Documente Academic

Documente Profesional

Documente Cultură

Fitting Instructions for EBC Brakes: Clean Rotors and Mount to Rust Free Flanges

Încărcat de

Ndao860 evaluări0% au considerat acest document util (0 voturi)

111 vizualizări1 paginărouters

Titlu original

Ebc Fitting Instructions

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentrouters

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

111 vizualizări1 paginăFitting Instructions for EBC Brakes: Clean Rotors and Mount to Rust Free Flanges

Încărcat de

Ndao86routers

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Fitting Instructions For EBC Brakes

Disc Brake Rotors Disc Brake Pads

Instructions for Replacement

1 of Brake Rotors DRIVER SAFETY WARNING

Brakes are a safety critical part of your vehicle and should be installed

1. The corrosion protective film by a competent mechanic following vehicle manufacturers installation

on non-grooved EBC rotors procedure. The surface of these brake pads is coated with a red

must be removed carefully coating known as BRAKE-INTM. This coating helps your newly installed

from new rotors with a brake pads to “seat” or bed in quickly. However, pads should be used

suitable contact cleaner (meths gently for the first 100 miles until optimum braking is observed.

or white spirit) to avoid

contaminating pads. INSPECT BRAKE PADS FOR WEAR every 3000 miles as varying load and

2. Important: The wheel use conditions can greatly influence pad wear rate. Badly worn or

mounting flange must be totally worn brake pads can cause partial or total loss of brake and

cleaned before fitting the may result in an accident. This product may last longer than or even

brake rotors. Rust or scale will LESS MILES THAN other types of brake pad when used in the same

Clean rotors cause runout & brake judder. conditions.

3. Check: After having fitted the

brake rotor a dial indicator Some Asian fitment brake pads are fitted with audible wear indicator

with a magnetic base ideally devices called screech clips. These are a “U” shaped clip rivetted to the

2 should be placed on the

vehicle. The brake rotor should

left or right side of the brake pad backing plate. Screech clips are

designed to contact the rotor when pad is worn dangerously low and

be rotated and tested for axial emit a screeching sound. When the noise is observed pads must be

runout. If runout exceeds 0,15- changed immediately to avoid loss of brake efficiency.

0,20mm the rotor must be

dismounted and rotated one NOTES FOR INSTALLING MECHANIC

bolt hole. Repeat the test. If Most EBC pads are now fitted with noise reduction shims on the

runout still excessive, remove reverse side of the pad and also now have edge chamfers to reduce

rotor, check for debris/damage low speed brake noise. Depending on rotor condition some minor

& repeat procedure. noises can occur during early pad life and are not a reason for

4. Always fit new rotor brake warranty. Please recommend to customers that they allow their brakes

pads and allow 300 miles to run for at least 500 miles before claiming warranty under noise. The

urban driving for pads BRAKE-IN coating on the pad surface is a major aid in helping pads to

and rotors to bed in. seat quickly and should not be removed or sanded. Avoid

Mount to clean rust free 5. Check that caliper pistons slide contamination of pad surface with any forms of grease that you may

flanges freely and are not seized, use to lubricate caliper sliders.

binding calipers will cause

uneven braking or judder.

6. EBC Grooved rotors are coated

3 with gold or black zinc finish

which will wear off during the

first 100 miles of braking. Do

not attempt to remove this

coating on installation.

EBC BRAKES BRAKE KITS

S-ar putea să vă placă și

- Fitting Instructions For EBC BrakesDocument1 paginăFitting Instructions For EBC BrakesAlbert LugoÎncă nu există evaluări

- HDBIDocument5 paginiHDBIkevlar315Încă nu există evaluări

- How to Service Drum BrakesDocument5 paginiHow to Service Drum BrakesJACOB MUDONHIÎncă nu există evaluări

- SRB, Z31 Polyurethane Steering Rack Bushings.: CautionDocument2 paginiSRB, Z31 Polyurethane Steering Rack Bushings.: CautionmittyÎncă nu există evaluări

- Popular Mechanics - Servicing Drum BrakesDocument5 paginiPopular Mechanics - Servicing Drum BrakesGeorgiana MarinÎncă nu există evaluări

- 2008 Viper ACR 1stDocument28 pagini2008 Viper ACR 1stLuis YOÎncă nu există evaluări

- Drum BrakesDocument5 paginiDrum Brakesomer afridiÎncă nu există evaluări

- How To Replace The Front Brake Pads of Disc Brake On Peugeot 407Document6 paginiHow To Replace The Front Brake Pads of Disc Brake On Peugeot 407Razvan ChirilovÎncă nu există evaluări

- Electric Motor Maintenance and Troubleshooting GuideDocument7 paginiElectric Motor Maintenance and Troubleshooting GuidealexfrizÎncă nu există evaluări

- BMW M3 E46 - Rear Installation Manual - 98-137-1471 - Rev. B - 08-22-05Document24 paginiBMW M3 E46 - Rear Installation Manual - 98-137-1471 - Rev. B - 08-22-05rajkonaprtaÎncă nu există evaluări

- Korando B4 D0 NJDocument10 paginiKorando B4 D0 NJlink2ndÎncă nu există evaluări

- Dobinsons MRA Adjustable Remote Reservoir Shock Absorbers Fitting GuideDocument7 paginiDobinsons MRA Adjustable Remote Reservoir Shock Absorbers Fitting Guidedavidelias1001Încă nu există evaluări

- 00 Brake Testing and Bleeding: 2008 BMW 328xi 2008 BMW 328xiDocument554 pagini00 Brake Testing and Bleeding: 2008 BMW 328xi 2008 BMW 328xi=IceBurn=Încă nu există evaluări

- Fork Owners Manual 2018Document83 paginiFork Owners Manual 2018Deivisson CarvalhoÎncă nu există evaluări

- Installation Instructions: Spring Brake Chamber and Service Brake Chamber Installation and Clocking (Air Disc Brake)Document8 paginiInstallation Instructions: Spring Brake Chamber and Service Brake Chamber Installation and Clocking (Air Disc Brake)Elmer Tintaya MamaniÎncă nu există evaluări

- Brembo Motorcycle Braking Catalog GuideDocument54 paginiBrembo Motorcycle Braking Catalog GuideIntiGowthamSaiÎncă nu există evaluări

- 12 Frenos Suzuki IntruderDocument32 pagini12 Frenos Suzuki Intruderbenjapana100% (2)

- Hilliard Flame Clutch InstallationDocument4 paginiHilliard Flame Clutch InstallationDavid CarsonÎncă nu există evaluări

- 2003 Axle Owners Manual PDFDocument6 pagini2003 Axle Owners Manual PDFEric MoryÎncă nu există evaluări

- HR 12 Ee BRDocument13 paginiHR 12 Ee BRКонстантин ДубенкоÎncă nu există evaluări

- Backstop P-1346-1-MCDocument8 paginiBackstop P-1346-1-MCJaime Valenzuela MarchantÎncă nu există evaluări

- MP8 - D13 Injector Cup Info 45-sb211007-1Document6 paginiMP8 - D13 Injector Cup Info 45-sb211007-1ONE SOURCE DIESELÎncă nu există evaluări

- Dropoff SL 2006Document20 paginiDropoff SL 2006Insight PeruÎncă nu există evaluări

- Owner S Manual: Suspension Front Fork W. Coil Spring or MCUDocument2 paginiOwner S Manual: Suspension Front Fork W. Coil Spring or MCUformilÎncă nu există evaluări

- Components of LMSSDocument14 paginiComponents of LMSSWilliamÎncă nu există evaluări

- Ball Bearing Disc Brake: Installation and Setup GuideDocument14 paginiBall Bearing Disc Brake: Installation and Setup GuideAKILI PSIÎncă nu există evaluări

- 001 Electric BrakesDocument5 pagini001 Electric BrakesHamza AlkafreÎncă nu există evaluări

- Identification: Drive Axle Noise DiagnosisDocument48 paginiIdentification: Drive Axle Noise DiagnosisRoberto Ortega MicalizziÎncă nu există evaluări

- TimkenTT en Vol1 Iss3Document2 paginiTimkenTT en Vol1 Iss3grupa2904Încă nu există evaluări

- Instruction - VCC 143895 1Document7 paginiInstruction - VCC 143895 1dovla091Încă nu există evaluări

- Top Entry Mixer Features For EkatoDocument2 paginiTop Entry Mixer Features For EkatoShankarÎncă nu există evaluări

- Rod BearingsDocument29 paginiRod BearingsDaniel SarmientoÎncă nu există evaluări

- MMBK8FDocument4 paginiMMBK8FAnond UseryÎncă nu există evaluări

- Rear Brakes: Section 4EDocument24 paginiRear Brakes: Section 4EAndres RochaÎncă nu există evaluări

- Trooper Brake DisksDocument3 paginiTrooper Brake DisksJairo SoriaÎncă nu există evaluări

- Easton Wheels InstallationDocument3 paginiEaston Wheels Installationdesign100Încă nu există evaluări

- MSU KOL Metro TC 0104Document5 paginiMSU KOL Metro TC 0104CosmosÎncă nu există evaluări

- Manitou 2003 Axel Service ManualDocument6 paginiManitou 2003 Axel Service Manualsloth185Încă nu există evaluări

- Tech Common Drum ProblemsDocument3 paginiTech Common Drum ProblemsGustavo MosqueraÎncă nu există evaluări

- 206-03 Front Disc Brake PICKUP JMCDocument11 pagini206-03 Front Disc Brake PICKUP JMCRusonegroÎncă nu există evaluări

- ALCO Enduro ManualDocument8 paginiALCO Enduro ManualAntonio F.M. PalloneÎncă nu există evaluări

- 04-Axel EngDocument4 pagini04-Axel Engsupervalera1309Încă nu există evaluări

- BC Ma Backstop: Service & Installation InstructionsDocument8 paginiBC Ma Backstop: Service & Installation InstructionsDênis DáyolÎncă nu există evaluări

- Caliper Ranger and Explorer Disassembly and Assembly PDFDocument2 paginiCaliper Ranger and Explorer Disassembly and Assembly PDFMichael HernandezÎncă nu există evaluări

- BIKE SHOCK USER MANUALDocument6 paginiBIKE SHOCK USER MANUALfaizÎncă nu există evaluări

- Eng Shimano Manu 07218Document1 paginăEng Shimano Manu 07218Ken SidhartaÎncă nu există evaluări

- Drive ShaftDocument9 paginiDrive ShaftSteven AmadorÎncă nu există evaluări

- York Trailer Service ManualDocument17 paginiYork Trailer Service ManualPraveen Kumar RÎncă nu există evaluări

- High Ambient 3GZV500002-6 9AKK104910 ML 06 - 2009 - WebDocument32 paginiHigh Ambient 3GZV500002-6 9AKK104910 ML 06 - 2009 - WebLogist ChinaÎncă nu există evaluări

- Aftermarket Wheel Installation GuidelinesDocument1 paginăAftermarket Wheel Installation GuidelinesCindyÎncă nu există evaluări

- Guia de Embreagens LUKDocument36 paginiGuia de Embreagens LUKXman BrazilÎncă nu există evaluări

- Pamphlet On Instruction For Axle Mounted Brake Disc in LHB Coach (FTIL Type)Document8 paginiPamphlet On Instruction For Axle Mounted Brake Disc in LHB Coach (FTIL Type)Dasari RamamohanaÎncă nu există evaluări

- RTR 200 4VDocument92 paginiRTR 200 4VKinki RiosÎncă nu există evaluări

- 11 2E 后悬架Document15 pagini11 2E 后悬架Alexander cesar neyra sotoÎncă nu există evaluări

- zmajalicaDocument7 paginizmajalicaboypiti30Încă nu există evaluări

- KXR50 Cap 12 (Ruota Freni Sospens Ant)Document19 paginiKXR50 Cap 12 (Ruota Freni Sospens Ant)tutifruti649Încă nu există evaluări

- Specifications: Application Specification Metric EnglishDocument21 paginiSpecifications: Application Specification Metric Englishjhon greigÎncă nu există evaluări

- INPRO SEAL Bearing-IsolatorDocument8 paginiINPRO SEAL Bearing-IsolatorRamonÎncă nu există evaluări

- Power of Attorney: Tax Form Instructions: 1. PurposeDocument3 paginiPower of Attorney: Tax Form Instructions: 1. PurposeNdao86Încă nu există evaluări

- Laws of The Bible, Litigation Tool #09.001Document199 paginiLaws of The Bible, Litigation Tool #09.001Sovereignty Education and Defense Ministry (SEDM)100% (3)

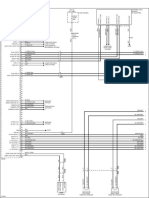

- 2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 6 of 7Document1 pagină2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 6 of 7Ndao86Încă nu există evaluări

- 2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 3 of 3Document1 pagină2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 3 of 3Ndao86Încă nu există evaluări

- Operator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleDocument18 paginiOperator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleNdao86Încă nu există evaluări

- 2014 Ram Pickups PDFDocument45 pagini2014 Ram Pickups PDFNdao86Încă nu există evaluări

- 2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 4 of 7Document1 pagină2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 4 of 7Ndao86Încă nu există evaluări

- Affidavit of Material FactsDocument17 paginiAffidavit of Material FactsNdao86Încă nu există evaluări

- Affidavit Acceptance for Value ExplainedDocument5 paginiAffidavit Acceptance for Value ExplainedNdao86100% (1)

- 2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 5 of 7Document1 pagină2013 Dodge Ram 1500 Color Schematics Engine Controls 5 7l 5 of 7Ndao86Încă nu există evaluări

- 2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 2 of 3Document1 pagină2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 2 of 3Ndao86Încă nu există evaluări

- 2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 1 of 3Document1 pagină2013 Dodge Ram 1500 Color Schematics Sound Systems Premium Radio Circuit 1 of 3Ndao86Încă nu există evaluări

- Operator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleDocument18 paginiOperator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleNdao86Încă nu există evaluări

- 022624Document17 pagini022624Ndao86Încă nu există evaluări

- Ram Speaker InstallDocument9 paginiRam Speaker InstallNdao86Încă nu există evaluări

- Milwak Hckzall ManualDocument11 paginiMilwak Hckzall ManualNdao86Încă nu există evaluări

- 2017E Radio Uconnect 30 Multimedia 1stDocument41 pagini2017E Radio Uconnect 30 Multimedia 1stNdao86Încă nu există evaluări

- Milwak Hckzall ManualDocument11 paginiMilwak Hckzall ManualNdao86Încă nu există evaluări

- 1140 Impact Manual PDFDocument60 pagini1140 Impact Manual PDFNdao86Încă nu există evaluări

- 2017E Radio Uconnect 30 Multimedia 1stDocument41 pagini2017E Radio Uconnect 30 Multimedia 1stNdao86Încă nu există evaluări

- Affidavit of SovereigntyDocument9 paginiAffidavit of SovereigntyindpcontractorÎncă nu există evaluări

- Basic Thermostat InstructionsDocument1 paginăBasic Thermostat InstructionsNdao86Încă nu există evaluări

- Airless Paint Sprayers: Campbell HausfeldDocument12 paginiAirless Paint Sprayers: Campbell HausfeldNdao86Încă nu există evaluări

- Open Posi Differential ChryslerDocument1 paginăOpen Posi Differential ChryslerNdao86Încă nu există evaluări

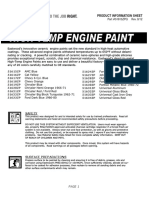

- Ceramic Engine PaintsDocument2 paginiCeramic Engine PaintsNdao86Încă nu există evaluări

- 0 Spraytech Apex Manual 0512770HDocument52 pagini0 Spraytech Apex Manual 0512770HNdao86Încă nu există evaluări

- Kit Installation Instructions: Please Read Completely Before InstallationDocument19 paginiKit Installation Instructions: Please Read Completely Before InstallationNdao86Încă nu există evaluări

- 1100 XC Airless Sprayer PDFDocument28 pagini1100 XC Airless Sprayer PDFNdao86Încă nu există evaluări

- Common Law Abatement PDFDocument88 paginiCommon Law Abatement PDFPat Riot96% (53)

- Affidavit of SovereigntyDocument9 paginiAffidavit of SovereigntyindpcontractorÎncă nu există evaluări

- Đề 9ch 1Document6 paginiĐề 9ch 1Nhi NguyễnÎncă nu există evaluări

- 4th Periodical Test g12 P.EDocument8 pagini4th Periodical Test g12 P.EYram LemÎncă nu există evaluări

- Communication Strategy of VodafoneDocument35 paginiCommunication Strategy of VodafoneArgha Gupta100% (2)

- Iron Kingdoms - Adventure - Fool's Errand (LVL 3-5) PDFDocument29 paginiIron Kingdoms - Adventure - Fool's Errand (LVL 3-5) PDFnomad79Încă nu există evaluări

- Principles of Contemporary Marketing 14th Edition Kurtz Test BankDocument38 paginiPrinciples of Contemporary Marketing 14th Edition Kurtz Test Bankaidenqpepe100% (14)

- Empowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesDocument3 paginiEmpowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesHannah MajadoÎncă nu există evaluări

- Quiz 3 - RizalDocument4 paginiQuiz 3 - RizalCoco SpencerÎncă nu există evaluări

- Department of Education Schools Division of Ilocos Sur Nagbukel National High SchoolDocument3 paginiDepartment of Education Schools Division of Ilocos Sur Nagbukel National High Schoolperlita galla100% (1)

- Service ManualDocument53 paginiService ManualnistoreduardcristianÎncă nu există evaluări

- Ms Alcatel Lucent Enterprise Lan Product Services Price Catalog October Sept2015Document81 paginiMs Alcatel Lucent Enterprise Lan Product Services Price Catalog October Sept2015Osmar AmadeuÎncă nu există evaluări

- Michelle Morrisey CVDocument3 paginiMichelle Morrisey CVmichmorriseyÎncă nu există evaluări

- Submitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Document15 paginiSubmitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Maniya GillaniÎncă nu există evaluări

- ĐỀ 09 và 10 thườngDocument5 paginiĐỀ 09 và 10 thườngMai ThanhÎncă nu există evaluări

- Preview of SweetDocument20 paginiPreview of SweetMisha MK25% (4)

- DuckTales - Title ThemeDocument2 paginiDuckTales - Title ThemeAngel Javier Mamani Anara100% (1)

- Puerto Rico Culture, History & PoliticsDocument3 paginiPuerto Rico Culture, History & PoliticsJesusa VillanuevaÎncă nu există evaluări

- Strength Training (For Teens) - Nemours KidsHealthDocument1 paginăStrength Training (For Teens) - Nemours KidsHealthSlayerÎncă nu există evaluări

- Temporary Enchantment: by Barak BlackburnDocument6 paginiTemporary Enchantment: by Barak BlackburnAngel Belisle Jr.Încă nu există evaluări

- UAQ Assignment 2 by RajeevDocument14 paginiUAQ Assignment 2 by RajeevRajeev KumarÎncă nu există evaluări

- CESLINK BUSINESS PLAN - 中英版Document24 paginiCESLINK BUSINESS PLAN - 中英版Setiawan RustandiÎncă nu există evaluări

- ML Tank-Horizontal Tank Sizing Rev 0Document1 paginăML Tank-Horizontal Tank Sizing Rev 0AJAY1381Încă nu există evaluări

- PE3 - Module 2Document9 paginiPE3 - Module 2diego lopezÎncă nu există evaluări

- Toni Stone History Making Baseball LegendDocument15 paginiToni Stone History Making Baseball LegendO'Dwayne Wilson100% (1)

- What Is Contemporary Literature? (10) : Personal Point of ViewDocument5 paginiWhat Is Contemporary Literature? (10) : Personal Point of ViewJeremie F. AlejandroÎncă nu există evaluări

- Finding affection and appreciationDocument19 paginiFinding affection and appreciationRose JennetÎncă nu există evaluări

- Michael Lightbringer: Protectoraasimar Lawful Neutral 900Document3 paginiMichael Lightbringer: Protectoraasimar Lawful Neutral 900Hüseyin Emir KıvançÎncă nu există evaluări

- CCM RS232 Cable Wire ConnectionDocument2 paginiCCM RS232 Cable Wire Connectionlinkangjun0621Încă nu există evaluări

- Petrang Kabayo Cast and CrewDocument8 paginiPetrang Kabayo Cast and CrewAlexis Beatriz PeretÎncă nu există evaluări

- Flux Meter Hioki EMF 3470Document4 paginiFlux Meter Hioki EMF 3470industrialindiaÎncă nu există evaluări