Documente Academic

Documente Profesional

Documente Cultură

BBR CMI Tendon Brochure - Optimize

Încărcat de

Wenix008 Oni0 evaluări0% au considerat acest document util (0 voturi)

38 vizualizări3 paginiPost-Tensioning kit

Concrete Construction Article

Titlu original

3. BBR CMI Tendon Brochure_optimize

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPost-Tensioning kit

Concrete Construction Article

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

38 vizualizări3 paginiBBR CMI Tendon Brochure - Optimize

Încărcat de

Wenix008 OniPost-Tensioning kit

Concrete Construction Article

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

Solving reinforcement

congestion problems

Creative detailing and welded wire fabric

combine to speed ductile concrete frame construction

BY ROBERT C. RICHARDSON

VICE PRESIDENT, STRUCTURAL FABRIC DIVISION

DAVIS WALKER CORPORATION

T he ductile moment-resisting space frame concept

makes high-rise construction feasible and safe in

earthquake-prone regions such as California’s San Fran-

cisco Bay area. Ductile concrete frames are designed so

that all structural elements continue to carry loads

without collapse even after heavy seismic forces have

caused yielding of the reinforcing steel and large defor-

mations. The concept works because “plastic” hinges

form at beam/column connections, absorbing energy

and dissipating it through the large deformations.

Beams, columns and their connections must be de-

tailed to meet or exceed American Concrete Institute

(ACI) and Uniform Building Code (UBC) requirements,

and very heavy transverse reinforcement within and

near the joints is required to confine or “basket” the

concrete.

In meeting and implementing the code-imposed de-

tailing requirements for beam/column connections, the

concrete construction industry has faced a continuing

problem: congestion of steel at and near the joints. De-

tailing and placement of steel at these connections have

slowed job progress and contributed to higher costs,

limiting the growth of construction in concrete ductile

frames. Howe ve r, these obstacles can be overcome.

Thoughtful detailing practices helped to ease steel

congestion at beam/column connections on the Pacific

Plaza condominium tower in Emeryville, California and

fabric cages cut labor costs while making it easier to cor-

rectly position the transverse steel. The author’s compa-

ny supplied welded wire fabric reinforcement for this 30-

story building, scheduled for completion in January

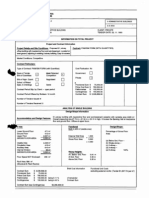

1984. In consultation with the design principals, he as- Figure 1. Connection details showing steps taken to

sisted in preparation of specifications for the fabric and, minimize congestion.

at the same time, learned of their innovative approach to to reduce bottom bar interference. Arrow C indicates

detailing the joints. the bottom of the beam intersecting from the right,

with its bottom bars well below the bottom bars of the

Why concrete was chosen beam normal to it.

Careful investigation preceded the choice of a ductile • Bent bars terminated outside exterior columns—At

concrete frame and the development of details. The ar- perimeter beam/column connections, a 5-inch stub

chitect and the developer preferred the use of a framed of concrete was provided on the outside face, thus

structure because of the space planning flexibility it of- permitting bent beam bars to be terminated outside

fered, but they had a choice between structural steel and the column, away from the region of steel congestion

concrete. Preliminary studies indicated that structural within the joint. Arrow D indicates the concrete stub,

costs for the two alternatives were similar. Howe ve r, by and arrow E shows the position of the bent bars in the

eliminating the need for fireproofing, metal decking and stub.

hung ceilings—expensive add-ons to steel frames—sub-

Figure 2 shows a typical completed beam/column

stantial savings would be realized. The developers chose

joint on the building’s perimeter. One of the top beam

the ductile concrete frame option, and Pacific Park Plaza

bars passes outside the column and the bent ends ter-

is being built for $69.30 per square foot, several dollars

minate in the beam extension.

less than the steel alternative.

Implementation of the seismic design included two Use of welded wire fabric

other decisions: the use of low (9 1/2-foot) floor-to-floor

Two other decisions contributed to the speed, econo-

heights and moderate spans within the tri-winged floor

my, and precision of construction.

plan. These contributed to increased lateral resistance

Welded wire fabric ties and stirrups. The structural en-

and thus helped in achieving cost-effective design which

gineers specified wire fabric, a prefabricated reinforce-

exceeded UBC requirements by 30 to 50 percent (as ne-

ment, because they anticipated that faster field work

cessitated by the stricter requirements of the City of

would result from the easier handling and assembly of

Emeryville).

the fabric shapes for column cages and beam stirrups. In

Detailing procedures to reduce congestion

Three specific detailing procedures shown in Figure 1

were used where applicable in reducing steel congestion

within the beam/column connections:

• Inset beam faces—The faces of the beams were inset 2

inches from the faces of the columns in order to min-

imize rebar interference. Arrow A points to the inset

beam face, with the column face to its left. As a result,

the corner beam bar passes just inside the corner col-

umn bar, as indicated by arrow B.

• Varied beam depths—Beams joining or intersecting at

columns were designed with varying depths in order

Figure 3. At right, stub end of column cage assembly from

three floors below. At left, steel worker tightens threaded

couplers which join the cage assemblies.

addition, the prefabricated reinforcement helped pro-

vide the accuracy of steel placement that they consid-

ered essential. Three-story column cage assemblies were

made up at the fabricator’s plant. Column rebars had

Figure 2. Typical completed beam/column joint on building threaded couplers at the ends to join the assemblies,

perimeter. Note that the top beam bar at the left passes which were lifted into place by crane. Beam bars were

outside the column steel and also that the bent end then threaded through the intersection at each floor,

terminates in the beam extension. with the bottom cage of beam stirrups already in place.

Placing of the top cage completed the operation.

Time savings as a result of these procedures were im-

p re s s i ve: Column cages were placed in about half the

time site-assembled cages would have required and

placement of the preshaped stirrup cages was done in

only one-fifth the time needed for individual stirrups.

75,000 psi fabric column ties specified. A final detail-

ing decision which contributed to the reduction of steel

congestion and to ease of handling was specification of

a high strength (75,000 psi yield) welded wire fabric

specifically for the column ties. Based upon their own re-

search and structural analysis, the structural engineers

had made a case for an 85,000 psi fabric. Although at

variance with ACI, this would have satisfied both UBC

and City of Emeryville requirements. But the author ad-

vised use of the 75,000 psi product because ready avail-

ability and assurance of steady, on-time delivery were

needed to meet the requirements of a 13-month sched-

ule for frame construction. (85,000 psi fabric, made of Figure 4. After threading beam bars through the

intersection, worker places top cage, capping the beam

micro-alloy steel, is not yet available on a broad, assured,

stirrup in a single operation.

steady supply basis.)

Ties in the beam column joints were spaced at 21⁄2-

inch centers. Engineer T. Y. Lin was only allowed to con-

sider 60,000 psi yield strength bars for ties used as shear

reinforcement in the joints. For ties between the joints, major reinforcing steel, an entire 23,000 square feet of

howe ve r, the drawings gave the option of substituting floor was completed every 7 working days. Right on

D20 wires for #5 bars and D16 wires for #4 bars, at the schedule.

same spacings. Requirements for substitution of struc-

tural fabric for reinforcing bars in the beam stirrups were Credits

similar. This resulted in a significant weight reduction of Developer: Emery Associates and Penn Mutual Life, a joint

materials, lower field labor costs and faster placing. venture offered by Pacific Union Company

Project meets schedule Architect: Whisler-Patri

Application of these innovations worked well. Because Structural Engineer: T. Y. Lin International

of reduced congestion and prefabrication of much of the General Contractor: Lathrop/Kiewit, a joint venture

PUBLICATION #C830669

Copyright © 1983, The Aberdeen Group

All rights reserved

S-ar putea să vă placă și

- Concrete Construction Article PDF - Solving Reinforcement Congestion ProblemsDocument3 paginiConcrete Construction Article PDF - Solving Reinforcement Congestion ProblemsridminjÎncă nu există evaluări

- Steel and Concrete Composite Design For Long-Span BridgesDocument6 paginiSteel and Concrete Composite Design For Long-Span BridgesamigotÎncă nu există evaluări

- The Design of The Ruck-A-Chucky BridgeDocument7 paginiThe Design of The Ruck-A-Chucky BridgeAbdelaziz AbdelazizÎncă nu există evaluări

- JL-88-September-October Precast Prestressed Concrete Horizontally Curved Bridge BeamsDocument46 paginiJL-88-September-October Precast Prestressed Concrete Horizontally Curved Bridge BeamsRam RakshithÎncă nu există evaluări

- Precast Prestressed Concrete Horizontally Curved Bridge BeamsDocument42 paginiPrecast Prestressed Concrete Horizontally Curved Bridge BeamsEdward van Martino100% (1)

- Design and Analysis of Heavily Loaded RC Link BeamDocument17 paginiDesign and Analysis of Heavily Loaded RC Link BeamWasin WaiyasusriÎncă nu există evaluări

- Precast Prestressed Concrete Horizontally Curved Bridge BeamsDocument42 paginiPrecast Prestressed Concrete Horizontally Curved Bridge BeamsYasser AlghrafyÎncă nu există evaluări

- ACI STRDocument11 paginiACI STRYan Naung KoÎncă nu există evaluări

- Steel Structures in The New MillenniumDocument16 paginiSteel Structures in The New MillenniumChris FindlayÎncă nu există evaluări

- The Dogbone Connection: Part IIDocument9 paginiThe Dogbone Connection: Part IIAndreea CrisanÎncă nu există evaluări

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocument27 paginiComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirÎncă nu există evaluări

- Applications of Sustainable Post-Tensioned Concrete SlabsDocument12 paginiApplications of Sustainable Post-Tensioned Concrete Slabsmohamed.s.elsayedÎncă nu există evaluări

- Construction of Brazil's First Cable Stayed Stress-Laminated Timber FootbridgeDocument4 paginiConstruction of Brazil's First Cable Stayed Stress-Laminated Timber Footbridgejfunltd1Încă nu există evaluări

- Composite Floor System With CFS Trussed Beams ConcDocument9 paginiComposite Floor System With CFS Trussed Beams ConcmulualemÎncă nu există evaluări

- Engineering Structures: Zhihua Chen, Xiangyuan Niu, Jiadi Liu, Kashan Khan, Yuecong LiuDocument15 paginiEngineering Structures: Zhihua Chen, Xiangyuan Niu, Jiadi Liu, Kashan Khan, Yuecong LiuBayuAgungGilangWibowoÎncă nu există evaluări

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDe la EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsÎncă nu există evaluări

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 paginiCE 416 Prestressed Concrete Sessional (Lab Manual)RahulKikaniÎncă nu există evaluări

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 paginiCE 416 Prestressed Concrete Sessional (Lab Manual)julesÎncă nu există evaluări

- Repair and Retrofit of Non-Ductile Reinforced Concrete FramesDocument10 paginiRepair and Retrofit of Non-Ductile Reinforced Concrete FramesmanalÎncă nu există evaluări

- Smeared Crack Models of RC Beams With Externally Bonded CFRP PlatesDocument8 paginiSmeared Crack Models of RC Beams With Externally Bonded CFRP Platessmadireddy1Încă nu există evaluări

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDocument9 paginiNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALÎncă nu există evaluări

- Journal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia MonacoDocument15 paginiJournal of Constructional Steel Research: Piero Colajanni, Lidia La Mendola, Alessia Monacosuran_qutbiÎncă nu există evaluări

- The Design and Construction of Concrete-Filled Steel Tube Column FramesDocument12 paginiThe Design and Construction of Concrete-Filled Steel Tube Column FramesrohitÎncă nu există evaluări

- FRPC Reinforced Concrete Beam-Column Joints Under Cyclic ExcitationDocument15 paginiFRPC Reinforced Concrete Beam-Column Joints Under Cyclic ExcitationMagdy BakryÎncă nu există evaluări

- Columns and PipesDocument15 paginiColumns and Pipessotiris100% (2)

- 20-0005 Alawneh MA22Document21 pagini20-0005 Alawneh MA22Nicholas FeatherstonÎncă nu există evaluări

- An in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsDocument7 paginiAn in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsvipinÎncă nu există evaluări

- Hybrid Design Reduces CostsDocument5 paginiHybrid Design Reduces Costsericpardo59Încă nu există evaluări

- Behavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckDocument10 paginiBehavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckIoannis BazosÎncă nu există evaluări

- Construction Methods in Industrialized BuildingsDocument37 paginiConstruction Methods in Industrialized BuildingsJoseph EzekielÎncă nu există evaluări

- Practical Shear Reinforcement For Concrete Flat Slabs - tcm45-341902Document2 paginiPractical Shear Reinforcement For Concrete Flat Slabs - tcm45-341902Deana WhiteÎncă nu există evaluări

- Materials and Jacketing TechniqueDocument5 paginiMaterials and Jacketing TechniqueHoussam Al MoussawiÎncă nu există evaluări

- Composite Steel JoistsDocument10 paginiComposite Steel Joistsv2299100% (1)

- Short Proposal Finite ElementDocument9 paginiShort Proposal Finite ElementMuhammad Ilham ZulkipllyÎncă nu există evaluări

- Chen Et Al.Document12 paginiChen Et Al.fsimaÎncă nu există evaluări

- CFSEI Tech Note X Bracing L001-09Document8 paginiCFSEI Tech Note X Bracing L001-09Jane EyreÎncă nu există evaluări

- Experimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024Document13 paginiExperimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024KRISHNA MURARIÎncă nu există evaluări

- Materials 13 05804 v2Document16 paginiMaterials 13 05804 v2deviationzÎncă nu există evaluări

- Sarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresDocument17 paginiSarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresMais Maher AldwaikÎncă nu există evaluări

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 paginiSteel-Concrete Composite Coupling Beams - Behavior and DesigncyrusnasiraiÎncă nu există evaluări

- Kamal - 2015 - Encased Beam With Variable Upper SteelDocument8 paginiKamal - 2015 - Encased Beam With Variable Upper SteelRene Rodrigues O. SilvaÎncă nu există evaluări

- Reinforced: Redistribution of Design Bending Moments in Concrete BeamsDocument12 paginiReinforced: Redistribution of Design Bending Moments in Concrete BeamsRizwan SaleheenÎncă nu există evaluări

- 1 s2.0 S0143974X19307886 MainDocument19 pagini1 s2.0 S0143974X19307886 MainSiva GuruÎncă nu există evaluări

- Sunder CFT Column ReportDocument33 paginiSunder CFT Column Reportsunder kumawatÎncă nu există evaluări

- Seismic Performance of Post-Tensioned Precast ConcDocument9 paginiSeismic Performance of Post-Tensioned Precast ConcAbderrahmane SaidÎncă nu există evaluări

- Understanding SJ PDFDocument4 paginiUnderstanding SJ PDFTony StarkÎncă nu există evaluări

- Code Tiltup PrecastDocument47 paginiCode Tiltup Precastkorosh75Încă nu există evaluări

- Constructability of Embedded Steel Plates in CIP ConcreteDocument7 paginiConstructability of Embedded Steel Plates in CIP ConcreteimranÎncă nu există evaluări

- Learning From A Structural FailureDocument3 paginiLearning From A Structural FailureangelbarbaÎncă nu există evaluări

- Structural Behavior of Concrete Encased Steel Beams: Ain Shams Engineering Journal January 2005Document14 paginiStructural Behavior of Concrete Encased Steel Beams: Ain Shams Engineering Journal January 2005LeonardoMadeira11Încă nu există evaluări

- Dundu 2011Document15 paginiDundu 2011fahmi aballiÎncă nu există evaluări

- Link Slab Deck JointsDocument20 paginiLink Slab Deck JointsAnton Husen PurboyoÎncă nu există evaluări

- Husana, Thessaly Aubrey S. - Bt115 - Research No. 2bDocument11 paginiHusana, Thessaly Aubrey S. - Bt115 - Research No. 2bThessaly HusanaÎncă nu există evaluări

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2Document36 paginiSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2m7j7a7Încă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- A Guide to Some of the Equations used in Constructing a Suspension BridgeDe la EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeÎncă nu există evaluări

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDe la EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyÎncă nu există evaluări

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910De la EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Încă nu există evaluări

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDe la EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesEvaluare: 4.5 din 5 stele4.5/5 (16)

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173De la EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173Încă nu există evaluări

- Rebar - Wikipedia, The Free EncyclopediaDocument12 paginiRebar - Wikipedia, The Free EncyclopediaBaguma Grace GariyoÎncă nu există evaluări

- Special Application of Asphaltic Concrete For Dam Water Barrier ConstructionDocument10 paginiSpecial Application of Asphaltic Concrete For Dam Water Barrier ConstructionAlberto GaxiolaÎncă nu există evaluări

- Seismic Design of Low-Rise Steel Frames With BucklDocument10 paginiSeismic Design of Low-Rise Steel Frames With BucklAlex MolinaÎncă nu există evaluări

- Buckling: From Wikipedia, The Free EncyclopediaDocument6 paginiBuckling: From Wikipedia, The Free EncyclopediaPretheesh Paul CÎncă nu există evaluări

- Lecture Reading 6: Design Problem of One-Way Slab: Institute of Architecture and Fine ArtsDocument9 paginiLecture Reading 6: Design Problem of One-Way Slab: Institute of Architecture and Fine ArtsKim CalaguiÎncă nu există evaluări

- Foundations and Basements: Building Technology (EG 626 CE)Document35 paginiFoundations and Basements: Building Technology (EG 626 CE)Romharsh OliÎncă nu există evaluări

- Siwestechnicalreport PDFDocument68 paginiSiwestechnicalreport PDFishaq kazeem100% (1)

- Concrete The Reinforced Design Manual PDFDocument9 paginiConcrete The Reinforced Design Manual PDFsansarep20% (5)

- Reodata41 PDFDocument68 paginiReodata41 PDFMunzuara AktherÎncă nu există evaluări

- Lat Pile BDocument20 paginiLat Pile BSabrina ImloulÎncă nu există evaluări

- Retrofitting of Heritage and Historical BuildingsDocument8 paginiRetrofitting of Heritage and Historical BuildingsAyushDwivediÎncă nu există evaluări

- Equivalents of Carbon Steel QualitiesDocument7 paginiEquivalents of Carbon Steel QualitiesIhab El AghouryÎncă nu există evaluări

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 paginăConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelÎncă nu există evaluări

- Steel Framing For Service YardDocument1 paginăSteel Framing For Service YardNana BarimaÎncă nu există evaluări

- Article Marine Pile Repairs by Concrete Encasement PDFDocument13 paginiArticle Marine Pile Repairs by Concrete Encasement PDFChen Wai Peng100% (1)

- 8211 - S-000-1310-001-01 Yel Spec WindDocument84 pagini8211 - S-000-1310-001-01 Yel Spec WindWasi SamiÎncă nu există evaluări

- LintelsDocument3 paginiLintelsSA023Încă nu există evaluări

- Web Buckling and CripplingDocument3 paginiWeb Buckling and CripplingManoj Nagarkond100% (2)

- Design For Torsion For Steel StructureDocument32 paginiDesign For Torsion For Steel StructurePrantik Adhar Samanta100% (1)

- Equipment Schedule HVACDocument7 paginiEquipment Schedule HVACHussainShabbirÎncă nu există evaluări

- P Delta AnalysisDocument4 paginiP Delta AnalysisAnonymous dxsNnL6S8hÎncă nu există evaluări

- Construction Notes: Schedule of ColumnDocument1 paginăConstruction Notes: Schedule of ColumnAeron AcioÎncă nu există evaluări

- Load Considerations (From National Structural Code of The Philippines 2010, 6Document3 paginiLoad Considerations (From National Structural Code of The Philippines 2010, 6kleinmagdaraogÎncă nu există evaluări

- Proposed 5 Storey Office BuildingDocument4 paginiProposed 5 Storey Office BuildingmrlobboÎncă nu există evaluări

- CE 415 Columns Part 1Document66 paginiCE 415 Columns Part 1bilalÎncă nu există evaluări

- Project Formwork and Concrete Costing TablesDocument3 paginiProject Formwork and Concrete Costing TablesAizuddinÎncă nu există evaluări

- Chapter 8 PlastringDocument30 paginiChapter 8 PlastringIbrahim Mostazid0% (1)

- Build 134 36 Design Right Roof Bracing PDFDocument3 paginiBuild 134 36 Design Right Roof Bracing PDFTuroyÎncă nu există evaluări

- Table 7 3 Available Shear Strength For Slip Critical ConnectionsDocument2 paginiTable 7 3 Available Shear Strength For Slip Critical Connectionsjhess QuevadaÎncă nu există evaluări

- PROJECT MANAGEMENT (Rowhouse)Document78 paginiPROJECT MANAGEMENT (Rowhouse)Marke Paraguya100% (1)