Documente Academic

Documente Profesional

Documente Cultură

Introduction and Objectives Results: Methods

Încărcat de

Ashwina GroverTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Introduction and Objectives Results: Methods

Încărcat de

Ashwina GroverDrepturi de autor:

Formate disponibile

Introduction and Objectives Results

In 2005, the polystyrene (PS) casting system was developed Circumference Chart Most Height Chart

Elastic bag Non-Elastic bag accurate level

by Wu Yeongchi, utilizing polystyrene foam beads attached to 327

Circumference (mm)

52

control Elastic bag Non-Elastic bag

Height (mm)

325

a vacuum pressure pump to create a negative cast, for the 51

control

323 50

Transtibial prostheses. 321 49

Problem Statement : According to the report of ISPO 319 48

Vancouver in 2007, the PS casting tends to shrink the 317 47

negative cast, although in some cases there were induced 315 46

tight fitting. Objective: This study aims to Surface roughness Chart Durability Graph

Non-Elastic bag 8

optimize the PS casting by 3 Plaster based

7

2.5 Reduce Elastic bag

Displacement (mm)

(PS Rq / POP Rq)

determining the accuracy,

Roughness index

6

roughness Increase Non-Elastic bag

2 5

durability and surface 1.5 roughness 4

roughness, then comparing 1 Elastic bag

3

2

with the common plaster 0.5 1

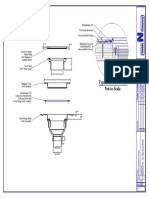

Figure 1. Polystyrene Casting

casting method. 0 0

4.9

9.8

49

0

14.7

19.6

24.5

29.4

34.3

39.2

44.1

53.9

58.8

63.7

68.6

73.5

78.4

Force (N)

Methods Stable Dummy 170mg /80kpa 170mg /50kpa 170mg /20kpa

Plaster Base Casting 28mg /80kpa 28mg /50kpa 28mg /20kpa

Casting accuracy [Test1], Durability [Test2] and Surface

roughness [Test3] have been evaluated by; casting a cylindrical Discussion

POM* with fixed parameters. Best durability Satisfaction rating score

Table 1. Casting specimen Best surface 170mg/Ela./80kpa

6

28mg/Ela./20kpa 5

170mg/Ela./50kpa 6 : Excellent

Material Circumference Diameter Height 4 5 : Good

POM 325 mm 103 mm 400 mm plaster base casting 3 170mg/Non-Ela./80kpa 4 : Normal

* POM: Polyoxymethylene (Solid engineering plastic) 2 3 : Fair

Best accuracy 1 2 : Bad

PS casting parameters are shown table 2. 170mg/Ela./20kpa 0 170mg/Non-Ela./50kpa 1 : Very bad

Evaluated different conditions are shown table 3.

Accuracy

Table 2. PS casting parameters 170mg/Non-Ela./20kpa 28mg/Ela./50kpa

Grain size (mm) 0.5-1.2 Durability

28mg/Non-Ela./80kpa 28mg/Non-Ela./50kpa

Density (mg/cm3) High: (170) Low: (28) Fine Surface

28mg/Ela./80kpa

Bag material Elastic TPU** Non-elastic HDPE

& Thickness (mm) ( 0.03 ) (0.17) Conclusion

Vacuum pressure (kPa) High: (80) Mid: (50) Low: (20) Recommended Original PS casting

* *TPU: Thermoplastic Polyurethane condition by Dr. Wu

Ranking Score (%)

condition

100%

100

Table 3. Variable conditions of PS casting Elastic bag Non-Elastic bag

80

1. Density 170 / Elastic/ vacuum 80kpa 7. Density 28 / Elastic/ vacuum 80kpa 60 Plaster base

2. Density 170 / Elastic/ vacuum 50kpa 8. Density 28 / Elastic/ vacuum 50kpa 40

casting

3. Density 170 / Elastic/ vacuum 20kpa 9. Density 28 / Elastic/ vacuum 20kpa

20

4. Density 170 / Non-elastic/ vacuum 80kpa 10. Density 28 / Non-elastic/ vacuum 80kpa

0

(Original PS casting condition by Dr. Wu) 170mg 170mg 170mg 28mg 28mg 28mg 170mg 170mg 170mg 28mg 28mg

5. Density 170 / Non-elastic/ vacuum 50kpa 11. Density 28 / Non-elastic/ vacuum 50kpa /80kpa /50kpa /20kpa /80kpa /50kpa /20kpa /80kpa /50kpa /20kpa /80kpa /50kpa

6. Density 170 / Non-elastic/ vacuum 20kpa 12. Density 28 / Non-elastic/ vacuum 20kpa

Best result in this study

Force Best (accuracy & durability)

[Test1] Accuracy: 0-80N

Best (accuracy & surface)

Cast models taken by variable Φ= 30 mm

Measure plastic Hydrostatic casting (need

conditions of PS casting also deformation compressible casting

includes POP casting, were condition)

compared with specimen table 1.

[Test2] Durability: Tests were

References

Weighing scale

1. Yeongchi Wu, and other editors, CIR casting system for making

conducted similar to the stress- Fig 2. Durability test Transtibial sockets, 33(1): 1–9, March 2009, Center for

strain test. The cast brim was

Cast model moves forward by using

International Rehabilitation, Chicago, and 2Northwestern

compressed 0 - 80N by a steel University Feinberg School of Medicine, Chicago, USA

the handle.

rod (Fig.2) 2. Thanh, N. H. Field Experience with Sand-casting and Wu-

[Test3] Surface roughness: Casting system in Vietnam, 12th World Congress of the

evaluated by calculating the International Society for Prosthetics and OrthoticsVancouver,

Dial gauge

Root Mean Square roughness accuracy Canada, July 29 –August 3, 2007

0.05mm

(Rq) by following ISO 4288 Acknowledgements

assessment rules & ISO 3274 This research was supported by Sirindhorn School of Prosthetics and

using a Dial gauge. (Fig3). Orthotics, Faculty of Medicine Siriraj Hospital, Mahidol University.

Fig 3. Surface roughness test We would like to thank Assoc. Prof. Dr. Nisarat Opartkiattikul

director of Sirindhorn School of Prosthetics and Orthotics, the

Rq: Root Mean Square roughness

𝟏 𝑳 research committee and our supervisors; Mr. Kazuhiko Sasaki and

Rq = 𝒇(𝒙) 𝟐 𝒅𝒙

L: Scanning evaluation length (40mm x 3 times)

𝑳 𝟎 Ms. Prawina Sutdet, who provided insight and expertise that greatly

x: Sampling distance (0.5mm)

assisted the research.

TEMPLATE DESIGN © 2008

www.PosterPresentations.com RE-F-28-1-11/04/60

S-ar putea să vă placă și

- SITE BOOK Good Practice Guide PDFDocument66 paginiSITE BOOK Good Practice Guide PDFFernando VázquezÎncă nu există evaluări

- Folder NoCut 2017 EN SpanSetDocument6 paginiFolder NoCut 2017 EN SpanSetRenato VieiraÎncă nu există evaluări

- Rolled Ball Screws / Precision Ball Screws: - Selection ProcessDocument1 paginăRolled Ball Screws / Precision Ball Screws: - Selection Process杜文欽Încă nu există evaluări

- E-Brochure PETposter Oct 2010Document5 paginiE-Brochure PETposter Oct 2010Melvin Mateo RodriguezÎncă nu există evaluări

- BioMatrix FlexDocument2 paginiBioMatrix FlexRizca HardiantiÎncă nu există evaluări

- CMSFull PDFDocument1 paginăCMSFull PDFAlexsandro Pereira Dos ReisÎncă nu există evaluări

- ENGD3000 - Project PosterDocument1 paginăENGD3000 - Project PosterLegendaryNÎncă nu există evaluări

- DVS 2203-2Document3 paginiDVS 2203-2Miteshshinde17Încă nu există evaluări

- Bridge Construction ScheduleDocument2 paginiBridge Construction SchedulerussellÎncă nu există evaluări

- The Observer - Magazine - 1806Document40 paginiThe Observer - Magazine - 1806CésarParedesÎncă nu există evaluări

- Flying - December 2021Document76 paginiFlying - December 2021Met KentÎncă nu există evaluări

- Design WeldDocument1 paginăDesign WeldPabloScurraÎncă nu există evaluări

- MIS Conical Connection Prosthetic OptionsDocument76 paginiMIS Conical Connection Prosthetic OptionsGiancarla ForondaÎncă nu există evaluări

- Petra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431Document103 paginiPetra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431ady putraÎncă nu există evaluări

- Chassis Maintenance Service InstructionsDocument1 paginăChassis Maintenance Service Instructionssemu cÎncă nu există evaluări

- Oh La La Baby BlanketDocument17 paginiOh La La Baby BlanketBella Haiat100% (1)

- Polamco Product Finder PDFDocument1 paginăPolamco Product Finder PDFpaula09Încă nu există evaluări

- Q83-Gujrat - Sas Architecture - Rev8Document13 paginiQ83-Gujrat - Sas Architecture - Rev8azlaanshah12901Încă nu există evaluări

- MY21 Lynx Brochure PAC enDocument29 paginiMY21 Lynx Brochure PAC enoriyyi61Încă nu există evaluări

- Connectors: For Cold-Formed Steel ConstructionDocument244 paginiConnectors: For Cold-Formed Steel ConstructionDavid PazmiñoÎncă nu există evaluări

- Design Practice Manual: GeneralDocument5 paginiDesign Practice Manual: GeneralmohammedÎncă nu există evaluări

- Sanchez 2022Document6 paginiSanchez 2022Satria WijayaÎncă nu există evaluări

- Western Hydraulic Parts PosterDocument1 paginăWestern Hydraulic Parts Posterhadeer84jÎncă nu există evaluări

- KOYO BearingDocument245 paginiKOYO BearingPeerasak Arun100% (2)

- How To Replace A Drysuit ZipDocument2 paginiHow To Replace A Drysuit Ziptonyrobinson111Încă nu există evaluări

- Mx800dual Cable SchemaDocument2 paginiMx800dual Cable SchemaAditya K SinghÎncă nu există evaluări

- Least Squares Fitting of A Straight Line (LSFASL)Document1 paginăLeast Squares Fitting of A Straight Line (LSFASL)astridÎncă nu există evaluări

- Eliciting Latent Predictions From Transformers With The Tuned LensDocument23 paginiEliciting Latent Predictions From Transformers With The Tuned LensHelen MylonaÎncă nu există evaluări

- Catalogo Woodtec Prensa VacioDocument7 paginiCatalogo Woodtec Prensa VacioJORGE MUÑOZÎncă nu există evaluări

- Digital Notebook-Portrait-BrownDocument50 paginiDigital Notebook-Portrait-BrownLizeth Rodríguez•Încă nu există evaluări

- Proposed Project Grow - Ajinomoto: 27 3 10 17 24 1 8 15 22 29 5 12 19 26 2 9 Aug-19 May-19 Jun-19 Jul-19Document1 paginăProposed Project Grow - Ajinomoto: 27 3 10 17 24 1 8 15 22 29 5 12 19 26 2 9 Aug-19 May-19 Jun-19 Jul-19joselito navarroÎncă nu există evaluări

- TXDOT Traffic Signal Pole FoundationDocument1 paginăTXDOT Traffic Signal Pole FoundationfiercecatÎncă nu există evaluări

- Bain Wet Shave CoDocument13 paginiBain Wet Shave CoJohn ChaoÎncă nu există evaluări

- Studio Ghibli Medley-VioloncelloDocument3 paginiStudio Ghibli Medley-VioloncelloGaz ArtimisÎncă nu există evaluări

- Photolithography 1 PDFDocument9 paginiPhotolithography 1 PDFWilliam Sin Chau WaiÎncă nu există evaluări

- Áo ĐanDocument4 paginiÁo Đanthuytrang.kt52Încă nu există evaluări

- Precis: UDEC. The Problems Are Divided Into Two Categories. The First Contains Verification ProblemsDocument4 paginiPrecis: UDEC. The Problems Are Divided Into Two Categories. The First Contains Verification ProblemsRakshit MishraÎncă nu există evaluări

- 490.121-En LowDocument8 pagini490.121-En LowDr.Riya CorreaÎncă nu există evaluări

- Isara Marsupiu Ergonomic Quick Full Buckle Marine Life Oceania 7133Document2 paginiIsara Marsupiu Ergonomic Quick Full Buckle Marine Life Oceania 7133Adelina Maria TurcanuÎncă nu există evaluări

- D112 ENGLISH VersionDocument2 paginiD112 ENGLISH VersionRinor Rushiti100% (1)

- Protum en 01Document24 paginiProtum en 01patavioÎncă nu există evaluări

- Chainsawman Foam Pattern USLetter SizeDocument9 paginiChainsawman Foam Pattern USLetter SizecrisoundÎncă nu există evaluări

- Typical Install Detail: (Socket Bottom)Document1 paginăTypical Install Detail: (Socket Bottom)D MÎncă nu există evaluări

- Freudenberg - en - Technical Elastomers-Web PDFDocument37 paginiFreudenberg - en - Technical Elastomers-Web PDFdhowardjÎncă nu există evaluări

- Creasing Behaviour of Corrugated BoardDocument69 paginiCreasing Behaviour of Corrugated BoardPolygrapack SA DE CVÎncă nu există evaluări

- ABS - Filaments - DirectoryDocument1 paginăABS - Filaments - DirectorychaitanyaÎncă nu există evaluări

- Austral DeckTechnical GuideDocument31 paginiAustral DeckTechnical Guidebappy01_cuet9921100% (1)

- Jan - Dez 92238.13Document92 paginiJan - Dez 92238.13Joao Pedro Rendeiro Correia de SousaÎncă nu există evaluări

- In Scaliozatoraa - Ca: Consecint - Ci Iceni Lordoza Intrauterine GiDocument1 paginăIn Scaliozatoraa - Ca: Consecint - Ci Iceni Lordoza Intrauterine GiPatrascu MihaiÎncă nu există evaluări

- Pexco PDS Winged Slat Product SheetDocument1 paginăPexco PDS Winged Slat Product SheetprivacyslatkingÎncă nu există evaluări

- PP Perfectly Pieced Block InstructionsDocument4 paginiPP Perfectly Pieced Block Instructions2mzprrr88gÎncă nu există evaluări

- KVT Plasticcomposites en 12-2013 WebDocument16 paginiKVT Plasticcomposites en 12-2013 WebWK SinnÎncă nu există evaluări

- Example 1Document1 paginăExample 1SaravananÎncă nu există evaluări

- KVT Plasticcomposites en 12-2013 WebDocument16 paginiKVT Plasticcomposites en 12-2013 WebWK SinnÎncă nu există evaluări

- Snatch Block With Shackle Fitting, SINGLE SHEAVE, 15-60t: BlocksDocument1 paginăSnatch Block With Shackle Fitting, SINGLE SHEAVE, 15-60t: BlocksYAKUBU A. AROGEÎncă nu există evaluări

- Bohrschablone - Marker Duke Baron Tour PDFDocument1 paginăBohrschablone - Marker Duke Baron Tour PDFLayher Scaff0% (2)

- Glacier One T30Document2 paginiGlacier One T30Vladimir SolomatinÎncă nu există evaluări

- ZEISS Hunting Catalogue 2019Document43 paginiZEISS Hunting Catalogue 2019Jean DelaronciereÎncă nu există evaluări

- Introduction and Objectives Results: MethodsDocument1 paginăIntroduction and Objectives Results: MethodsAshwina GroverÎncă nu există evaluări

- Exercises of Mole Concept (Basic) - SolDocument7 paginiExercises of Mole Concept (Basic) - Solsfkwong100% (1)

- G1 Presentation2Document27 paginiG1 Presentation2Ashwina GroverÎncă nu există evaluări

- Invest (Final) Revised Final Draft 1.0Document24 paginiInvest (Final) Revised Final Draft 1.0Ashwina GroverÎncă nu există evaluări

- Ice CastDocument24 paginiIce CastAshwina GroverÎncă nu există evaluări

- CE TTP PresentatiomDocument24 paginiCE TTP PresentatiomAshwina GroverÎncă nu există evaluări

- SWOT Analysis of India Rubber IndustryDocument6 paginiSWOT Analysis of India Rubber IndustryKeshav Gupta33% (3)

- 20 Jul 2018 153328220AELG1KSWAnnexure-Pre-feasibilityReport (PFR) FileDocument56 pagini20 Jul 2018 153328220AELG1KSWAnnexure-Pre-feasibilityReport (PFR) FileMohitÎncă nu există evaluări

- Pereaksi GrignardDocument8 paginiPereaksi Grignardisya_nurhidaÎncă nu există evaluări

- All Types of ValvesDocument64 paginiAll Types of Valvessparkarc40% (1)

- Research PlanDocument3 paginiResearch PlanBryan AlbesÎncă nu există evaluări

- Column Chromatography in Chemistry Is A Method Used To Purify Individual Chemical Compounds From Mixtures of CompoundsDocument12 paginiColumn Chromatography in Chemistry Is A Method Used To Purify Individual Chemical Compounds From Mixtures of CompoundsHuzaini IsmailÎncă nu există evaluări

- Organic Sub-Part 1Document16 paginiOrganic Sub-Part 1ahsaanahmadÎncă nu există evaluări

- Tutorial 4Document1 paginăTutorial 4sakinah azizanÎncă nu există evaluări

- Character Is at Ion and Engineering Properties of Singapore Residual SoilsDocument26 paginiCharacter Is at Ion and Engineering Properties of Singapore Residual SoilsChengHian YapÎncă nu există evaluări

- Work Instruction: Liquid Limit DeterminationDocument4 paginiWork Instruction: Liquid Limit DeterminationCris LegaspiÎncă nu există evaluări

- BS en 12568-2010Document32 paginiBS en 12568-2010Mohamed Ali100% (1)

- A Supplier Crater TrainingDocument14 paginiA Supplier Crater TrainingP K Senthil KumarÎncă nu există evaluări

- AEL Surface Bulk Explosives 2016Document16 paginiAEL Surface Bulk Explosives 2016DOC LABÎncă nu există evaluări

- G5779Document296 paginiG5779supriyadhageÎncă nu există evaluări

- Catalogo CRC PDFDocument84 paginiCatalogo CRC PDFAlex CordovaÎncă nu există evaluări

- SECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralDocument5 paginiSECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralfatREVITÎncă nu există evaluări

- Clinical Applications of Potentiometry Electrogravimetry and Coulometry 1Document15 paginiClinical Applications of Potentiometry Electrogravimetry and Coulometry 1Migs BernalÎncă nu există evaluări

- Comparative StudyDocument4 paginiComparative StudyPaclibar ElphegeÎncă nu există evaluări

- Item BarangDocument5 paginiItem BarangRinaldhi JimmyÎncă nu există evaluări

- Photosynthesis Cellular Respiration (Module 5)Document51 paginiPhotosynthesis Cellular Respiration (Module 5)Trisha DeniseÎncă nu există evaluări

- Infra-View LitDocument2 paginiInfra-View LitGavinsiauÎncă nu există evaluări

- Bruice Organic Chemistry 6eDocument26 paginiBruice Organic Chemistry 6esdfasf asdasdasd100% (1)

- 6 PCC Lubricants S NetDocument40 pagini6 PCC Lubricants S Net34-coreÎncă nu există evaluări

- The Innate Immune ResponseDocument38 paginiThe Innate Immune ResponseJosue LopezÎncă nu există evaluări

- Abst PDFDocument167 paginiAbst PDFKrishnamoorthi BalasubaramanianÎncă nu există evaluări

- JOC PeptidesDocument14 paginiJOC PeptidesludoÎncă nu există evaluări

- General Chemistry 2 Asynchronous Activity 1Document7 paginiGeneral Chemistry 2 Asynchronous Activity 1casinillojilianÎncă nu există evaluări

- Oxalate IonDocument15 paginiOxalate IonÃňìřùďhķãpťīỵãĺÎncă nu există evaluări

- Bateria 12 V 40ah GELDocument2 paginiBateria 12 V 40ah GELelmerÎncă nu există evaluări

- Fibre Reinforced ConcreteDocument45 paginiFibre Reinforced Concretetusshaarpatil100% (6)