Documente Academic

Documente Profesional

Documente Cultură

USB ျဖင့္Windows တင္နည္း

Încărcat de

gonri lynn0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări3 paginifuel injection

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentfuel injection

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări3 paginiUSB ျဖင့္Windows တင္နည္း

Încărcat de

gonri lynnfuel injection

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

CHAPTER 1

INTRODUCTION

Combustion in the cylinder of a diesel engine has a critical effect on the

efficiency of the engine and the contamination caused by the engine. In a diesel

engine, combustion is controlled by means of fuel injection. Therefore, it is of great

importance that the injection process of the fuel is controlled in a proper manner.

Conventionally, the injection system of a diesel engine comprises fuel-

injection pump, high-pressure pipe, and fuel injector. When the fuel is supplied via

through the high-pressure pipe by the injection pump, the fuel is sprayed into the

combustion chamber in finely atomized particles. These droplets vaporize due to heat

transfer from the compressed air in the combustion chamber and form a fuel-air

mixture. Due to continued heat transfer from hot air to the fuel, the temperature

reaches a value higher than its self-ignition temperature. This causes the fuel to ignite

spontaneously initiating the combustion process.

Quick and complete combustion is ensured by a well designed fuel injector

nozzle. The fuel injector nozzle is a part of the fuel injector which the liquid fuel is

sprayed into the combustion chamber. The design of fuel injector nozzle must be such

that the liquid fuel forced through the nozzle will be broken up into fine droplets, or

atomized, as it passes into the combustion chamber. Atomization is done by forcing

the fuel through a small orifice of nozzle under high pressure.

As mentioned above, investigating the fuel injector nozzle and designing the

fuel injector nozzle play a critical role in a diesel engine since it affects on the engine

performance and fuel economy. The fuel injector nozzle flow can be studied

experimentally or by means of a model.

In the diesel engine, the ignition is occurred by the compression. When the

temperature is reached to ignite the fuel, the ignition of the diesel engine is started and

burning of the fuel is continued and combustion of the fuel produces the power of the

engine as a form of mechanical power by turning of the crankshaft. However, if the

particle of the fuel sprayed by the nozzle is not correct in size and the amount, the

ignition of the diesel engines cannot start to burn the fuel.

2

Therefore, the life of the diesel engine is depended on the operation of the

nozzle. In this paper, fuel injection nozzle, one of the essential parts of the diesel

engines is presented. The fuel injection nozzle is a device which can spray the fuel

into the combustion chamber or cylinder of the diesel engine.

1.1. Aim and Objectives

The main aim of this thesis is to design the fuel injector nozzle used in Light

Truck diesel engine for local industrial zone (Pakokku).

The objectives are explained below:

to enable to know the fuel injection system of the diesel engine,

to study the operation of fuel injection system,

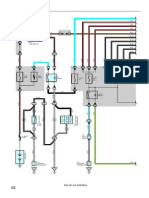

to study the injection system for 2c-diesel engine (light truck),

to explain the working principle of fuel injection nozzle,

to give the design calculation of fuel injection nozzle, and

to improve the industrial production of the industrial zone of Myanmar.

1.2. Scope of Thesis

Fuel injection nozzle is a main component of the diesel engines. Its fuel

injection is to inject fuel into the combustion chamber of the internal combustion

engines. In this thesis, fuel injection nozzle is designed. The required fuel pressure,

amount of the fuel and spray pattern are measured and calculated.

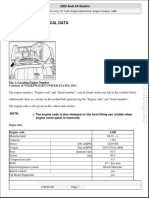

In the design calculation, 94hp four cylinder diesel engines are chosen for a

sample design. Therefore, the results of the design calculation of this thesis are just

for 94hp diesel engine. This design calculation can be used as an example for the

other size of the diesel engine but its results are not used directly for the other size of

the diesel engine.

1.3. Implementation Program

colleting the books related to the diesel engine, fuel injection system,

machine design, material, design consideration and calculation,

studying the related theoretical background for fuel injection nozzle,

discussion with the people who are using the diesel engine,

looking at the damage parts of the fuel injection nozzle,

disassembling fuel injection nozzle and inquired functions of the each part

searching the required data of the design calculation, and

considering the selection material for the economic product.

1.4. Outline of Thesis

This thesis is organized with six chapters. Each chapter expresses clearly the

respective contents with the diagrams. The arrangement of this thesis is as follows;

3

Chapter one is introduction. Chapter two is fuel injection system of diesel engine.

Chapter three presents the components and operation of fuel injection nozzle. Chapter

four consists of design consideration of fuel injection nozzle. Chapter five is design

calculation of fuel injection nozzle. Chapter six is discussion, conclusion and

recommendations.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Code IsuzuDocument390 paginiCode IsuzuIchalcorey Rock On100% (6)

- Fuel Injection PumpDocument8 paginiFuel Injection PumpSai Indrakaran Reddy Cherabuddi100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Diesel MechanicDocument23 paginiDiesel MechanicAtif MahmoodÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- WP10series Manual PDFDocument127 paginiWP10series Manual PDFnguyenmanhquanÎncă nu există evaluări

- Amb ENGINE 1.8LDocument650 paginiAmb ENGINE 1.8LNP100% (1)

- 1106D Training PresentationDocument64 pagini1106D Training Presentationbagus100% (7)

- VW JETTA 2006 - 1.9l Diesel Engine, BRM - Wiring Diagrams, Pin Connector, LocationDocument36 paginiVW JETTA 2006 - 1.9l Diesel Engine, BRM - Wiring Diagrams, Pin Connector, LocationOscar MoralesÎncă nu există evaluări

- Serv1837 TXTDocument109 paginiServ1837 TXTGissel CQ100% (5)

- Sistema Inyección CR BoschDocument8 paginiSistema Inyección CR BoschRodolfo Leiva100% (1)

- Engine Control Celica 2000Document12 paginiEngine Control Celica 2000Giovanni Morales100% (2)

- Toyota Hilux (1997 - 2005) Fuse Box DiagramsDocument8 paginiToyota Hilux (1997 - 2005) Fuse Box DiagramsSonny Raymundo50% (2)

- Operator'S Manual: D25A MS/MT D30A MS/MTDocument93 paginiOperator'S Manual: D25A MS/MT D30A MS/MTAbdul Fvck Meganz KhojinÎncă nu există evaluări

- O B D I I R e A D e RDocument100 paginiO B D I I R e A D e RUbaldo SanchezÎncă nu există evaluări

- Ajuste de Valvulas PDFDocument8 paginiAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- SSP 211 New BeetleDocument48 paginiSSP 211 New BeetleAlexandru CraiovanÎncă nu există evaluări

- D2848 LE Operating ManualDocument68 paginiD2848 LE Operating ManualSpree100% (1)

- Engine Display GEMDocument20 paginiEngine Display GEMAlvaro PradaÎncă nu există evaluări

- 2-Critical Speed of ShaftDocument5 pagini2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- Operation & Maintenance Manual d260 S3a-En Okt. 2014Document166 paginiOperation & Maintenance Manual d260 S3a-En Okt. 2014DrBollapu Sudarshan50% (2)

- Technological University (Mandalay) Mechanical Engineering: Machine DrawingDocument7 paginiTechnological University (Mandalay) Mechanical Engineering: Machine DrawinggonriÎncă nu există evaluări

- Supply 2Document5 paginiSupply 2gonri lynnÎncă nu există evaluări

- Supply 1Document1 paginăSupply 1gonri lynnÎncă nu există evaluări

- Chapter 15 Fluid Lecture NoteDocument17 paginiChapter 15 Fluid Lecture Notegonri lynnÎncă nu există evaluări

- Thermal Conversion of Biomass and WasteDocument1 paginăThermal Conversion of Biomass and Wastegonri lynnÎncă nu există evaluări

- 1.classification of Reciprocating PumpsDocument8 pagini1.classification of Reciprocating Pumpsgonri lynnÎncă nu există evaluări

- Academic Research Paper ေရးသားျခင္းDocument2 paginiAcademic Research Paper ေရးသားျခင္းgonri lynnÎncă nu există evaluări

- ONE DROP TEST - Tissue Test PDFDocument2 paginiONE DROP TEST - Tissue Test PDFAsep ShaifurrahmanÎncă nu există evaluări

- HT-150600 - PS Elite 750 InfoDocument4 paginiHT-150600 - PS Elite 750 InfoschoeyRGVÎncă nu există evaluări

- Crdi System PDFDocument20 paginiCrdi System PDFsanath santhoshÎncă nu există evaluări

- KEMSTREAM Vapbox500Document4 paginiKEMSTREAM Vapbox500thuronÎncă nu există evaluări

- 1.4 l/55 KW - 4AV, Engine Codes AHW, AKQ: Current Flow DiagramDocument9 pagini1.4 l/55 KW - 4AV, Engine Codes AHW, AKQ: Current Flow DiagramSaul CalderónÎncă nu există evaluări

- (See PCM Terminal Voltage Table (Reference) .)Document8 pagini(See PCM Terminal Voltage Table (Reference) .)surajÎncă nu există evaluări

- Operating Instructions - en - OM470LA OM471LA OM473LA - 6R 1100 1300 1500 - A4705844581 - enDocument72 paginiOperating Instructions - en - OM470LA OM471LA OM473LA - 6R 1100 1300 1500 - A4705844581 - enjz.jonaszoltanÎncă nu există evaluări

- Adapt Parms GBDocument250 paginiAdapt Parms GBsergioutreraÎncă nu există evaluări

- Diesel Injection Rate Shaping: Potential For EURO6 CalibrationDocument2 paginiDiesel Injection Rate Shaping: Potential For EURO6 CalibrationRamesh Kumar AÎncă nu există evaluări

- Analysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerDocument7 paginiAnalysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerSyahriRomadhoniÎncă nu există evaluări

- Boosted Gasoline Engine Concept For BS VI and Beyond: Presented at GT India Conference 2019Document24 paginiBoosted Gasoline Engine Concept For BS VI and Beyond: Presented at GT India Conference 2019Santosh TrimbakeÎncă nu există evaluări

- Working Instructions - enDocument774 paginiWorking Instructions - enWorld ServiceÎncă nu există evaluări