Documente Academic

Documente Profesional

Documente Cultură

Boiler and Air Compressor Maritime

Încărcat de

Julius Pampola0 evaluări0% au considerat acest document util (0 voturi)

90 vizualizări4 paginiTitlu original

boiler and air compressor maritime.docx

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

90 vizualizări4 paginiBoiler and Air Compressor Maritime

Încărcat de

Julius PampolaDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

Cross Drum Water Tube Boiler- In Cross Drum Boiler

the steam drum is placed at cross ways to the heat source as

shown in the figure. Here, the down-comer is fitted on the bottom

of the drum and riser is fitted on the top of the drum via a

horizontal tube as shown in the figure.

What is a Boiler?

W

A boiler is a closed vessel in which heat change water,

under pressure, into steam. Boilers are one of the essential

equipment's on-board ships. It's purpose is to provide

heating to the main diesel propulsion engine, to the bunker Working Principle of Cross Drum Boiler

F.O. tanks(to make it less viscous for transfer purposes as The working principle of cross drum boiler is same as

well as easy ignition). The steam generated by the boiler longitudinal drum boiler.

can also be use for cleaning, and heating of the seawater in 1. The feed water is fed to the cross drum through

feed water inlet.

the freshwater generator thus evaporating it to make it

2. Then this water comes down through the down-

potable water.

comer pipe and enters into inclined water tube

placed in hot chamber.

There are two major types of boiler 3. Here, the water becomes hot and steam is produced

1.Water tube boiler in the water which comes into steam chamber.

4. Here in the steam drum steam is separated from

2.Fire-tube boiler

water in natural way

Water tube boiler - is a type of boiler in which

water circulates in tubes heated externally by the fire.

Fuel is burned inside the furnace, creating hot gas Bend Tube Boiler or Sterling Boiler- Bend

which heats water in the steam-generating tubes. Tube Boiler or Sterling Boiler is the developed version

of water tube boiler. The working principle of bend

Types of Water Tube Boiler tube boiler is more or less same as other water tube

1. Horizontal Straight Tube Boiler boilers, but it utilizes four drums.

2. Bent Tube Boiler.

3. Cyclone Fired Boiler.

Horizontal Straight Tube Boiler again can be

sub-divided into two different types.

1. Longitudinal Drum Boiler.

2. Cross Drum Boiler.

Babcock-Wilcox Boiler is also known as Longitudinal

.

Drum Boiler or Horizontal Tubes Boiler In this type

of boiler, one cylindrical drum is longitudinally placed above

the heat chamber. In rear of the drum down comer tube is Working Principle of Bent Tube or Stirling

filled and in front of the drum riser tube is fitted as shown

in the figure. Boiler

The feed water first enters into right most upper drum.

Due to more density this water comes down in the

lower water drum. The water within that water drum

and the connecting pipes to the other two upper

drums, are heated up and consequently steam bubbles

are produced.

Fire tube boiler- A fire tube boiler is a type

of boiler in which hot gases pass from a fire

through one or (many) more tubes running

through a sealed container of water. The heat of

the gases is transferred through the walls of the

tubes by thermal conduction, heating the water

and ultimately creating steam.

Scotch Marine Boiler is a fire tube boiler, in that

hot flue gases pass through tubes set within a tank of

water. The general layout is that of a squat horizontal

cylinder. One or more large cylindrical furnaces are in

the lower part of the boiler shell. Above this is a large

number of small-diameter fire-tubes.

Different types of fire boiler

1. Cornish boiler

2. Lancashire boiler

3. Scotch marine boiler

4. Locomotive boiler

Locomotive boiler has three main components: a

5. Vertical fire tube boiler double-walled firebox; a horizontal, cylindrical "boiler barrel"

containing a large number of small flue-tubes; and a smoke

box with chimney, for the exhaust gases. The boiler barrel contains

Cornish boiler is a simple horizontal boiler larger flue-tubes to carry the super heater elements, where present.

Forced draught is provided in the locomotive boiler by injecting

which belong to the shell and tube class of boilers. Cornish exhausted steam back into the exhaust via a blast pipe in the smoke

boiler is much like the Lancashire boiler. Cornish boiler has box.

the ability to produce steam at the rate of 1350 kg/hr. and

can take the maximum pressure of about 12 bar. Dimensions

of the Cornish boiler shell is 4 m to 7 m in length and 1.2 m

to 1.8 m in diameter. Cornish boiler is a fire tube type of

boiler that is hot gases flow in tubes and water surround

these tubes in shell.

Vertical fire-tube boiler is a vertical boiler where the

heating surface is composed of multiple small fire-tubes,

arranged vertically. It is the simplest fire tube boiler which

consist of a cylindrical shell containing greater portion of

water and remaining portion is occupied by steam

Lancashire Boiler is a horizontal type and

stationary fire tube boiler. Generally flue gases passes

through the fire tube. It is present inside the boiler shell or

body and for this reason it is a fire tube boiler. Lancashire

Boiler is an internally fired boiler because the furnace uses

to present inside the boiler. This boiler generates low

pressure steam and it is a natural circulation boiler.

D AIR COMPRESSOR

- An air compressor is a device that

converts power (using an electric motor,

diesel or gasoline engine, etc.) into

potential energy stored in pressurized air

(i.e., compressed air). By one of several Rotary Screw Compressors work on the

principle of air filling the void between two helical mated screws and

methods, an air compressor forces more their housing. As the two helical screws are turned, the volume is

reduced resulting in an increase of air pressure. Most rotary screw

and more air into a storage tank, compressors inject oil into the bearing and compression area. The

reasons are for cooling, lubrication and creating a seal between

increasing the pressure. screws and the housing wall to reduce internal leakage. After the

compression cycle, the oil and air must be separated before the air

can be used by the air system.

Types of Air Compressors

There are mainly four types of compressors:

1. Centrifugal compressor

2. Rotary vane compressor

3. Rotary screw compressor

4. Reciprocating air compressor

Centrifugal Boiler- A centrifugal compressor

is a type of dynamic compressor, or turbo compressor, with a radial

design. that work at a constant flow, dynamic compressors work at Reciprocating or Piston compressors are

a constant pressure and the performance is affected by external the most common machines available on the market. They

are positive displacement compressors and can be found in

conditions such as changes in inlet temperatures.

ranges from fractional to very high horse powers. Positive

displacement air compressors work by filling an air chamber

with air and then reducing the chamber’s volume

(Reciprocating, Rotary Screw and Rotary Sliding Vane are all

positive displacement compressors). Reciprocating

compressors work in a very similar manner as does as

internal combustion engine but basically in a reverse

process. They have cylinders, pistons, crankshafts, valves

and housing blocks.

So, how does a centrifugal compressor work?

Air is drawn into the center of a rotating impeller with radial blades

and is pushed toward the center by centrifugal force. This radial

movement of air results in a pressure rise and the generation of

kinetic energy. Before the air is led into the center of the impeller,

the kinetic energy is also converted into pressure by passing

through a diffuser and volute.

Rotary vane compressor-Rotary Sliding Vane Compressors

like Reciprocating and Rotary Screw compressors are positive displacement

compressors. The compressor pump consists primarily of a rotor, stator, and 8

blades. The slotted rotor is eccentrically arranged within the stator providing a

crescent shaped swept area between the intake and exhaust ports. As the

rotor turns a single revolution, compression is achieved as the volume goes

from a maximum at the intake ports to a minimum at the exhaust port. The

Uses of Air Compressor on Ship

vanes are forced outward from within the rotor slots and held against the stator On board a ship, compressed air is used for several

wall by rotational acceleration. Oil is injected into the air intake and along the purposes. On the basis of application, different air

stator walls to cool the air, lubricate the bearings and vanes, and provide a

seal between the vanes and the stator wall. After the compression cycle, the compressors are kept for a particular usage. Normally,

oil and air must be separated before the air can be transferred to the air air compressors on board ships are:

system. • Main air compressor

• Topping up compressor

• Deck air compressor

• Emergency air compressor

Main air compressor is used for supplying

high pressurised air for starting of main and auxiliary

engines. The pressurised air generated by the air

compressor is stored in air storage bottle. These are

high capacity compressors and the air pressure that is

required from these compressors to start the main

engine is 30 bars. Control air is also supplied from air bottle

through a pressure reducing valve and a control air filter.

Normally they are twice in number and can be more than that

for redundancy.

Emergency air compressor is used for

starting auxiliary engine at the time of an emergency or when

the main air compressor has failed for filling up the main air

receiver. This type of compressor can be motor driven or

engine driven. If motor driven, it should be supplied from

emergency source of power.

Topping up compressor takes up the lead to

cover up for the leakage in the system. This means that as

soon as the air pressure in the system goes below a

particular level, the topping up compressor replenished the

system with pressurized air.

Deck air compressor is used for deck use

and as service air compressor and might have a

separate service air bottle for the same. These

are lower capacity pressure compressors as

pressure required for service air is in between the

range of 6 to 8 bar

S-ar putea să vă placă și

- Elements of Mechanical Engineering by V. K. ManglikDocument616 paginiElements of Mechanical Engineering by V. K. ManglikHariprasad_vp100% (1)

- Advanced Turbo MachineryDocument2 paginiAdvanced Turbo Machineryjvinod2025Încă nu există evaluări

- Efficient Boiler Operations Source Book Payne & ThompsonDocument325 paginiEfficient Boiler Operations Source Book Payne & Thompsonmr294Încă nu există evaluări

- Boiler Book PDFDocument44 paginiBoiler Book PDFmpgzyah100% (5)

- Steam Boilers ME 1103 Introduction To MeDocument27 paginiSteam Boilers ME 1103 Introduction To MePriyadarshee ShaswatÎncă nu există evaluări

- Sliver Line Composite Textile MillsDocument23 paginiSliver Line Composite Textile Millsmac2022100% (1)

- Carr and Latham's Technology of Clothing ManufactureDe la EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerEvaluare: 4 din 5 stele4/5 (1)

- Boiler CalculationsDocument6 paginiBoiler CalculationsJesther Marlou C. OrongÎncă nu există evaluări

- From Wikipedia, The Free Encyclopedia: Process Duct WorkDocument17 paginiFrom Wikipedia, The Free Encyclopedia: Process Duct WorkB DASÎncă nu există evaluări

- T30Document4 paginiT30V P Singh0% (1)

- Qafco 5 RG BoilerDocument156 paginiQafco 5 RG BoilerfakhanÎncă nu există evaluări

- Water Tube BoilerDocument5 paginiWater Tube Boilerhamid0099100% (2)

- Power Plant ChemistryDocument80 paginiPower Plant Chemistrybanukiran sambojuÎncă nu există evaluări

- Polyurethane: A Versatile Polymer Used in Insulation, Furniture, Automotive and MoreDocument1 paginăPolyurethane: A Versatile Polymer Used in Insulation, Furniture, Automotive and MoreJulius PampolaÎncă nu există evaluări

- Boiler Preservation Methods Dry and WetDocument14 paginiBoiler Preservation Methods Dry and WetTin Aung KyiÎncă nu există evaluări

- Steam Power Plant DevicesDocument85 paginiSteam Power Plant DevicesOk SokÎncă nu există evaluări

- Traverse Point For MeasurementDocument2 paginiTraverse Point For MeasurementsudheerÎncă nu există evaluări

- Used Boiler O&M ManualDocument194 paginiUsed Boiler O&M ManualAlexis CruzÎncă nu există evaluări

- Fabric Manufacturing Technology Lab-1 Final Exam SolutionDocument16 paginiFabric Manufacturing Technology Lab-1 Final Exam SolutionAlif SheikhÎncă nu există evaluări

- Energy Conservation in TextileDocument5 paginiEnergy Conservation in TextilekaydeeyouÎncă nu există evaluări

- Coal FeedDocument8 paginiCoal FeedaakashtrivediÎncă nu există evaluări

- Building Services - Iii: 3 Year BS - Semester 1Document32 paginiBuilding Services - Iii: 3 Year BS - Semester 1TaanayaÎncă nu există evaluări

- Design of Power Screws: Torque, Stress CalculationsDocument15 paginiDesign of Power Screws: Torque, Stress CalculationsVenkatesh GangadharÎncă nu există evaluări

- Dry Finishing of Wool Fabrics - Pailthorpe M.Document14 paginiDry Finishing of Wool Fabrics - Pailthorpe M.Hugo Eduardo Ipiales MesaÎncă nu există evaluări

- 1298806680-Scraper Chain ConveyorDocument2 pagini1298806680-Scraper Chain ConveyorAlexandro SouzaÎncă nu există evaluări

- Tolerances, Limits, Fits and Surface FinishDocument6 paginiTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Scouring & Bleaching of Cotton at Double StageDocument3 paginiScouring & Bleaching of Cotton at Double StageMd Abdullah Al NomanÎncă nu există evaluări

- Dynamic Force Analysis on Slider Crank MechanismDocument39 paginiDynamic Force Analysis on Slider Crank MechanismSAI PRAMOD RAVADAÎncă nu există evaluări

- PVI Aerzen Screw Compressors (Old) (En)Document32 paginiPVI Aerzen Screw Compressors (Old) (En)pitichai_pÎncă nu există evaluări

- Equipment For Burning Coal in Lump FormDocument23 paginiEquipment For Burning Coal in Lump FormMudduKrishna shettyÎncă nu există evaluări

- Inspection of Waste Extracted by Different Machines of Spinning Department.Document3 paginiInspection of Waste Extracted by Different Machines of Spinning Department.Ammar Naeem BhattiÎncă nu există evaluări

- Chapter 6 - Lubricating SystemDocument29 paginiChapter 6 - Lubricating SystemEugine BalomagaÎncă nu există evaluări

- 17 SitraDocument26 pagini17 SitraRohit GuptaÎncă nu există evaluări

- Thermax FSDocument2 paginiThermax FSOscar Alvitez DominguezÎncă nu există evaluări

- Fan Selection Guide PDFDocument16 paginiFan Selection Guide PDFHarsh KhatriÎncă nu există evaluări

- Hydraulic Actuator SpecificationsDocument3 paginiHydraulic Actuator SpecificationsRizky RamadhaniÎncă nu există evaluări

- Belt Drive Types Material Applications Advantages Disadvantages PPT 1Document19 paginiBelt Drive Types Material Applications Advantages Disadvantages PPT 1Sandesh yadavÎncă nu există evaluări

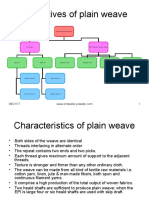

- Plain WeaveDocument8 paginiPlain Weaveghosh7171Încă nu există evaluări

- STRUTO BrochureDocument4 paginiSTRUTO BrochureShovan Das100% (1)

- Renewable Energy Resources: Textile ProcessingDocument17 paginiRenewable Energy Resources: Textile ProcessingrohithÎncă nu există evaluări

- Gas Turbine Thermal Power PlantDocument7 paginiGas Turbine Thermal Power PlantAkshay ManzaÎncă nu există evaluări

- Textile Technology Internship ReportDocument24 paginiTextile Technology Internship Reportgunashekarkalluri100% (1)

- Attock Cement MaintenanceDocument20 paginiAttock Cement Maintenancedanialme089Încă nu există evaluări

- Advantages of 4 Stroke Engine:-: DifferencesDocument3 paginiAdvantages of 4 Stroke Engine:-: DifferencescidracÎncă nu există evaluări

- RefrigerationDocument19 paginiRefrigerationDDCMÎncă nu există evaluări

- Itema R880 Rapier Weaving MachineDocument8 paginiItema R880 Rapier Weaving MachineRudi HermantoÎncă nu există evaluări

- Improving Yarn Quality Using Novel Mingling Chamber TechniqueDocument4 paginiImproving Yarn Quality Using Novel Mingling Chamber TechniqueKannan KrishnamurthyÎncă nu există evaluări

- Chapter - 9: Indiaboiler Dot ComDocument28 paginiChapter - 9: Indiaboiler Dot ComkiranÎncă nu există evaluări

- INTERNAL COMBUSTION ENGINES & TURBINESDocument24 paginiINTERNAL COMBUSTION ENGINES & TURBINESBanwari Lal Prajapat100% (1)

- Exergy Analysis of Organic Rankine CycleDocument9 paginiExergy Analysis of Organic Rankine CycleMukul GoyalÎncă nu există evaluări

- 10 Boiler Ash Removal System Commissioning Procedure-TöàtéëTÖñtü T +T+ƑF Âf Ò Ä Û+Document32 pagini10 Boiler Ash Removal System Commissioning Procedure-TöàtéëTÖñtü T +T+ƑF Âf Ò Ä Û+kvsagar100% (1)

- Blower and Motor CalculationsDocument9 paginiBlower and Motor CalculationsChris LaytonÎncă nu există evaluări

- Chapter 10Document78 paginiChapter 10Si Thu AungÎncă nu există evaluări

- BestDocument25 paginiBestadmasuÎncă nu există evaluări

- AllignmentDocument2 paginiAllignmentVishnu Vardhan . CÎncă nu există evaluări

- B Des FT 1 PDFDocument9 paginiB Des FT 1 PDFSushil Bishnoi0% (3)

- Dorner 3200 Vacuum ConveyorDocument8 paginiDorner 3200 Vacuum ConveyorBobKatÎncă nu există evaluări

- Looper and Spreader Mechanism of Flatlock MachineDocument5 paginiLooper and Spreader Mechanism of Flatlock MachineTauqeer Raza100% (1)

- Screw Conveyor DesignDocument3 paginiScrew Conveyor DesignNihalRajapakshaÎncă nu există evaluări

- Method Study of Cuff AttachmentDocument12 paginiMethod Study of Cuff AttachmentKshitij LauÎncă nu există evaluări

- Lap Former Machine - Features of Lap Former Machine - Textile LearnerDocument1 paginăLap Former Machine - Features of Lap Former Machine - Textile LearnerTanmay JagetiaÎncă nu există evaluări

- Elective 3Document6 paginiElective 3Marc JabarÎncă nu există evaluări

- Fire Tube & Water Tube BoilerDocument9 paginiFire Tube & Water Tube BoilerZaib Rehman100% (3)

- Steam Generators (Boilers) : SubhankarDocument24 paginiSteam Generators (Boilers) : Subhankarশুভঙ্কর মুখার্জীÎncă nu există evaluări

- Water Tube Boiler 5Document4 paginiWater Tube Boiler 5Cisco StarkÎncă nu există evaluări

- A Water Tube BoilerDocument9 paginiA Water Tube BoilerNawaf faisalÎncă nu există evaluări

- Water Tube Boiler 4Document2 paginiWater Tube Boiler 4Cisco StarkÎncă nu există evaluări

- FinaloutputDocument43 paginiFinaloutputJulius PampolaÎncă nu există evaluări

- FilmoraDocument1 paginăFilmoramattenriqueÎncă nu există evaluări

- D Fun Go ProposalDocument6 paginiD Fun Go ProposalJulius PampolaÎncă nu există evaluări

- The Origin and Activities of Ginubat Festival in Gubat, SorsogonDocument1 paginăThe Origin and Activities of Ginubat Festival in Gubat, SorsogonJulius PampolaÎncă nu există evaluări

- Name of ProprietorDocument1 paginăName of ProprietorJulius PampolaÎncă nu există evaluări

- Steering Gear in ShipsDocument19 paginiSteering Gear in ShipsJulius PampolaÎncă nu există evaluări

- Chapter VDocument6 paginiChapter VJulius PampolaÎncă nu există evaluări

- Report in Deck Watch KeepingDocument20 paginiReport in Deck Watch KeepingJulius PampolaÎncă nu există evaluări

- Boiler and Air Compressor MaritimeDocument4 paginiBoiler and Air Compressor MaritimeJulius PampolaÎncă nu există evaluări

- CHAPTER 1 (AutoRecovered)Document4 paginiCHAPTER 1 (AutoRecovered)Julius PampolaÎncă nu există evaluări

- ReferencesDocument1 paginăReferencesJulius PampolaÎncă nu există evaluări

- Chapter IVDocument10 paginiChapter IVJulius PampolaÎncă nu există evaluări

- Chapter IIIDocument2 paginiChapter IIIJulius PampolaÎncă nu există evaluări

- Boiler and Air Compressor MaritimeDocument4 paginiBoiler and Air Compressor MaritimeJulius PampolaÎncă nu există evaluări

- Principle of SpeechDocument1 paginăPrinciple of SpeechJulius PampolaÎncă nu există evaluări

- Boiler and Air Compressor MaritimeDocument4 paginiBoiler and Air Compressor MaritimeJulius PampolaÎncă nu există evaluări

- Appreciating Shipping Career As A Maritime Profession: Group 5Document2 paginiAppreciating Shipping Career As A Maritime Profession: Group 5Julius PampolaÎncă nu există evaluări

- SHS Maritime PREBAC - Introduction To Maritime Safety - May 2016Document9 paginiSHS Maritime PREBAC - Introduction To Maritime Safety - May 2016Alran Eric CifraÎncă nu există evaluări

- Print MediaDocument36 paginiPrint MediaJulius PampolaÎncă nu există evaluări

- Boiler and Air Compressor MaritimeDocument4 paginiBoiler and Air Compressor MaritimeJulius PampolaÎncă nu există evaluări

- Boiler and Air Compressor MaritimeDocument1 paginăBoiler and Air Compressor MaritimeJulius PampolaÎncă nu există evaluări

- Inner PlanetsDocument7 paginiInner PlanetsJulius PampolaÎncă nu există evaluări

- Flammable & Combustible-LiquidsDocument5 paginiFlammable & Combustible-LiquidsJulius PampolaÎncă nu există evaluări

- May Day Eve S Script EnlishDocument6 paginiMay Day Eve S Script EnlishJulius Pampola100% (1)

- E Module-3 Steam BoilersDocument105 paginiE Module-3 Steam BoilersJasraj GillÎncă nu există evaluări

- Project ReportDocument103 paginiProject ReportSeth CamachoÎncă nu există evaluări

- Thermo CycleDocument59 paginiThermo CycleDries CaersÎncă nu există evaluări

- ABMA Todays Boiler - Spring 2017Document24 paginiABMA Todays Boiler - Spring 2017JacoboÎncă nu există evaluări

- Steam SystemsDocument20 paginiSteam Systemschristian vergaray gonzalesÎncă nu există evaluări

- EGBDocument8 paginiEGBvenugopalÎncă nu există evaluări

- Mechanical Engineering Multiple Choice QuestionsDocument10 paginiMechanical Engineering Multiple Choice QuestionsSathis KumarÎncă nu există evaluări

- CPSF Me Spe 01 CP2017 001 00Document97 paginiCPSF Me Spe 01 CP2017 001 00Siro BabiroÎncă nu există evaluări

- BoilersDocument69 paginiBoilersSantosh C0% (1)

- 2) Module - 1 Boiler Mountings and AccessoriesDocument33 pagini2) Module - 1 Boiler Mountings and AccessoriesA48Rayan PereiraÎncă nu există evaluări

- Performance Enhancement of An Industrial Fire Tube BoilerDocument6 paginiPerformance Enhancement of An Industrial Fire Tube BoilerZaid YahyaÎncă nu există evaluări

- High Pressure Boilers PDFDocument38 paginiHigh Pressure Boilers PDFgokul viratÎncă nu există evaluări

- Cbex Elite: Boiler Book 09/2019Document22 paginiCbex Elite: Boiler Book 09/2019Luis Miguel Rios CuentasÎncă nu există evaluări

- Construction of Babcock and Wilcox BoilerDocument10 paginiConstruction of Babcock and Wilcox BoilerBalkunde100% (1)

- 750-225 OM ModelCBR-125-800HP Apr07Document180 pagini750-225 OM ModelCBR-125-800HP Apr07kosmc123Încă nu există evaluări

- 230911Document84 pagini230911Dhenil ManubatÎncă nu există evaluări

- CBL Boiler BookDocument18 paginiCBL Boiler Bookfauzi endraÎncă nu există evaluări

- Assistant Professor Mechanical Department, Vasad: Presented byDocument24 paginiAssistant Professor Mechanical Department, Vasad: Presented byshivani sutharÎncă nu există evaluări

- Basic Mechanical Engineering All Units Question BankDocument39 paginiBasic Mechanical Engineering All Units Question BankKshitij SalaveÎncă nu există evaluări

- 750-91 OM Manual ModelCBLE-250-350HP Dec09Document194 pagini750-91 OM Manual ModelCBLE-250-350HP Dec09randallshÎncă nu există evaluări

- Section A1 CB-LE BoilersDocument66 paginiSection A1 CB-LE BoilersmaurozuriÎncă nu există evaluări

- A Preface On The BoilersDocument46 paginiA Preface On The Boilerslaloo01Încă nu există evaluări