Documente Academic

Documente Profesional

Documente Cultură

Engineering and Development Corporation of The Philippines

Încărcat de

mark ignacioTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engineering and Development Corporation of The Philippines

Încărcat de

mark ignacioDrepturi de autor:

Formate disponibile

PROJECT : DED Study of TRMP

Engineering and Development DESCRIPTION : DECKSLAB DESIGN

Corporation of the Philippines DATE : JULY 2018

DESIGNED BY : MJRI CHECKED BY JVP

DESIGN OF REINFORCED CONCRETE DECK GIRDER

LOAD ANALYSIS: intermediate Slab

Geometry:

Effective Span Length, L = 19.0 m

Deck Slab Thickness, t = 220 mm

Tributary Length / Girder, S = 1.80 m

Overhang Length = 1.25 m

Future Wearing Surface = 50 mm = 1.05 Kpa

DEAD LOADS: DGCS Vol. 5, Section 10.6

Concrete Density = 24.0 KN/m3

2

COMPONENT AREA, m PRESSURE, KPa LOAD, kN / m

Desk Slab (DC) 0.396 5.280

FWS (DW) 1.05 1.050

TOTAL, 1.25DC + 1.5DW 8.175

TOTAL DEAD LOAD MOMENT:

MU_DL = WD S 2 / 8

= 3.311 KN*m/m width of slab

LIVE LOADS: DGCS Vol. 5, Section 10.7

DYNAMIC LOAD: DGCS Vol 5, Section 10.8

Main Reinforcement Perpendicular to Traffic (DGCS Vol 5, Section 11.3.2.1.2)

HL-93 TRUCK LOADING

PHL-93 = 72.5 KN, one wheel load acting at a time

MHL-93 = PHL-93 /(660 + 0.55S) (+) MOMENT

= 43.94 KN*m/m width of slab

= PHL-93 /(1220 + 0.25S) (-) MOMENT

= 43.41 KN*m/m width of slab

Moment for Live Loads:

MU_LL = LLF (MHL-93+ Dynamic Load)

LLF = 1.75

MU_HL-93 = 102.27 KN*m/m width of slab (+) MOMENT

= 101.04 KN*m/m width of slab (-) MOMENT

DESIGNING MOMENT:

MU_DESIGN = MU_DL + MU_LL

MU_DESIGN = 105.580 kN*m/m (+) MOMENT

= 104.355 kN*m/m (-) MOMENT

DESIGN OF DECKSLAB:

Parameters

øper = 50 mm Concrete cover

d = 162 mm Effective Depth

b = 1000 mm Width of strip analysis

1 = 0.850 Factor of Comp. stress block

Reinforcement of Deckslab

øper = 16 mm Bar Diameter Perpendicular to Traffic,

Sper = 100 mm Bar Spacing Perpendicular to Traffic,

øper = 16 mm Bar Diameter Parallel to Traffic,

Sper = 200 mm Bar Spacing Parallel to Traffic,

f'C = 28 MPa Concrete Strength

Fy = 414 MPa Yield Strength of Reinforcement

f = 0.9 Reduction Factor

Checking for Maximum Flexural Reinforcement

max = 0.75 b

0.85 1 f'c 600

b =

Fy 600 + Fy

= 0.0289

max = 0.0217 Max. Ratio of Reinforcement

2

As_prov'd = 2010.619 mm Area of steel per meter length

= 0.01241 Provided Ratio of Reinforcement

PASS - not exceed in maximum ratio

Checking for Flexural Capacity

MU_DESIGN = 105.580 kN*m/m Designing Moment

a = d - sqrt(d2 - 2Mu / f 0.85f'c b) Depth of NA from extreme compression face

= 33.99 mm

øf Mn = øf As_prov'd*Fy (d - a / 2) Moment Capacity of Section

= 108.631 kN*m/m PASS - section is safe for bending

Checking for Minimum Reinforcement / Cracking Moment (AASHTO LRFD 2012 Section 5.7.3.3.2)

For minimum reinforcement, the provided reinforcement shall be adequate to develop a moment atleast 1.2 times the

cracking moment calculated.

Mcr = 3 1fr Ig / yt CRACKING MOMENT

where: 1 = 1.6 Flexural cracking variability factor

1 = 0.67 Ratio of specified min. yield strength to ult. tensile strength of reinf.

fr = 0.67 f'c Modulus of Rupture

Ig = 1000 t3 /12 Effective Moment of Inertia

ys = t/2 Distance from centroidal axis

Mcr = 32.031 kN*m/m

Since øf Mn > (1.2Mcr) PASS - Provided Reinforcement is Adequate

Distribution of Reinforcement (DGCS Vol 5, Section 14.4.3.1)

For main reinforcement perpendicular to traffic

Percentage = 3840 / S ; maximum of 67%

= 67.00%

As = Area of Reinforcement Perpendicular to Traffic

A_req'd = As * Percentage

= 1347.11 mm2

A_prov'd = 2010.619 mm2 PASS - Area of reinforcement provided is greater than required

Cantilever / Exterior Slab

Overhang Length,L = 1.05 m

Slab Thickness, t = 220 mm

Dead Loads, DL:

3

Concrete Density = 24.0 KN/m

PRESSURE, Moment Moment,

COMPONENT AREA, m2 LOAD, kN / m

KPa Arm, m kN*m

Desk Slab (DC) 0.231 5.544 0.525 2.911

FWS (DW) 1.05 1.050 0.525 0.551

Side Walk (DC) 0.210 5.040 0.525 2.646

Rail Post (DC) 0.036 0.871 0.825 0.719

Railings (DC) 0.080 1.920 0.825 1.584

TOTAL, 1.25DC + 1.5DW 18.294 10.651

Impact Load, IL:

P_IL = 44.5 kN

Moment Arm, Moment,

COMPONENT LOAD, kN / m

m kN*m

P1 22.250 1.222 27.190

P2 22.250 1.022 22.740

TOTAL 48.149

Reinforcement of Cantilever Slab

øper = 16 mm Bar Diameter Perpendicular to Traffic,

Sper = 100 mm Bar Spacing Perpendicular to Traffic,

øper = 16 mm Bar Diameter Parallel to Traffic,

Sper = 200 mm Bar Spacing Parallel to Traffic,

f'C = 28 MPa Concrete Strength

Fy = 414 MPa Yield Strength of Reinforcement

f = 0.9 Reduction Factor

Designing Moment

Mu = MDL + MIL

= 58.800 kN*m Ultimate Moment

Checking for Maximum Flexural Reinforcement

max = 0.75 b

0.85 1 f'c 600

b =

Fy 600 + Fy

= 0.0289

max = 0.0217 Max. Ratio of Reinforcement

2

As_prov'd = 2010.619 mm Area of steel per meter length

= 0.02011 Actual Ratio of Reinforcement

PASS - not exceed in maximum ratio

Checking for Flexural Capacity

MU_DESIGN = 58.800 kN*m/m Designing Moment

2

a = d - sqrt(d - 2Mu / f 0.85f'c b) Depth of NA from extreme compression face

= 17.94 mm

øf Mn = øf As_prov'd*Fy (d - a / 2) Moment Capacity of Section

= 114.644 kN*m/m

PASS - section is safe for bending

Checking for Minimum Flexural Reinforcement

For minimum reinforcement, the provided reinforcement shall be adequate to develop a moment atleast 1.2 times the

cracking moment calculated.

Mcr = 3 1fr Ig / yt CRACKING MOMENT

where: 1 = 1.6 Flexural cracking variability factor

1 = 0.67 Ratio of specified min. yield strength to ult. tensile strength of reinf.

fr = 0.63 f'c Modulus of Rupture

3

Ig = 1000 t /12 Effective Moment of Inertia

ys = t/2 Distance from centroidal axis

Mcr = 28.828 kN*m/m

Since øf Mn > 1.2Mcr PASS - Provided Reinforcement is Adequate

SERVICEABILTY REQUIREMENT:

Support/Seat Length: BSDS Section 7.2

SE_prov'd = 900 mm Provided Seat Length

SE = uR + uG SEM

where: uR = 0 m Max. relative displacement bet. Superstructure and the edge of the top of the

substructure due to Level 2 Earth Ground Motion

l = 19.0 m Span length

L = 127.0 m Bridge deck length

uG = GL m Relative displacement of the ground caused by seismic ground strain

G = 0.005 m Sesmic ground strain (0.0025, 0.00375 and 0.005)

= 0.635 m

SEM = 0.7 + 0.005l Minimum seating length of a girder at the support

= 0.795 m

SE = 795.0 mm Required seat length

PASS - Provided Seat Lenght is Adequate

*For Two or more Span

Gap Between Two Adjacent Girders

SB = us + LA Between a superstructure and an abutment

= cB us + LA Between two adjacent girders

where: us = 25.52 mm Maximum Relative Displacement (from STAAD)

LA = 15 mm Gap allowance for adjacent girders (normally 15mm)

cB = 1.00 Gap modification factor

SB = 40.52 mm

Use 50.0 mm

S-ar putea să vă placă și

- Appendix GB - 16.6m C/C SPAN & 7.32m CLEAR BRIDGE WIDTH R.C.D.Girder Superstructure Design by LRFD MethodDocument28 paginiAppendix GB - 16.6m C/C SPAN & 7.32m CLEAR BRIDGE WIDTH R.C.D.Girder Superstructure Design by LRFD MethodSudip ShresthaÎncă nu există evaluări

- 1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignDocument10 pagini1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignAddisu Gizaw Addis Ye AbereyeÎncă nu există evaluări

- Cantilever Beam Design - RHSDocument1 paginăCantilever Beam Design - RHSberylqz5878100% (1)

- SF10 and SF16Document22 paginiSF10 and SF16Shanil BussooaÎncă nu există evaluări

- Dimns. & Reinf. of Pier CapDocument1 paginăDimns. & Reinf. of Pier Capsantosh yevvariÎncă nu există evaluări

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDocument8 paginiGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalÎncă nu există evaluări

- For Review and Approval: SECTION-1-1Document1 paginăFor Review and Approval: SECTION-1-1Mandar GÎncă nu există evaluări

- VivaDocument76 paginiVivaRam NepaliÎncă nu există evaluări

- OneSteel Reinforcing Area CalculatorDocument12 paginiOneSteel Reinforcing Area CalculatormingmingminglesÎncă nu există evaluări

- Karur To Dindigul Vol - Iiic of III (A B C D)Document200 paginiKarur To Dindigul Vol - Iiic of III (A B C D)ArushiBiswasÎncă nu există evaluări

- 2911 3Document44 pagini2911 3rambinodÎncă nu există evaluări

- 2-Col Bent On Bored PilesDocument29 pagini2-Col Bent On Bored PilesHenry DiyokeÎncă nu există evaluări

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 paginăPile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiÎncă nu există evaluări

- 2 Grillage Analysis of Bridge DecksDocument11 pagini2 Grillage Analysis of Bridge Decksahmad fakhruddinÎncă nu există evaluări

- CHAPTER XI-Design of Septic Water TankDocument9 paginiCHAPTER XI-Design of Septic Water TankMahmudul Hasan100% (4)

- A Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansDocument6 paginiA Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansHabeeb ShaikÎncă nu există evaluări

- Isolated FootingDocument59 paginiIsolated Footingsrinivasa raoÎncă nu există evaluări

- 2 MDocument6 pagini2 MUmesgÎncă nu există evaluări

- Geometric Design of Highways: Tewodros NDocument36 paginiGeometric Design of Highways: Tewodros NPs Potchi ReddyÎncă nu există evaluări

- Ce 342 Tutorial 2Document5 paginiCe 342 Tutorial 2Deus IrechoÎncă nu există evaluări

- BleachersDocument5 paginiBleachersMardeOpamenÎncă nu există evaluări

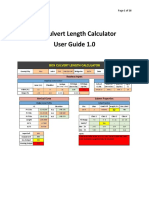

- Box Culvert Length Calculator User Guide 1.0Document16 paginiBox Culvert Length Calculator User Guide 1.0aamir kalimÎncă nu există evaluări

- Road Estimate FormatDocument7 paginiRoad Estimate Formatalok jhaÎncă nu există evaluări

- Basement Wall DesignDocument2 paginiBasement Wall DesignArindam RoyÎncă nu există evaluări

- Steel Structures - I: B.E. (Civil Engineering) Sixth Semester (C.B.S.)Document16 paginiSteel Structures - I: B.E. (Civil Engineering) Sixth Semester (C.B.S.)Pratik GhimireÎncă nu există evaluări

- Wind Load IS Code 875Document2 paginiWind Load IS Code 875Hazhar AtrushiÎncă nu există evaluări

- Case Study Tech AbutmentDocument7 paginiCase Study Tech AbutmentGajendra BishtÎncă nu există evaluări

- Chapter 1-3 PDFDocument27 paginiChapter 1-3 PDFRyle AquinoÎncă nu există evaluări

- 2Document105 pagini2Zankar R ParikhÎncă nu există evaluări

- Precast Dowel ConnectionDocument1 paginăPrecast Dowel ConnectionmathuÎncă nu există evaluări

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 paginiDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelÎncă nu există evaluări

- Calculating Bulk Volumes Using Simpson Rule PDFDocument10 paginiCalculating Bulk Volumes Using Simpson Rule PDFEng Ravi Kant SharmaÎncă nu există evaluări

- Design Data - T-Girder - Jan 11 - 2017 PDFDocument1 paginăDesign Data - T-Girder - Jan 11 - 2017 PDFYirga BezabehÎncă nu există evaluări

- RCP 24 Inch Class 2Document5 paginiRCP 24 Inch Class 2noto.sugiartoÎncă nu există evaluări

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 paginiDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranÎncă nu există evaluări

- Detailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaDocument44 paginiDetailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaVIKASÎncă nu există evaluări

- Economic Design of RCC Box Culvert ThrouDocument7 paginiEconomic Design of RCC Box Culvert ThrouOscarKonzultÎncă nu există evaluări

- Deckslab - Slab On Metal Deck Analysis DesignDocument22 paginiDeckslab - Slab On Metal Deck Analysis DesignSpinals JoÎncă nu există evaluări

- Unbraced WallDocument7 paginiUnbraced WallakanagesÎncă nu există evaluări

- Feasibility ReportDocument68 paginiFeasibility ReportSaudagar BiswalÎncă nu există evaluări

- Sloping Slab - Analysis and Design of Sloping SlabDocument5 paginiSloping Slab - Analysis and Design of Sloping SlabAbuturab SharikmaslatÎncă nu există evaluări

- Advantages and Disadvantages of Prestressed ConcreteDocument1 paginăAdvantages and Disadvantages of Prestressed ConcreteMarlou Salazar SabanganÎncă nu există evaluări

- Detailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box CulvertDocument1 paginăDetailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box Culvertnandu523Încă nu există evaluări

- IRC 5 Amendment Silt Factor May 2021Document1 paginăIRC 5 Amendment Silt Factor May 2021Biswaprakash DasÎncă nu există evaluări

- Cable Profile For Prestressing and Calculation of Eccentricities of Substiture CableDocument4 paginiCable Profile For Prestressing and Calculation of Eccentricities of Substiture Cablerabindra choudhary0% (1)

- All Plug-Ins of Arc BdsDocument48 paginiAll Plug-Ins of Arc BdsAshish LoyaÎncă nu există evaluări

- Parapet CapacityDocument4 paginiParapet CapacityJemicah YumenaÎncă nu există evaluări

- Calculation of Roof WeightDocument6 paginiCalculation of Roof WeightAnonymous pmwNrPum1CÎncă nu există evaluări

- Retaining Wall Analysis & Design (BS8002 - 1994)Document10 paginiRetaining Wall Analysis & Design (BS8002 - 1994)IKÎncă nu există evaluări

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDocument34 paginiAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaÎncă nu există evaluări

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsDocument19 paginiModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- Sepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Document4 paginiSepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Afiq SyahmiÎncă nu există evaluări

- Superimposed Dead Loads and Live Loads Load MagnitudeDocument8 paginiSuperimposed Dead Loads and Live Loads Load MagnitudeLouieÎncă nu există evaluări

- Examples of Improper Beam Plate ConnectivityDocument4 paginiExamples of Improper Beam Plate ConnectivityPiv0terÎncă nu există evaluări

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFDocument56 paginiDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- Design Basis ReportDocument26 paginiDesign Basis Reportnikki naidu100% (1)

- Sign Board CalcsDocument34 paginiSign Board CalcsMimi MoragnÎncă nu există evaluări

- Decathlon Udl CheckDocument3 paginiDecathlon Udl CheckAnonymous Clm40C1Încă nu există evaluări

- Annexure-2 (Section Design Calcs)Document107 paginiAnnexure-2 (Section Design Calcs)blisscutest beagleÎncă nu există evaluări

- Design of Trade Off III Precast ConcreteDocument9 paginiDesign of Trade Off III Precast ConcretemateojullieanneÎncă nu există evaluări

- Engineering and Development Corporation of The PhilippinesDocument1 paginăEngineering and Development Corporation of The Philippinesmark ignacioÎncă nu există evaluări

- Structurepoint - Spcolumn V5.10 (TM) - Licensed To: Yuni Aulia Hasibuan, Yu. License Id: - 2af30Document1 paginăStructurepoint - Spcolumn V5.10 (TM) - Licensed To: Yuni Aulia Hasibuan, Yu. License Id: - 2af30Yuni AuliaÎncă nu există evaluări

- Khosla's Theory For Uplift PressureDocument2 paginiKhosla's Theory For Uplift Pressuremark ignacioÎncă nu există evaluări

- Engineering and Development Corporation of The Philippines: H P H PDocument2 paginiEngineering and Development Corporation of The Philippines: H P H Pmark ignacioÎncă nu există evaluări

- Engineering and Development Corporation of The Philippines: M / M M M KN M KN.MDocument16 paginiEngineering and Development Corporation of The Philippines: M / M M M KN M KN.Mmark ignacioÎncă nu există evaluări

- (2/3H of Backfill) : Resultant Location Within BaseDocument1 pagină(2/3H of Backfill) : Resultant Location Within Basemark ignacioÎncă nu există evaluări

- Drilling and Test PitDocument3 paginiDrilling and Test Pitmark ignacioÎncă nu există evaluări

- Design Base Shear Elastic Design SpectraDocument1 paginăDesign Base Shear Elastic Design Spectramark ignacioÎncă nu există evaluări

- Seismic Analysis For Buried StructureDocument2 paginiSeismic Analysis For Buried Structuremark ignacioÎncă nu există evaluări

- Soil Spring Calcs PDFDocument1 paginăSoil Spring Calcs PDFmark ignacioÎncă nu există evaluări

- With Surcharge LoadDocument2 paginiWith Surcharge Loadmark ignacioÎncă nu există evaluări

- Pipe StressesDocument6 paginiPipe Stressesmark ignacioÎncă nu există evaluări

- Amorato Stadium, Don Alejandro Roces Avenue, Quezon City (100m)Document1 paginăAmorato Stadium, Don Alejandro Roces Avenue, Quezon City (100m)mark ignacioÎncă nu există evaluări

- Backwall DesignDocument1 paginăBackwall Designmark ignacioÎncă nu există evaluări

- 145class 7 Integers CH 1Document2 pagini145class 7 Integers CH 17A04Aditya MayankÎncă nu există evaluări

- All New Keys DictionaryDocument7 paginiAll New Keys DictionaryvishntÎncă nu există evaluări

- 2 - The British Legal SystemDocument4 pagini2 - The British Legal SystemSTAN GABRIELA ELENAÎncă nu există evaluări

- Learn JQuery - Learn JQuery - Event Handlers Cheatsheet - CodecademyDocument2 paginiLearn JQuery - Learn JQuery - Event Handlers Cheatsheet - Codecademyilias ahmedÎncă nu există evaluări

- Ethics - FinalsDocument18 paginiEthics - Finalsannie lalangÎncă nu există evaluări

- Types of Sutures and Their IndicationsDocument6 paginiTypes of Sutures and Their IndicationsAdina BurciuÎncă nu există evaluări

- Mahabharata Reader Volume 1 - 20062023 - Free SampleDocument107 paginiMahabharata Reader Volume 1 - 20062023 - Free SampleDileep GautamÎncă nu există evaluări

- Minimum Structural Properties and Test Procedure For TG20 Compliant Prefabricated Structural Transom UnitsDocument16 paginiMinimum Structural Properties and Test Procedure For TG20 Compliant Prefabricated Structural Transom UnitsPrimelift Safety Resources LimitedÎncă nu există evaluări

- Leseprobe Aus: "Multilingualism in The Movies" Von Lukas BleichenbacherDocument20 paginiLeseprobe Aus: "Multilingualism in The Movies" Von Lukas BleichenbachernarrverlagÎncă nu există evaluări

- Africanas Journal Volume 3 No. 2Document102 paginiAfricanas Journal Volume 3 No. 2Gordon-Conwell Theological Seminary100% (2)

- 2011 Physics B Form B Scoring GuidelinesDocument16 pagini2011 Physics B Form B Scoring GuidelinesMichael CÎncă nu există evaluări

- Asphalt Hot Mix Training ManualDocument91 paginiAsphalt Hot Mix Training Manualyazqa50% (2)

- Knapp TestDocument2 paginiKnapp TestGeorge Litu67% (3)

- Rizal Course ReviewerDocument6 paginiRizal Course ReviewerMarianne AtienzaÎncă nu există evaluări

- Physiotherapy For ChildrenDocument2 paginiPhysiotherapy For ChildrenCatalina LucaÎncă nu există evaluări

- Dwnload Full Western Civilization Beyond Boundaries 7th Edition Noble Solutions Manual PDFDocument36 paginiDwnload Full Western Civilization Beyond Boundaries 7th Edition Noble Solutions Manual PDFgramendezwv100% (8)

- Malaria SymptomsDocument3 paginiMalaria SymptomsShaula de OcampoÎncă nu există evaluări

- Caucasus University Caucasus Doctoral School SyllabusDocument8 paginiCaucasus University Caucasus Doctoral School SyllabusSimonÎncă nu există evaluări

- Reflection IntouchablesDocument2 paginiReflection IntouchablesVictoria ElazarÎncă nu există evaluări

- Gesture and Speech Andre Leroi-GourhanDocument451 paginiGesture and Speech Andre Leroi-GourhanFerda Nur Demirci100% (2)

- PSYCHODYNAMICS AND JUDAISM The Jewish in Uences in Psychoanalysis and Psychodynamic TheoriesDocument33 paginiPSYCHODYNAMICS AND JUDAISM The Jewish in Uences in Psychoanalysis and Psychodynamic TheoriesCarla MissionaÎncă nu există evaluări

- Deborah Schiffrin .Tense Variation in NarrativeDocument19 paginiDeborah Schiffrin .Tense Variation in Narrativealwan61Încă nu există evaluări

- Revision Notes On Section 1.6 - Belief, Uncertainty & UnbeliefDocument5 paginiRevision Notes On Section 1.6 - Belief, Uncertainty & Unbeliefnisalielisha rodrigoÎncă nu există evaluări

- Building Social CapitalDocument17 paginiBuilding Social CapitalMuhammad RonyÎncă nu există evaluări

- IJONE Jan-March 2017-3 PDFDocument140 paginiIJONE Jan-March 2017-3 PDFmoahammad bilal AkramÎncă nu există evaluări

- Wardancer 4e HomebrewDocument3 paginiWardancer 4e HomebrewWyjecÎncă nu există evaluări

- Admission English Test 10thDocument4 paginiAdmission English Test 10thEduardo100% (1)

- My AnalysisDocument4 paginiMy AnalysisMaricris CastillanoÎncă nu există evaluări

- A Re Ection On The Dominant Learning Theories: Behaviourism, Cognitivism and ConstructivismDocument13 paginiA Re Ection On The Dominant Learning Theories: Behaviourism, Cognitivism and Constructivismchill protocolÎncă nu există evaluări

- K Unit 1 SeptemberDocument2 paginiK Unit 1 Septemberapi-169447826Încă nu există evaluări