Documente Academic

Documente Profesional

Documente Cultură

Final Book 1

Încărcat de

Abul Khaier LipuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Final Book 1

Încărcat de

Abul Khaier LipuDrepturi de autor:

Formate disponibile

AHSANULLAH UNIVERSITY OF SCIENCE AND

TECHNOLOGY

DEPARTMENT OF TEXTILE ENGINEERING

Course No : Tex 500

Course Title : Industrial Training

Session : Fall 2015

Industrial Training Report On

Fariha Knit Tex Ltd.

Submitted by

Name ID No.

S.A. SHADMAN 12.01.06.125

HOSSAIN AL FUAD 12.01.06.133

SHAKIL MAHMUD 12.01.06.143

Supervised by

Mr. A.N.M Masudur Rahman

Assistant Professor

Department of Textile Engineering

October, 2016

ACKNOWLEDGEMENT

First of all, we would like to express our sincerest gratitude to the almighty Allah for enabling

us to complete the industrial training successfully.

We offer heartiest thanks to our honorable supervisor Mr. A.N.M Masudur Rahman,

Assistant Professor, Department of Textile Engineering of Ahsanullah University of Science

and Technology for his proper guidance, supervision, encouragement and valuable

suggestions during the period of our industrial training.

We would like to give our special thanks to Prof. Dr. Ahmed Jalal Uddin, Head of the

Department of Textile Engineering, for his support and official permission for internship at

Fariha Knit Tex Ltd.

Our deepest appreciation goes to Mr. Alamgir Kabir, Assistant Manager, Knitting

Department of Fariha Knit Tex Ltd. for his enormous support and guidance.

We would also like to thank to the authority of Fariha Knit Tex Ltd. for giving us the

opportunity to complete our industrial training. Thanks to all the technicians, employees,

stuffs of knitting department for helping us to get proper information during training.

Intern report on Fariha Knit Tex Ltd. 1

Table of Contents

CHAPTER 1: INTRODUCTION

1.1 Introduction:..................................................................................................................................2

1.2 Objectives:.......................................................................................................................................2

CHAPTER 2: GENERAL INFORMATION ABOUT THE MILL

2.1 About The Company:.......................................................................................................................4

2.2 General Information About The Factory:.........................................................................................5

2.3 Address:...........................................................................................................................................6

2.3.1 Factory Location on Google Map:.................................................................................................7

2.4 Facilities:..........................................................................................................................................8

2.5 Sister Concern of Asrotex Group:.....................................................................................................8

2.6 Asrotex Knit Divisions Business Turnover (USD):..............................................................................8

2.7 Mission:...........................................................................................................................................9

2.8 Vision:..............................................................................................................................................9

2.9 Future plan:.....................................................................................................................................9

2.10 Knitting Organogram:...................................................................................................................11

2.11 Layout Plan:.................................................................................................................................12

2.11.1 Layout Plan of Fariha Knit Tex Ltd.(Knitting floor):....................................................................12

CHAPTER 3: RAW MATERIAL

3.1 Type of raw material:.....................................................................................................................15

3.2 Yarn Sources:.................................................................................................................................16

CHAPTER 4: DESCRIPTION OF THE MACHINE AND MACHINE PARTS

4.1 Knitting Machine of Fariha Knit Tex Ltd:.........................................................................................21

4.1.1 Circular knitting machine:...........................................................................................................21

4.1.2 Flat bed knitting machine:..........................................................................................................22

4.2 Knitting Machine Pictures:.............................................................................................................23

4.3 Different parts of circular knitting machine:..................................................................................28

4.4 Different Parts of Flatbed Knitting Machine:..................................................................................34

Intern report on Fariha Knit Tex Ltd. 2

4.5 Specification of Needle, Sinker and Needle oil:.............................................................................36

CHAPTER 5: PRODUCT MIX AND THEIR SEQUENCE OF OPERATION

5.1 Production parameters:.................................................................................................................38

5.2 Products of Knitting Floor:.............................................................................................................38

5.3 Yarn count selection:.....................................................................................................................39

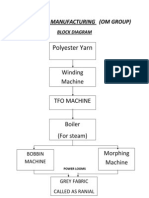

5.4 Knitting process flow chart:...........................................................................................................40

5.6 Fabric specification:.......................................................................................................................41

5.7 Methods of Increasing Production:................................................................................................41

5.8 Sequence of Operation:.................................................................................................................42

CHAPTER 6: PRODUCTION AND EFFICIENCY CALCULATION

6.1 Formula for production calculation and efficiency calculation:.....................................................47

6.1.1 Calculation for Single Jersey Fabric:............................................................................................48

6.1.2 Calculation for Lycra Single Jersey Fabric:...................................................................................49

6.1.3 Calculation for rib machine (1×1 rib fabric):...............................................................................50

6.1.4 Calculation for rib machine (2×1 rib fabric):...............................................................................51

6.1.4 Calculation for Interlock:.............................................................................................................52

6.1.4 Production for Fleece (3 Thread):...............................................................................................53

6.1.5 Calculation Efficiency of machine:..............................................................................................54

CHAPTER 7: QUALITY ASSURANCE

7.1 Object of quality control:...............................................................................................................57

7.2 Online Quality Control:..................................................................................................................57

7.3 Off Line Quality Control:................................................................................................................57

7.4 Fabric Inspection system:...............................................................................................................58

7.5 Total defect points per 100 square meter are then calculated:.....................................................59

7.6 Grading system:.............................................................................................................................59

7.7 List of equipments for quality control:...........................................................................................60

7.8 Physical Lab Equipment’s:..............................................................................................................62

7.6 Fabric defects:................................................................................................................................64

CHAPTER 8: MAINTENANCE

8.1 Types of maintenance:...................................................................................................................70

Intern report on Fariha Knit Tex Ltd. 3

8.1.1 Preventive maintenance:............................................................................................................70

8.1.2 Routine maintenance:.................................................................................................................70

8.2 Routine maintenance task followed in the factory:.......................................................................71

8.3 Servicing Procedures of Circular Knitting Machine:.......................................................................72

8.4 Maintenance tools and equipment:...............................................................................................73

CHAPTER 9:UTILITY

9.1 Utility:............................................................................................................................................77

9.2 Source of utility:.............................................................................................................................77

9.3 Machine for utility services:...........................................................................................................77

9.4 Air compressor:..............................................................................................................................77

9.5 Power generator:...........................................................................................................................79

CHAPTER 10: MARKETING INFORMATION

9.6 Utility costs:...................................................................................................................................80

10.1 Knitting Charge for Various Structure:.........................................................................................82

10.2 Buyer Information:.......................................................................................................................83

CHAPTER 11: CONCLUDING PART

11.1 Limitation of our training and report:..........................................................................................85

11.2 Suggestions:.................................................................................................................................85

11.3 Conclusion:..................................................................................................................................85

Intern report on Fariha Knit Tex Ltd. 4

CHAPTER 1:

INTRODUCTION

Intern report on Fariha Knit Tex Ltd. 1

1.1 Introduction:

It is very important for an engineer to have practical knowledge along with theories.

Industrial training is the only way to acquire practical ideas and experiences for a textile

student. Practical knowledge is enriched through the industrial training.

Industrial training is one of the most important parts of engineering and technical education.

The industrial training is the process, which builds understanding, skills and attitude of the

performer, which improves our knowledge in boosting productivity and services. University

education provides us vast theoretical knowledge, in spite of all these theoretical

knowledge, industrial training helps us to be familiar with technical support of modern

machinery, skills about various processing stages in the real field.

Industrial training is essential part of four years B.Sc. program in Textile Engineering to make

an engineer technically sound in this field. In Fariha Knit Tex Ltd. (Asrotex Group) we have

completed 08 (eight) weeks long industrial training. Such training minimized the gap

between theoretical and practical knowledge.

1.2 Objectives:

1. To experience and understand real life situations in industrial organizations and their

related environments.

2. To acquire practical knowledge about the production process of knitting.

3. To gain experience for finding the optimal solution in critical situation.

4. To develop and enhance professional awareness & communication skills.

5. To be familiar with the practical working procedure in production.

Intern report on Fariha Knit Tex Ltd. 2

CHAPETR 2:

GENERAL INFORMATION ABOUT

THE MILL

Intern report on Fariha Knit Tex Ltd. 3

2.1 About The Company:

Fariha Knit Tex Ltd (FKTL) is the largest Composite Knit Apparel and Textile manufacturing

business unit of Asrotex Group. It started its journey in 1997. FKTL is comprised of Knitting,

Dyeing, Cutting, Sewing, Finishing, Printing and accessories sections. It has the state of art

vertically integrated garments manufacturing facility which ensures one stop service to the

buyers. The products of FKTL range from mens wear, ladies wear and kids wear. These are

manufactured using technologically efficient machinery imported from USA, Europe and

Asian countries. Its mission is to produce the latest design; quality knit fabrics and apparels

for international markets. It is one of the few elite private sector business group, which

contributed wealth as well as welfare to the struggling economy of Bangladesh.

FKTL has team of skilled and dedicated technocrats backed by adequate number of modern

efficient machinery and equipment’s imported from USA, Europe and Asian countries to

match international standards of all kinds of knitwear products.

Fig : Fariha Knit Tex Ltd.

Intern report on Fariha Knit Tex Ltd. 4

2.2 General Information About The Factory:

Name of the composite plant Fariha Knit Tex Ltd.

Type 100% Export Oriented Knit Composite Garments

Manufacturing Industry

Year of establishment 1997

Name of the chairman Md. Mamun Bhuiyan

Status Private Limited

Ownership Asrotex Group

Production area(knitting) 7,00,000 sq. f

Market/destination Europe, Asia, U.S.A, Australia

Production capacity(knitting) 7000 ton yearly (open and tubular form)

Total manpower 7,317

Major customer H&M (Sweden) Next (United Kingdom)

NKD (Germany) Matalan (Unite

Kingdom)

Springfield (Spain) Splash (UAE)

Walmart (United States) Siplec (France)

Kmart (Australia) Takko Fashion

(Germany)

Membership and certification Member of BGMEA, BKMEA, BTMEA, EPB & the

Metropolitan Chamber of Commerce. They are an

approved supplier of BSCI, WRAP, OEKO-TEX,

SEDEX, ISO 9001 -2008, GOTS.

2.3 Address:

Intern report on Fariha Knit Tex Ltd. 5

Factory Address : Baroibogh, Enayet Nagar, Fatullah Narayanganj-1400,

Bangladesh.

Telephone : +88 02 7670381

Fax : +88 02 7670380

Web Address : http://asrotexgroup.com

Corporate Office : House 85, Road 4, Block B Banani, Dhaka 1213 Bangladesh.

Telephone : +88 (02) 883-5670-1

Fax : +88 (02) 989-1921

E-Mail : info@asrotex.com

Web Address : www.asrotexgroup.com

USA Office : 1407 Broadway, Suite 1402 NYC, NY 10018

Telephone : +1 (929) 278-9042

E-mail : info.usa@asrotex.com

Web Address : www.asrotexgroup.com

2.3.1 Factory Location on Google Map:

Intern report on Fariha Knit Tex Ltd. 6

Figure: Site location of FKTL factory office from AUST

Fig: Earth view of FKTL factory office

2.4 Facilities:

Knitting

Dyeing

Intern report on Fariha Knit Tex Ltd. 7

Finishing

Sewing

Printing (all over print and chest print)

Embroidery

Trims & packaging

Washing

2.5 Sister Concern of Asrotex Group:

Asrotex Ltd.

Rimshod tex Ltd.

Asro fashion Ltd.

Fariha Knit Tex Ltd.

Rich apparels Ltd.

Ruma industries Ltd.

Logic software Ltd.

Fariha dyechem Ltd.

Standard holdings Ltd.

Fariha trims and accessories Ltd.

Fibre 2 fashion Bd Ltd.

2.6 Asrotex Knit Divisions Business Turnover (USD):

Table: List of Asrotex Group Business Turnover

facilities 2010-2011 2011-2012 2012-2013 2013-2014 2014-2015

Asrotex $20,050,797 $19,967,639 $21,369,181 $24,371,779 $27,212,286

Asrotex Ltd $20,850,182 $23,664,750 $18,547,389 $19,603,636 $23,311,026

Fariha Knit $31,739,007 $36,236,375 $40,200,917 $62,167,052 $61,289,974

Tex Ltd

Total $72,639,986 $79,868,764 $80,117,486 $106,142,468 $111,813,286

Intern report on Fariha Knit Tex Ltd. 8

Figure: Yearly Growth of Asrotex Group

2.7 Mission:

The mission of Asrotex Group is to strengthen relationships around the world that will allow

Asrotex Group to offer competitive advantages in the global market. At Asrotex Group their

unmatched pursuit to execute products and services of the highest quality for their valued

customer is their ultimate mission.

2.8 Vision:

The vision of Asrotex Group is to be a leader in the global textile and apparel industry. They

want to lead the way going into the near future by strengthening the business units, by

continuous investments, and through devotion to the development of their most valuable

resource. They feel they are on the fore front of the apparel industry.

2.9 Future plan:

In addition to further strengthening their expertise and competencies in the RMG sector,

ASROTEX Group has plans for diversification in various industries where human benevolence

will be the prime focus. The vision of their management brought them here today, and they

are not coming too far, they’ve just arrived.

Intern report on Fariha Knit Tex Ltd. 9

They are cordially welcoming companies around the globe to be their development partner in

Agribusiness, Automobile, Ceramic, Distribution, Electronics, Food, Healthcare, Leather & Leather

Goods, Light Engineering, Medical Equipment, Pharmaceuticals, Plastic, Power, Professional

development, Real Estate, Renewable Energy, Ship Building, Telecommunication, Tourism,

Transportation or any other prospective sectors that will cater the demand of a massive population

of 160 million plus people. They are targeting to achieve $500 Million in 2021.

Intern report on Fariha Knit Tex Ltd. 10

2.10 Knitting Organogram:

AGM

Manager

Assistant Manager

Sr. Executive

Production Marketing

Officer

Sr. fitter Q.C Incharge Production officer

Fitter

Quality Controller Asst. production

Asst. Fitter Officer

Q.C inspector

Shift Incharge

Helper

Supervisor

Cleaner Operator

Asst. operator

Helper

Intern report on Fariha Knit Tex Ltd. 11

2.11 Layout Plan

2.11.1 Layout Plan of Fariha Knit Tex Ltd.(Knitting floor):

Fig : Layout plan of knitting floor-1

Intern report on Fariha Knit Tex Ltd. 12

Fig : Layout plan of knitting floor-2

Intern report on Fariha Knit Tex Ltd. 13

CHAPTER 3:

RAW MATERIAL

Intern report on Fariha Knit Tex Ltd. 14

Raw material is an important substance in any production oriented textile industry. It plays a

vital role in continuous production and for high quality fabric. Fariha Knit Tex Ltd. takes yarn

as its raw materials for its initial production of knitted fabrics to make garments.

3.1 Type of raw material:

Here mainly cotton, polyester and spandex yarn are used according to the requirements of

buyer. Some of the raw material used in Fariha Knit Tex Ltd are as follows:

1. Carded yarn

2. Combed yarn

3. CVC yarn (60% cotton, 40% polyester) & (80% cotton, 20% polyester)

4. PC yarn (65% polyester, 35% cotton)

5. 100% Polyester yarn

6. Mélange yarn

Grey mélange

(95% cotton, 5% viscose)

(90% cotton, 10% viscose)

(85% cotton, 15% viscose)

Ecru mélange (1-2% viscose, 99-98 % cotton)

7. Slub yarn

8. Spandex yarn

9. 100% viscose yarn

Intern report on Fariha Knit Tex Ltd. 15

3.2 Yarn Sources:

Spandex yarn used in Fariha Knit Tex Ltd:

S/L no Brand name Origin Count

1 Texlon China 40D

2 Ceora Korea 20D, 30D, 40D

Cotton yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count(Ne)

1 Trident India 30, 34

2 Purbani Bangladesh 10

3 Tafrid Bangladesh 32, 30

4 Rahamat Bangladesh 50, 30, 40,

5 Ayyanar India 40

6 BSB Bangladesh 30

7 R.S.W.M India 24, 30, 32

8 PT Ramgloria Shakti India 34

9 Akij Bangladesh 10, 20

10 S.M Bangladesh 28, 40

11 Mosharraf Bangladesh 30, 34

PC yarn used in Fariha Knit Tex Ltd:

Intern report on Fariha Knit Tex Ltd. 16

S/L no Source of yarn Origin Count(Ne)

1. N.Z Bangladesh 30

2. Mondol Bangladesh 12, 26, 34

3. Jamuna Bangladesh 24, 26

Mélange yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count(Ne)

1 Huafu China 26

2 Enayetpur Bangladesh 20,28,30

3 Thermax Bangladesh 28

4 Jamuna Bangladesh 24,30,34

5 N.Z Bangladesh 24

CVC yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count(Ne)

1 Akij Bangladesh 30, 34

2 Jamuna Bangladesh 24, 28, 30

3 S.M Bangladesh 20

4 Ha-meem Bangladesh 28, 32

5 Delta Bangladesh 34

6 Al-razee Bangladesh 20, 30

7 N.R.G India 30

Slub yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count(Ne)

1. Keya Bangladesh 28

2. Delta Bangladesh 22

Intern report on Fariha Knit Tex Ltd. 17

100% polyester yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count

1 Pt. sunsan India 75D

Viscose yarn used in Fariha Knit Tex Ltd:

S/L no Source of yarn Origin Count(Ne)

1 Pt. indo liberty Indonesia 30

Intern report on Fariha Knit Tex Ltd. 18

CHAPTER 4:

DESCRIPTION OF THE MACHINE AND

MACHINE PARTS

Intern report on Fariha Knit Tex Ltd. 19

4.1 Knitting Machine of Fariha Knit Tex Ltd:

Fariha Knit Tex Ltd knitting section is divided into two segments. One consisting of 76 circular

knitting machines and other contains 18 Flat Bed (v-bed) knitting machines. Specification of

machines are given below:

4.1.1 Circular knitting machine:

S/L Brand Name Country Machine Type of No of Machine

no of Origin Dia(inch) Machine Feeders Qty

and Gauge

1 Jiun Long Taiwan 38, 20 Single jersey 114 2

2 Ta Yu Taiwan 38, 20 Single jersey 114 7

3 Ta Yu Taiwan 40, 20 Single jersey 120 6

4 Lisky Taiwan 42, 24 Single jersey 126 1

5 Lisky Taiwan 44, 24 Single jersey 132 1

6 Zentex Singapore 30, 20 Single jersey 90 4

7 Jiun Long Taiwan 30, 20 Single jersey 30 2

8 Jiun Long Taiwan 36, 20 Single jersey 108 2

9 Jiun Long Taiwan 34, 20 Single jersey 102 2

10 Fukahara Japan 22, 20 Single jersey 88 1

11 Ta Yu Taiwan 24, 20 Single jersey 72 2

12 Fukahara Japan 26, 24 Single jersey 104 1

13 Fukahara Japan 22, 24 Single jersey 70 2

14 Ta Yu Taiwan 30, 25 Double jersey 90 4

15 Ta Yu Taiwan 28, 20 Double jersey 84 1

16 Ta Yu Taiwan 26, 20 Double jersey 78 2

Intern report on Fariha Knit Tex Ltd. 20

S/L Country Machine Type of No of Machine

no Brand Name of Origin Dia(inch) Machine Feeders Qty

and Gauge

17 Jiun Long Taiwan 32, 20 Double jersey 96 1

18 Jiun Long Taiwan 32, 20 Double jersey 96 3

19 Jiun Long Taiwan 42, 18 Double jersey 126 1

20 Lisky Taiwan 42, 18 Double jersey 88 3

21 Lisky Taiwan 38, 18 Double jersey 80 2

22 Lisky Taiwan 38, 9 Double jersey 80 1

23 Ta Yu Taiwan 32, 18 Double jersey 68 2

24 Ta China 42, 24 Single jersey 126 7

Yu(Xiamen)

25 Ta China 40, 24 Single jersey 120 4

Yu(Xiamen)

26 Ta China 36, 24 Single jersey 108 6

Yu(Xiamen)

27 Ta China 34, 24 Single jersey 102 6

Yu(Xiamen)

28 Pailung Taiwan 36, 24 Auto stripe 50 2

single jersey

29 Pailung Taiwan 34, 24 Auto stripe 48 2

single jersey

30 Ta Yu Taiwan 34, 28 Auto stripe 69 1

single jersey

31 Pailung Taiwan 30, 24 Auto stripe 42 2

single jersey

4.1.2 Flat bed knitting machine:

All the flat bed knitting machines are capable for producing collar, cuff and some rib fabric.

S/L Brand Name Country of M/C width No of Machine

No origin and gauge feeder quantity

1 Shima Seiki Japan 60″ × 14G 6 10

2 Jy- Leh Taiwan 80″ × 14G 4 8

4.2 Knitting Machine Pictures:

Intern report on Fariha Knit Tex Ltd. 21

Figure: Single Jersey Circular Knitting Machine (Ta Yu)

Intern report on Fariha Knit Tex Ltd. 22

Figure: Single Jersey Circular Knitting Machine (Jiun Long)

Intern report on Fariha Knit Tex Ltd. 23

Fig: Double Jersey Circulasr Knitting Machine (Ta Yu)

Intern report on Fariha Knit Tex Ltd. 24

Figure: Auto Stripe Single Jersey Circular Knitting Machine (PAILUNG)

Intern report on Fariha Knit Tex Ltd. 25

Figure : Flat bed Knitting Machine (Shima Seiki)

Figure : Flat bed Knitting Machine (Shima Seiki)

Intern report on Fariha Knit Tex Ltd. 26

4.3 Different parts of circular knitting machine:

1. Name: Needle

The needle is the primary knitting element. Needle is a

thin metal bar.

Function:

It is used to produce loop and thus produce fabric.

Fig: Needle

2. Name: Sinker

The sinker is the second primary knitting element. It is

a thin metal plate. It may perform one or more of the

following functions depending upon machines knitting

action, consequent sinker shape and movement.

Function:

Holding down Fig: Sinker for Auto striper

Knocking over

Loop formation

Fig: Sinker for Single Jersey Fig: Sinker for Fleece

3. Name: Knitting Cam

Intern report on Fariha Knit Tex Ltd. 27

Cam is the devices which convert rotary machine drive in to a

suitable reciprocation action for the needle.

Knit Cam:

Function:

To produce knit loop

Fig: Knit Cam

Tuck Cam:

Function:

To produce tuck loop

Fig: Tuck Cam

Miss Cam:

Function:

To produce miss loop

Fig: Knit Cam

4. Name: Cam Box

Intern report on Fariha Knit Tex Ltd. 28

Function:

It is used to hold the cam according to the

fabric design.

Fig: Cam Box

5. Name: Oiling or lubricating system

Function:

Lubrication system is used to reduce the heat generation and friction between metal

parts.

Fig: Lubrication system (Uniwave)

Technical data for Uniwave lubrication system:

1. 20 lubrication points.

2. Two, low-flow connections.

3. Compact oil reservoir.

4. Long, reliable service life guaranteed.

6. Name: Air Gun

Intern report on Fariha Knit Tex Ltd. 29

Function:

It is used to feed the yarn into the feeding device

through the yarn carrier. Sometimes it used to

clean external dust from the knitting zone and also

for cleaning machine parts.

Fig: Air Gun

7. Name: Variable Diameter of Quality

Pulley

Function:

It is used to control GSM by varying

the stitch length

Fig: Knit Cam

8. Name: Spandex Feeding Device (lycra

attachment)

Function:

It is used to apply negative feed of the

spandex

Fig: Lycra attachment

9. Name: Spandex Stop Motion

Intern report on Fariha Knit Tex Ltd. 30

Function:

When spandex yarn is worn, it stops the

machines.

Fig: Spandex Stop Motion

10. Name: Memminger Positive Feeder (MPF)

Function:

It is used to apply positive feed of the yarn

Fig: MPF

11.Name: Cylinder

Function:

Main part of the machine which hold the

other parts like cam box, trick plate and

rotates when machine run.

Fig: Cylinder

12. Name: Creel

Intern report on Fariha Knit Tex Ltd. 31

Function:

Creel is a part of knitting machine. Here

yarn package are store and ready to feed

into the machine

Fig: Creel

13. Name: Feeder

Function:

Feeder helps yarn to feed into the machine.

Fig: Feeder

15. Name: Needle Trick

Function:

Where all needle is placed together in a decent

Design.

Fig: Needle Trick

4.4 Different Parts of Flatbed Knitting Machine:

Intern report on Fariha Knit Tex Ltd. 32

Fig: Flat bed knitting machine (Jy Leh)

Tension Equipment: Provides tension force for yarn to be fed to the yarn feeder.

Cone Stand Plate: Table on which cone is arranged.

Fluorescent Lamp: It is necessary to see the condition of the needle bed gap and so on

during knitting. This lamp is turn on and off in controller screen.

Cone Stand: Holds the cone.

Signal Lamp: There are three indication lamps are as follows:

Green lamp--------------------Machine is in operation.

Blinking Green lamp---------Machine is stopped by operation.

Blinking yellow lamp-------Machine is stopped because of error or completion of

piece.

Carriage: Control the motion of the needle.

Intern report on Fariha Knit Tex Ltd. 33

Figure: Carriage

Operation Bar: Actuates and stops the carriage. Also used for clearing operation errors.

Figure: operating handle/Operation bar

Stop Switch: The purpose is to stop the machine in an emergency condition.

Side Cover: Installed at the both sides of safety cover.

Safety Cover: Suppresses the noise and dust.

Side Tension Equipment: Pulls the yarn fed to the feeder to create tension as tension

equipment does.

Intern report on Fariha Knit Tex Ltd. 34

Carrier Rail: Used for the carrier to move on.

Controller: Input the knitting data in the computer screen and command the machine to

execute the data. Modifying and inputting data are available in controller.

Lever: Lever operates a roller which helps the fabric to come outside of the machine.

Main Power Switch: Cuts off power supply. This switch has emergency stop function.

Oil Pump: Supplies oil to the machine parts.

Breaker Switch: This protects the machine from odd power source to the turned off

automatically. The breaker switch is back side of controller.

4.5 Specification of Needle, Sinker and Needle oil:

Item Brand Origin Model no

Groz-Beckert Germany VOL S 78.52. G007

VOL S 78.41. G0025

Needle Vota 78.60. G002

Organ Japan VO 75.50. S005

VO 95.48. S003

Sinker Groz-Beckert Germany

Needle oil TAE-WON Korea

Intern report on Fariha Knit Tex Ltd. 35

Chapter 5:

PRODUCT MIX AND THEIR SEQUENCE

OF OPERATION

Intern report on Fariha Knit Tex Ltd. 36

5.1 Production parameters:

Machine diameter

Machine rpm (revolution per minute)

No of feeders in use

Machine gauge

Count of yarn

Required time (machine running time)

5.2 Products of Knitting Floor:

Single Jersey:

Plain Single Jersey

Plain Single Jersey with Lycra

Single Lacoste

Double Lacoste

Polo Pique

Fleece Fabric

Double Jersey:

1x 1 Rib

1 x 1 Rib with Lycra

2 x 1 Rib

1 x 1 Interlock

1 x 1 Interlock with Lycra

Waffle

Ponte Di Roma

Mesh

5.3 Yarn count selection:

As we know VDQ pulley on the knitting machine controls GSM of fabric, but its raw material

has direct impact on GSM. Yarn counts and stitch length that are used to achieve required

GSM are given below:

Intern report on Fariha Knit Tex Ltd. 37

Single jersey:

Yarn count GSM Stitch length (mm)

20s 190 2.85

24s 175 2.94

26 s 160 2.95

28 s 160 2.70

150 2.80

175 2.65

30 s 130 3.20

140 2.75

150 2.70

34 s 180 3.00

40 s 190 3.45

Rib Fabric:

Count GSM Stitch length (mm) Fabric type

26 s 300 2.70 2x1

230 2.65 1x1

28 s 200 2.60 1x1

200 2.75 2x1

30 s 200 2.50 1x1

200 2.60 1x1

34 s 300 2.75 1x1

250 2.60 1x1

Interlock Fabric:

Count GSM Stitch length (mm) Fabric type

40 s 190-200 2.90 1x1

210-220 3.70

34 s 300 3.75 1x1

5.4 Knitting process flow chart:

Order from buyer

Marketing department

Intern report on Fariha Knit Tex Ltd. 38

Knitting department

Yarn requisition from the mill

Yarn receive by store

Knitting program setting

Yarn requisition from floor to store

Yarn received by floor in charge

Yarn loading on the machine

Knitting

Fabric inspection

Delivery to fabric store

Fabric delivery to dyeing section from store

5.6 Fabric specification:

Fabric type

Finished GSM

Finished diameter

Color

Yarn count

Intern report on Fariha Knit Tex Ltd. 39

5.7 Methods of Increasing Production:

By the following methods the production can be increased:

By Increasing Machine Speed:

Higher the m/c speed faster the movement of needle and ultimately production will be

increased.

By Increasing the Number of Feeder:

If the number of feeder is increased in the circumference of cylinder, then the number of

courses will be increased in one revolution at a time.

By Using Machine of Higher Gauge:

The higher the machine gauge, the more the production. So by using machine of higher

gauge production can be increased.

5.8 Sequence of Operation:

Intern report on Fariha Knit Tex Ltd. 40

Fig: Yarn Path Diagram of Single Jersey Machine

Intern report on Fariha Knit Tex Ltd. 41

Fig: Yarn Path Diagram of Single Jersey Machine with Lycra attachment

Intern report on Fariha Knit Tex Ltd. 42

Fig: Yarn Path Diagram of Double Jersey Machine

Intern report on Fariha Knit Tex Ltd. 43

Fig: Yarn Path Diagram of Double Jersey Machine with Lycra attachment

Intern report on Fariha Knit Tex Ltd. 44

Chapter 6:

PRODUCTION AND EFFICIENCY

CALCULATION

Intern report on Fariha Knit Tex Ltd. 45

6.1 Formula for production calculation and efficiency

calculation:

There are some formulas, commonly used for the calculation purpose in the knitting

industries:

Production/ shif in kg:

No of feeder × RPM ×60 × 12× No of needle × S . L× Efficiency( )

=

10 ×2.54 ×36 ×840 × yarn count × 2.2046

Efficiency (%) of machine:

Actual production

= × 100

Calculated production

In Fariha Knit Tex Ltd. Production is calculated in kg. So we calculated the production of

fabric in kg.

Intern report on Fariha Knit Tex Ltd. 46

6.1.1 Calculation for Single Jersey Fabric:

No of feeder : 132

R.P.M of machine : 15.2

Machine dia : 44 ″

Machine gauge : 24

Count of yarn :28/1 Ne

Stitch length : 2.73mm

Shift : 12 hr

Efficiency : 85%

Production/ shift in kg:

No of feeder × RPM ×60 × 12× NO of needle× S . L × Efficiency ()

=

10 ×2.54 × 36 ×840 × yarn count ×2.2046

132 ×15.2 ×60 ×12 × ( 3.1416 × 44 × 24 ) ×2.73 ×.85

=

10 × 2.54 ×36 × 840× 28 ×2.2046

= 234.55 kg

Intern report on Fariha Knit Tex Ltd. 47

6.1.2 Calculation for Lycra Single Jersey Fabric:

No of feeder : 96

R.P.M of machine : 15

Machine dia : 32 ″

Machine gauge : 24

Count of yarn :28/1 Ne

Stitch length : 2.90mm

Shift : 12 hr

Efficiency : 65%

Lycra (%) : 4%

Production/ shift in kg:

No of feeder × RPM ×60 × 12× NO of needle× S . L × Efficiency ()

=

10 ×2.54 × 36 ×840 × yarn count ×2.2046

96 ×15 ×60 ×12 × ( 3.1416 ×32 ×24 ) ×2.90 ×.65

=

10 × 2.54 ×36 × 840× 28 ×2.2046

= 99 kg

99 x 4

Weight of Lycra = kg

100

= 3.96 kg

Total production = ( 99+ 3.96 ) kg = 102.96 kg

Intern report on Fariha Knit Tex Ltd. 48

6.1.3 Calculation for rib machine (1×1 rib fabric):

No of feeder : 84

R.P.M of machine : 20

Machine dia : 28 ″

Machine gauge : 18

Time : 12 hr

Yarn count : 36s

Stitch length : 3.10 mm

Efficiency : 85%

Production/ shift in kg:

no of feeder × RPM ×60 ×12 × No of needle ×S . L × Efficiency ()

= ×2

10× 2.54 ×36 × 840× yarn count × 2.2046

84 ×20 ×60 ×12 ×3.1416 × 28× 18 ×3.10 ×.85 x 2

= 10 × 2.54 ×36 ×840 × 36 ×2.2046

= 166 kg

Intern report on Fariha Knit Tex Ltd. 49

6.1.4 Calculation for rib machine (2×1 rib fabric):

No of feeder : 96

R.P.M of machine : 17

Machine dia : 36 ″

Machine gauge : 18

Time : 12 hr

Yarn count : 36s

Stitch length : 2.48 mm

Efficiency : 70%

Production/ shift in kg:

no of feeder × RPM ×60 ×12 × No of needle ×S . L × Efficiency ()

= ×2/3

10× 2.54 ×36 × 840× yarn count × 2.2046

96 ×17 ×60 ×12 ×3.1416 × 36× 18 ×2.48 ×.70

= 10 × 2.54 ×36 × 840× 36 ×2.2046

x 2/3

= 186 kg

Intern report on Fariha Knit Tex Ltd. 50

6.1.4 Calculation for Interlock:

Machine Diameter : 30’’

Machine gauge : 24

Stitch length : 1.62mm

No. of feeder : 96

Machine RPM : 25

Time : 12 hr

Count : 36/1 Ne

Production kg/shift

No of feeder × RPM ×Time × No . of needle × Stitch length × Efficiency ()

=

10 X 2.54 X 36 X 840 X 2.2046 X Yarn count

96 ×25 ×60 ×12 ×.9 ×3.1416 × 30× 24 ×1.62

=

10 × 2.54 ×36 ×840 × 2.2046× 36

= 93 kg

Intern report on Fariha Knit Tex Ltd. 51

6.1.4 Production for Fleece (3 Thread):

Machine Diameter : 38’’

Machine gauge : 16

Stitch length : (4.45+3.95+1.75)mm

No. of feeder : 114

Machine RPM : 18

Time : 12 hr

Count : 20/1 Ne+20/1Ne+10/1Ne

Efficiency : 70%

Production in kg/shift

No of feeder × RPM ×Time × No . of needle × Stitch length × Efficiency ()

=

10 X 2.54 X 36 X 840 X Yarncount X 2.2046

38 x 18 x 60 x 12 x 3.1416 x 38 x 16 x 4.45 x .70

= +

10 x 2.54 x 36 x 840 x 20 x 2.2046

38 x 18 x 60 x 12 x 3.1416 x 38 x 16 x 3.95 x .70

+

10 x 2.54 x 36 x 840 x 20 x 2.2046

38 x 18 x 60 x 12 x 3.1416 x 38 x 16 x 1.75 x .70

+

10 x 2.54 x 36 x 840 x 10 x 2.2046

= ( 86+ 76+ 68 ) kg

= 230 kg

Intern report on Fariha Knit Tex Ltd. 52

6.1.5 Calculation Efficiency of machine:

Actual production

Efficiency = × 100

Calculated production

Production of Single Jersey Plain Machine:

Machine Diameter : 34’’

Machine gauge : 24

Stitch length : 2.7mm

No. of feeder : 84

Machine RPM : 28

Time : 12 hr

Count : 30/1 Ne

Production at 100% Efficiency in kg/shift

No of feeder × RPM ×Time × No. of needle × Stitch length

=

10 X 2.54 X 36 X 840 X 2.2046 X Yarncount

84 ×28 ×60 ×12 ×3.1416 × 34 ×24 × 2.7

= 10 ×2.54 × 36× 840 ×2.2046 ×30

= 230 kg/shift (Calculated Production)

Intern report on Fariha Knit Tex Ltd. 53

Actual Production = 185 kg/shift

Actual Production

Efficiency = X 100

Calculated Production

185

= x 100

230

= 80 %

Intern report on Fariha Knit Tex Ltd. 54

CHAPTER 7:

QUALITY ASSURANCE

Intern report on Fariha Knit Tex Ltd. 55

Quality assurance is defined as all those possible planed and systematic actions necessary to

provide adequate confidence that a product or service will satisfy given requirements for

quality. The quality assurance department is assigned to maintain consistently uniform

quality of the material in process and various stages of manufacturing.

7.1 Object of quality control:

Raw material test

Process control

Process development

Product testing

Research

7.2 Online Quality Control:

First of all, yarn lot and count is checked. Then the VDQ pulley diameter is checked for

specific stitch length. After running the machine, a sample of the fabric is cut. Then the stitch

length and GSM is checked. If the stitch length and GSM is not correct then necessary steps

are taken. Needle mark, sinker mark, hole and various types of faults are checked in the

machine. If any faults are identified, then necessary steps are taken to remove or minimize

the fault.

7.3 Off Line Quality Control:

After knitting,

The grey fabric was checked by inspection machine.

Find out the knitting fault & mark by marker pen.

Intern report on Fariha Knit Tex Ltd. 56

Make a report sheet in inspection tab (on 4 point system).

7.4 Fabric Inspection system:

All rolls are kept in front of the inspection machine time to time and are inspected over the

grey inspection machine visually in a pre-set speed against light. For any major or minor

faults like thick thin, barre marks, lycra out, contamination, fly, holes, oil lines, needle lines,

slubs etc. are recorded in grey inspection report to classify the fabric based on the four point

system.

Collar and cuff are inspected visually under light, any major & minor faulty collar/ cuff like

having wrong ply, hole, needle lines, slubs, wrong design, first line problem etc. properly

counted and recorded. The 4-points system is followed to inspect fabric.

The defects found and points given against are recorded in the inspection sheet. Following

table shows the four point grading system followed by Fariha Knit Tex Ltd:

Size of defects Penalty point

3 inches or less 1

Over 3 inch upto 6 inch 2

Over 6 inch upto 9 inch 3

Over 9 inch 4

7.5 Total defect points per 100 square meter are then

calculated:

Penalty per 100 square meter=

Intern report on Fariha Knit Tex Ltd. 57

total penalty point ×36 ×100

total length∈ yards× total width of the fabric inch

Fabric are then graded according to the penalty points

7.6 Grading system:

Points per 100 square meter Grading

0-20 A

21 to 28 B

Above 28 C (Rejected)

Figure: Inspection Report

7.7 List of equipments for quality control:

The list of equipment to assure quality:

1. Inspection machine

2. Electronic balance

Intern report on Fariha Knit Tex Ltd. 58

3. GSM cutter

4. Measuring tape

5. Scissors

6. Indication sticker

Fig: Inspection Machine

Intern report on Fariha Knit Tex Ltd. 59

7.8 Physical Lab Equipment’s:

No Machin Name Brand Name Model Figure

Light Fastness ENOTEST Xenotest

Tester 150S+

UV Perkin Elmer Lambda

Spectrometer 25

pH Tester METTLER TOLEDO

Intern report on Fariha Knit Tex Ltd. 60

4

Titan Universal

Strength Tester JAMES HEAL

5 Bursting Trueburst

Strength tester

6 Pilling Tester ICI Pilling box

7 Yarn Twist ESSJAY

Tester TECHNOMEASURE

Intern report on Fariha Knit Tex Ltd. 61

7.6 Fabric defects:

1. Needle mark:

Appearance: Spot line is found at wales direction.

Causes:

Due to decayed needle

Due to bend needle

Due to old needle

Due to improper needle setting

Remedies:

Change the defected needle.

Check the needle settings.

2. Sinker mark:

Appearance: Spot line is found at wales direction.

Causes:

Due to decayed sinker

Due to faulty adjustment of sinker with sinker cam.

Due to dirty track path.

Remedies:

Change the sinker

Make necessary adjustments of sinker with sinker cam as required.

Intern report on Fariha Knit Tex Ltd. 62

3. Hole:

Appearance: Hole on the fabric.

Causes:

If needle latch is not working properly.

Due to uneven tension.

Due to needle head breakage.

Due to improper cam setting.

Due to excessive take down tension.

Remedies:

Change the needle

Adjust the tension as required

Adjust cam setting properly

4. Drop stitches:

Appearance: A small hole is appeared on wales direction.

Causes:

Due to defective needle.

If yarn is not properly fed during loop formation. i.e. not properly laid on to the

needle hook.

Due to take down mechanism too loose.

Due to insufficient yarn tension

Remedies:

Needle should be straight

Intern report on Fariha Knit Tex Ltd. 63

Proper feeding of yarn during loop formation.

Correct take up of the fabric and correct fabric tension

Yarn tension should be properly

5. Barre/patta:

Appearance: Stripe effect is found towards the course on knit fabric.

Causes:

Due to lot mixing of yarn

If different counts and colors of yarn are missing together.

Improper cam adjustment

Remedies:

Operator should be careful about that different lots of yarn cannot be mix up.

Yarn should be tested before knitting.

6. Slub:

Appearance: A thick place is made in a particular place on fabric surface.

Causes:

Due to using of low quality yarn

Lint getting on to yarn face.

Remedies:

Yarn quality should be good

Yarn testing should be done properly

Intern report on Fariha Knit Tex Ltd. 64

7. Fly contamination:

Causes:

Presence of dead fibers & other foreign materials, such as; dyed fibers, husk &

synthetic fibers etc.

Dyed & other types of fibers flying from the adjacent Knitting machines cling to

the yarn being used for knitting & get embedded in the Grey Fabric.

Remedies:

Use rich fiber mixing for the yarns to be used for Knitting in order to have less

dead fibers appearing in the fabric.

Rigid control measures in the blow room to prevent the mixing of foreign matters

in the cotton mixing.

8. Oil spot:

Appearance: Oil spot on the fabric surface.

Causes:

Due to excessive lubrication in the machine

If there is any type of problem in needle and sinker, oil can be bled on the fabric.

Leakage of knitting oil

Remedies:

Change the faulty needle and sinker

Machine should be cleaned after scheduled time

Intern report on Fariha Knit Tex Ltd. 65

9. Lycra out:

Appearance: Lycra yarn is missing at course direction.

Causes:

If Lycra yarn is missed or breakage happened.

Remedies:

Operator should be more cautious to make necessary adjustment or replacement or

joining the yarn.

10. Press off (Set up):

Causes:

For badly needle break.

Improper yarn tension.

In case of Yarn breakage.

Remedies:

Remove bad needle.

Maintain proper tension of yarn.

11. Loop:

Causes:

Due to broken, decayed or bent needle.

Dirt in the needle latch or groove.

Remedies:

Change needle

Proper cleaning

Intern report on Fariha Knit Tex Ltd. 66

CHAPTER 8:

MAINTENANCE

Intern report on Fariha Knit Tex Ltd. 67

Maintenance of machineries is very important for any type of industries and it is must for a

knit composite factory.

8.1 Types of maintenance:

1. Preventive maintenance-

a. Mechanical maintenance

b. Electrical maintenance

2. Routine maintenance

3. Corrective maintenance-

a. Mechanical maintenance

b. Electrical maintenance

8.1.1 Preventive maintenance:

Preventive maintenance is a predetermined routine activity to ensure on time inspection/

checking of facilities to uncover conditions that may lead to production break downs or

harmful depreciation.

8.1.2 Routine maintenance:

Routine maintenance usually denotes those activities of maintenance which are bare

minimum to ensure efficient working of machines. These activities have to be performed

according to predetermined frequencies which are based on technical and quality

considerations.

Intern report on Fariha Knit Tex Ltd. 68

8.2 Routine maintenance task followed in the factory:

Daily work-

Floor cleaning

Positive feeder checking

Oil line checking

Airline checking

Take up roller checking

Motor sound checking

Every 25 days-

Gear box checking

All bearing checking

All bearing greasing

Panel board cleaning

Fan filter cleaning

Checking all control panels

Lubrication all motor bearing

All cable terminal tightening

Intern report on Fariha Knit Tex Ltd. 69

8.3 Servicing Procedures of Circular Knitting Machine :

Power off

MPF belt out

Yarn cut

Removing The fabric

Removing nitting drum (optional)

Running the machine at low rpmwith oil and cleaning

Cam box and sinker box out

Needle and sinker out

Needle and sinker cleaning by oil

Cam box cleaning by air

Sinker,needle,cam and cam boxs joining

Intern report on Fariha Knit Tex Ltd. 70

8.4 Maintenance tools and equipment:

1. Adjustable wrench:

Use: To set different types of nuts and bolts

Tightening and loosening of nuts and bolts

2. Spanner:

Use: To set nuts, bolts and pulley

Tightening and loosening of nuts and bolts

3. T-type L- key:

Use: Use to fitting cam box and other

machine parts

Tightening and loosening of nuts

and bolts

Intern report on Fariha Knit Tex Ltd. 71

4. Allen –key:

Use: Use to fitting cam box and other

machine parts

Tightening and loosening of nuts and

bolts

5. Screw driver:

Use: To fitting to fitting various type screw.

Tightening and loosening of nuts and bolts

6. Hammer:

Use: To drive nails, fit parts and forge metel.

Intern report on Fariha Knit Tex Ltd. 72

7. Pliers:

Use:

To hold machine parts

Cut metal wire

Set nuts and bolts

8. Cutting pliers:

Use: To cut metal wire.

Intern report on Fariha Knit Tex Ltd. 73

CHAPTER 9:

UTILITY

Intern report on Fariha Knit Tex Ltd. 74

9.1 Utility:

Utility is a major factor in any type of industry. In a textile industry there should be present

four types of utility for the smooth running of the operations. They are:

Electricity

Compressed air

Steam

Water

9.2 Source of utility:

Electricity: generator

Steam: boiler

Water: pump

Compressed air: compressor

9.3 Machine for utility services:

9.4 Air compressor:

Air compressor used to compress the air and increase the pressure of air. Air compressor

sucks air from the atmosphere, compress it and then deliver it at a high pressure to a storage

vessel. From the storage vessel it may be delivered by the pipeline to a place where the

supply of compressed air is required.

Intern report on Fariha Knit Tex Ltd. 75

Fig: Air compressor

SL no Brand Product type Max Motor Origin Qty

pressure Power

1 Kaeser Screw type 15 bar 75 kw America 05

compressor

2 Kaeser Screw type 15 bar 55 kw America 02

compressor

9.5 Power generator:

In fariha knit tex, there are eight power generator present and six of them are run by gas and

Intern report on Fariha Knit Tex Ltd. 76

rest of them run by diesel as fuel. In bellow some information about the generator are given:

Fig: Gas Generator

SL no Brand Model KW Volts R.P.M Fuel Origin Qty

1 Waukesha V.H.P- 900 400 1000 Gas America 05

5900LTDE

2 Waukesha V.H.P- 900 400 1000 Gas America 01

5900GSID

3 B&W AEG Man 1292 400/45 800 Diesel Sweden 02

0

9.6 Utility costs:

As Fariha Knit Tex Ltd. runs with its own electricity plant, it needs to buy gas and diesel to

run the generators. In bellow the bills of previous moths are given:

Month Bill in TK.

June 6252520

July 6597221

Intern report on Fariha Knit Tex Ltd. 77

Aug 6321557

Intern report on Fariha Knit Tex Ltd. 78

CHAPTER 10:

MARKETING INFORMATION

10.1 Knitting Charge for Various Structure:

Knitting Charge Per KG in taka

SI. No. Fabric Type

24 Ne -- 32 Ne 34 Ne -- 40 Ne

1. Single Jersey Plain 10 12

2. Single Jersey Slub Yarn 15 18

3. Single Jersey Dyed Yarn Feeder Stripe 20 22

4. Half Feeder Lycra Single Jersey 22 24

5. Full Feeder Lycra S/J Yarn Dyed Stripe 38 40

6. Pique Lacoste 16 18

Intern report on Fariha Knit Tex Ltd. 79

7. Pique Feeder Stripe 30 33

8. 1×1 Normal RIB 18 20

9. Yarn Dyed (1×1) Stripe RIB 25 28

10. (1×1) Half Feeder Lycra RIB 22 24

11. (1×1) Full Feeder Lycra RIB 26 28

12. (2×1) RIB 25 28

13. (2×1) Full Feeder Lycra RIB 34 36

14. (2×2) RIB 28 30

15. (2×2) Half Feeder Lycra RIB 32 34

16. (2×2) Full Feeder Lycra RIB 36 38

17. Plain Interlock 30 33

18. Interlock Half Feeder Lycra Attachment 38 40

19. Three thread fleece 20 22

20. Three thread Lycra Fleece 28 32

10.2 Buyer Information:

Buyer name Country

H&M Sweden

Next United Kingdom

Springfield Spain

Splash UAE

Intern report on Fariha Knit Tex Ltd. 80

Matalan United Kingdom

Walmart United States

Siplec France

Takko Fashion Germany

Kmart Australia

Intern report on Fariha Knit Tex Ltd. 81

CHAPTER 11:

CONCLUDING PART

11.1 Limitation of our training and report:

Due to lack of qualified technical personal, we did not get enough information about

technical aspects of knitting machines and process.

11.2 Suggestions:

- Marketing activities should be increased.

Intern report on Fariha Knit Tex Ltd. 82

- Working environment should be developed and modified.

- Technically skilled personal should be employed for improvisation of the unit.

Research center should be integrated in knitting department for developing new

fabric construction.

11.3 Conclusion:

We have completed our industrial training successfully by the grace of Allah. Fariha Knit Tex

Ltd. is a well-known factory in the textile field of Bangladesh. We are very grateful to the mill

authority for providing us the chance to acquire the practical knowledge about their large

and spacious field. It minimizes the gap between theoretical and practical knowledge and

also increase our thought a lot about textile technology. The main objective of industrial

training is to provide us the opportunity to observe, understand and practice the use of

engineering knowledge in textile industry. From this industrial attachment we captured a

detailed idea about the factory environment, factory maintenance system, total

management and many other very important details on the factory. Whatever knowledge

we have gained during our training period, it will help us to build up our carrier as a

successful textile engineer.

Intern report on Fariha Knit Tex Ltd. 83

S-ar putea să vă placă și

- Westerbeke 4,5BCGTC Instruction Manual PDFDocument53 paginiWesterbeke 4,5BCGTC Instruction Manual PDFcengiz kutukcu100% (2)

- GP Report QC 1Document50 paginiGP Report QC 1Rohan JetlingÎncă nu există evaluări

- Santoni SeamlessDocument2 paginiSantoni SeamlessSudheer SinghÎncă nu există evaluări

- 50 58 Eng Concrete TestingDocument92 pagini50 58 Eng Concrete TestingJimmy LopezÎncă nu există evaluări

- Type of Ac StatementDocument3 paginiType of Ac StatementRoberto SmithÎncă nu există evaluări

- Organic PoolsDocument163 paginiOrganic PoolsEdu Socolovsky100% (3)

- Fdocuments - in Companies List With Contact DetailsDocument80 paginiFdocuments - in Companies List With Contact DetailsNaren RawatÎncă nu există evaluări

- KnittingDocument32 paginiKnittingSandeep Ranjan100% (1)

- Carr and Latham's Technology of Clothing ManufactureDe la EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerEvaluare: 4 din 5 stele4/5 (1)

- Quality Control in Garment Manufacturing Process-Textile LearnerDocument17 paginiQuality Control in Garment Manufacturing Process-Textile LearnerMayaÎncă nu există evaluări

- Fabric Comparison of Rapier and Power LoomDocument40 paginiFabric Comparison of Rapier and Power LoomYogesh Balar100% (1)

- Plant Layout - IDocument16 paginiPlant Layout - ITanya rajÎncă nu există evaluări

- Deep Sea Research Submarine Report PDFDocument128 paginiDeep Sea Research Submarine Report PDFy_596688032Încă nu există evaluări

- Textile Internship (Compatibility Mode)Document90 paginiTextile Internship (Compatibility Mode)nalinkumar944Încă nu există evaluări

- Grey Cloth Manufacturing ProcessDocument8 paginiGrey Cloth Manufacturing ProcessPriya JainÎncă nu există evaluări

- NSQF - Knitting Machine Operator - Circular KnittingDocument23 paginiNSQF - Knitting Machine Operator - Circular KnittingSakibMDShafiuddinÎncă nu există evaluări

- WFT BRK CNTRLDocument17 paginiWFT BRK CNTRLसोमदत्त शर्म्माÎncă nu există evaluări

- Recent Development of Circular KnittingDocument32 paginiRecent Development of Circular KnittingHarshitha A100% (1)

- M01 Understand GarmentnproductinDocument51 paginiM01 Understand GarmentnproductinJocy ShiferaÎncă nu există evaluări

- Study On Weft Knitted Fabric Faults and Remedies-1Document75 paginiStudy On Weft Knitted Fabric Faults and Remedies-1asmkhanrahat50% (4)

- Knit Asia Operation ProcessDocument12 paginiKnit Asia Operation ProcessParvezMridhaÎncă nu există evaluări

- Alok IndustriesDocument37 paginiAlok IndustriesHitesh Kumar100% (1)

- Study On Knitting MachineriesDocument52 paginiStudy On Knitting MachineriesAhmad ButtÎncă nu există evaluări

- DyeingDocument41 paginiDyeingMehak JainÎncă nu există evaluări

- Complete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Document98 paginiComplete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Muhammad IlyasÎncă nu există evaluări

- Formal Trouser: Feasibility Report PresentationDocument64 paginiFormal Trouser: Feasibility Report Presentationbolaaajiii100% (1)

- Intermediate 5sDocument43 paginiIntermediate 5sManu BhardwajÎncă nu există evaluări

- Looper and Spreader Mechanism of Flatlock MachineDocument5 paginiLooper and Spreader Mechanism of Flatlock MachineTauqeer Raza100% (1)

- An Overview of Knitting Industry of IndiaDocument18 paginiAn Overview of Knitting Industry of IndiaJ.N.Vohra60% (5)

- Denim JeansDocument21 paginiDenim JeansFăÍż SăįYąð100% (1)

- Green University of Bangladesh Department of Textile: Lab ReportDocument5 paginiGreen University of Bangladesh Department of Textile: Lab Reportole.msfashionÎncă nu există evaluări

- Arvind Santej Internship Report PDFDocument107 paginiArvind Santej Internship Report PDFShripadÎncă nu există evaluări

- A Internship Report in Brabch Textile Technology For Diploma Holders.Document54 paginiA Internship Report in Brabch Textile Technology For Diploma Holders.Pawan Kumar RajputÎncă nu există evaluări

- HR Practises at VardhmanDocument49 paginiHR Practises at Vardhmankarma negiÎncă nu există evaluări

- Yarn Count Used According To Grey GSM - Textile CalculationDocument3 paginiYarn Count Used According To Grey GSM - Textile CalculationSZÎncă nu există evaluări

- Internship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteDocument30 paginiInternship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteAditya RainaÎncă nu există evaluări

- Textile Testing & Quality ControlDocument12 paginiTextile Testing & Quality ControlAshikur Rahman100% (1)

- Garment Industry 1Document28 paginiGarment Industry 1Mega MegalaÎncă nu există evaluări

- Textile Industry in PakistanDocument13 paginiTextile Industry in Pakistanraoumar100% (3)

- Steps To Garment MakingDocument12 paginiSteps To Garment MakingKhandaker Sakib FarhadÎncă nu există evaluări

- SpiralityDocument9 paginiSpiralitySenthil KumarÎncă nu există evaluări

- Intern ReportDocument121 paginiIntern ReportMd Chinto100% (2)

- Akshara Spinning MillsDocument42 paginiAkshara Spinning MillsbalaÎncă nu există evaluări

- Principles of Knitting TechnologyDocument18 paginiPrinciples of Knitting Technologysaadbinazad100% (1)

- Case Study: Arvind Mills LTD.: Prepared By: Kavita Chokshi (04) Digesh Shah (22) Pritesh Shah (25) Chirag SutharDocument83 paginiCase Study: Arvind Mills LTD.: Prepared By: Kavita Chokshi (04) Digesh Shah (22) Pritesh Shah (25) Chirag SutharDigesh Shah100% (3)

- Power Looms Summer Training ProjectDocument100 paginiPower Looms Summer Training ProjectSagar Virani100% (1)

- Arvind IntershipDocument52 paginiArvind IntershipAnurag MosanÎncă nu există evaluări

- Unit Iv Secondary and Auxilary Motions 12Document3 paginiUnit Iv Secondary and Auxilary Motions 129043785763Încă nu există evaluări

- DNLSDocument4 paginiDNLSshrutiagarwal9229Încă nu există evaluări

- Experiment Name:: Determination of Fabric Crease Recovery by Shirley Crease Recovery TesterDocument21 paginiExperiment Name:: Determination of Fabric Crease Recovery by Shirley Crease Recovery TesterFahima Rashid100% (1)

- Textile and Apparel Quality EvaluationDocument65 paginiTextile and Apparel Quality EvaluationvasineyÎncă nu există evaluări

- Description of Warping MachineDocument11 paginiDescription of Warping MachineAlhajAliÎncă nu există evaluări

- Project ReportDocument35 paginiProject ReportSK Azaharuddin100% (1)

- Aditya Itp FinalDocument56 paginiAditya Itp FinalAjay Kumar100% (2)

- Garment Testing StandardsDocument28 paginiGarment Testing StandardsTarekAbd-ElrahmanÎncă nu există evaluări

- Identifying Defect Causes of Weft Greige Knitted FabricDocument75 paginiIdentifying Defect Causes of Weft Greige Knitted FabricSakibMDShafiuddinÎncă nu există evaluări

- SILK - An IntroductionDocument27 paginiSILK - An IntroductionGuneet KaurÎncă nu există evaluări

- Potential Reasons For Broken, Skipped or Missing StitchesDocument6 paginiPotential Reasons For Broken, Skipped or Missing StitchesgetÎncă nu există evaluări

- Summer Training Project of Textile Industry"manjinder Singh"Document89 paginiSummer Training Project of Textile Industry"manjinder Singh"manjinder1933% (3)

- Arvind Internship, SantejDocument56 paginiArvind Internship, SantejShivani Rao0% (1)

- Internship ReportDocument20 paginiInternship Reportveenaos0% (1)

- Textile Internship Report: Ocm Private Limited Textile Unit, AmritsarDocument49 paginiTextile Internship Report: Ocm Private Limited Textile Unit, AmritsarJyoti Rawal100% (1)

- Fariha - 10th FebruaryDocument146 paginiFariha - 10th FebruaryMd Hafizullah SabbirÎncă nu există evaluări

- Incident Report: Executive Vice PresidentDocument1 paginăIncident Report: Executive Vice PresidentEvan MoraledaÎncă nu există evaluări

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 paginiTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalÎncă nu există evaluări

- 2015 Lanzar Web Optimized PDFDocument58 pagini2015 Lanzar Web Optimized PDFrecursowebÎncă nu există evaluări

- Updated Resume Kelly oDocument2 paginiUpdated Resume Kelly oapi-254046653Încă nu există evaluări

- SAFMC 2023 CAT B Challenge Booklet - V14novDocument20 paginiSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeÎncă nu există evaluări

- En Mirage Classic Installation GuideDocument4 paginiEn Mirage Classic Installation GuideMykel VelasquezÎncă nu există evaluări

- Fundamentals and History of Cybernetics 2Document46 paginiFundamentals and History of Cybernetics 2izzul_125z1419Încă nu există evaluări

- Be Katalog-Grabenfr 2013 Engl RZ KleinDocument36 paginiBe Katalog-Grabenfr 2013 Engl RZ Kleincherif100% (1)

- 11 443734731Document71 pagini11 443734731Prio ApÎncă nu există evaluări

- HC110110007 Data Forwarding ScenarioDocument17 paginiHC110110007 Data Forwarding ScenariojscansinoÎncă nu există evaluări

- Ad-All Ss Pressure GaugeDocument5 paginiAd-All Ss Pressure Gaugepankaj doshiÎncă nu există evaluări

- CCS Week 4 CBLMDocument6 paginiCCS Week 4 CBLMethel roseÎncă nu există evaluări

- FraceDocument12 paginiFraceIra MejiaÎncă nu există evaluări

- Release Notes Xcode 4.5.2Document7 paginiRelease Notes Xcode 4.5.2Anonymous gdJiDHÎncă nu există evaluări

- The Seven Deadly Sins of Strategy ImplementationDocument4 paginiThe Seven Deadly Sins of Strategy ImplementationNavigators ReunionÎncă nu există evaluări

- 7-67-0012 Rev 3 Short Sliding Support On ExistingDocument1 pagină7-67-0012 Rev 3 Short Sliding Support On Existingprince jaswalÎncă nu există evaluări

- 14 QuestionnaireDocument14 pagini14 QuestionnaireEkta SinghÎncă nu există evaluări

- Urban Bus Spec IIDocument33 paginiUrban Bus Spec IIBhawna SinghÎncă nu există evaluări

- Practice Questions PneumaticsDocument13 paginiPractice Questions Pneumaticssamer07hd100% (3)

- 3UG46251CW30 Datasheet enDocument5 pagini3UG46251CW30 Datasheet enDante AlvesÎncă nu există evaluări

- Marina Bay SandsDocument5 paginiMarina Bay SandsTauqeer A. BalochÎncă nu există evaluări

- Installation, Operation, and Maintenance Manual: Ansi Process PumpDocument56 paginiInstallation, Operation, and Maintenance Manual: Ansi Process Pumpfaundes100% (1)

- Computer Organization and Assembly Language: Lecture 1 - Basic ConceptsDocument13 paginiComputer Organization and Assembly Language: Lecture 1 - Basic ConceptsNosreffejDelRosarioÎncă nu există evaluări

- Criterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareDocument6 paginiCriterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareVinaya Babu MÎncă nu există evaluări