Documente Academic

Documente Profesional

Documente Cultură

Rules For Retrofiting - Beams and Columns PDF

Încărcat de

Enida MataTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rules For Retrofiting - Beams and Columns PDF

Încărcat de

Enida MataDrepturi de autor:

Formate disponibile

International Journal of Advanced Engineering Research and Studies E-ISSN2249 – 8974

Research Article

MATERIALS AND JACKETING TECHNIQUE FOR

RETROFITTING OF STRUCTURES

Shri. Pravin B. Waghmare

Address for Correspondence

Acharya Shrimannarayan Polytechnic,Pipri(M), Wardha –Maharashtra

ABSTRACT

Seismic protection of buildings is a need-based concept aimed to improve the performance of any structure under future

earthquakes. Earthquakes of varying magnitude have occurred in the recent past in India, causing extensive damage to life

and property. Some recently developed materials and techniques can play vital role in structural repairs, seismic

strengthening and retrofitting of existing buildings, whether damaged or undamaged. The primary concern of a structural

engineer is to successfully restore the structures as quickly as possible. Selection of right materials, techniques and

procedures to be employed for the repair of a given structures have been a major challenges. Innovative techniques of the

structural repairs have many advantages over the conventional techniques. Some guidelines regarding selection of materials

for repair work such as steel, fiber reinforced polymer, has been discussed in the present paper. The selection of materials

and techniques to be used depend on many aspects that may be viewed from different prospectives i. e. requirement and

availability of financial resources, applicability and suitability of materials for the repair of damaged structures. Use of

standard and innovative repair materials, appropriate technology, workmanship, and quality control during implementation

are the key factors for successful repair, strengthening and restoration of damaged structures.

KEYWORDS: confinement, jacketing, fiber reinforced polymer jacketing, steel jacketing, beam jacketing.

INTRODUCTION (ii) Where an oval or elliptical jacket has

Jacketing is the most popularly used method for sufficient stiffness to confine the concrete

strengthening of building columns. The most along the long dimension of the cross-

common types of jackets are steel jacket, reinforced section is open to question. The longitudinal

concrete jacket, fibre reinforced polymer composite fibers similar to longitudinal reinforcement

jacket, jacket with high tension materials like carbon can be effective in increasing the flexural

fibre, glass fibre etc. The main purposes of jacketing strength of member although they cannot

are: effectively increase the flexural capacity of

1. To increase concrete confinement by transverse building frames because the critical

fibre reinforcement, especially for circular moments are located at beam-column ends

cross-sectional columns, where most of the longitudinal fibers are

2. To increase shear strength by transverse fibre difficult to pierce through to get sufficient

reinforcement, anchorage.

3. To increase flexural strength by longitudinal Technical Considerations

fibre reinforcement provided. They were The main objective of jacketing is to increase the

anchored at critical sections. Transverse fibre seismic capacity of the moment resisting framed

should be wrapped all around the entire structures. In almost every case, the columns as well

circumference of the members possessing close .as beams of the existing structure have been

loops sufficiently overlapped or welded in order jacketed. In comparison to the jacketing of reinforced

to increase concrete confinement and shear concrete columns, jacketing of reinforced concrete

strength. This is how members with circular beams with slabs is difficult yielding good

cross-section will get better confinement than confinement because slab causes hindrance in the

member with rectangular cross-section. Where jacket. In structures with waffle slab, the increase in

square or rectangular cross-sections are to be stiffness obtained by jacketing columns and some of

jacketed, circular/oval/ elliptical jackets are most the ribs, have improved the efficiency of structures.

oftenly used and the space between the jacket In some cases, foundation grids are strengthened and

and column is filled with concrete. Such types of stiffened by jacketing their beams. An increase in

multi-shaped jackets provide a high degree of strength, stiffness and ductility or a combination of

confinement by virtue of their shape to the splice them can be obtained. Jacketing serves to improve

region proving to be more effective. Rectangular the lateral strength and ductility by confinement of

jackets typically lack the flexural stiffness compression concrete. It should be noted that

needed to fully confine the concrete. However, retrofitting of a few members with jacketing or some

circular and oval jackets may be less desirable other enclosing techniques might not be effective

due to: enough to improve the overall behaviour of the

(i) Need of large space in the building potential structure, if the remaining members are not ductile.

difficulties of fitting in the jackets with Jacketing of Columns

existing partition walls, exterior cladding, Jacketing of columns consists of added concrete with

and non-structural elements and longitudinal and transverse reinforcement around the

IJAERS/Vol. I/ Issue I/October-December, 2011/15-19

International Journal of Advanced Engineering Research and Studies E-ISSN2249 – 8974

existing columns. This type of strengthening (i) Increase in the shear capacity of columns in order

improves the axial and shear strength of columns to accomplish a strong column-weak beam design

while the flexural strength of column and strength of and

the beam-column joints remain the same. It is also (ii) To improve the column's flexural strength by the

observed that the jacketing of columns is not longitudinal steel of the jacket made continuous

successful for improving the ductility. A major through the slab system are anchored with the

advantage of column jacketing is that it improves the foundation. It is achieved by passing the new

lateral load capacity of the building in a reasonably longitudinal reinforcement through holes drilled in

uniform and distributed way and hence avoiding the the slab and by placing new concrete in the beam

concentration of stiffness as in the case of shear column joints as illustrated in figure 1. Rehabilitated

walls. This is how major strengthening of sections are designed in this way so that the flexural

foundations may be avoided. In addition the original strength of columns should be greater than that of the

function of the building can be maintained, as there beams. Transverse steel above and below the joint

are no major changes in the original geometry of the has been provided with details, which consists of two

building with this technique. The jacketing of L-shaped ties that overlap diagonally in opposite

columns is generally carried out by two methods: (i) corners. The longitudinal reinforcement usually is

reinforced concrete jacketing and (ii) steel jacketing. concentrated in the column corners because of the

REINFORCED CONCRETE existence of the beams where bar bundles have been

JACKETING: used as shown in figure 1. It is recommended that not

more than 3 bars be bundled together. Windows are

Reinforced concrete jacketing can be employed as a

usually bored through the slab to allow the steel to go

repair or strengthening scheme. Damaged regions of

through as well as to enable the concrete casting

the existing members should be repaired prior to their

process.

jacketing. There are two main purposes of jacketing

of columns:

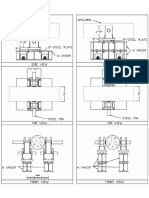

Figure No.1: Construction Technique for Column Jacketing

Table No. 1:Details For Reinforced Concrete Jacketing.

Properties of jackets • Match with the concrete of the existing structure.

• Compressive strength greater than that of the existing structures by 5 N/mm2or at

least equal to that of the existing structure.

Minimum width of jacket • 10 cm for concrete cast-in-place and 4 cm for shotcrete.

• If possible, four-sided jacket should be used.

• A monolithic behaviour of the composite column should be assured.

• Narrow gap should be provided to prevent any possible increase in flexural capacity.

Minimum area of •

3Afy, where, A is the area of contact in cm2 and fy is in kg/cm2

longitudinal reinforcement • Spacing should not exceed six times of the width of the new elements (the jacket in

the case) up to the limit of 60 cm.

• Percentage of steel in the jacket with respect to the jacket area should be limited

between 0.015and 0.04.

• At least, 12 mm bar should be used at every corner for a four sided jacket.

Minimum area of transverse • Designed and spaced as per earthquake design practice.

reinforcement • Minimum bar diameter used for ties is not less than 10 mm or 1/3 of the diameter of

the biggest longitudinal bar.

• The ties should have 135-degree hooks with 10bar diameter anchorage.

IJAERS/Vol. I/ Issue I/October-December, 2011/15-19

International Journal of Advanced Engineering Research and Studies E-ISSN2249 – 8974

• Due to the difficulty of manufacturing 135-degree hooks on the field, ties made up of

multiple pieces, can be used.

Shear stress in the interface • Provide adequate shear transfer mechanism to assured monolithic behaviour.

• A relative movement between both concrete interfaces (between the jacket and the

existing element) should be prevented.

• Chipping the concrete cover of the original member and roughening its surface may

improve the bond between the old and the new concrete.

• For four-sided jacket, the ties should be used to confine and for shear reinforcement

to the composite element.

Connectors • Connectors should be anchored in both the concrete such that it may develop at least

80% of their yielding stress.

• Distributed uniformly around the interface, avoiding concentration in specific

locations.

• It is better to use reinforced bars (rebar) anchored with epoxy resins of grouts.

Steel jacketing

Local strengthening of columns has been frequently accomplished by jacketing with steel plates. A general

feature of steel jacketing is mentioned in Table 2.

Table No. 2: Details Of Steel Jacketing.

Steel plate thickness • At least 6 mm.

Height of jacket • 1.2 to 1.5 times splice length in case of flexural columns.

• Full height of column in case of shear columns.

Shape of jackets • Rectangular jacketing, prefabricated two L-shaped panels The use of

rectangular jackets has proved to be successful in case of small size

columns upto 36 inch width that have been successfully retrofitted with %"

thick steel jackets combined with adhesive anchor bolt, but has been

less successful on larger rectangular columns. On larger columns, rectangular

jackets appear to be incapable to provide adequate confinement.

Free ends of jackets bottom • Welded throughout the height of jacket, size of weld1”

clearance. • 38 mm (1.5 inch), steel jacket may be terminated above the top of footing to

avoid any possible bearing of the steel jacket against the footing, to avoid local

damage to the jacket and/or an undesirable or unintended increase in

flexural capacity.

Gap between steel jacket and • 25 mm fill with cementations grout.

concrete column Size of anchor • 25 mm in diameter and 300 mm long embedded in 200 mm into concrete

Number of anchor bolts column.

• Bolts were installed through pre-drilled holes on the steel jacket using an epoxy

adhesive.

• Two anchor bolts are intended to stiffen the steel jacket and improve

confinement of the splice.

Figure No.2: Construction Technique for Steel Jacketing

IJAERS/Vol. I/ Issue I/October-December, 2011/15-19

International Journal of Advanced Engineering Research and Studies E-ISSN2249 – 8974

FRP JACKETING causes beam hinging. The location of the beam

critical section and the participation of the existing

E x istin g C o lu m n reinforcement should be taken into consideration.

Jacketing of beam may be carried out under different

ways, the most common are one-sided jackets or 3-

and 4-sided jackets. At several occasions, the slab has

C a rb o n fib re / been perforated to allow the ties to go through and to

stra p d ip p e d in to

e p o x y re sin enable the casting of concrete. The beam should be

jacketed through its whole length. The reinforcement

C a rb o n fib re w in d in g has also been added to increase beam flexural

capacity moderately and to produce high joint shear

Figure No. 3:Carbon Fibre winding stresses. Top bars crossing the orthogonal beams are

Several researchers have investigated the possibility put through holes and the bottom bars have been

and feasibility of fibre reinforced polymer composite placed under the soffit of the existing beams, at each

jackets for seismic strengthening of columns winding side of the existing column. Beam transverse steel

them with high strength carbon fibres around column consists of sets of U-shaped ties fixed to the top

surface to add spiral hoops (figure no. 3) The merits jacket bars and of inverted U-shaped ties placed

of this method are: through perforations in the slab, closely spaced ties

• Carbon fibre is flexible and can be made to have been placed near the joint region where beam

contact the surface tightly for a high degree hinging is expected to occur (figure no. 4). The main

of confinement; features of reinforcement details of beam jacketing

• Confinement is of high degree because are given in table 3.

carbon fiber is of high strength and high

modules of elasticity are used;

• The carbon fibre has light weight and

rusting does not occur.

Limitations:

There are some disadvantages associated with the

column jacketing techniques well,

• In some cases the presence of beams may

require majority of new longitudinal b to be

bundled into the corners of the jacket;

• With the presence of the existing column it'

difficult to provide cross ties for new

longitudinal bars which are not at the

corners of the jackets;

• Jacketing is based mostly on engineering

judgment as there is a dearth of guidelines.

BEAM JACKETING Figure No. 4: Construction Technique for Beam

Jacketing of beams is recommended for several Jacketing.

purposes as it gives continuity to the columns and Although those guidelines can give a rational basis

increases the strength and stiffness of the structure. for practical design, research still needs to address

critical aspects in the behavior of jacketed elements.

While jacketing a beam, its flexural resistance must

be carefully computed to avoid the creation of a The change in behaviour in jacketed elements, whose

strong beam-weak column system. In the retrofitted shear span/depth ratios are significantly reduced, due

structure, there is a strong possibility of change of to their jacketing, needs to be clarified.

mode of failure and redistribution of forces as a result

of jacketing of column, which may consequently

Table No. 3: Reinforcement of beam jacketing.

Minimum width for jacket Longitudinal • 8 cm if concrete cast in place or 4 cm for shotcrete

reinforcement • Percentage of steel on the jacket should be limited to 50 of the total area of the

composite section.

Shear reinforcement • Ignore the effect of existing shear reinforcement

• New reinforcement should have 135 hooks and at each corner of the tie there must be at

least one longitudinal bar.

• The bar used for the tie should have at least 8 mm diameter

• Multiple piece ties can be used, as discussed before for columns.

Depth of jacketed beam • Span/depth ratio

• Storey height

• Ductile behaviour

IJAERS/Vol. I/ Issue I/October-December, 2011/15-19

International Journal of Advanced Engineering Research and Studies E-ISSN2249 – 8974

REFERENCES

1. Pankaj Agrawal & Manish Shrikhande,”Earthquake

Resistant Design of Structures”, Printice Hall of

India Private Limited, New Delhi, 2006, pp 256-289.

2. UNDP/UNIDO Project RER/79/015,”Repair and

strengthening of Reinforced Concrete, Stone and

brick Masonry Buildings”, Building Construction

Under Seismic Conditions in the Balkan Regions,

1983, United Nations Industrial Development

Programme, Austraia, Vol.5.

3. Rodriguez. and Park R., ‘Repairing and

strengthening of Reinforced Concrete Buildings for

Seismic Resistance”, Earthquake Spectra, 1991,Vol.

7, No. 3.

4. Katsumata, H.and Kobatake, Y., “Seismic Retrofit

with carbon fibers for Reinforced Concrete

Columns”, Eleventh World Conference on

Earthquake Engineering, Paper No. 293,1996.

5. Alcocer, S. M., “rehabilitation of RC Frame

Connections using Jacketing”, Tenth World

Conference on Earthquake Engineering, Madrid,

Spain, 19-24 July, 1992

6. IS13945, Repair and Seismic Strengthening of

Buildings –Guidelines, Bureau of Indian Standards,

New Delhi, 1993.

IJAERS/Vol. I/ Issue I/October-December, 2011/15-19

S-ar putea să vă placă și

- Ow To Use Timber Structures To Create Large Span Architecture SpaceDocument12 paginiOw To Use Timber Structures To Create Large Span Architecture SpaceEnida MataÎncă nu există evaluări

- This Is Not A Boarding Pass: Milan MalpensaDocument13 paginiThis Is Not A Boarding Pass: Milan MalpensaEnida MataÎncă nu există evaluări

- Structural Design Example of Timber Beam According To Eurocode 5pdfDocument5 paginiStructural Design Example of Timber Beam According To Eurocode 5pdfEnida MataÎncă nu există evaluări

- Reliability-Based Interaction CurveDocument8 paginiReliability-Based Interaction CurveEnida MataÎncă nu există evaluări

- Floatability and Stability of Oating Dock-Docked Ship SystemDocument7 paginiFloatability and Stability of Oating Dock-Docked Ship SystemEnida MataÎncă nu există evaluări

- 3 Specimen Support Details Roller Support Is On Left Pinned SupDocument1 pagină3 Specimen Support Details Roller Support Is On Left Pinned SupEnida MataÎncă nu există evaluări

- Dormitory Nr.13 - Existing StructureDocument3 paginiDormitory Nr.13 - Existing StructureEnida MataÎncă nu există evaluări

- Final Report - Transboundary MonitoringDocument129 paginiFinal Report - Transboundary MonitoringEnida MataÎncă nu există evaluări

- This Is Not A Boarding Pass: Milan MalpensaDocument1 paginăThis Is Not A Boarding Pass: Milan MalpensaEnida MataÎncă nu există evaluări

- Nhess 2016 297 RC2 Supplement PDFDocument39 paginiNhess 2016 297 RC2 Supplement PDFEnida MataÎncă nu există evaluări

- Cad ManualDocument116 paginiCad ManualEnida MataÎncă nu există evaluări

- Table of Lengths For Vriable Bars With BordersDocument2 paginiTable of Lengths For Vriable Bars With BordersEnida MataÎncă nu există evaluări

- Resumo PDFDocument9 paginiResumo PDFEnida MataÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- U-House, Toyo ItoDocument19 paginiU-House, Toyo Itobhavin24007Încă nu există evaluări

- Landscaping Pavement DetailsDocument23 paginiLandscaping Pavement DetailsyasserÎncă nu există evaluări

- Ap2 - Documenting The CityDocument26 paginiAp2 - Documenting The CityErika PunoÎncă nu există evaluări

- DOH 90 % Site Inspection Required ChecklistDocument3 paginiDOH 90 % Site Inspection Required Checklistarshad209Încă nu există evaluări

- Thesis - Structural Design Basis For High-Rise Residential BuildingsDocument44 paginiThesis - Structural Design Basis For High-Rise Residential BuildingsSatwinder SinghÎncă nu există evaluări

- ASTM-E2392 Standard Guide For Design of Earthen Wall Building SystemsDocument10 paginiASTM-E2392 Standard Guide For Design of Earthen Wall Building SystemsAlejandro JiménezÎncă nu există evaluări

- Triangles Used in Architecture - SciencingDocument3 paginiTriangles Used in Architecture - SciencingAditya KumarÎncă nu există evaluări

- Structural Plan PDFDocument10 paginiStructural Plan PDFPaul Anjelo MilagrosaÎncă nu există evaluări

- Baroque Architecture: San Agustin Church in ManilaDocument12 paginiBaroque Architecture: San Agustin Church in ManilaShamara PolangiÎncă nu există evaluări

- MR - Thakare Bunglow Living Sofa Elevation 2 SeptemberDocument1 paginăMR - Thakare Bunglow Living Sofa Elevation 2 SeptemberNEHA kÎncă nu există evaluări

- Stirling Lloyd - Tunnels BrochureDocument8 paginiStirling Lloyd - Tunnels BrochureRaul Radu100% (1)

- Sobha 2 InternshipDocument52 paginiSobha 2 Internshipchinmay vijay67% (3)

- Structure RelocationDocument8 paginiStructure RelocationBarbara MouratidouÎncă nu există evaluări

- 2-Stage D - Part 2 - Structural Design Report - FX Rev1Document168 pagini2-Stage D - Part 2 - Structural Design Report - FX Rev1Prima AdhiyasaÎncă nu există evaluări

- Case Study On Jeddah TowerDocument20 paginiCase Study On Jeddah TowerAbhijeet GawaiÎncă nu există evaluări

- Design For Pile Horizontal CapacityDocument25 paginiDesign For Pile Horizontal CapacityfiazshahÎncă nu există evaluări

- Firmitas, Utilitas, Venustas: Pengantar Arsitektur Minggu 4Document28 paginiFirmitas, Utilitas, Venustas: Pengantar Arsitektur Minggu 4Messy CoolÎncă nu există evaluări

- LS-435 R28Document3 paginiLS-435 R28Er Digvijay SinghÎncă nu există evaluări

- Cultural Basis of ArchitectureDocument24 paginiCultural Basis of ArchitectureRiz Ann Papa100% (2)

- Various Types of Jacketing in Construction. - CivilwalaDocument15 paginiVarious Types of Jacketing in Construction. - CivilwalaJhon shonÎncă nu există evaluări

- 2023 PortfolioDocument11 pagini2023 PortfolioAllan de Paula PossaÎncă nu există evaluări

- Architectural Patterns - Queen Anne (PDF) - 201505211539311450Document14 paginiArchitectural Patterns - Queen Anne (PDF) - 201505211539311450Pedro Henrique MaranhãoÎncă nu există evaluări

- Intd 1010 PortfolioDocument60 paginiIntd 1010 Portfolioapi-512292162Încă nu există evaluări

- BLDG Est GuideDocument11 paginiBLDG Est GuideVALIENT CANCERANÎncă nu există evaluări

- Proposed MRF Plan Technical DrawingsDocument2 paginiProposed MRF Plan Technical DrawingsLawrence TingÎncă nu există evaluări

- Min Plumbing FacilitiesDocument11 paginiMin Plumbing FacilitiesPronton, Hermie F.Încă nu există evaluări

- A Detailed Lesson Plan in Partial Fulfillment of The Course Requirements in (FS 1 AND 2)Document15 paginiA Detailed Lesson Plan in Partial Fulfillment of The Course Requirements in (FS 1 AND 2)Angel Clarence BasilioÎncă nu există evaluări

- Standard Plans 2009Document472 paginiStandard Plans 2009Martin E. Ruvalcaba100% (1)

- Seaton Whitevale Price Package - Single and Double Car Garage Detached Home - Feb 4 2021Document4 paginiSeaton Whitevale Price Package - Single and Double Car Garage Detached Home - Feb 4 2021Bill GuanÎncă nu există evaluări

- Black & Decker The Complete Guide To Floor DecorDocument274 paginiBlack & Decker The Complete Guide To Floor Decorshadowling2013100% (10)