Documente Academic

Documente Profesional

Documente Cultură

490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)

Încărcat de

dexiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)

Încărcat de

dexiDrepturi de autor:

Formate disponibile

[Reference Design 86]

490 kW, Tier III, Chilled Water,

Prefabricated, 697 m2

INTRODUCTION

DESIGN OVERVIEW The planning process of most projects can be iterative and thereby expensive.

Data center projects are burdened with these challenges and can benefit

Data Center IT Capacity greatly from simplification and time savings. Schneider Electric’s data center

490 kW reference designs help optimize the planning process by providing validated,

Adaptable from 95 kW to 490 kW proven, and documented data center physical infrastructure designs. The use

of these designs has a positive impact on not just the project itself, but also on

Target Availability the performance, reliability, and efficiency of the data center over its lifetime.

Tier III

Reference Design 86 includes information for three spaces: facility power,

Annualized PUE at 100% Load facility cooling and IT space. This design is constructed of prefabricated

1.33 in Beijing, China modules, comprising the integrated power, cooling and structural systems

1.30 in Paris, France required to meet its specifications in this overview document.

1.41 in Singapore

This design is Uptime Institute TIER-ready III compliant. This assures the

Total Racks and Average Density

design can be deployed onsite, and then quickly and cost-effectively certified

98 racks at 5 kW/rack

by Uptime Institute for industry-standard TIER III reliability.

Data Center Overall Space

Min. 697 m2

Regional Voltage and Frequency

400V, 50Hz

ABOUT THIS DESIGN

• Highly scalable and adaptable with

Prefabricated IT, Power, and Cooling

Modules

• Integrated room-based air

distribution

• Chilled water system using Uniflair

air-cooled packaged chillers with

variable-speed compressors to

increase efficiency

• Redundant design for increased

availability and concurrent

maintenance

[Reference Design 86] 2

Facility Power

FACILITY POWER BLOCK DIAGRAM The facility power system supplies power to the critical and non-critical

components within the data center. In this Tier 3 design, power is supplied

through two 500 kW power modules. The two modules provide 2N UPS power to

the IT space, altogether backed up by a 2N generator configuration. Inside each

power module, a 1600-amp main bus feeds a 625 kW Galaxy VX UPS with 5

minutes of runtime and a 1000-amp Prisma switchboard. The main bus also feeds

three packaged chillers. The 2N power distribution architecture from the electrical

room to the IT space utilizes a combination of LV panels and busways to the IT

racks. To provide continuous cooling, the 2N UPS also feeds the computer room

air handler (CRAH) units in the Data Hall and the chillers’ control and on-board

pumps.

The facility power system is designed to support integrated peripheral devices like

fire panels, access control systems, and environmental monitoring and control

devices. Power meters in the electrical path monitor power quality and allow for

predictive maintenance & diagnostics of the system. These meters also integrate

with EcoStruxure Power Monitoring Expert.

Every component in this design is built and tested to the applicable IEC or IEEE

standards.

Further design details and schematics are available in the engineering package.

DESIGN OPTIONS FACILITY POWER ATTRIBUTES

This reference design can be modified as

follows without a significant effect on the Name Value Unit

design’s performance attributes: Total amps (main bus) 1600 A

Input voltage (main bus) 400 V

• Add EcoStruxure Power Monitoring Switchboard kAIC 36 kA

Expert Power path Dual

• Provision for load bank Generator redundancy 2N

• Change UPS batteries

IT space UPS capacity 625 kW

• Add/change standby generator options:

IT space UPS redundancy 2N

• Location

IT space UPS runtime @ rated load 5 minutes © 2018 Schneider Electric. All rights reserved.

• Tank size

• Fuel type IT space UPS output voltage 400 V

Facility cooling UPS capacity N/A kW

Facility cooling UPS redundancy N/A

Facility cooling UPS runtime @ rated load N/A minutes

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

[Reference Design 86] 3

Facility Cooling

FACILITY COOLING BLOCK DIAGRAM

The facility cooling design is comprised of a chilled water cooling system with dual

path piping system, three Uniflair TSAF packaged chillers with free cooling

capabilities and 8 Uniflair LE chilled water room-based computer room air

handlers (CRAHs) that delivers clean and conditioned supply air to the IT and

electrical rooms, in an N+1 configuration.

The Uniflair TSAF chillers leverage variable speed technology to all main

components (compressors, pumps, etc.) and economization to achieve great

efficiency. Economization is achieved with a dedicated free-cooling pump to pump

water through special heat-exchange coils to be cooled by ambient temperature

during favorable outdoor conditions. For applications where the use of antifreeze

solutions is not allowed, Schneider Electric free-cooling chillers can be equipped

with the glycol-free solution. This option permits only free-cooling circuits in units

to be filled with a glycol/water mixture, leaving pure water on the other parts of

the circuit. The unit is equipped with an onboard intermediate heat exchanger that

isolates the principal hydraulic circuit and the free-cooling circuit.

The redundant piping system across the IT hall provides an alternate path for

chilled water in case of cooling equipment failure. These CRAH units, and the

chiller’s controls and on-board pumps are also fed by 2N UPS power to provide

continuous cooling. A thermal storage system is offered to provide 5 minutes of

continuous cooling after a power outage or chiller restart. The Uniflair TSAF

chillers can fully restart within 5 minutes.

More information on the CRAHs’ configuration is provided in the IT space section

of this document.

This design is instrumented to work with EcoStruxure IT Expert.

Further design details such as dimensions, equipment placement, temperature

set points, pipe sizing, flow rates, and pressure drops are available in the

engineering package.

FACILITY COOLING ATTRIBUTES

DESIGN OPTIONS

Name Value Unit

This reference design can be modified as Total cooling capacity (N) 617 kW

follows without a significant effect on the

Input voltage 400 V

design’s performance attributes:

Heat rejection medium Chilled water

• Add EcoStruxure IT Expert Mechanical redundancy N+1

© 2018 Schneider Electric. All rights reserved.

• Change storage tank size Packaged chiller

Outdoor heat exchange

• Use air-cooled version instead of with free-cooling

free-cooling version for the chillers Coolant supply temperature 15 °C

Coolant return temperature 20.6 °C

Storage tank size 8 m3

Ride-through time 5 minutes

Outdoor ambient temperature range -18.5 – 41.6 °C

Economizer type Water-side

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

[Reference Design 86] 4

IT Space

This data hall comprises of 7 modules and makes up the IT space of this design.

IT HALL LAYOUT The data hall is comprised of 7 rows of 14 racks reach for a total of 98 racks. Each

rack is capable of an average of 5kW for a total of 490 kW of IT capacity.

The data hall is designed to be a scalable multi-module prefabricated solution for

deployment of 50-200 racks; smaller starting loads can be supported by using

fewer modules to make the data hall. Likewise, this design can be used as a

baseline for larger loads by using a step and repeat approach to the design. This

flexibility drives efficiency and defers capital expenditure until need.

Each rack is powered by having taps off redundant (2N) 160 A Canalis KN

busway. Every rack is configured with redundant (2N) metered rack-mount PDU

to enable remote monitoring of the units for efficiency and capacity management.

The data hall is cooled by N+1 redundant chilled water perimeter Uniflair LE

CRAHs. The racks are placed to form alternating hot and cold aisles, where the

hot air is contained and ducted back to the CRAHs. To ensure Tier 3 reliability,

this design includes redundant valves and piping.

The security of the room is maintained at multiple points. At the rack level, access

is controlled by a door lock and sensor. At the room level, security cameras are

utilized for monitoring.

DESIGN OPTIONS

This reference design can be modified as

follows without a significant effect on the

design’s performance attributes:

• Add environmental and security

management

• Change rack options (tall, wide,

deep) IT SPACE ATTRIBUTES

• Change power distribution options

(rack PDU type: basic, switched) Name Value Unit

• Change from 16A, 3-phase to 32A, IT load 490 kW

1-phase tap-off units to racks

Input voltage 400 V

• Add isolation transformer

• Add EcoStruxure IT Expert Supply voltage to IT 230 V

Average density 5 kW/rack

Number of racks 98 racks

IT floor space 244 m2

Single or dual cord Dual © 2018 Schneider Electric. All rights reserved.

Heat rejection medium Chilled water

CRAC/CRAH type Perimeter CRAH

CRAC/CRAH redundancy N+1

Containment type Hot Aisle

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

[Reference Design 86] 5

Design Attributes

OVERVIEW Value Unit

Target availability Tier 3 Tier

Annualized PUE at 100% load 1.33 / 1.30 / 1.41

Data center IT capacity 490 kW

Data center overall space 697 m2

Average density 5 kW/rack

FACILITY POWER Value Unit

Total amps (main bus) 1600 A

Input voltage (main bus) 400 V

Switchboard kAIC 36 kA

Power path Dual

Generator redundancy 2N

IT space UPS capacity 625 kW

IT space UPS redundancy 2N

IT space UPS runtime @ rated load 5 minutes

IT space UPS output voltage 400 V

Facility cooling UPS capacity N/A kW

Facility cooling UPS redundancy N/A

Facility cooling UPS runtime @ rated load N/A minutes

FACILITY COOLING Value Unit

Total cooling capacity (N) 617 kW

Input voltage 400 V

Heat rejection medium Chilled water

Mechanical redundancy N+1

Outdoor heat exchange Packaged chiller with free-cooling

Coolant supply temperature 15 C

Coolant return temperature 20.6 C

Storage tank size 7.3 m3

Ride-through time 5 minutes

Economizer type Water-side

IT SPACE Value Unit

IT load 490 kW

Input voltage 400 V

© 2018 Schneider Electric. All rights reserved.

Supply voltage to IT 230 V

Average density 5 kW/rack

Number of racks 98 Racks

IT floor space 244 m2

Single or dual cord Dual

Heat rejection medium Chilled water

CRAC/CRAH type Perimeter CRAH

CRAC/CRAH redundancy N+1

Containment type Hot Aisle

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

[Reference Design 86] 6

EcoStruxure Data Center

EcoStruxure TM is Schneider Electric’s open, interoperable, integrated Internet of Things (IOT)-enabled system architecture and

platform. EcoStruxure delivers enhanced value around safety, reliability, efficiency, sustainability, and connectivity for our

customers. EcoStruxure leverages advancements in IoT, mobility, sensing, cloud, analytics, and cybersecurity to deliver Innovation

at Every Level. It consists of three layers: connected products, edge control, and applications, analytics, and services. This

includes Connected Products, Edge Control, and Apps, Analytics & Services. EcoStruxure TM has been deployed in 480,000+

sites, with the support of 20,000+ system integrators and developers, connecting over 1.6 million assets under management

through 40+ digital services.

The connected products layer communicates with the edge control layer, which allows users to remotely monitor and control the

connected products in real time. The edge control layer communicates with the application, analytics, and services, which will

translate data into actionable intelligence and better business decisions. All three layers are secured with end-to-end cybersecurity.

EcoStruxure can either be located on-premise (this will only consist of the connected products and edge control layers) or the

cloud.

EcoStruxure Data Center is a combination of three domains of EcoStruxure: Power, Building, and IT. Each domain is focused on a

subsystem of the data center: power, cooling, and IT. These three domains combined will reduce risks, increase efficiencies, and

speed operations across the entire facility.

• EcoStruxure Power monitors power quality, generates alerts, while protecting and controlling the electrical distribution the

electrical distribution system of the data center from the MV level to the LV level. It uses any device for monitoring and

alerting, uses predictive analytics for increased safety, availability, and efficiency, while lowering maintenance costs.

• EcoStruxure Building controls cooling effectively while driving reliability, efficiency, and safety of building management,

security, and fire systems. It performs data analytics on assets, energy use, and operational performance.

• EcoStruxure IT makes IT infrastructure more reliable and efficient while simplifying management by offering complete

visibility, alerting and modelling tools. It receives data, generates alerts, predictive analytics, and system advice on any

device to optimize availability and efficiency in the IT space.

© 2018 Schneider Electric. All rights reserved.

> Visit EcoStruxure for Data Center for more details.

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

[Reference Design 86] 7

Schneider Electric Life-Cycle Services

Team of over 7,000 trained specialists covering

every phase and system in the data center

Standardized, documented, and validated

methodology leveraging automation tools and

repeatable processes developed over 45 years

Complete portfolio of services to solve your

technical or business challenge, simplify your life,

and reduce costs

Get more information for this design:

Engineering Package

Every reference design is built with technical documentation

for engineers and project managers. This includes

engineering schematics (CAD, PDF), floor layouts,

equipment lists containing all the components used in the

design and 3D images showing real world illustrations of our

Floor layouts reference designs.

3D spatial views

Documentation is available in multiple formats to suit the

needs of both engineers and managers working on data

center projects.

© 2018 Schneider Electric. All rights reserved.

Bill of materials

One-line schematics

> Email ReferenceDesigns@Schneider-Electric.com to receive the Engineering Package for this design

Schneider Electric www.schneider-electric.com

Document Number RD86DS Revision 4 / November 2018

S-ar putea să vă placă și

- Power Electronics Design Handbook: Low-Power Components and ApplicationsDe la EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsEvaluare: 4 din 5 stele4/5 (2)

- 77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)Document7 pagini77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)dexiÎncă nu există evaluări

- 90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUDocument7 pagini90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUahmadgce04Încă nu există evaluări

- Semi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerDocument7 paginiSemi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerdexiÎncă nu există evaluări

- 900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)Document7 pagini900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)dexiÎncă nu există evaluări

- 520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)Document7 pagini520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)dexiÎncă nu există evaluări

- 910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)Document7 pagini910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)dexiÎncă nu există evaluări

- RD11 2.1 Facility Power Overview EN R0Document1 paginăRD11 2.1 Facility Power Overview EN R0АндрейТрубниковÎncă nu există evaluări

- 1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)Document7 pagini1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)dexiÎncă nu există evaluări

- 200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)Document7 pagini200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)dexiÎncă nu există evaluări

- RD10DSR2Document7 paginiRD10DSR2MarlonÎncă nu există evaluări

- 170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)Document7 pagini170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)dexiÎncă nu există evaluări

- RD11 5.1 Management Use Case en R0Document25 paginiRD11 5.1 Management Use Case en R0АндрейТрубниковÎncă nu există evaluări

- 345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)Document7 pagini345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)dexiÎncă nu există evaluări

- RD21DSR1 PDFDocument7 paginiRD21DSR1 PDFdexiÎncă nu există evaluări

- 790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)Document7 pagini790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)dexiÎncă nu există evaluări

- 3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)Document7 pagini3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)dexiÎncă nu există evaluări

- 170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)Document7 pagini170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)dexiÎncă nu există evaluări

- 175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)Document7 pagini175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)dexiÎncă nu există evaluări

- 1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)Document7 pagini1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)dexiÎncă nu există evaluări

- 48 KW, Pod-Based Build, Tier I, 646 FT: Design OverviewDocument6 pagini48 KW, Pod-Based Build, Tier I, 646 FT: Design Overviewahmadgce04Încă nu există evaluări

- 780 KW, Pod-Based Build, Tier I, 1873 FT: Design OverviewDocument6 pagini780 KW, Pod-Based Build, Tier I, 1873 FT: Design Overviewahmadgce04Încă nu există evaluări

- UPS & Battery Room CoolingDocument12 paginiUPS & Battery Room CoolingRamÎncă nu există evaluări

- How To Make Data Centre Resilient EfficientDocument22 paginiHow To Make Data Centre Resilient Efficientbehnoosh bamaniÎncă nu există evaluări

- Guide To ICT - Server Room Energy EfficiencyDocument12 paginiGuide To ICT - Server Room Energy EfficiencyIbr MohÎncă nu există evaluări

- Modular Data Centres in ContainersDocument24 paginiModular Data Centres in Containersnassim ouaÎncă nu există evaluări

- Symmetra PX: Scalable From 16 KW To 500 Kw. Parallel-Capable Up To 2,000 KWDocument12 paginiSymmetra PX: Scalable From 16 KW To 500 Kw. Parallel-Capable Up To 2,000 KWcilok nangkaÎncă nu există evaluări

- Abb Estorage Max: Scalable Energy Storage SystemDocument3 paginiAbb Estorage Max: Scalable Energy Storage Systemsaravananem1986Încă nu există evaluări

- 03.InfraSuite Manager-Module - PUE Energy - v4Document6 pagini03.InfraSuite Manager-Module - PUE Energy - v4Huy ĐặngÎncă nu există evaluări

- Vavr-5tdtef R1 enDocument10 paginiVavr-5tdtef R1 enJeffrey ArandiaÎncă nu există evaluări

- AKA Energy Storage DataSheet V2.00Document4 paginiAKA Energy Storage DataSheet V2.00Florin CrihanÎncă nu există evaluări

- Digital PWM System Controller: FeaturesDocument38 paginiDigital PWM System Controller: FeaturesAnamÎncă nu există evaluări

- Powerlink Intelligent Panelboards Brochure (Digital File) PDFDocument16 paginiPowerlink Intelligent Panelboards Brochure (Digital File) PDFisaac oropezaÎncă nu există evaluări

- Calculating Total Power Requirements For Data CentersDocument11 paginiCalculating Total Power Requirements For Data CentersDomingo RuizÎncă nu există evaluări

- Huawei Modular Datacenter Solution (IDS2000) : Huawei Technologies Co., LTDDocument4 paginiHuawei Modular Datacenter Solution (IDS2000) : Huawei Technologies Co., LTDDmitriy BaybulatovÎncă nu există evaluări

- 48KW1Document7 pagini48KW1William QuintelaÎncă nu există evaluări

- OF OPT - CS Mar2023 - tcm702 101896Document2 paginiOF OPT - CS Mar2023 - tcm702 101896angga.snc29Încă nu există evaluări

- 50-220KW Chiller ManualDocument67 pagini50-220KW Chiller Manualjrza78Încă nu există evaluări

- Moxa Embedded Solution On IEC 61850Document25 paginiMoxa Embedded Solution On IEC 61850vovick_vovickÎncă nu există evaluări

- Components and Systems For Electric Vehicles (Hevs/Evs)Document7 paginiComponents and Systems For Electric Vehicles (Hevs/Evs)NaniÎncă nu există evaluări

- Inrow RC (ASTE-6Z5S8Z - R1 - ENDocument40 paginiInrow RC (ASTE-6Z5S8Z - R1 - ENjoseÎncă nu există evaluări

- Eaton 93E UPS: Product BrochureDocument2 paginiEaton 93E UPS: Product BrochureCristian ManzanoÎncă nu există evaluări

- G55tupsm30hin enDocument8 paginiG55tupsm30hin enDeepak VermaÎncă nu există evaluări

- IS920 Product Information: Inverter System 48 V DC For TelecommunicationDocument9 paginiIS920 Product Information: Inverter System 48 V DC For TelecommunicationOleg KuryanÎncă nu există evaluări

- IS920 Product Information: Inverter System 48 V DC For TelecommunicationDocument10 paginiIS920 Product Information: Inverter System 48 V DC For TelecommunicationOleg KuryanÎncă nu există evaluări

- Smart-UPS On-Line SRT 2.2kVA - 10kVA Brochure 230V ModelsDocument12 paginiSmart-UPS On-Line SRT 2.2kVA - 10kVA Brochure 230V ModelsThanh SonÎncă nu există evaluări

- Data Center Design Best PracticesDocument41 paginiData Center Design Best PracticesEmerson Network Power's Liebert products & solutions100% (12)

- Symmetra PX 20: Scalable To 20 KWDocument8 paginiSymmetra PX 20: Scalable To 20 KWTartaro AltamiranoÎncă nu există evaluări

- Smart-UPS SRT1-3kVA V2Document13 paginiSmart-UPS SRT1-3kVA V2carlosÎncă nu există evaluări

- 998-1243569 Gma-Us BDocument14 pagini998-1243569 Gma-Us BMuh Zaki NovriÎncă nu există evaluări

- Smart-Ups ™ With Apc™ Smartconnect: The World'S Most Popular Network and Server UpsDocument11 paginiSmart-Ups ™ With Apc™ Smartconnect: The World'S Most Popular Network and Server UpsIosvany PoeyÎncă nu există evaluări

- Liebert PCW Brochure EnglishDocument8 paginiLiebert PCW Brochure Englishktp070Încă nu există evaluări

- Bi-Directional Storage Converter - AEGDocument2 paginiBi-Directional Storage Converter - AEGJitheshÎncă nu există evaluări

- F-Bull Sequana X1000 En4-WebDocument4 paginiF-Bull Sequana X1000 En4-WebSurajit PalÎncă nu există evaluări

- Apc Smart Ups RTDocument8 paginiApc Smart Ups RTjose2525Încă nu există evaluări

- Symmetra PX 100 KW: Scalable From 10 KW To 100 KWDocument8 paginiSymmetra PX 100 KW: Scalable From 10 KW To 100 KWJesus Enrique AnayaÎncă nu există evaluări

- Eaton UPS Communications: The Power Inside The BoxDocument4 paginiEaton UPS Communications: The Power Inside The BoxjoseÎncă nu există evaluări

- SHPPEAK3Document8 paginiSHPPEAK3Sudara RandombageÎncă nu există evaluări

- Netsure™: Itm With Esure™ Technology Row-Based, Scalable 48V DC UpsDocument12 paginiNetsure™: Itm With Esure™ Technology Row-Based, Scalable 48V DC UpsALEX ALEXÎncă nu există evaluări

- Computer Power in DSP 40 400 Kva KW Jun2020Document6 paginiComputer Power in DSP 40 400 Kva KW Jun2020andreschangeÎncă nu există evaluări

- Sigma C Master Clock Instructions PDFDocument46 paginiSigma C Master Clock Instructions PDFdexiÎncă nu există evaluări

- 643J31 Time Server SecureSyncDocument4 pagini643J31 Time Server SecureSyncdexiÎncă nu există evaluări

- 653B21 Time Server Netsilon PDFDocument4 pagini653B21 Time Server Netsilon PDFdexiÎncă nu există evaluări

- User Manual Netsilon PDFDocument74 paginiUser Manual Netsilon PDFdexiÎncă nu există evaluări

- 643O41 Time Server Netsilon PDFDocument4 pagini643O41 Time Server Netsilon PDFdexiÎncă nu există evaluări

- Apc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsDocument9 paginiApc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsdexiÎncă nu există evaluări

- Knuerr CoolFlex PDFDocument6 paginiKnuerr CoolFlex PDFdexiÎncă nu există evaluări

- IPack2005 73273 PDFDocument8 paginiIPack2005 73273 PDFdexiÎncă nu există evaluări

- Airflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterDocument11 paginiAirflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterdexiÎncă nu există evaluări

- Ksih-6y6tlv R0 en 2 PDFDocument9 paginiKsih-6y6tlv R0 en 2 PDFdexiÎncă nu există evaluări

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 paginiAPC Application Note #69: Air Distribution Unit ApplicationdexiÎncă nu există evaluări

- Jnin-6n7srz R0 en PDFDocument12 paginiJnin-6n7srz R0 en PDFdexiÎncă nu există evaluări

- Iso 22301 Business Continuity Management PDFDocument13 paginiIso 22301 Business Continuity Management PDFdexi100% (3)

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 paginiAPC Application Note #69: Air Distribution Unit ApplicationdexiÎncă nu există evaluări

- Interpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersDocument8 paginiInterpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersdexiÎncă nu există evaluări

- Fulltext01 PDFDocument64 paginiFulltext01 PDFdexiÎncă nu există evaluări

- Intel-Air-Cooled Data Centers PDFDocument20 paginiIntel-Air-Cooled Data Centers PDFdexiÎncă nu există evaluări

- h14515 VNX Family Ds PDFDocument6 paginih14515 VNX Family Ds PDFdexiÎncă nu există evaluări

- Group Business Continuity Plan Summary 2018 PDFDocument4 paginiGroup Business Continuity Plan Summary 2018 PDFdexiÎncă nu există evaluări

- Impact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFDocument14 paginiImpact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFdexiÎncă nu există evaluări

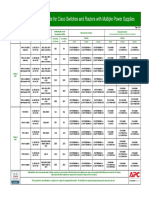

- APC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesDocument2 paginiAPC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesdexiÎncă nu există evaluări

- AXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsDocument3 paginiAXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsdexiÎncă nu există evaluări

- In-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsDocument63 paginiIn-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsdexiÎncă nu există evaluări

- Guide To BCM Third Edition ProtivitiDocument66 paginiGuide To BCM Third Edition ProtivitiaalfonsopÎncă nu există evaluări

- Energy Efficient Electric Motor Selection PDFDocument66 paginiEnergy Efficient Electric Motor Selection PDFdexiÎncă nu există evaluări

- Effects of Doors On Airflow and Cooling WP PDFDocument10 paginiEffects of Doors On Airflow and Cooling WP PDFdexiÎncă nu există evaluări

- Enclosure Heat Load PDFDocument55 paginiEnclosure Heat Load PDFdexiÎncă nu există evaluări

- ME Harmonization Curricilum FinalDocument307 paginiME Harmonization Curricilum Finalratchagaraja33% (3)

- PDFDocument255 paginiPDFwrite2arshad_mÎncă nu există evaluări

- Pace Power System Presentation - 0Document15 paginiPace Power System Presentation - 0everetteÎncă nu există evaluări

- ARSTRUCTS Chapter1Document15 paginiARSTRUCTS Chapter1Aila MaeÎncă nu există evaluări

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDocument38 paginiSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakÎncă nu există evaluări

- Allen BradleyDocument36 paginiAllen BradleyotrepaloÎncă nu există evaluări

- Java SampleExamQuestionsDocument18 paginiJava SampleExamQuestionshmasryÎncă nu există evaluări

- Epi Gear 1 PDFDocument21 paginiEpi Gear 1 PDFTrevaughn ParkinsonÎncă nu există evaluări

- MyNotes ConcreteDocument18 paginiMyNotes ConcreteKarl Si AkoÎncă nu există evaluări

- Wood Magazine Issue #189Document96 paginiWood Magazine Issue #189bangbang63100% (1)

- PSC Girder MethodologyDocument12 paginiPSC Girder MethodologySaurabh KumarÎncă nu există evaluări

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDocument3 paginiPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesÎncă nu există evaluări

- The Family Handyman - October 2020 PDFDocument86 paginiThe Family Handyman - October 2020 PDFFabian MaunaÎncă nu există evaluări

- Technical LetteringDocument12 paginiTechnical LetteringMaverick Timbol50% (2)

- Handling Tickets Is Called Issue Tracking System.: Sap SDDocument6 paginiHandling Tickets Is Called Issue Tracking System.: Sap SDNaveen KumarÎncă nu există evaluări

- Antena 700 2m - TongyuDocument2 paginiAntena 700 2m - TongyuLenin Alejandro Ramirez HuaypatinÎncă nu există evaluări

- Amplitude Shift KeyingDocument3 paginiAmplitude Shift KeyingPurnendh ParuchuriÎncă nu există evaluări

- KolkataSTK5 16092019Document9 paginiKolkataSTK5 16092019Nausheen RahmanÎncă nu există evaluări

- Karcher K - 791 - MDocument12 paginiKarcher K - 791 - MJoão Paulo FernandesÎncă nu există evaluări

- On The Gaussian Error Function (1935) : Robert J. KolkerDocument4 paginiOn The Gaussian Error Function (1935) : Robert J. KolkerSanthosh KulandaiyanÎncă nu există evaluări

- Gate Ee 1991Document7 paginiGate Ee 1991Bhavani Chandra UniqueÎncă nu există evaluări

- Arup Scheme Design GuideDocument139 paginiArup Scheme Design GuideDean TyrrellÎncă nu există evaluări

- Oracle Exadata Technical Series: Smart ScanDocument59 paginiOracle Exadata Technical Series: Smart ScanVishnusivathej PotukanumaÎncă nu există evaluări

- Home,: A Solace To Which A Journey Is Never Too Long..Document25 paginiHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyÎncă nu există evaluări

- 16PPE723Document2 pagini16PPE723DrArun KaliappanÎncă nu există evaluări

- Basic Electronics - AC - DC PDFDocument20 paginiBasic Electronics - AC - DC PDFRowena ResurreccionÎncă nu există evaluări

- FM200Document23 paginiFM200Ahmed SherifÎncă nu există evaluări

- Home Automation Control System Using DTMFDocument25 paginiHome Automation Control System Using DTMFengaydiÎncă nu există evaluări

- Result Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDDocument14 paginiResult Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDLexÎncă nu există evaluări

- Hindalco Aluminium Catalogue PDFDocument4 paginiHindalco Aluminium Catalogue PDFVansu Saini0% (1)