Documente Academic

Documente Profesional

Documente Cultură

Copas Terminales

Încărcat de

Jaime Contreras0 evaluări0% au considerat acest document util (0 voturi)

80 vizualizări12 paginiInstalaciones de Copas terminales

Titlu original

Copas terminales

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentInstalaciones de Copas terminales

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

80 vizualizări12 paginiCopas Terminales

Încărcat de

Jaime ContrerasInstalaciones de Copas terminales

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 12

Raychem Product installation Instructions

MOD-3-HVT

MOD 3X, 3Y, 3A, 3B

High Voltage Termination

Modification Kit for 3/C Shielded

and Non-Shielded Power Cable

Raychem Corporation PIL-53163, Rev AE

Electrical Products Division DCR 027625

220 Lake Diive PCN 369999.

Nowark, OE 19702 Effective Date: November 20, 1995,

‘Suggested Installation Equipment (not supplied with Kity

+ Cable preparation tools

+ Raychem P63 cable preparation kt or

cable manufacturer approved solvent

+ Clean, lint-free clothe

+ Non-conducting abrasive cloth, 120,

tit or finer

+ Electrician's tape

General Instructions

+ Connector(s) and installation tools

+ Raychem recommended torch

Recommended Raychem Torches

Install heat-shrinkable cable accessories

with a “clean burning’ torch, ie. a

propane torch that does not deposit

‘conductive contaminants on the product

‘Glean burning torches include the

Raychem FH-2629 (uses refilable

propane cylinders) and FH-2616A1

(uses disposable cylinder

Safety Instructions

Warning: When installing electrical

power system accessories, faiure to

‘olow applicable personal safety

‘requirements and written installation

instructions could result in fie or

‘explosion and serious or fatal injuries.

‘To avoid risk of accidental fire or

explosion when using gas torches,

always check all connections for leeks

bore igniting the torch and follow the

torch manufacturers safety insiructions.

“To minimize any effect of fures

produced during installation, always

provide good ventilation of confined

‘work spaces.

‘As Raychem has no control over field

‘condifons which influence product

installation, itis understood that the

‘user must take this into account and

‘apply his own experionce and

‘expertise when installing product.

‘Adjusting the Torch

Adjust regulator and torch as required to

provide an overall 12-inch bushy flame.

‘The FH-2629 willbe al blue, the other

torches will have a 3- to 4inch yellow

tip. Use the yellow tip for shrinking.

Regulator Pressure

FH2616Ai Full pressure

FH-2629, 15 psig

Cleaning the Gabie

Use an approved solvent, such as the

‘one suppiiod in the P63 Gablo Prep Kit,

toclean the cable. Be sure to follow th

‘manufacturer's instructions. Failure to

follow these instructions could lead to

product failure.

‘Some newer solvents do not evaporate

Quickly and need to be removed with a

clean, lint-free cloth. Failure to do s0.

‘could change the volume resistivity of

the substrate or leave a residue on the

surface.

Please follow the manufacturer's

instructions carefully

General Shrinking Instructions

+ Apply outer 3-to 4inch tp of the

{lam to hoat-shrinkable material with a

rapid brushing motion,

+= Keep flame moving to avoid

scorching

* Unless otherwise instructed, start

shrinking tube at center, working flame

‘around al sides of the ube to apply

‘unform heat

Installation Instructions

To determine if a tube has completely

recovered, look for the following,

‘especially on the back and underside of

the tube:

1. Uniform wall thickness,

2 Conformance to substrate,

3. No fiat spots or chill marks.

4. Visible sealant flow if the tube is

coated.

‘Note: When installing multiple tubes,

‘make sure thatthe surface of the last

{ube is still warm bofore positioning and

shrinking the next tube. if Installed tube

has cooled, re-heat the entire surface.

1. Product selection.

‘Check kit selection with cable

diameter dimensions in Table 1.

Note: Table is for 100% insulated

‘cable. For 133% insulated cable,

‘check actual cable dimensions.

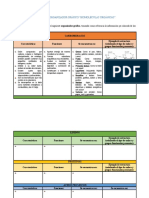

Table 1

Minimum/Maximum Minimum/Maximum

Kit Insulation Diameter Jacket Diameter

MOD-3X-HVT (indoor) 0.50-1.35" (13.34mm)

MOD-3Y-HVT (Indoor) 1,00-2.70" (25-69mm)

MOD-30-HVT (Outdoor) 0.50-1.25" (13.32mm) 1.28-3.85" (32-98mm)

MOD-3B-HVT (Outdoor) 1.00-2.10" (25-53mm) 2.65-5.80" (67-135mm)

PIkSS169, Rev AE

DCR C2762

2

PON 869699-000

Effective Date: November 20, 1895

& Determine jacket cutback; mark cable.

Installation Instructions

Cutback must be long enough to allow positioning of insulated conductors =

without violating the bend radius (usually 10 times the diameter of the 7 |

cable) and fit within the min/max dimensions shown in Table 2. 1

“Note: If a sealing boot is to be used, at least 4" (102mm) of jacket must be u Measure

visible extending from the conduit opening. H i Jacket

Table 2 My 1} Cutback

Voltage Class Minimum Maximum SY

6a 8Kv 19" (483mm) 50° (1270mm) fe

1SKV 23" (584mm) 84° (1372mm) } “Note?

25KV 34" (664mm) 67" (1702mm) +

38kV 41" (104imm) 74° (1880mm)

“if greater length is required, order bulk tubing. se

3. Remove outer jacket. g

Remove the outer jacket (and/or armor) and any filler or bedding tapes 8

around all three phases to the mark made in Step 2.

Note: Do not cut into the shielding layer or phase insulation, |— Phase Shield

‘Ground Wire(s)

Cable Jacket

50

4. Position rejacketing tubes.

Husing UniShield cable, discard rejacketing tubes and go to Step 7.

Place one rejacketing tube (larger diameter) over each phase. Bottom of

‘tube should be within 1° (25mm) of the jacket cutback.

5. Shrink rejacketing tubes in place.

‘Shrink in place beginning at the cable jacket end. Work the torch around

teach tube and to the end of the phase with a smooth brushing motion to

censure even shrinkage.

Rejacketing

Tubes

Cable Jacket

faa \. 299

Eir83165, Rov AE 3 PON 360899060

oR c27é25 Bfocive Date: November 20, 1985

S-ar putea să vă placă și

- Preguntas de 100 Mexicanos Dijeron PDFDocument1 paginăPreguntas de 100 Mexicanos Dijeron PDFNohemi Vera San Roman100% (2)

- 50PLANTAS ATRAEN POSTIVdocxDocument7 pagini50PLANTAS ATRAEN POSTIVdocxArmando Gonzalez JÎncă nu există evaluări

- Resumen Curso de TermografiaDocument53 paginiResumen Curso de TermografiaJaime Contreras100% (3)

- Recetario 2 El Libro de Los Grandes Secretos - Montañez Ed. 1968Document64 paginiRecetario 2 El Libro de Los Grandes Secretos - Montañez Ed. 1968Irving CastañedaÎncă nu există evaluări

- La Tía Julia y El EscribidorDocument1 paginăLa Tía Julia y El Escribidorelias maca tuanamaÎncă nu există evaluări

- Problemas Propuesto de Máquinas AsincronasDocument7 paginiProblemas Propuesto de Máquinas AsincronasJaime ContrerasÎncă nu există evaluări

- Manual de Reproductor LGDocument14 paginiManual de Reproductor LGJaime ContrerasÎncă nu există evaluări

- Probl - Res - Maq. Sincronas PDFDocument147 paginiProbl - Res - Maq. Sincronas PDFYulissa MNÎncă nu există evaluări

- Cómo Se Produce El Cobre - Codelco PDFDocument152 paginiCómo Se Produce El Cobre - Codelco PDFJaime ContrerasÎncă nu există evaluări

- E3.1 Probl. Prop. de Maq. SincronasDocument9 paginiE3.1 Probl. Prop. de Maq. SincronasJaime ContrerasÎncă nu există evaluări

- E1.1 Probl. Prop TransformadoresDocument12 paginiE1.1 Probl. Prop TransformadoresJaime ContrerasÎncă nu există evaluări

- Máquinas Eléctricas I - Examen FinalDocument5 paginiMáquinas Eléctricas I - Examen FinalgabaooÎncă nu există evaluări

- Problemas Propuesto de Máquinas AsincronasDocument7 paginiProblemas Propuesto de Máquinas AsincronasJaime ContrerasÎncă nu există evaluări

- Manual de Usuario - Operación Planta de EmergenciaDocument27 paginiManual de Usuario - Operación Planta de EmergenciaMariaRocioZamoraÎncă nu există evaluări

- Problemas de máquinas de corriente continuaDocument10 paginiProblemas de máquinas de corriente continuaJaime ContrerasÎncă nu există evaluări

- Probl - Res Trafos WEBDocument159 paginiProbl - Res Trafos WEBjehseed chiaraÎncă nu există evaluări

- Problemas de máquinas de corriente continuaDocument10 paginiProblemas de máquinas de corriente continuaJaime ContrerasÎncă nu există evaluări

- CT 0 Publi2003-IndiceDocument45 paginiCT 0 Publi2003-IndicefuckyouÎncă nu există evaluări

- C-Etgs-Eem-171 R0Document30 paginiC-Etgs-Eem-171 R0Jaime ContrerasÎncă nu există evaluări

- Especificaciones técnicas de tableros y gabinetes de controlDocument11 paginiEspecificaciones técnicas de tableros y gabinetes de controlJaime ContrerasÎncă nu există evaluări

- C-Etgs-Pas-001 R1Document18 paginiC-Etgs-Pas-001 R1Jaime ContrerasÎncă nu există evaluări

- 104-200-Cm-Gen-Ca-0021 R2Document20 pagini104-200-Cm-Gen-Ca-0021 R2Jaime ContrerasÎncă nu există evaluări

- Diseño y Calculo de Transformador MonofasicoDocument165 paginiDiseño y Calculo de Transformador Monofasicoposetasucia100% (1)

- CamposDocument85 paginiCamposTeodoro GonzalesÎncă nu există evaluări

- C-Etgs-Eem-171 R0Document30 paginiC-Etgs-Eem-171 R0Jaime ContrerasÎncă nu există evaluări

- 104-200-Cm-Gen-Ma-0001 R3Document263 pagini104-200-Cm-Gen-Ma-0001 R3Jaime Contreras0% (1)

- 104-200-Cm-Gen-Ca-0001 R1Document7 pagini104-200-Cm-Gen-Ca-0001 R1Jaime ContrerasÎncă nu există evaluări

- DJ 2016 Editable 0Document2 paginiDJ 2016 Editable 0materialfabyÎncă nu există evaluări

- SYLABUSDocument8 paginiSYLABUSRodrigo Borja VegaÎncă nu există evaluări

- 104-200-Cm-Gen-Ca-0001 R3Document7 pagini104-200-Cm-Gen-Ca-0001 R3Jaime ContrerasÎncă nu există evaluări

- P&ID DescripcionDocument8 paginiP&ID Descripcioncarlosca8Încă nu există evaluări

- 104-200-Cm-Gen-Ca-0024 R1Document2 pagini104-200-Cm-Gen-Ca-0024 R1Jaime ContrerasÎncă nu există evaluări

- 104-265-Cm-Spt-Ca-0001 R1Document116 pagini104-265-Cm-Spt-Ca-0001 R1Jaime ContrerasÎncă nu există evaluări

- Otazu Garcia Duverly OmarDocument117 paginiOtazu Garcia Duverly OmarcinthiaÎncă nu există evaluări

- Actividad 3 Gabriel Salinas SoteloDocument8 paginiActividad 3 Gabriel Salinas SoteloGABRIEL SALINAS SOTELOÎncă nu există evaluări

- Hotel Riu Naiboa Punta Cana Todo IncluidoDocument4 paginiHotel Riu Naiboa Punta Cana Todo IncluidoGema BardalesÎncă nu există evaluări

- Caracteristicas Fisicas y Organolepticas de La Carne PDFDocument11 paginiCaracteristicas Fisicas y Organolepticas de La Carne PDFLalo GAÎncă nu există evaluări

- 4° Inglés. Daily RoutinesDocument4 pagini4° Inglés. Daily RoutinesAlejandra PerezÎncă nu există evaluări

- Mitos Nutricion DeportivaDocument1 paginăMitos Nutricion Deportivamanuel.freire2Încă nu există evaluări

- Actividad de Puntos Evaluables - Escenario 2 - PRIMER BLOQUE-CIENCIAS BASICAS - VIRTUAL - PROBABILIDAD - (GRUPO B06)Document6 paginiActividad de Puntos Evaluables - Escenario 2 - PRIMER BLOQUE-CIENCIAS BASICAS - VIRTUAL - PROBABILIDAD - (GRUPO B06)Carolina LeyvaÎncă nu există evaluări

- Protocolo para La Produccion de Grano de Cacao de Calidad648Document44 paginiProtocolo para La Produccion de Grano de Cacao de Calidad648papsa.petenÎncă nu există evaluări

- Diagrama en BlancoDocument1 paginăDiagrama en BlancoBrayan TecÎncă nu există evaluări

- Enologia Practica y Cata de Vinos UD 1Document21 paginiEnologia Practica y Cata de Vinos UD 1juan sanzÎncă nu există evaluări

- Practica#7 (3a, Mat, Equipo4)Document5 paginiPractica#7 (3a, Mat, Equipo4)Jahdi Almeida0% (1)

- Actividad 2 Organizador Gráfico - Biomoléculas Orgánicas - TSQ IiDocument4 paginiActividad 2 Organizador Gráfico - Biomoléculas Orgánicas - TSQ IiEidan ArredondoÎncă nu există evaluări

- Nutrein - 11.17.22 11 - 27 PMDocument2 paginiNutrein - 11.17.22 11 - 27 PMMonica LuqueÎncă nu există evaluări

- Sem5 RED Seminario Concordancia Nominal 2021.3Document4 paginiSem5 RED Seminario Concordancia Nominal 2021.3reicyÎncă nu există evaluări

- Práctica N°7 Nutrición Heterótrofa: Sistema Digestivo Humano I. IntroducciónDocument14 paginiPráctica N°7 Nutrición Heterótrofa: Sistema Digestivo Humano I. IntroducciónJUAN DAVID ARCELA ORDINOLAÎncă nu există evaluări

- Alcampo Folleto - Trafico 2 HG Nacional Del 20 de Enero Al 2 de Febrero de 2022Document24 paginiAlcampo Folleto - Trafico 2 HG Nacional Del 20 de Enero Al 2 de Febrero de 2022Emilio ViÎncă nu există evaluări

- Nutrientes en los alimentos ancestralesDocument6 paginiNutrientes en los alimentos ancestralesverónicaÎncă nu există evaluări

- UntitledDocument31 paginiUntitledNicky ReyÎncă nu există evaluări

- 1Document5 pagini1sicajapabloÎncă nu există evaluări

- Cerveceria 5 de MayoDocument7 paginiCerveceria 5 de Mayoapi-242186267100% (1)

- Cremas y RellenosDocument16 paginiCremas y RellenosMelany Gonsalez ReaÎncă nu există evaluări

- El Inquieto Anacobero-Héctor MujicaDocument130 paginiEl Inquieto Anacobero-Héctor MujicaMario Alfonso Navarrete NavarreteÎncă nu există evaluări

- 2do Grado - Examen Mensual Octubre (2021-2022)Document13 pagini2do Grado - Examen Mensual Octubre (2021-2022)Aarhacely O'ConnorsÎncă nu există evaluări

- Excrecion Seres VivosDocument7 paginiExcrecion Seres VivosOscar Yamid JovenÎncă nu există evaluări

- EL ADJETIVO Y SUS FUNCIONES-Lengua CastellanaDocument8 paginiEL ADJETIVO Y SUS FUNCIONES-Lengua CastellanaSantiago Alejandro Martinez ParraÎncă nu există evaluări

- Qué Son Los Compuestos OrgánicosDocument8 paginiQué Son Los Compuestos Orgánicosgabriel chamorroÎncă nu există evaluări