Documente Academic

Documente Profesional

Documente Cultură

QB1 Quick Break Tester - Operating Manual - Jun18

Încărcat de

aravindanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QB1 Quick Break Tester - Operating Manual - Jun18

Încărcat de

aravindanDrepturi de autor:

Formate disponibile

Product Data Sheet

WB-12

Water-based Fluorescent Magnetic Ink

MAGNAGLO® WB-12 is a liquid concentrate used to prepare water-based fluores-

cent inks for wet method magnetic particle testing. Inks made with WB-12 give clear

bright yellow/green indications when viewed in a darkened area under UV(A) of

peak wavelength 365 nm, and offer enhanced corrosion protection.

When used in conjunction with suitable magnetising equipment and a UV(A) source, WB-12 inks will

locate fine surface and slightly subsurface defects.

FEATURES APPLICATIONS

• Clear, bright indications under UV light Defect location: surface and slightly subsurface

• High sensitivity Ideal for:

• Easy post-testing clean up • Detecting very fine to fine discontinuities

• Excellent fluorescent contrast for quick • Machined parts

identification • Smooth surface finish

• Excellent particle mobility • Critical applications

• Good dispersion stability • High volume testing

• After secondary processing

• Great concentration consistency

• Mixing with hard-water

• Superior surface wetting

Ideal for:

• Non-foaming

• Inclusions

• Even surface coverage for better detection • Seams

• Good corrosion protection • Shrink cracks

• Tears

SPECIFICATION COMPLIANCE

• Laps

• AMS3044 • Flakes

• ASME B & PV Code, Sec V • Welding defects

• ASTM E1444/E1444M • Grinding cracks

• Quenching cracks

• EN ISO 9934-2

• Fatigue cracks

• GOST R ISO 9934-2-2011

• Rolls Royce RRP 58004 (CSS 231)

• SAE AS4792

Revised: September2018 eu.magnaflux.com

Product Data Sheet

WB-12

COMPOSITION INSTRUCTIONS FOR USE

A mixture of fluorescent magnetic particles, a Clean the component before testing to provide a

corrosion inhibitor, wetting agents and foam suitable test surface.

control additives.

Use an appropriate measuring device to make

PRODUCT PROPERTIES up the ink bath based on the following guide

volumes:

Form and colour Brown liquid

Density 1.2 g/ml Quantity of WB-12 Quantity of water

SAE sensitivity 7-8 0.5 litres (500 ml) 25 litres

Particle size range 5 - 12 µm 0.75 litres (750 ml) 37.5 litres

pH (2% solution) 9.0 1 litre (1,000 ml) 50 litres

Like all Magnaflux materials, WB-12 is closely

Once the bottle is empty, rinse it with water to

controlled to ensure batch-to-batch consistency,

capture any remaining product and add this to the

optimum process control and inspection reliability.

bath. Mix thoroughly and check that the bath has

USER RECOMMENDATIONS the correct settlement volume of 0.1 - 0.4 ml (at 20

ml/litre, after one hour) before use.

Magnetic Particle

NDT Method Testing, Fluorescent, Apply the ink by spraying, flooding or immersion,

Wet Method depending on your chosen method (see below).

Storage temperature 10oC to 30oC

Wet continuous method

Usage temperature -5oC to 48oC

Apply the ink to all surfaces of the component

Suspension Vehicle Water and apply a magnetising current. Remember to

WA-1 water conditioner stop the flow of ink before the current is switched

Water Bath Additive

WA-2 antifoam off, otherwise the force of the ink flood can wash

Magnetic Particles 14A, MG 601 away indications.

Cleaner SKC-S

Wet residual method

UV lamps EV6000, ST700 This method is generally less sensitive than the

Accessories Centrifuge Tube continuous method and is more susceptible to

rapid particle depletion and bath contamination.

• Pre-magnetise the part to be tested.

• Imerse the part in a bath of the ink.

• Remove it and allow it to drain.

• Inspect the part.

Revised: September2018 eu.magnaflux.com

Product Data Sheet

WB-12

Be sure to agitate the ink before and regularly

during use to ensure uniformity of mix. During

use, the magnetic content of any ink will become

depleted so you will need to check your bath

strength at least once each day. The most widely-

used way of checking an ink’s settlement volume

is by using a graduated ASTM pear-shaped

centrifuge tube.

When the settlement volume approaches the

lower limit, check the bath. If it appears contam-

inated, or if it has been in use for a long time,

replace the contents. If it is still clean and un-

contaminated, add either some more WB-12 OR

some 14A particles to the bath.

As before, make sure that the ink is agitated

immediately prior to use to ensure complete

mixing of the contents.

After inspection, remember to completely

demagnetise your components before cleaning,

to ensure easy removal of any residual powder

particles. Cleaned components can be treated

with a temporary film protective coating if you

need longer-lasting corrosion protection.

PACKAGING AND PART NUMBERS

058C033 (x 6)

HEALTH AND SAFETY

Review all relevant health and safety information

before using this product. For complete health

and safety information, refer to the Safety Data

Sheets, which are available at eu.magnaflux.com.

Revised: September2018 eu.magnaflux.com

S-ar putea să vă placă și

- 14HF, 410HF: Oil-Based Fluorescent Magnetic InksDocument3 pagini14HF, 410HF: Oil-Based Fluorescent Magnetic InksaravindanÎncă nu există evaluări

- Fluorescent Magnetic Particle Premix: Product Data SheetDocument3 paginiFluorescent Magnetic Particle Premix: Product Data SheetSandro ChiliquingaÎncă nu există evaluări

- Liquid fluorescent ink concentrate for wet magnetic particle testingDocument2 paginiLiquid fluorescent ink concentrate for wet magnetic particle testingMai Anh TaiÎncă nu există evaluări

- Wet Method Fluorescent Magnetic Particles: Product Data SheetDocument3 paginiWet Method Fluorescent Magnetic Particles: Product Data SheetLuis Yupa TapiaÎncă nu există evaluări

- 14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionDocument3 pagini14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionSandro ChiliquingaÎncă nu există evaluări

- Fluorescent Magnetic Particles Product Data SheetDocument3 paginiFluorescent Magnetic Particles Product Data Sheetஅன்புடன் அஸ்வின்Încă nu există evaluări

- Oil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetDocument4 paginiOil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetSandro ChiliquingaÎncă nu există evaluări

- Wet Method Fluorescent Magnetic ParticlesDocument4 paginiWet Method Fluorescent Magnetic ParticlesInaamÎncă nu există evaluări

- Solvent-Based Developer: Product Data SheetDocument3 paginiSolvent-Based Developer: Product Data SheetaravindanÎncă nu există evaluări

- ZP 14a Pds July17Document3 paginiZP 14a Pds July17aravindanÎncă nu există evaluări

- Steelshield Ve: Product DescriptionDocument2 paginiSteelshield Ve: Product DescriptionMoin AltafÎncă nu există evaluări

- Water-Washable Visible Penetrant: Product Data SheetDocument3 paginiWater-Washable Visible Penetrant: Product Data SheetShashi VindranÎncă nu există evaluări

- Skl-Wp2: Water-Washable Visible PenetrantDocument3 paginiSkl-Wp2: Water-Washable Visible PenetrantRussell ShacklefordÎncă nu există evaluări

- Ficha Particula Negra en Polvo PDFDocument3 paginiFicha Particula Negra en Polvo PDFCarlos JacoboÎncă nu există evaluări

- Magnaglo Reg 14A Fluorescent Magnetic Powder Wet MethodDocument2 paginiMagnaglo Reg 14A Fluorescent Magnetic Powder Wet Methodharanus2000Încă nu există evaluări

- Hydrophilic Emulsifier: Product Data SheetDocument3 paginiHydrophilic Emulsifier: Product Data SheetMiguelÎncă nu există evaluări

- ZL 440 Product Data SheetDocument3 paginiZL 440 Product Data SheetVishal ChudasamaÎncă nu există evaluări

- Product Data Sheet for #8A Red Non-fluorescent Magnetic ParticlesDocument2 paginiProduct Data Sheet for #8A Red Non-fluorescent Magnetic ParticlesSankar KrishnanÎncă nu există evaluări

- A11122XG W/B Gloss Coating: Technical Data SheetDocument1 paginăA11122XG W/B Gloss Coating: Technical Data SheetYenifer LinaresÎncă nu există evaluări

- Aculon AL-B TDSDocument2 paginiAculon AL-B TDSAlan TanÎncă nu există evaluări

- Protective & Marine Coatings: Magnalux 40VDocument2 paginiProtective & Marine Coatings: Magnalux 40VMd Usama100% (1)

- Apcotrak WBR: Product DescriptionDocument2 paginiApcotrak WBR: Product DescriptionTally AnuÎncă nu există evaluări

- Magnetic Particle InspectionDocument7 paginiMagnetic Particle InspectionalouisÎncă nu există evaluări

- ZL-15B, ZL-19, ZL-60C, ZL-60D, ZL-67B, ZL-56: Water-Washable Fluorescent PenetrantsDocument4 paginiZL-15B, ZL-19, ZL-60C, ZL-60D, ZL-67B, ZL-56: Water-Washable Fluorescent PenetrantsChoice OrganoÎncă nu există evaluări

- Product Data Sheet 410HF: Ready To Use Fluorescent MPI InkDocument2 paginiProduct Data Sheet 410HF: Ready To Use Fluorescent MPI InkMai Anh TaiÎncă nu există evaluări

- #1 Gray: Non-Fluorescent Magnetic ParticlesDocument2 pagini#1 Gray: Non-Fluorescent Magnetic ParticlesReadersmoÎncă nu există evaluări

- l2) Steelshield1200 3041Document2 paginil2) Steelshield1200 3041Syed FaridÎncă nu există evaluări

- Total Vulsol 5200 MSFDocument2 paginiTotal Vulsol 5200 MSFMajdin ZahirovicÎncă nu există evaluări

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocument2 pagini#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaÎncă nu există evaluări

- Wet Method Fluorescent Particles: Product Data SheetDocument3 paginiWet Method Fluorescent Particles: Product Data SheetMai Anh TaiÎncă nu există evaluări

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 paginiCarboguard 635 Thinned 50% - Sealer PDSjakeÎncă nu există evaluări

- TDS - Pool-Fix-FileDocument2 paginiTDS - Pool-Fix-Fileemre sönmezÎncă nu există evaluări

- ZL 405 Product Data SheetDocument2 paginiZL 405 Product Data SheetVishal ChudasamaÎncă nu există evaluări

- Pickling LiquidDocument2 paginiPickling LiquidAhmedAl-agwedÎncă nu există evaluări

- Apcoline 4100Document2 paginiApcoline 4100Moin AltafÎncă nu există evaluări

- ROYALPOXY UW 410-tdsDocument3 paginiROYALPOXY UW 410-tdsSyed FaridÎncă nu există evaluări

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pagini113.007 - Zinc Clad Xi WB BR PDFFernando VittoÎncă nu există evaluări

- Stycast 1266 EpoxyDocument3 paginiStycast 1266 EpoxyAlex22222Încă nu există evaluări

- Zyglo Bulk Operating InstructionsDocument3 paginiZyglo Bulk Operating InstructionsIlker TekeliÎncă nu există evaluări

- VBC FINEDRAW 1900K Drawing Fluid for Stainless SteelDocument1 paginăVBC FINEDRAW 1900K Drawing Fluid for Stainless SteelSinh LeÎncă nu există evaluări

- SKC-S: NDT Cleaner & RemoverDocument2 paginiSKC-S: NDT Cleaner & Removerஅன்புடன் அஸ்வின்Încă nu există evaluări

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 paginiLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraÎncă nu există evaluări

- SURFACE PRETREATMENT For Powder Coating - 1Document39 paginiSURFACE PRETREATMENT For Powder Coating - 1PhucÎncă nu există evaluări

- Simaguard MB Ep Coating: Product Data SheetDocument3 paginiSimaguard MB Ep Coating: Product Data Sheetantonsugiarto20_7049Încă nu există evaluări

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 paginiB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaÎncă nu există evaluări

- Elcometer 130 Scm400 Salt Contamination Meter Data SheetDocument1 paginăElcometer 130 Scm400 Salt Contamination Meter Data SheetRinush SinagaÎncă nu există evaluări

- b6) Zincanode690 2886Document2 paginib6) Zincanode690 2886Anonymous XVEucVMsEÎncă nu există evaluări

- Steel Shield 1200Document2 paginiSteel Shield 1200Moin AltafÎncă nu există evaluări

- Tds Kansai Conducoat 209 WBDocument2 paginiTds Kansai Conducoat 209 WBAdam FauzanÎncă nu există evaluări

- b3) Zincanode685 4586Document2 paginib3) Zincanode685 4586Syed FaridÎncă nu există evaluări

- Carboguard 504 PDSDocument4 paginiCarboguard 504 PDSNicholas ColesÎncă nu există evaluări

- Epoxy Grout for ConstructionDocument3 paginiEpoxy Grout for Constructionarunjacobn100% (2)

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pagini1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanÎncă nu există evaluări

- 2401-00 Simacover EP UnicoatDocument3 pagini2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINÎncă nu există evaluări

- MAJOON WRB Data SheetDocument2 paginiMAJOON WRB Data SheetChristos LeptokaridisÎncă nu există evaluări

- Product Data Sheet SKL-WP: Spotcheck Red PenetrantDocument3 paginiProduct Data Sheet SKL-WP: Spotcheck Red PenetrantMai Anh TaiÎncă nu există evaluări

- Introduction To Non-Destructive TestingDocument96 paginiIntroduction To Non-Destructive TestingLydia100% (2)

- DEC Riston EM213 DataSheetDocument7 paginiDEC Riston EM213 DataSheetks_spyroÎncă nu există evaluări

- D30a D30plus Pds Nov18Document3 paginiD30a D30plus Pds Nov18aravindanÎncă nu există evaluări

- Operating Instructions For Eclipse Refractometer - 2013 - English PDFDocument8 paginiOperating Instructions For Eclipse Refractometer - 2013 - English PDFaravindanÎncă nu există evaluări

- Operating Instructions For Eclipse Refractometer - 2013 - English PDFDocument8 paginiOperating Instructions For Eclipse Refractometer - 2013 - English PDFaravindanÎncă nu există evaluări

- Operating Instructions For Eclipse Refractometer - 2013 - EnglishDocument16 paginiOperating Instructions For Eclipse Refractometer - 2013 - Englisharavindan100% (1)

- Disposable Field Indicator - Operating Manual - Jun18Document2 paginiDisposable Field Indicator - Operating Manual - Jun18aravindanÎncă nu există evaluări

- ZP 14a Pds July17Document3 paginiZP 14a Pds July17aravindanÎncă nu există evaluări

- Rp20lt Pds July17Document2 paginiRp20lt Pds July17aravindanÎncă nu există evaluări

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 paginăYuasa NP12-6 VRLA Battery Technical Data SheetaravindanÎncă nu există evaluări

- Operating Instructions - Ketos Test Ring - Oct14Document2 paginiOperating Instructions - Ketos Test Ring - Oct14aravindanÎncă nu există evaluări

- Liquid Penetrant Testing Product Data SheetDocument1 paginăLiquid Penetrant Testing Product Data SheetaravindanÎncă nu există evaluări

- Sample of UT InstructionDocument4 paginiSample of UT Instructionmusaismail8863Încă nu există evaluări

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 paginăYuasa NP12-6 VRLA Battery Technical Data SheetaravindanÎncă nu există evaluări

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 paginăYuasa NP12-6 VRLA Battery Technical Data SheetaravindanÎncă nu există evaluări

- Disposable Field Indicator - Operating Manual - Jun18Document2 paginiDisposable Field Indicator - Operating Manual - Jun18aravindanÎncă nu există evaluări

- Activated Carbon PDS July17Document1 paginăActivated Carbon PDS July17aravindanÎncă nu există evaluări

- L10 Electromagnetic Coil: Use To Detect Transverse CracksDocument1 paginăL10 Electromagnetic Coil: Use To Detect Transverse CracksaravindanÎncă nu există evaluări

- Test Pieces LPI PDS Jun18Document9 paginiTest Pieces LPI PDS Jun18aravindanÎncă nu există evaluări

- L10 Electromagnetic Coil: Use To Detect Transverse CracksDocument1 paginăL10 Electromagnetic Coil: Use To Detect Transverse CracksaravindanÎncă nu există evaluări

- Understanding casting defects and their causesDocument94 paginiUnderstanding casting defects and their causestanydhillon100% (1)

- Solvent-Based Developer: Product Data SheetDocument3 paginiSolvent-Based Developer: Product Data SheetaravindanÎncă nu există evaluări

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pagini1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanÎncă nu există evaluări

- Stepdown Transformerl PDS Aug17Document1 paginăStepdown Transformerl PDS Aug17aravindanÎncă nu există evaluări

- QQIs - Operating Manual - Jun18Document4 paginiQQIs - Operating Manual - Jun18aravindanÎncă nu există evaluări

- Solvent-Based Developer: Product Data SheetDocument3 paginiSolvent-Based Developer: Product Data SheetaravindanÎncă nu există evaluări

- Magnetic Yokes Brochure - Jan18Document3 paginiMagnetic Yokes Brochure - Jan18aravindanÎncă nu există evaluări

- QB1 Quick Break Tester - Operating Manual - Jun18Document4 paginiQB1 Quick Break Tester - Operating Manual - Jun18aravindanÎncă nu există evaluări

- Disposable Field Indicator - Operating Manual - Jun18Document2 paginiDisposable Field Indicator - Operating Manual - Jun18aravindanÎncă nu există evaluări

- QB1 Quick Break Tester - Operating Manual - Jun18Document4 paginiQB1 Quick Break Tester - Operating Manual - Jun18aravindanÎncă nu există evaluări

- ETT Series - Operating Manual - Jun18Document10 paginiETT Series - Operating Manual - Jun18aravindanÎncă nu există evaluări

- Tugas B InggrisDocument9 paginiTugas B InggrisDellyna AlmaÎncă nu există evaluări

- BOF, LF & CasterDocument14 paginiBOF, LF & CastermaklesurrahmanÎncă nu există evaluări

- RUKUS March 2010Document32 paginiRUKUS March 2010RUKUS Magazine29% (14)

- Valvula de Leve MasterDocument20 paginiValvula de Leve Masterguillermo trejosÎncă nu există evaluări

- 50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDocument15 pagini50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDeena A. AlshwairikhÎncă nu există evaluări

- Nursing Diagnosis TemplateDocument6 paginiNursing Diagnosis Templatesdk6972Încă nu există evaluări

- 2 English Course BDocument8 pagini2 English Course BAnjana27Încă nu există evaluări

- HVDC BasicDocument36 paginiHVDC BasicAshok KumarÎncă nu există evaluări

- COVID 19 Impacts On The Construction IndustryDocument46 paginiCOVID 19 Impacts On The Construction IndustryAlemayehu DargeÎncă nu există evaluări

- Full SyllabusDocument409 paginiFull SyllabusSanthana BharathiÎncă nu există evaluări

- MAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFDocument2 paginiMAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFXavi AnpiÎncă nu există evaluări

- Solids Level Measurement Application Guide en 78224 PDFDocument144 paginiSolids Level Measurement Application Guide en 78224 PDFwalcalÎncă nu există evaluări

- Reach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramDocument2 paginiReach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramPR.comÎncă nu există evaluări

- Executive Order 000Document2 paginiExecutive Order 000Randell ManjarresÎncă nu există evaluări

- Owners Manual Water Mist PDFDocument6 paginiOwners Manual Water Mist PDFZeeÎncă nu există evaluări

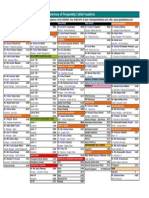

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 paginăDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoÎncă nu există evaluări

- Sub Erna RekhaDocument2 paginiSub Erna Rekhasurabhi mandalÎncă nu există evaluări

- Ignition System Spark Test DiagnosisDocument24 paginiIgnition System Spark Test DiagnosisMohamed l'Amine75% (4)

- EcR - 1 Leading and Lagging IndicatorsDocument10 paginiEcR - 1 Leading and Lagging IndicatorsMiloš ĐukićÎncă nu există evaluări

- Lesson Plan 7 Tabata TrainingDocument4 paginiLesson Plan 7 Tabata Trainingapi-392909015100% (1)

- Live Performance Award Ma000081 Pay GuideDocument48 paginiLive Performance Award Ma000081 Pay GuideDan LijndersÎncă nu există evaluări

- SVIMS-No Que-2Document1 paginăSVIMS-No Que-2LikhithaReddy100% (1)

- Biology (Paper I)Document6 paginiBiology (Paper I)AH 78Încă nu există evaluări

- DR - Hawary Revision TableDocument3 paginiDR - Hawary Revision TableAseel ALshareefÎncă nu există evaluări

- Genetically Engineered MicroorganismsDocument6 paginiGenetically Engineered Microorganismsaishwarya joshiÎncă nu există evaluări

- Grab Go Porter S 5 ForcesDocument2 paginiGrab Go Porter S 5 ForcesUtkarsh SharmaÎncă nu există evaluări

- Infinite & Finite Slope1Document38 paginiInfinite & Finite Slope1CHUKKALA LEELA RAVALIÎncă nu există evaluări

- PHAR342 Answer Key 5Document4 paginiPHAR342 Answer Key 5hanif pangestuÎncă nu există evaluări

- Adolescent Development & Competency in Juvenile JusticeDocument16 paginiAdolescent Development & Competency in Juvenile JusticeJudith KÎncă nu există evaluări

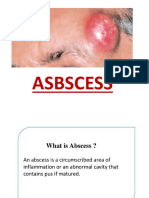

- ABSCESSDocument35 paginiABSCESSlax prajapatiÎncă nu există evaluări