Documente Academic

Documente Profesional

Documente Cultură

Risk Assessment - CHW Pump

Încărcat de

Adnan AttishTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Risk Assessment - CHW Pump

Încărcat de

Adnan AttishDrepturi de autor:

Formate disponibile

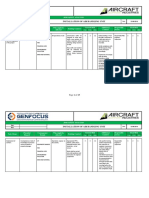

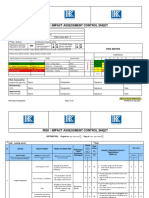

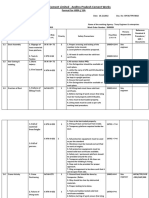

RISK ASSESSMENT FOR TESTING AND COMMISSIONING OF CHILLED WATER PUMPS

INVENTORY OF WORK ACTIVITIES

Company: RAK JV

No. Process/Location Testing and Commissioning of Chilled Water Pumps

General Workplace Hazards

Assessed by Reviewed by Reviewed by Approved by

Name: Rohail Asghar Name: Mahboob Pasha Name: Muhammad Safeer Tareen Name: John Hadfield

Designation: HSE Supervisor Designation: Construction Manager Designation: HSE Manager Designation: Project Manager

Date: Date: Date: Date:

Signature: Signature: Signature: Signature:

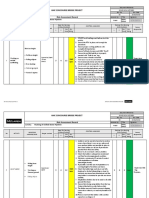

RISK ASSESSMENT FORM - TESTING AND COMMISSIONING OF CHILLED WATER PUMPS

Company RAK JV Work Activities

Worksite Education City

Process/ Location: EDU Station Conducted by:

Shakil Rao – Mechanical Engineer Next Review Date: When change in

TESTING AND COMMISSIONING OF Mahboob Pasha - Construction Manager method or Incident happening or

Work Scope:

CHILLED WATER PUMPS Increase in manpower.

Checked by (Tech M): Construction Manager Date of Review:

Mahboob Pasha Work Commencement date: TBC

Document Number: M007-RAK-TCH-PRO-00001 Rev 02 Page 1 of 4 Date:24-03-2018

Uncontrolled if printed, refer to EDMS for current version

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d 3e

Possible

likely hood

likely hood

Risk Level

Risk Level

Severity

Severity

Accident / Action Officer

No Work Activity Hazard Health & Existing Risk Control (if Any) Additional Risk Control (Designation)

Persons at (Follow-up date)

Risk

T & C engineer will request to main HSE Officer to verify / ensure PTW is in place

contractor for PTW before one day. for the T&C activity prior to start.

Improper & RAK will follow the approved LOTO Proper LOTO shall be secured to avoid any

Incomplete procedure (M007-RAKHMS-PRO-00001) unauthorized operation

PTW T & C Engineer,

Document Proper signage will be provided regarding All the contractors and working team will be

1 Incomplete Operatives 3 3 9 3 1 3 Supervisor,

arrangements the testing and commissioning procedures informed and coordinate properly about ongoing

LOTO

and authorized personal only. testing and their hazards.

procedure

requirements PPEs will be given to all operatives Third party certification of LOTO in-charge

relevant to their job. engineer.

Start briefing prior to start the activity.

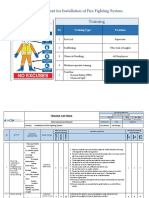

PPEs will be given to all operatives

relevant to their job. Housekeeping of area prior to start and while

Access ways shall be ensuring by leaving the work area. T & C Engineer,

2 Site Arrangement Slip and trip Operatives competent person that all access and 3 2 6 Designated team will be assigned for 3 1 3 Supervisor,

egress points are free from obstructions. housekeeping.

Material will be stacked properly at

designated place.

RAK approved Heat stress plan (M007-

Fatigue Glucose juice shall be given.

Heat stress RAK-HMS-PLN-00002) will be followed.

Close supervision

To involved Proper monitoring of temperature

T & C Engineer,

Heat stroke 12 Proper communication arrangements Supervisor,

3 Working in Summer personnel 4 3 4 1 4

Dehydration Breaks and rotations will be given to all

Training will be given to all workers on heat

involved workers

stress.

Easy access to cool water

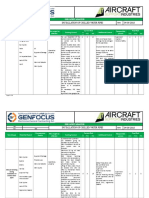

Electrocution. Personal System under test has been correctly Only trained personnel shall conduct test.

Poor Lighting Injury installed and inspected. In House Training will be given to the workers.

Spillage of Finger Injury Ensure approved work permit is available Proper hand protection gloves shall be worn.

Testing and Water Hand Injury Electrical Engineer / Supervisor shall be T & C Engineer,

prior to beginning of any testing

4 Commissioning of 5 3 15 available on task 5 1 5 Supervisor,

48 Hrs. notice to CCC prior to the testing

Chilled Water Pumps LOTO procedure (M007-RAK-HMS-PRO-

and approval shall be obtained /

coordinated. 00001)shall be followed.

Calibrated equipment will be used Acquired permit to work from the contractor.

Document Number: M007-RAK-TCH-PRO-00001 Rev 02 Page 2 of 4 Date:24-03-2018

Uncontrolled if printed, refer to EDMS for current version

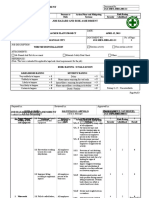

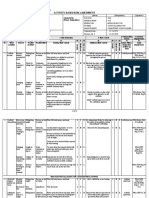

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d 3e

Possible

likely hood

likely hood

Risk Level

Risk Level

Severity

Severity

Accident / Action Officer

No Work Activity Hazard Health & Existing Risk Control (if Any) Additional Risk Control (Designation)

Persons at (Follow-up date)

Risk

Tools & equipment TPC to be available at In case of an emergency, Emergency Rescue

site. plan of main contractor will be followed.

Area shall be barricaded (Physical barrier) Fire Extinguisher shall be placed nearby at the

and Signs placed for unauthorized entry. area of the task activity.

Ensure availability of water spill kit Proper supervision of the testing activities shall

during testing of CHW Pumps. be implemented.

PPEs will be provided as per their job.

Main contractors approved heat stress

Task lights will be provided for illumination.

plan will be followed.

Proper Communication system shall be

Sufficient lighting will be provided by

provided.

main contractor.

Injuries such Muscle pain Task Briefing conducted to workers on Only competent personnel will be allowed

as Back Eye strain, ergonomics and manual handling safety Main contractors PTW will be followed

Strain, headache, Training related to manual handling RAK approved HSE plan will be followed T & C Engineer,

4 Manual Handling Bruised or fatigue Close supervision by site supervisor 3 3 9 Ensure housekeeping of all areas. 3 1 3 Supervisor,

broken toes or Stress Manual Handling Risks briefed to

feet. Minor injuries workforce by the task in charge before

Sharp edges commencement of work.

It may cause Hand injuries All equipment will be inspected prior to Task Briefing conducted to workers on

injuries such Property use. ergonomics and use of hand tools safely

T & C Engineer,

as Back damage Use of Personal Protective Equipment at Colour code will be followed of main contractor.

5 Hand Tools 3 2 6 3 1 3 Supervisor,

Strain, all times (hard hats, safety glasses, gloves, Training related to hand tools.

Defective Ear Protection, etc.)

hand tools

Fire Injury and Main contractor rescue plan will be Designated rescue team

First aid property followed. ER team posters will be displayed at site.

Dizziness damage Provision of sufficient and suitable fire Refresher trainings of ER team after 03

months T & C Engineer,

Emergency Heat stroke extinguishers at site

6 4 3 12 Good coordination and communication with 4 1 4 Supervisor,

arrangements Provision of first aid box, Stretcher,

eyewash at site CCC male nurse.

Designated fire wardens team

Designated first aider teams

Document Number: M007-RAK-TCH-PRO-00001 Rev 02 Page 3 of 4 Date:24-03-2018

Uncontrolled if printed, refer to EDMS for current version

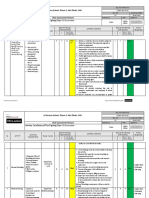

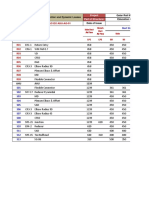

Table I: Accident Severity categories

Catastrophic 5 Single or multiply loss of life from injury or occupational disease, immediately or delayed: and/or

Loss of whole production for greater than 3-man days and /or

Total loss in excess of S$ 1 million

Moderate 4 Hospital care over 72-man hours.

Broken/fractured bones, loss of sight, major burns.

Total loss in excess of QR 0.5 million but up to QR 1 million

Major 3 Causing Major Injuries (e.g. unconsciousness, heat stroke)

Hospital care in excess of 24 hours

Damage to works or plant causing delay of up to 1 man-days: and /or

Total loss in excess of QR250,000 but up to QR 0.5 million

Serious 2 Causing significant injuries (e.g. Cuts requiring stitches, laceration, burn) Hospital care for less than 24 hours

Minor 1 Minor injury, no lost time or person involved returns to work during the shift

Minor damage to works or plant does not cause significant delays.

Table II: Risk Index Matrix Accident Severity Category

(5) (4) (3) (2) (1)

Catastrophic Moderate Major Serious Minor

(5) Frequent 25 20 15 10 5

(4) Probable 20 16 12 8 4

(3) Occasional 15 12 9 6 3

(2) Remote 10 8 6 4 2

(1) Improbable 5 4 3 2 1

Likelihood Rating Description

Frequent 5 Likely to occur repeatedly

Probable 4 Likely to occur more than once

Occasional 3 Could possibly occur

Remote 2 Unlikely to occur

Improbable 1 Extremely unlikely to occur based on judgment and where possible, supported by industry experience

Table III: Definition of Risk Index

Risk Index Description Definition

1-5 Acceptable Further action may not be necessary

6-10 Moderately Acceptable Further action is to taken where reasonably practicable to do so.

Management attention is required. A careful evaluation of the hazards should be carried out to ensure that the risk level is reduced to as low as is practicable within a

12-16 Not Acceptable

defined period of time. Interim risk control measures, such as administrative controls may be implemented.

Immediate management intervention is required before work commences. Very high-risk level must be reduced to at least Medium Risk before work commences.

20-25 Strictly Not acceptable There should not be any interim risk control measures and should not be overly dependent on personal protective equipment or appliances. If need be, the hazard

should be eliminated before work commences.

Document Number: M007-RAK-TCH-PRO-00001 Rev 02 Page 4 of 4 Date:24-03-2018

Uncontrolled if printed, refer to EDMS for current version

S-ar putea să vă placă și

- Spin QuestionsDocument2 paginiSpin QuestionsMiguel Alfonso Ruiz MendezÎncă nu există evaluări

- Risk Assessment For Installation of Light FittingsDocument11 paginiRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Installation of Fire Fighting SystemDocument14 paginiRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Installation of Air Handling UnitDocument15 paginiInstallation of Air Handling UnitAnandu Ashokan100% (2)

- Risk Assessment - Fire Pump SetDocument8 paginiRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasÎncă nu există evaluări

- 20) Pumping of WaterDocument7 pagini20) Pumping of WaterMobin Thomas Abraham75% (12)

- JSA For Fire Water LineDocument4 paginiJSA For Fire Water Linemyo lwinÎncă nu există evaluări

- Risk Assessment of Concrete PouringDocument13 paginiRisk Assessment of Concrete PouringAbdul MujeebÎncă nu există evaluări

- Risk Assessment For Installation of Fire Fighting SystemDocument12 paginiRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- 009 Installation of Pumps Risk AssessmentDocument2 pagini009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Site Specific Health Safety Environment Plan HvacDocument74 paginiSite Specific Health Safety Environment Plan Hvacsyed khaja misbhuddin100% (1)

- RA For Man Lift OperationDocument6 paginiRA For Man Lift Operationalla malikÎncă nu există evaluări

- Risk Assessment For Installation of Diesel Generator111111Document8 paginiRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- JGS SHES JHRA 002 13 Wire Mesh InstallationDocument2 paginiJGS SHES JHRA 002 13 Wire Mesh Installationarnel sungkip100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 paginiRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 paginiRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inÎncă nu există evaluări

- 6.chain Pulley BlockDocument2 pagini6.chain Pulley BlockFrancis Vinoj100% (3)

- Chiller Plant RADocument2 paginiChiller Plant RAarifzakir67% (9)

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 paginiRisk Assessment - Installation of Air-Cooled ChillersBabar ShehzadÎncă nu există evaluări

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 paginiRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- 07.01 Risk Assessment For Fire Alarm SystemDocument15 pagini07.01 Risk Assessment For Fire Alarm SystemShah MuzzamilÎncă nu există evaluări

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 paginiRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Method Statement & Risk Assessment For Roller ShutterDocument3 paginiMethod Statement & Risk Assessment For Roller Shutterchandanprakash30100% (1)

- RA For Installation of FanDocument8 paginiRA For Installation of FanAnandu AshokanÎncă nu există evaluări

- AHU Chilled Water Hook Up DetailsDocument1 paginăAHU Chilled Water Hook Up DetailsAdnan Attish100% (1)

- 09-1 Mechanical & Electrical EquipmentDocument24 pagini09-1 Mechanical & Electrical EquipmentAdnan AttishÎncă nu există evaluări

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pagini005 Risk Assessment T&C Fire Suppression SystemJohn RazaÎncă nu există evaluări

- Risk-Assessment Ducts & AccessoriesDocument13 paginiRisk-Assessment Ducts & AccessoriesMohammed Amer PashaÎncă nu există evaluări

- Risk Assessment & Control Register - Grease Trap CleaningDocument7 paginiRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanÎncă nu există evaluări

- Scaffold - Erection, Use & Dismantling-RADocument15 paginiScaffold - Erection, Use & Dismantling-RAAl AminÎncă nu există evaluări

- RA Equipment MobilizationDocument1 paginăRA Equipment MobilizationSn Ahsan100% (1)

- Risk Assessment (Installation of Cables & Wires)Document6 paginiRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 paginiRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 paginiJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- RA For Installation of Air Colled ChillersDocument8 paginiRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Test Commissioning Plan Rev 1 Al RiDocument133 paginiTest Commissioning Plan Rev 1 Al RiAdnan Attish100% (3)

- Risk Assessment - Installation of Air CurtainDocument25 paginiRisk Assessment - Installation of Air CurtainMohsin MohdÎncă nu există evaluări

- 2 - Pulling CablesDocument5 pagini2 - Pulling CablesAhmed KhaledÎncă nu există evaluări

- Risk Assessment For Flushing of Chilled Water PipingDocument9 paginiRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanÎncă nu există evaluări

- Ra For Installation of Grills, Diffusers & LouversDocument8 paginiRa For Installation of Grills, Diffusers & LouversAnandu Ashokan100% (1)

- Risk Assessment For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument3 paginiRisk Assessment For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (4)

- Risk Assessment of Fire Hose Reel InstallationDocument9 paginiRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Risk Assessment For Water Heaters InstallationDocument6 paginiRisk Assessment For Water Heaters Installationfidgety100% (1)

- OnboardingDocument19 paginiOnboardingWilliamAllanGibson100% (4)

- Installation of Chilled Water PipesDocument6 paginiInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- Installation of LPG Gas Line - Jha 1Document5 paginiInstallation of LPG Gas Line - Jha 1Ralph CastilloÎncă nu există evaluări

- Coapplication Iswp JamshedpurDocument8 paginiCoapplication Iswp JamshedpurAnkit KumarÎncă nu există evaluări

- Pipe Sizing V2.3-ASPEDocument56 paginiPipe Sizing V2.3-ASPEAdnan AttishÎncă nu există evaluări

- Sample Employee Performance AppraisalDocument6 paginiSample Employee Performance AppraisalAnnie Sarah0% (1)

- Risk Assessment - FM 200Document5 paginiRisk Assessment - FM 200Nangyal KhanÎncă nu există evaluări

- Insulation of Ducting and PipingDocument1 paginăInsulation of Ducting and PipingKrishna PatilÎncă nu există evaluări

- Risk Assessment For Installation of Automatic Sliding DoorDocument6 paginiRisk Assessment For Installation of Automatic Sliding DoorKalid JmalÎncă nu există evaluări

- Heat DissipationDocument16 paginiHeat DissipationAdnan Attish100% (1)

- JSA For Installation of Fire PumpsDocument2 paginiJSA For Installation of Fire Pumpsperquino oasan100% (2)

- Booster Pump Head Calculation - AaDocument5 paginiBooster Pump Head Calculation - AaAdnan AttishÎncă nu există evaluări

- Risk Assessment For Aluminium Handrail InstallationDocument5 paginiRisk Assessment For Aluminium Handrail InstallationKalid Jmal100% (1)

- Ra - Water Tank CleaningDocument3 paginiRa - Water Tank CleaningYousaf Richu50% (2)

- Education City CHW Pump HeadDocument33 paginiEducation City CHW Pump HeadAdnan AttishÎncă nu există evaluări

- Design Data & References: Unit Tag StationDocument12 paginiDesign Data & References: Unit Tag StationAdnan AttishÎncă nu există evaluări

- Design Data & References: Unit Tag StationDocument12 paginiDesign Data & References: Unit Tag StationAdnan AttishÎncă nu există evaluări

- Water Tank Risk AssessmentDocument2 paginiWater Tank Risk AssessmentHijikata Shiroi100% (3)

- A Study On Employee Satisfaction in The IT IndustryDocument69 paginiA Study On Employee Satisfaction in The IT IndustryArnav0% (3)

- Wastewater Treatment Plant Design... : Chapter 01 - Stormwater, Sewers and Sewage..Document6 paginiWastewater Treatment Plant Design... : Chapter 01 - Stormwater, Sewers and Sewage..Adnan AttishÎncă nu există evaluări

- Construction Safety and Health ManualDocument86 paginiConstruction Safety and Health ManualReggie RosalÎncă nu există evaluări

- AHU Friction Loss CalculationsDocument4 paginiAHU Friction Loss CalculationsAdnan AttishÎncă nu există evaluări

- JSA Hydrant Pipe LineDocument7 paginiJSA Hydrant Pipe Lineakshay pradeepÎncă nu există evaluări

- Installation of Fire Fighting SystemDocument66 paginiInstallation of Fire Fighting SystemAnandu AshokanÎncă nu există evaluări

- 011 Duct Lifter SWMSDocument2 pagini011 Duct Lifter SWMSJ JohnsonÎncă nu există evaluări

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 paginăTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanÎncă nu există evaluări

- JET Fan InstallationDocument2 paginiJET Fan InstallationKrishna Patil100% (2)

- Wall Painting Risk AssesmentDocument3 paginiWall Painting Risk AssesmentJacob ChirayilÎncă nu există evaluări

- Hira-09 Copper Slag Blasting and Spray Penting WorkDocument14 paginiHira-09 Copper Slag Blasting and Spray Penting WorkRaju100% (1)

- RA - Plumbing Works Rev. BDocument8 paginiRA - Plumbing Works Rev. BResearcherÎncă nu există evaluări

- HIRA JSA For Duct Assembly & ErectionDocument4 paginiHIRA JSA For Duct Assembly & ErectionRaju100% (2)

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 paginăJob Safety Analysis (JSA) - HVAC Ducting DatenabeelÎncă nu există evaluări

- 9 RA Scaffold Erection and DismantleDocument4 pagini9 RA Scaffold Erection and DismantlethevinÎncă nu există evaluări

- Hidrac NewDocument3 paginiHidrac NewSarivin KannanÎncă nu există evaluări

- Drainage STD DetailsDocument1 paginăDrainage STD DetailsAdnan AttishÎncă nu există evaluări

- Field Quarantine Unit G+2 BLDG - Cooling Load Calculations.1Document23 paginiField Quarantine Unit G+2 BLDG - Cooling Load Calculations.1Adnan Attish100% (1)

- Design Cold Water Flow References Animal Water ConsumptionDocument2 paginiDesign Cold Water Flow References Animal Water ConsumptionAdnan AttishÎncă nu există evaluări

- Area Vs Cooling Load FDocument17 paginiArea Vs Cooling Load FAdnan AttishÎncă nu există evaluări

- MH - EQS - Ventilation FansDocument1 paginăMH - EQS - Ventilation FansAdnan AttishÎncă nu există evaluări

- Rhino F PDFDocument9 paginiRhino F PDFAdnan AttishÎncă nu există evaluări

- Bear Corr FDocument18 paginiBear Corr FAdnan AttishÎncă nu există evaluări

- Bear F3Document6 paginiBear F3Adnan AttishÎncă nu există evaluări

- Bear F3Document6 paginiBear F3Adnan AttishÎncă nu există evaluări

- Fan Coil Units External System Resistance Calculation (Static Pressure)Document4 paginiFan Coil Units External System Resistance Calculation (Static Pressure)Adnan AttishÎncă nu există evaluări

- Pwa Roads and Drainage Cad Standards Manual Ver 4.0Document145 paginiPwa Roads and Drainage Cad Standards Manual Ver 4.0Anonymous 7z6OzoÎncă nu există evaluări

- Rhino F PDFDocument9 paginiRhino F PDFAdnan AttishÎncă nu există evaluări

- M007 Rak MHV DWG Ucst010 CL 00100Document1 paginăM007 Rak MHV DWG Ucst010 CL 00100Adnan Attish0% (1)

- Zoo - OptimizationDocument6 paginiZoo - OptimizationAdnan AttishÎncă nu există evaluări

- Operation and Maintenance Training Manual For Sand Filter Red Line North Elevated and at GradeDocument55 paginiOperation and Maintenance Training Manual For Sand Filter Red Line North Elevated and at GradeAdnan AttishÎncă nu există evaluări

- HIAS-CHW Pump Head Calculations R.1Document26 paginiHIAS-CHW Pump Head Calculations R.1Adnan AttishÎncă nu există evaluări

- AHUs Calculations Air Side Friction & Dynamic Losses.F.1 01.17PMDocument73 paginiAHUs Calculations Air Side Friction & Dynamic Losses.F.1 01.17PMAdnan AttishÎncă nu există evaluări

- Duct Risers Front ElevationsDocument1 paginăDuct Risers Front ElevationsAdnan AttishÎncă nu există evaluări

- ELEM0916ra Catar e PDFDocument48 paginiELEM0916ra Catar e PDFPhilBoardResultsÎncă nu există evaluări

- Behavioral Based Interview QuestionsDocument9 paginiBehavioral Based Interview QuestionsArunÎncă nu există evaluări

- Santuyo vs. Remerco Garments Vol. Arbitrator Jurisdiction 2010Document8 paginiSantuyo vs. Remerco Garments Vol. Arbitrator Jurisdiction 2010Ulysses RallonÎncă nu există evaluări

- HMC Housing GuideDocument19 paginiHMC Housing GuideHamdy Gabal100% (1)

- Introduction To IHRMDocument39 paginiIntroduction To IHRMAbdKareem100% (1)

- Report Construction Law Topic 1Document28 paginiReport Construction Law Topic 1KARTHIK VASUDEVANÎncă nu există evaluări

- L5 International HRMDocument23 paginiL5 International HRMRajat ShettyÎncă nu există evaluări

- Kot Addu Power Company LimitedDocument17 paginiKot Addu Power Company LimitedShanzae KhalidÎncă nu există evaluări

- Practicum FlyerDocument2 paginiPracticum Flyeresl9204Încă nu există evaluări

- Summer Training Report Final 1 (Muskan)Document70 paginiSummer Training Report Final 1 (Muskan)PRACHI DASÎncă nu există evaluări

- Career DevelopmentDocument15 paginiCareer DevelopmentMaisa JessicaÎncă nu există evaluări

- Evaluation of Occupational Safety and Health Administration Status of College of Health Sciences and Technology, Idah Kogi StateDocument11 paginiEvaluation of Occupational Safety and Health Administration Status of College of Health Sciences and Technology, Idah Kogi StateInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Job Interview Soft SkillsDocument12 paginiJob Interview Soft SkillsMonika DomańskaÎncă nu există evaluări

- 02 Entrep MythsDocument3 pagini02 Entrep MythsSanjida IslamÎncă nu există evaluări

- Questionnaire PsuDocument2 paginiQuestionnaire Psu9986212378Încă nu există evaluări

- Canuel vs. Magsaysay Maritime CorporationDocument27 paginiCanuel vs. Magsaysay Maritime CorporationCamille Yasmeen SamsonÎncă nu există evaluări

- Circular 44 2021Document166 paginiCircular 44 2021thomasÎncă nu există evaluări

- Organisation Study On Atlus Garment CompanyDocument68 paginiOrganisation Study On Atlus Garment CompanyAravinth Seetharaman100% (1)

- Interview Application FormDocument3 paginiInterview Application Formkaran maheshwariÎncă nu există evaluări

- A Study On The Differences of Entreprene PDFDocument11 paginiA Study On The Differences of Entreprene PDFCarlos Francisco Bitencourt JorgeÎncă nu există evaluări

- Safe Working On Low Voltage Electrical SystemsDocument34 paginiSafe Working On Low Voltage Electrical SystemsSelvn SubramanianÎncă nu există evaluări

- Coca-Cola Femsa Philippines, Inc., (Formerly Known As Coca-Cola Bottlers Phils.,Inc.), V. Jesse L. AlpuertoDocument3 paginiCoca-Cola Femsa Philippines, Inc., (Formerly Known As Coca-Cola Bottlers Phils.,Inc.), V. Jesse L. AlpuertoMark Anthony ReyesÎncă nu există evaluări

- Objectives:: Job EvaluationDocument10 paginiObjectives:: Job Evaluationanusha anuÎncă nu există evaluări

- Statement in Accordance With Rule 5 (2) of Companies (Appointment and Remuneration of Managerial Personnel) Rules 2014Document2 paginiStatement in Accordance With Rule 5 (2) of Companies (Appointment and Remuneration of Managerial Personnel) Rules 2014417 Rachit SinglaÎncă nu există evaluări