efficiency at maximum current 76% 71%

Wire feed speed 75–700 in./min. 55–770 in./min.

Burnback time 0–0.25 sec. 0–0.25 sec.

Spot welding time 0.2–2.5 sec. 0.2–2.5 sec.

Creep start Selectable Selectable

Voltage steps 12 21

Dimensions L x W x H 33 x 16.7 x 32.7 in. (840 x 425 x 830 mm) 32 x 22 x 36.5 in. (840 x 552 x 925 mm)

Weight 216 lb (98 kg) 308 lb (140 kg)

Operating temperature 14 to 104°F (-10 to +40°C) 14 to 104°F (-10 to +40°C)

Enclosure class IP 23 S IP 23 S

Wire Dimensions

Steel .023–.045 in. (0.6–1.2 mm)

Aluminum .047 in. (1.2 mm)

Stainless .023–.045 in. (0.6–1.2 mm)

Cored-wire .035–.045/.052–.062 in. (0.9–1.6 mm)

ESAB Welding and Cutting Products

esabna.com / 1.800.ESAB.123

S-ar putea să vă placă și

- High-Security Mechanical Locks: An Encyclopedic ReferenceDe la EverandHigh-Security Mechanical Locks: An Encyclopedic ReferenceEvaluare: 5 din 5 stele5/5 (9)

- Mitech Welder ManualDocument13 paginiMitech Welder ManualkapasuduÎncă nu există evaluări

- Manual de Instalacion YSFE IDDocument82 paginiManual de Instalacion YSFE IDklein GonzalezÎncă nu există evaluări

- Elektra Beckum PT260 ManualgreenDocument16 paginiElektra Beckum PT260 ManualgreengrmjagodaÎncă nu există evaluări

- Mov (Varistor)Document488 paginiMov (Varistor)saeidraminaÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Iso 16232 10 2007 en PDFDocument8 paginiIso 16232 10 2007 en PDFyağmurÎncă nu există evaluări

- Chrysler Dodge Ram Jeep Drive Cycle InformationDocument2 paginiChrysler Dodge Ram Jeep Drive Cycle InformationslpkthÎncă nu există evaluări

- Beyond The Breech Trial. Maggie BanksDocument4 paginiBeyond The Breech Trial. Maggie Bankspurpleanvil100% (2)

- Ielts Reading Actual Tests With Suggested Answers Oct 2021 JDocument508 paginiIelts Reading Actual Tests With Suggested Answers Oct 2021 JHarpreet Singh JohalÎncă nu există evaluări

- ARC 23281A en US FactSheet Main 01Document2 paginiARC 23281A en US FactSheet Main 01Pedido VentasÎncă nu există evaluări

- Origo Mig 652c Flexible Heavy Duty Solution: Ordering InformationDocument2 paginiOrigo Mig 652c Flexible Heavy Duty Solution: Ordering InformationcarlosÎncă nu există evaluări

- Caddy Tig 2200i DC: Ordering InformationDocument2 paginiCaddy Tig 2200i DC: Ordering InformationcarlosÎncă nu există evaluări

- Origo Mig 320-410 NA MVDocument2 paginiOrigo Mig 320-410 NA MVcarlosÎncă nu există evaluări

- Aristo Feed 3004 U6 With Mig 4002c/6502c Power SupplyDocument3 paginiAristo Feed 3004 U6 With Mig 4002c/6502c Power SupplyChinta IulianÎncă nu există evaluări

- Manual Maquina Soldar ESAB LKA-240-2Document23 paginiManual Maquina Soldar ESAB LKA-240-2Diego Ferreira FernándezÎncă nu există evaluări

- ARC-23304 Warrior Product DataDocument4 paginiARC-23304 Warrior Product DataAmando FuentesÎncă nu există evaluări

- Transformadores de Aislamiento CompletoDocument16 paginiTransformadores de Aislamiento CompletoSinty JvÎncă nu există evaluări

- 9421CT0301Document44 pagini9421CT0301patomanzaÎncă nu există evaluări

- Eltorque User ManualDocument29 paginiEltorque User Manualdhlinva3205Încă nu există evaluări

- G120X - Equipos de ProteccionDocument31 paginiG120X - Equipos de ProteccionsebastianÎncă nu există evaluări

- Instruction Manual: ES65 / ES100 / ES200 / ES300 and ES630 Single Stage Rotary Vane PumpsDocument56 paginiInstruction Manual: ES65 / ES100 / ES200 / ES300 and ES630 Single Stage Rotary Vane PumpsJVH1978Încă nu există evaluări

- V430017 Fabricator 211iDocument4 paginiV430017 Fabricator 211icarlosÎncă nu există evaluări

- ARC-23000 - Arc Welding Equipment Catalog - 2009Document113 paginiARC-23000 - Arc Welding Equipment Catalog - 2009Misko PiskoÎncă nu există evaluări

- TM MAC (60Hz) 2011Document28 paginiTM MAC (60Hz) 2011Mohamed SanosÎncă nu există evaluări

- ESAB Rebel EMP 215icDocument4 paginiESAB Rebel EMP 215icEDUARDO ALCANTARA JRÎncă nu există evaluări

- 3851/3852/3856 - 3/4 Diameter Panel Control: FeaturesDocument6 pagini3851/3852/3856 - 3/4 Diameter Panel Control: FeaturesGerman MedinaÎncă nu există evaluări

- Kemppi Minarc-Evo-180 en US PDFDocument2 paginiKemppi Minarc-Evo-180 en US PDFIonel ȘearpeÎncă nu există evaluări

- 12581EMP en - US FactSheet - Main 01Document4 pagini12581EMP en - US FactSheet - Main 01Audha Zen5Încă nu există evaluări

- 570 Data SheetDocument2 pagini570 Data Sheetsaid_rahmansyah4750Încă nu există evaluări

- Technical Data: Rotanode E7252X E7252FX E7252GXDocument22 paginiTechnical Data: Rotanode E7252X E7252FX E7252GXNguyen HaiÎncă nu există evaluări

- TM AHU 60R410A Onoff T SA NA 171205Document67 paginiTM AHU 60R410A Onoff T SA NA 171205Sam RVÎncă nu există evaluări

- Index Current / Voltage Transformers and ShuntsDocument54 paginiIndex Current / Voltage Transformers and ShuntsHoang Le Dang100% (1)

- Auweld Welding Machines Accessories Catalogue(s)Document28 paginiAuweld Welding Machines Accessories Catalogue(s)nyaungzinÎncă nu există evaluări

- Esa AutDocument2 paginiEsa AutmohdfaridabubakarÎncă nu există evaluări

- Operating Manual: Models C200 & C300 Rotary Head Wire Strippers and TwistersDocument8 paginiOperating Manual: Models C200 & C300 Rotary Head Wire Strippers and TwisterssnsidhpuriÎncă nu există evaluări

- DDocument47 paginiDSusheel RajÎncă nu există evaluări

- Rel Series KolarcDocument4 paginiRel Series KolarcDarko NikolovskiÎncă nu există evaluări

- Instruction Manual: E2M28 and E2M30 Rotary Vacuum PumpsDocument48 paginiInstruction Manual: E2M28 and E2M30 Rotary Vacuum PumpsWinÎncă nu există evaluări

- Mig195 230teDocument31 paginiMig195 230teAlex PisaÎncă nu există evaluări

- Millermatic 140 Spec SheetDocument4 paginiMillermatic 140 Spec SheetPaisaje SilenciosoÎncă nu există evaluări

- ps-62000 11 Feb 21Document2 paginips-62000 11 Feb 21api-170472102Încă nu există evaluări

- Siemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesDocument88 paginiSiemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesaminardakaniÎncă nu există evaluări

- OPzV2 1000Document2 paginiOPzV2 1000HabibÎncă nu există evaluări

- Resistor & Capacitor CatalogDocument61 paginiResistor & Capacitor CatalogAmbrosiousÎncă nu există evaluări

- Protective Devices For SINAMICS G120XDocument31 paginiProtective Devices For SINAMICS G120XjoseÎncă nu există evaluări

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 paginiLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloÎncă nu există evaluări

- Ampco 15: Technical Data SheetDocument1 paginăAmpco 15: Technical Data SheetdedosimoesÎncă nu există evaluări

- Plasmarc Accessories: Remote Hand Switches Torch Guide KitsDocument2 paginiPlasmarc Accessories: Remote Hand Switches Torch Guide KitscarlosÎncă nu există evaluări

- Manual Instalare Proteco LEADERDocument12 paginiManual Instalare Proteco LEADERInventor TestÎncă nu există evaluări

- Shovel Specifi Cations: Dimensions and Working RangesDocument2 paginiShovel Specifi Cations: Dimensions and Working RangesMiguel Angel RodriguezÎncă nu există evaluări

- Control Products CatalogDocument50 paginiControl Products Catalogmk saravananÎncă nu există evaluări

- Cable-Extension Position TransducerDocument3 paginiCable-Extension Position TransducermelquicedecÎncă nu există evaluări

- 30N60A4D Fairchild SemiconductorDocument9 pagini30N60A4D Fairchild SemiconductorJaviera MuñozÎncă nu există evaluări

- Welding Automation CatalogDocument112 paginiWelding Automation CatalogVirgil SorcaruÎncă nu există evaluări

- Owner's Manual SGA 100 and SGA 100C: 1. Safety Symbol DefinitionsDocument10 paginiOwner's Manual SGA 100 and SGA 100C: 1. Safety Symbol DefinitionsJeffrey HurleyÎncă nu există evaluări

- Miller TIG HandbookDocument20 paginiMiller TIG Handbookquiron2010Încă nu există evaluări

- Power Electronics Design: A Practitioner's GuideDe la EverandPower Electronics Design: A Practitioner's GuideEvaluare: 4.5 din 5 stele4.5/5 (3)

- Bagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIDocument4 paginiBagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIYahien PutriÎncă nu există evaluări

- 50 Interview Question Code Galatta - HandbookDocument16 pagini50 Interview Question Code Galatta - HandbookSai DhanushÎncă nu există evaluări

- Charging Station For E-Vehicle Using Solar With IOTDocument6 paginiCharging Station For E-Vehicle Using Solar With IOTjakeÎncă nu există evaluări

- Instructional Decision MakingDocument5 paginiInstructional Decision Makingapi-257693907Încă nu există evaluări

- Pemisah ZirconDocument10 paginiPemisah ZirconLorie Banka100% (1)

- Учебный предметDocument2 paginiУчебный предметorang shabdizÎncă nu există evaluări

- ADAPT-Builder 2019 GUI Quick Reference GuideDocument103 paginiADAPT-Builder 2019 GUI Quick Reference GuideephremÎncă nu există evaluări

- 2012 Karshaniya YavaguDocument4 pagini2012 Karshaniya YavaguRANJEET SAWANTÎncă nu există evaluări

- Thermal ComfortDocument50 paginiThermal ComfortSSÎncă nu există evaluări

- Branch & Category Wise Opening & Closing Rank of JEE (Main) 2019Document46 paginiBranch & Category Wise Opening & Closing Rank of JEE (Main) 2019soni dwivediÎncă nu există evaluări

- Proac Studio 100: Monitor Level Performance From An Established Compact DesignDocument2 paginiProac Studio 100: Monitor Level Performance From An Established Compact DesignAnonymous c3vuAsWAÎncă nu există evaluări

- GCGM PDFDocument11 paginiGCGM PDFMiguel Angel Martin100% (1)

- Firststep To AlaskaDocument28 paginiFirststep To AlaskaBarbara NelsonÎncă nu există evaluări

- 250 Conversation StartersDocument28 pagini250 Conversation StartersmuleÎncă nu există evaluări

- Christine Remembered That Today Is The Birthday of Her BossDocument1 paginăChristine Remembered That Today Is The Birthday of Her BossA.Încă nu există evaluări

- UVEX - Helmets & Eyewear 2009Document19 paginiUVEX - Helmets & Eyewear 2009Ivica1977Încă nu există evaluări

- T HR El 20003 ST PDFDocument20 paginiT HR El 20003 ST PDFAngling Dharma100% (1)

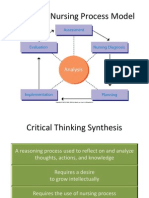

- NUR 104 Nursing Process MY NOTESDocument77 paginiNUR 104 Nursing Process MY NOTESmeanne073100% (1)

- The Journeyto Learning Throughthe Learning StylesDocument93 paginiThe Journeyto Learning Throughthe Learning Stylesastria alosÎncă nu există evaluări

- High School Department PAASCU Accredited Academic Year 2017 - 2018Document6 paginiHigh School Department PAASCU Accredited Academic Year 2017 - 2018Kevin T. OnaroÎncă nu există evaluări

- 2 TolentinoDocument12 pagini2 TolentinoMA. ANGELINE GRANADAÎncă nu există evaluări

- Management Accounting/Series-4-2011 (Code3024)Document18 paginiManagement Accounting/Series-4-2011 (Code3024)Hein Linn Kyaw100% (2)

- THE PERFECT DAY Compressed 1 PDFDocument218 paginiTHE PERFECT DAY Compressed 1 PDFMariaÎncă nu există evaluări

- IAU Logbook Core 6weeksDocument7 paginiIAU Logbook Core 6weeksbajariaaÎncă nu există evaluări

- Gita Ananda SDocument10 paginiGita Ananda Srosaanggita76Încă nu există evaluări