Documente Academic

Documente Profesional

Documente Cultură

Nasm1312-13 Double Shear Test PDF

Încărcat de

Michelle Camacho HerediaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nasm1312-13 Double Shear Test PDF

Încărcat de

Michelle Camacho HerediaDrepturi de autor:

Formate disponibile

NATIONAL AEROSPACE STANDARD

ID COPYRIGHT 2003 AEROSPACE INDUSTRIES ASSOCIATION OP AMERICA, INC.

ALL RIGHTS RESERVED

NASM1312-13

STANDARD PRACTICE

FASTENER TEST METHODS

METHOD 13

DOUBLE SHEAR TEST

Aerospace

Industries

Association

THE INITIAL RELEASE OF THIS DOCUMENT SUPERSEDES MIL-STD-1312-13A

DESIGNATION FOR THIS TEST METHOD REMAINS MIL-STD-1312-13

L1ST OF CURRENT SHEETS

NO. 1 2 3 4 5 6 7

REV. 1 1 1 1 1 1 1

SHEET 1 OF 7 FSC 53GP

APPROVAL DATE AUGUST 1997 REVISION February 2003

USE OF OR REUANCE ON THIS DOCUMENT OR ANY NATIONAL AEROSPACE STANDARD IS ENTIRELY VOLUNTARY AJA DOES NOT OUALIFY SUPPLIERS OR CERTIFY

CONFORMANCE OF ÍTEMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS AIA MAKES NO REPRESENTATION OR CLAIM RESPECTING (1) THE SUITADILITY

OF ÍTEMS FOR ANY PARTICULAR APPLICATION, OR (2) THE D(ISTENCE OF OR APPUCABILTTY THERETO OF PATENT OR TRADEMARK RIGHTS .

Copyright Aerospace Industries Association of America Inc

Sold lo INFORMATION HANDLING SERVICES 01874946

Provided by IHS under license with AIA/NAS

No reproduclion or networking perrnitted without license from IHS Not for Resale,2011/9/1 15 57:59 GMT

NATIONAL AEROSPACE STANDARD

COPYRIGHT 2003 AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA,

ALL RIGHTS RESERVED

NASM1312-13

TABLE OF CONTENTS

PARAGRAPH SHEET

1. SCOPE 3

2. REFERENCE DOCUMENTS 3

2.1 AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM)

2.2 THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) ....... 3

2.3 NATIONAL CONFERENCE OF STANDARDS LABS (NCSL) 3

3. DEFINITIONS ......... ... ...... ......... 3

4. GENERAL REQUIREMENTS 3

4.1 TEST APPARATUS 3

4.1.1 TESTING MACHINE 3

4.2 TEST FIXTURES 3

4.3 TEST SPECIMEN 4

5. DETAILED REQUIREMENTS 4

5.1 TEST PROCEDURES . ...... ........ ............... ...... ...... ....... 4

6. NOTES 4

6.1 TEST REPORT 4

FIGURES

FIGURE

1. DOUBLE SHEAR FIXTURE ............. .................. ...... ................ ..... ......... . 5

2. FIXTURE BLADE 6

3. FIXTURE FORK ......... ........................... ................. ...... .......... 6

4 . FIXTURE BASE ......................... ................. ........... .......... ............... 6

TABLES

TABLE

DOUBLE SHEAR LOAD RATES ......... .................... ...... ....... ....... 5

11 DOUBLE SHEAR FIXTURE DIMENSIONS 7

OCOMPLETELY REVISED

SHEET 2

APPROVAL DATE AUGUST 1997 REVISION Q February 2003

ENTIRELY VOLUNTARY. AJA DOES NOT OUAUFY SUPPLIERS OR CERTIFY

USE OF OR REUANCE ON THIS DOCUMENT OR ANY NATIONAL AEROSPACE STANDARD 1S

CONFORMANCE OF ÍTEMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS. AIA MAKES NO REPRESENTAT1ON OR CUITA RESPECTING (1) THE SUITABILITY

OF RENS FOR ANY PARTICULAR APPLICATION, OR (2) THE ENSTENCE OF OR APPUCASILITY THERETO OF PATENT OR TRADEMARK RIGHTS.

Copyright Aerospace Industries Association of Amenca Inc.

Sold to:INFORMATION HANDLING SERVICES, 01874846

Provided by IHS under license with AIA/NAS

Not for Resale,201119/1 16:57:59 GMT

No reproduction or nehvorking permitted without license from IHS

NATIONAL AEROSPACE STANDARD

) COPYRIGHT 2003 AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA, INC.

A.LL ~me RESERVED

NASM1312-13

1. SCOPE

1.1 This specification defines the procedure and apparatus for testing fasteners in double shear in a

half-hole fixture.

1.2 Recommendations for improvements or corrections of this speclfication should be directed to an

NASC representative of a using aerospace company or to the Executive Secretary of the National

Aerospace Standards Committee.

1.3 Specifications Usted herein, of issue in effect on date of price inquiry are a part of this specification

to the extent indicated. In case of conflict, the requírements herein shall take precedence.

1.4 All test equipment and test procedures shall meet and/or comply with applícable environmental and

occupational safety hazard requirements and statutes.

2. REFERENCED DOCUMENTS

2.1 American Society for Testing and Materials (ASTM)

ASTM E4 - 01, Standard Practice for Force Verification of Testing Machines

2.2 American Society of Mechanical Engineers

ASME Y14.5M - 1994, Dimensioning and Tolerancing

2.3 National Conference of Standards Labs

NCSL Z540.1-1994, Calibration Laboratories and Measuring and Test Equipment -

General Requirements

3. DEFINITIONS

3.1 The ultimate double shear load in pounds is the highest load attained at any time during the test.

3.2 The ultimate single shear load in PSI (Pound per Square Inch) is calculated by dividing the highest

load attained in pounds at any time during the double shear test by two (2) times the actual shank

diameter ama.

4. GENERAL REQUIREMENTS

4.1 Test Apparatus

4.1.1 The testing machine shall be capable of applying a compressive load at a controllable rete. The

calibrating system for the machine shall conform to ANSI Z540,1. Its accuracy shall be verified

every twelve (12) months by a method complying with ASTM E4, utilizing calibration equipment

whích has been calibrated by, or its accuracy is traceable to, the National Institute of Standards

and Technology (NIST) not more than two (2) years prior to its use. The fastener or test specimen

loads shall be within the range of the testing machine as defined in ASTM E4.

4.2 Test Fixtures

4.2.1 Test fixtures shall be in accordance with FIGURES 1 through 4 except as noted in TABLE II, Note 3.

O COMPLETELY REVISED

SHEET 3

APPROVAL DATE AUGUST 1997 REVIS1ON OFebruary 2003

USE OF OR RELIANCE ON THIS DOCUMENT PR ANY NATIONAL AEROSPACE STANDARD IS ENTIRELY VOLUNTARY AIA ROES NOT OUALIFY SUPPLIERS OR CERTIFY

CONFORMANCE OF REMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS. AIA MAKES NO REPRESENTATION OR CLAN RESPECTING (1) THE SUITABILITY

OF ITEMS FOR ANY PARTICULAR APPLICATION, OR (2) THE EXISTENCE OF OR APPLICABILRY THERETO OF PATENT OR TRADEMARK RIGHTS

.

Copynciht Aerospace Industries Associatan of America Inc.

Sold to INFORMATION HANDLING SERVICES, 01874946

Prowded by IHS under license with MAMAS

Not for Resale,2011/911 16'57'59 GMT

No reproduction or networking perrnitted without license froni IHS

NATIONAL AEROSPACE STANDARD

C COPYRIGHT 2003 AEROSPACE DIDUSTRIES ASSOCIATION OF AMERICA, INC.

ALL RIGHTS RESERVED

NASM1312-13

4.3 Test Specimen

4.3.1 Test specimens shall be processed from the same heat of material as that usad in the fabrication of the

fastener production lot, fabricated to the same shank or grip diameter as required for the fastener lot being

tested, and thermally processed, coated and/or plated with the fastener manufacturing lot. Final product

fasteners from the same manufacturing lot may be used as test specimens if the configuration satisfies the

requirements on this specification.

4.3.2 Test Specimens Length Limitations: Unless otherwise specified, in the procurement specificatíon and/or

product standard or document, the test specimen shall have a minimum length of two (2) unthreaded shank

diameters excluding the fillet radius and shank to thread transition area.

6. DETAILED REQUIREMENTS

5.1 TEST PROCEDURE: The fastener or test specimen shall be placed in the receiving haif-holes of the fork

portion of the fixture with neither threads nor fillet radius in bearing.

5.1.1 The blade (guillotine) portion of the fixture shall be placed in position on the specimen and the test machine

activated to provide contad of all load bearing surfaces of the machina, fixture, and specimen prior to

applying the test load.

5.1.2 The test load shall be applied at the uniform rate specified in TABLE I within a load rate tolerance of ± 10%.

Load rates for larger or smaller size fasteners or test specimens shall be calculated to give an initial stress

rate of 100,000 pounds per minute per square inch of the nominal double shear area (two times the nominal

diameter cross sectional area).

5.1.3 The testing laboratory, at their option, may use a constant strain rafe which Mil produce the specified load

rate ( ± 10%) in the elastic range. That is, the strain rate shall be equal to the initial stress rate of 100,000

pounds per minute per square inch divided by the elastic modulus in shear.

5.1.4 The applied load may be discontinuad upon obtaining the specification minimum test load requírement if the

product specification requírement is for a verification of the mínimum shear value. The test may be continuad

to a point in which the stress-strain curve is flat or to total shear rupture of the specimen if maximum data is

desired. Performing tests to total shear rupture can deteriorate the integrity of the shear dies.

6. NOTES

6.1 TEST REPORT: The test report shall include the foliowing data as a mínimum.

a) Fastener or test specimen description.

b) Part Number.

c) Material.

d) Manufacturar.

e) Mínimum double shear load specified (if applicable).

f) The maximum applied load to each fastener or test specimen.

6.2 Unless otherwise specified by the purchase contract and/or product specification, the actual diameter

of each fastener or test specimen need not be reportad. If the reportad test data is expressed in pounds

per square inch (PSI), the actual diameter of each fastener or test specimen shall be used in the

calculation to develop the pound per square inch (PSI) value.

O COMPLETELY REVISED

SHEET 4

APPROVAL DATE AUGUST 1997 REVISION O February 2003

USE OF OR RELJANCE ON THIS DOCUMENT OR ANY NATIONAL AEROSPACE STANDARD IS ENTIRELY VOLUNTARY. AIA DOES NOT OUALIFY SUPPLIERS OR CERTIFY

MAKF_S NO REPRESENTATION OR CLAtM RESPECTING (1) THE SUITASILITY

CONFORMANCE OF fTEMS PROCUREO UNDER NATIONAL AEROSPACE STANDARDS AJA

OF ÍTEMS FOR ANY PARTICULAR APPLICATION, OR (2) THE EXISTENCE OF OR APPUCABILITY THERETO OF PATENT OR TRADEMARK RIGHTS.

Copyright Aerospace Industries Association of America Inc.

Sold trrINFORMATION HANDLING SERVICES, 01874946

Provded by IHS under ficense with AIA/NAS

No reproduction or networldng permitted without license from IHS Not for Resale,2011/9/1 16.57.59 GMT

NATIONAL AEROSPACE STANDARD

C COPYRIGHT 2003 AEROSPACE INDUSTRISS ASSOCIATION OF ~RICA, INC.

ALL RIGHTS RESERVED

NASM1312-13

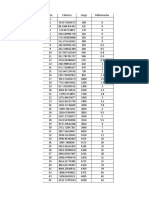

- DOUBLE SHEAR L OAD RATES

NOMINAL LOAD RATE NOMINAL LOAD RATE

DIAMETER LB/MIN DIAMETER LB/MIN

.125 2,480 .563 49,600

.156 3,840 .625 61,200

.164 4,200 .750 88,000

.188 5,600 .875 120,000

.250 10,000 1.000 156,000

.313 15,400 1.125 200,000

.375 22,000 1.250 244,000

.438 30,000 1.375 296,000

.500 39,200 1.500 352,000

BLADE

4S ///

MAX

_

— — II r ----

Le„ T T

I

FORK

BASE

FIGURE 1 - DOUBLE SHEAR FIXTURE

COMPLETELY REVISED

SHEET 5

APPROVAL DATE AUGUST 1997 REVISION O February 2003

USE OF OR RELIANCE ON THIS DOCUMENT OR ANY NAT1ONAL AEROSPACE STANDARD IS ENTIRELY VOLUNTARY. AlA DOES NOT OUALIFI, SUPPLIERS OR CERTIFY

CONFORMANCE OF ITEMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS. AIA MAKES NO REPRESENTATION OR CLAN RESPECTING (1) THE suiTAsiLITY

OF ITEMS FOR ANY PARTICULAR APPLICATION, OR (2) THE EXISTENCE OF OR APPLICABILITY THERETO OF PATENT OR TRADEMARK RIGHTS.

Copyright Aerospace I ndustnes Association of America Inc.

Sold lo INFORMATION HANDLING SERVICES, 01874946

Provided by IHS under license w,th AIA/NAS

Not for Resale,2011/9/1 16:5759 GMT

No reproduction or nelworking per -matead without license from IHS

NATIONAL AEROSPACE STANDARD

C COPYRIGHT 2003 AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA, INC.

ALL SHORTS RESERVED

NASM1312-13

6W MINIMUM lz

A 4-1 1 -z-1

FORK 1/2 HOLE

EDGES -SEE

.5D TABLE II, NOTE 1.

1

A 4-

o .

111 .0011Z 1Y I 1 0 .001

/1 0 .002

FIGURE 2 - FIXTURE BLADE (dimensions per TABLE II)

1//1 O .00i 1Y .oei 1x 1

OD 8' —V— j

0 .001 W 1—

I/ 0 .002

—1> S 4-± 3 46---

°

‹.

.000/.060

FORK 1/2 ROLE

EDGES - SEE

TABLE II, NOTE 1.

A

k 6W MINIMUM SECTION A-A

FIGURE 3 - FIXTURE FORK (dimensions per TABLE II)

R RADIUS

A4,

4W

MIN

A4--1 6 W MINIMUM

6W MINIMUM SECTION A-A

FIGURE 4 - FIXTURE BASE (dimensions per TABLE II)

COMPLETELY REVISED SHEET 6

APPROVAL DATE AUGUST 1991 REVISION February 2003

AJA DOES NOT QUALIFY SUPPLIERS OR CERTiFY

USE OF OR RELIANCE ON THIS DOCUMENT OR ANY NATIONAL AEROSPACE STANDARD 15 ENTIRELY VOLUNTARY.

CONFORMANCE OF ITEMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS. AIA MAKES NO REPRESENTATION OR CLAN RESPECTING (1) THE sui-ukelury.

DF (TEMS FOR ANY PARTICULAR APPUCAT1ON, OR a) THE EXISTENCE OF OR APPUCABILITY THERETO OF PATENT OR TRADEMARK

Copyright Aerospace Industries Association o( America Inc

Sold to INFORMATION HANDLING SERVICES, 01874946

Provided by IHS under license with AIAJNAS

Not for Resale,2011/9/1 16'5759 GMT

No reproduction or networking permitted without license from IHS

NATIONAL AEROSPACE STANDARD

COPYRIGHT 2003 AEROSPACE INDUSTRIES ASSOCIATION OP AMERICA, INC.

ALL RIGHTS RESERVED

NASM1312-13

NOMINAL OD S T W R

FASTENER +.0010 +.0000 +.0010

MAXIMUM MINIMUM REFERENCE

SIZE -.0000 -.0010 -.0000

.112 .1130 .1123 .056 .1120 .1130 .156

.125 .1260 .1253 .063 .1250 .1260 .156

.138 .1390 .1383 .069 .1380 .1390 .188

.156 .1573 .1566 .078 .1563 .1573 .188

.164 .1650 .1643 .082 .1640 .1650 .188

.188 .1885 .1878 .094 .1875 .1885 .219

.190 .1910 .1903 .095 .1900 .1910 .219

.250 .2510 .2503 .125 .2500 .2510 .281

.313 .3135 .3128 .156 .3125 .3135 .344

.375 .3760 .3753 .188 .3750 .3760 .406

.438 .4385 .4378 .219 .4375 .4385 .468

.500 .5010 .5003 .250 .5000 .5010 .531

.563 .5635 .5628 .281 .5625 .5635 .594

.625 .6260 .6253 .313 .6250 .6260 .656

.750 .7510 .7503 .375 .7500 .7510 .781

.875 .8760 .8753 .438 .8750 .8760 .906

1.000 1.0010 1.0003 .500 1.0000 1.0010 1.031

1.125 1.1260 1.1253 .563 1.1250 1.1260 1.156

1.250 1.2510 1.2503 .625 1.2500 1.2510 1.281

1.375 1.3760 1.3753 .688 1.3750 1.3760 1.406

1.500 1.5010 1.5003 .750 1.5000 1.5010 1.531

Notes: 1. The charnfer, radius or edge break of the OD half-hole edges of the blade or fork shall be .005.

The fixture shall be reworked when the edge wear results in a chamfer, radius or edge break of

.010 on any portion of the half-hole edges. In case of controversy, the OD half-hole edges pf the

blade and fork shall be .005 maximum.

2. The depth of the 0D haif-hole centertine in both the blade (.5D) and the fork (.000 to .060) may

be increased as a result of rework due to wear, but shall not be increased to a point where any

part of the fastener or test specímen makes contact with any part of the test fixture other than

the designed load bearing surfaces.

3. For fixture sizes other than those listed, the proportions specified in TABLE II shall be maintained.

4. The "R" dimension in FIGURE 4 defines the radius in the fixture base. This radius shall be modified

as necessary to prevent contad with the test specimen.

5. Altemative fixture configurations utilizing dowel fixture guides may be used as long as the

relationship of the blade and fork remains as shown in FIGURE 1, 2, and 3.

COMPLETELY REVISED

SHEET 7

APPROVAL DATE AUGUST 1997 REVISION O February 2003

USE OF OR RELIANCE ON THIS DOCUMENT OR ANY NATIONAL AEROSPACE STANDARD iS ENTIRELY VOLUNTARY. AIA DOES NOT QUALIFY SUPPLIERS OR CERTIFY

CONFORMANCE OF ITEMS PROCURED UNDER NATIONAL AEROSPACE STANDARDS. AIA MAKES NO REPRESENTATION OR CLAMA RESPECTING (1) THE SUITABILITY

OF ITEMS FOR ANY PARTICULAR APPLICATION, OR (2) THE EXISTENCE OF OR APPLICABILITY THERETO OF PATENT OR TRADEMARK RIGHTS.

Copyright Aerospace Industrias Association of America Inc.

Sold to INFORMATION HANDLING SERVICES, 01874946

Progded by IHS under license with AIA/NAS

Not for Resale,2011/9/1 16:57:59 GMT

No reproducbon or networking permitted without license from IHS

S-ar putea să vă placă și

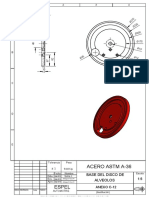

- Acero Astm A-36: Base Del Disco de AlveolosDocument3 paginiAcero Astm A-36: Base Del Disco de AlveolosMichelle Camacho HerediaÎncă nu există evaluări

- Acero Astm A-36: Base de La RuedaDocument3 paginiAcero Astm A-36: Base de La RuedaMichelle Camacho HerediaÎncă nu există evaluări

- Acero Astm A-36: ChasisDocument1 paginăAcero Astm A-36: ChasisMichelle Camacho HerediaÎncă nu există evaluări

- TraccionDocument2 paginiTraccionMichelle Camacho HerediaÎncă nu există evaluări

- The High Performance CompanyDocument5 paginiThe High Performance CompanyMichelle Camacho HerediaÎncă nu există evaluări

- Curvas Cavitacion Ok PDFDocument9 paginiCurvas Cavitacion Ok PDFMichelle Camacho HerediaÎncă nu există evaluări

- Nasm1312-13 Double Shear TestDocument7 paginiNasm1312-13 Double Shear TestMichelle Camacho HerediaÎncă nu există evaluări

- Your First Meeting - SBG - SP - NODocument5 paginiYour First Meeting - SBG - SP - NOMichelle Camacho HerediaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Kinder DLL Week 8Document15 paginiKinder DLL Week 8Jainab Pula SaiyadiÎncă nu există evaluări

- Project ReportDocument14 paginiProject ReportNoah100% (7)

- Rachel Joyce - A Snow Garden and Other Stories PDFDocument118 paginiRachel Joyce - A Snow Garden and Other Stories PDFИгорь ЯковлевÎncă nu există evaluări

- Prevailing Torque Locknut Technical SpecificationsDocument3 paginiPrevailing Torque Locknut Technical SpecificationsLiu YangtzeÎncă nu există evaluări

- Hevi-Bar II and Safe-Lec 2Document68 paginiHevi-Bar II and Safe-Lec 2elkabongscribdÎncă nu există evaluări

- Science Magazine February 2020Document133 paginiScience Magazine February 2020Elena González GonzálezÎncă nu există evaluări

- Management of DredgedExcavated SedimentDocument17 paginiManagement of DredgedExcavated SedimentMan Ho LamÎncă nu există evaluări

- Paper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg AlloysDocument4 paginiPaper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg Alloysjavo0128Încă nu există evaluări

- Daftar PustakaDocument3 paginiDaftar PustakaMel DaÎncă nu există evaluări

- Carrefour-SA Shopping Center TurkeyDocument2 paginiCarrefour-SA Shopping Center TurkeyVineet JogalekarÎncă nu există evaluări

- GSD Puppy Training Essentials PDFDocument2 paginiGSD Puppy Training Essentials PDFseja saulÎncă nu există evaluări

- Haldex-Barnes 2-Stage Pump For Log SplittersDocument2 paginiHaldex-Barnes 2-Stage Pump For Log SplittersPer Akkamaan AgessonÎncă nu există evaluări

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocument3 pagini1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaÎncă nu există evaluări

- Assessment of Diabetic FootDocument7 paginiAssessment of Diabetic FootChathiya Banu KrishenanÎncă nu există evaluări

- Tips For A Healthy PregnancyDocument2 paginiTips For A Healthy PregnancyLizaÎncă nu există evaluări

- Chapter 7 Dopant Diffusion - IDocument32 paginiChapter 7 Dopant Diffusion - I강준호Încă nu există evaluări

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocument7 paginiW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyÎncă nu există evaluări

- IBM BladeCenter S RedBookDocument36 paginiIBM BladeCenter S RedBookGuillermo García GándaraÎncă nu există evaluări

- G10Mapeh Exam First QuaterDocument8 paginiG10Mapeh Exam First QuaterJonas LamcisÎncă nu există evaluări

- 988611457NK448908 Vehicle Scan ReportDocument5 pagini988611457NK448908 Vehicle Scan ReportVictor Daniel Piñeros ZubietaÎncă nu există evaluări

- TheBasicsofBrainWaves - RS PDFDocument4 paginiTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaÎncă nu există evaluări

- Practice For Mounting Buses & Joints-374561Document11 paginiPractice For Mounting Buses & Joints-374561a_sengar1Încă nu există evaluări

- SOPDocument16 paginiSOPjerome marquezÎncă nu există evaluări

- End of Summer Course Test August 2021Document16 paginiEnd of Summer Course Test August 2021Thanh Nguyen vanÎncă nu există evaluări

- Sample Appellant BriefDocument6 paginiSample Appellant BriefKaye Pascual89% (9)

- Manuscript FsDocument76 paginiManuscript FsRalph HumpaÎncă nu există evaluări

- Nomenclatura SKFDocument1 paginăNomenclatura SKFJuan José MeroÎncă nu există evaluări

- Comparative Study On Serial and Parallel Manipulators - ReviewDocument23 paginiComparative Study On Serial and Parallel Manipulators - ReviewShaik Himam SahebÎncă nu există evaluări

- Basics of Population EducationDocument4 paginiBasics of Population EducationLAILANIE DELA PENAÎncă nu există evaluări

- Pitot/Static Systems: Flight InstrumentsDocument11 paginiPitot/Static Systems: Flight InstrumentsRoel MendozaÎncă nu există evaluări