Documente Academic

Documente Profesional

Documente Cultură

Advantages of VT Pump

Încărcat de

ravindra_27437153Drepturi de autor

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Advantages of VT Pump

Încărcat de

ravindra_27437153Drepturi de autor:

ADVANTAG E S O F TH E VE RTIC AL PU M P File No: f51.

111

Date: aug. 15, 2005

Supersedes: new

Date: new

Armstrong Vertical pumps provide a number of important 10 Full range of drivers for maximum flexibility. Electric motor,

advantages over horizontal pumps. diesel engine, steam turbine, right angle gear drives.

1 Space savings – a vertical pump uses 75% less floor space 11 Adaptable to wide range of water supplies and different

than a horizontal pump with electric motor drive. water levels. Column length can be varied to fit application

and tailored to fit any water level situation (floods, tides), off

2 Steeper head capacity curve - less reduction in capacity with

shore platforms, rivers, wells, reservoirs, ponds.

fluctuations in head.

12 Available sizes serve a wide range of capacity and

3 Non-overloading at flow rates to the right of the best

pressure requirements. Can vary the number of stages and

efficiency point (bep) - in many cases drives with small

the size of bowl assembly and impeller trim for maximum

horsepower can be used.

system flexibility.

4 Driver is up off the floor, therefore there is less danger of

13 Minimum wear - inherent design eliminates any radial thrust

damage due to flooding.

on shaft and prevents uneven bearing wear.

5 Self-priming. Impellers remain submerged in water at all

14 Vertical turbine pumps must be used where a suction lift is

times. Pump can be fully automatic - start up at full capacity.

present. Refer to nfpa-20 para. 3-K application The horizon-

6 May be installed in wells, which eliminates the need for a tal centrifugal pump in horizontal or vertical position shall

surface reservoir or tank. This also eliminates the need for not be used where a static suction lift is involved.

an additional well supply pump.

15 Versatility - can be installed with a suction barrel to take

7 One packing box instead of two - lower maintenance. water from adjacent water source (i.e., swimming pools,

storage tanks, water mains, etc.).

8 Entirely self-aligning between the driver and pump.

Cannot get out of alignment due to rabbet fit between

pump and driver.

9 Anti-friction bearings are protected from water spray as

they are located in motor above the pump. Easily accessible

- lower maintenance.

toronto

+1 416 755 2291

buffalo

+1 716 693 8813

birmingham

+44 (0) 8444 145 145

manchester

+44 (0) 8444 145 145

bangalore

+91 (0) 80 4906 3555

a r m s t r o n g f lu i d t e c h n o lo g y

shanghai established 1934 a r m s t r o n g f lu i d t e c h n o lo g y. c o m

+86 21 3756 6696

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Materials For Saline Water, Desalination and Oilfield Brine PumpsDocument0 paginiMaterials For Saline Water, Desalination and Oilfield Brine PumpsWaleed El-azabÎncă nu există evaluări

- Material Equivalent TableDocument8 paginiMaterial Equivalent Tableprashantpan1776% (21)

- Advantages of VT PumpDocument1 paginăAdvantages of VT Pumpravindra_27437153Încă nu există evaluări

- ButterflyDocument5 paginiButterflyPrakash VijiÎncă nu există evaluări

- Material Equivalent TableDocument8 paginiMaterial Equivalent Tableprashantpan1776% (21)

- Prtoblem J BDocument24 paginiPrtoblem J BjhpandiÎncă nu există evaluări

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocument57 paginiAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaÎncă nu există evaluări

- Material Equivalent TableDocument8 paginiMaterial Equivalent Tableprashantpan1776% (21)

- Materials Selection For Seawater PumpsDocument8 paginiMaterials Selection For Seawater PumpsIjabiÎncă nu există evaluări

- Is 1570Document139 paginiIs 1570jajodia239Încă nu există evaluări

- 2010 Improved Centrifugal Pump PerformanceDocument4 pagini2010 Improved Centrifugal Pump Performanceravindra_27437153Încă nu există evaluări

- 04 GD&T IntroTutorialDocument73 pagini04 GD&T IntroTutorialrust_02Încă nu există evaluări

- SP 46Document118 paginiSP 46Nilabh RoyÎncă nu există evaluări

- Engineering Drawing ManualDocument128 paginiEngineering Drawing Manualadnan100% (6)

- Balance Quality GradesDocument1 paginăBalance Quality GradesVijay SainiÎncă nu există evaluări

- BIS Standard Softcopy ViewerDocument10 paginiBIS Standard Softcopy ViewersandeepatellÎncă nu există evaluări

- CFturbo enDocument587 paginiCFturbo enravindra_27437153Încă nu există evaluări

- Is-2048 - Specification For Parallel Keys and KeywaysDocument7 paginiIs-2048 - Specification For Parallel Keys and Keywayssrtools1980y100% (1)

- Material & SpecificatiosDocument6 paginiMaterial & Specificatiosravindra_27437153Încă nu există evaluări

- Difference Between Duplex and Super Duplex MaterialDocument3 paginiDifference Between Duplex and Super Duplex Materialravindra_27437153Încă nu există evaluări

- Engineering DataDocument12 paginiEngineering Dataravindra_27437153Încă nu există evaluări

- Container Sizes StandardDocument1 paginăContainer Sizes Standardravindra_27437153Încă nu există evaluări

- Is 1570Document139 paginiIs 1570jajodia239Încă nu există evaluări

- International Container Design Regulations and ISO StandardsDocument24 paginiInternational Container Design Regulations and ISO Standardsravindra_27437153Încă nu există evaluări

- Is 1570Document139 paginiIs 1570jajodia239Încă nu există evaluări

- O-Ringe en Aeu PDFDocument35 paginiO-Ringe en Aeu PDFdinustanÎncă nu există evaluări

- Material Use For Pumps-QuestionsDocument4 paginiMaterial Use For Pumps-Questionsravindra_27437153Încă nu există evaluări

- Is 1570Document139 paginiIs 1570jajodia239Încă nu există evaluări

- GRUNDFOS - Mechanical Shaft SealsDocument106 paginiGRUNDFOS - Mechanical Shaft Sealsrdavid@hotmail.it100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Nota Kuliah 2Document13 paginiNota Kuliah 2Amin IqmalÎncă nu există evaluări

- 570st - Tractor Loader Backhoe (08/16 - ) 84 - Booms, Dippers & Buckets 84.114.af (04) - Swing Cylinders Sub AssyDocument3 pagini570st - Tractor Loader Backhoe (08/16 - ) 84 - Booms, Dippers & Buckets 84.114.af (04) - Swing Cylinders Sub AssyСтаниславÎncă nu există evaluări

- Wiring Diagram of Universal MotorDocument10 paginiWiring Diagram of Universal MotorYunus SiregarÎncă nu există evaluări

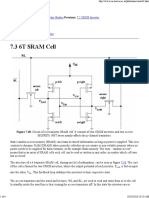

- 7.3 6T SRAM Cell: 7.4 Ring Oscillator 7. Case Studies 7.2 CMOS InverterDocument4 pagini7.3 6T SRAM Cell: 7.4 Ring Oscillator 7. Case Studies 7.2 CMOS InverterGowtham SpÎncă nu există evaluări

- Presentation 2Document20 paginiPresentation 2preferredcustomerÎncă nu există evaluări

- TDBE4-U200/300: Plug-In Railway Relay With 4 C/O ContactsDocument13 paginiTDBE4-U200/300: Plug-In Railway Relay With 4 C/O ContactsMohammadÎncă nu există evaluări

- Bobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFDocument29 paginiBobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFjnfksmemms0% (1)

- Hardlock Set Screw: AdvantagesDocument4 paginiHardlock Set Screw: AdvantagesJayden BarnesÎncă nu există evaluări

- High Horsepower Subsea 14Document30 paginiHigh Horsepower Subsea 14FlorincrihanÎncă nu există evaluări

- CSP FAN and WALL CAP Page13Document24 paginiCSP FAN and WALL CAP Page13MINYAN GUIÎncă nu există evaluări

- Mech 203 Auto Differential Transmission ProjectDocument29 paginiMech 203 Auto Differential Transmission ProjectYugi SupriatnaÎncă nu există evaluări

- Manual 4MDocument118 paginiManual 4MJoão Manoel Bruna GarciaÎncă nu există evaluări

- Expression of Interest (E.O.I.) Fire Fighting System BOQ (NSRDocument3 paginiExpression of Interest (E.O.I.) Fire Fighting System BOQ (NSRKarthick MahadevanÎncă nu există evaluări

- Suspension Section ForcesDocument21 paginiSuspension Section ForcesIndranil BhattacharyyaÎncă nu există evaluări

- Lathe Default MMDocument5 paginiLathe Default MMMaqsood WarÎncă nu există evaluări

- Tilt Float SwitchDocument1 paginăTilt Float Switchdcf67myÎncă nu există evaluări

- Airworthiness Directive Schedule: Helicopters Bell 47 Series & Kawasaki Bell 47 Series 25 June 2009Document12 paginiAirworthiness Directive Schedule: Helicopters Bell 47 Series & Kawasaki Bell 47 Series 25 June 2009Cristian PugaÎncă nu există evaluări

- Multiplex Communication System (CAN) Connector DiagramDocument4 paginiMultiplex Communication System (CAN) Connector DiagramHenryHutabaratÎncă nu există evaluări

- WSHP 120 KBTH - LH - 220V3ph - STD - Tstat - Technical Data SheetDocument2 paginiWSHP 120 KBTH - LH - 220V3ph - STD - Tstat - Technical Data SheetAilefo DelimaÎncă nu există evaluări

- DAS Price List 2011 04Document14 paginiDAS Price List 2011 04Mavi ErtunaÎncă nu există evaluări

- Science: Quarter 3 - Module 6: Factors Affecting The Strength of An ElectromagnetDocument12 paginiScience: Quarter 3 - Module 6: Factors Affecting The Strength of An ElectromagnetChester Allan EduriaÎncă nu există evaluări

- ZF TERRAPOWER TPT 20 transmission overviewDocument2 paginiZF TERRAPOWER TPT 20 transmission overviewMiguelÎncă nu există evaluări

- Onkyo TX-NR646Document132 paginiOnkyo TX-NR646gcataÎncă nu există evaluări

- ATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersDocument4 paginiATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersedgarcooÎncă nu există evaluări

- Radiator Connection MethodsDocument1 paginăRadiator Connection Methodsgox458Încă nu există evaluări

- Catalog Specifications Caterpillar 7495 Electric Rope Shovel Rope CrowdDocument3 paginiCatalog Specifications Caterpillar 7495 Electric Rope Shovel Rope Crowdahmed zhranÎncă nu există evaluări

- Everything You Need to Know About DC DrivesDocument10 paginiEverything You Need to Know About DC DrivesSuyog ShingareÎncă nu există evaluări

- Komatsu Wheel Loader Wa380 6 Operation and Maintenance ManualDocument20 paginiKomatsu Wheel Loader Wa380 6 Operation and Maintenance Manualreva100% (41)

- 1.01.20 Stay Current WOPDocument12 pagini1.01.20 Stay Current WOPAndreyIvanovÎncă nu există evaluări

- Brochure Greenstar Galaxy-SolarisDocument16 paginiBrochure Greenstar Galaxy-Solarissam2010rÎncă nu există evaluări