Documente Academic

Documente Profesional

Documente Cultură

Pump Design Final

Încărcat de

Ahmer SohailTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pump Design Final

Încărcat de

Ahmer SohailDrepturi de autor:

Formate disponibile

6.

1 Pumps

Pump is a device that imparts momentum and mechanical energy to the process fluid. Pumps

are used to transfer fluid from one location to other.

A pump is a device used to raise, compress, or transfer fluids. The motors that power most

pumps can be the focus of many best practices. It is common to model the operation of pumps

via pump and system curves. Pump curves offer the horsepower, head, and flow rate figures

for a specific pump at a constant rpm. System curves describe the capacity and head required

by a pump system.

Pump Types

Various types of pumps are used in the chemical industry, including centrifugal, reciprocating,

and helical rotor pumps.

Centrifugal Pump

Centrifugal pumps operate by applying a centrifugal force to fluids, many times with the

assistance of impellers. These pumps are typically used in moderate to high flow applications

with low-pressure head, and are very common in chemical process industries. There are three

types of centrifugal pumps—radial, mixed, and axial flow pumps. In the radial pumps, pressure

is developed completely through a centrifugal force, while in axial pumps pressure is developed

by lift generated by the impeller. Mixed flow pumps develop flow through a centrifugal force

and the impeller.

Reciprocating Pump

Reciprocating pumps compress liquid in small chambers via pistons or diaphragms. These

pumps are typically used in low-flow and high-head applications. Piston pumps may have

single or multiple stages and are generally not suitable for transferring toxic or explosive

material. Diaphragm pumps are more commonly used for toxic or explosive materials.

Helical Rotor Pump

Helical rotor pumps use a rotor within a helical cavity to develop pressure. These pumps are

useful for submersible and waste applications.

Selection Criteria of Pumps

Many different factors can influence the final choice of the pump for a particular operation

.The following list indicates the major factors that govern the pump selection

The amount of liquid that must be pumped out.

The properties of the fluid.

The increase in presence of the fluid due to work input of the pump.

Types of the flow distributions.

Types of the power supply.

Cost and mechanical efficiency of the pump.

We have selected centrifugal pumps for a process because of the following outstanding

advantages:

They are simple in operation and cheap.

Fluid is delivered at uniform pressure without shocks or pulsation.

They are no valves involved in pump operation.

They operate at high speed (up to 4000 rpm) therefore they can be coupled directly to

an electric motor.

The discharge line may be partly shut off or completely closed off without changing

the pump.

They are much smaller than other pumps of equal capacity.

Maintenance costs are lower than other types of pumps.

Pump (P-1)

Pump Selection

Pump type is selected from the below graph:

Capacity = 61372.4 kg/hr

= 370.02 gpm of Selexol

P(g)

Head = 𝑠𝑝.𝑔𝑟∗0.4367

Head = 39 ft

Figure : Selection of pump

Hence, the Pump Selected is Centrifugal Pump.

Pump Sizing Calculation Steps

Locate the process equipment

Estimate z1 and z2.

Estimate Frictional pressure losses ED and ES

Calculate Pump Work.

Calculate Pump shaft horsepower & estimate its Efficiency.

Calculate electric-motor horsepower & estimate its Efficiency.

Select a standard electric-motor horsepower.

Calculate NPSH

Pump Calculation

Define the inlet and outlet pressures:

The inlet pressure is = P1 = 1.2 bar

The outlet pressure is = P2 = 30 bar

Locate the process equipment:

Locate the process equipment according to the rule of thumb listed in following table…

Figure : Selection of pump head

As we need to pump the liquid in to the absorber so our process equipment is absorber which

is supported by a skirt having skirt height of about 3.5 ft or 1.069 m.

Estimation of z1 & z2:

Z1 with respect to pump = 0

Z2 = skirt height + height of column

Z2 = 1.069 + 16.5

Z2 = 17.57m

Z2 = 57.64 ft

Estimation Frictional pressure losses ED and ES

Figure : Flow system component pressure drop

So, ES & ED is equal to 0.35

Calculate the pump work:

𝒈 𝑷 𝟏 − 𝑷𝟐

𝑾= (𝒛𝟏 − 𝒛𝟐 ) + − (𝑬𝑺 − 𝑬𝑫 )

𝒈𝑪 ʃ

9.8 (1.2 ∗ 105 − 3.0 ∗ 106 ) (0.35 + 0.35) ∗ 105

𝑊= (0 − 57.64) + −

32 1009 1009

𝑁𝑚

𝑊 = −2941

𝐾𝑔

Calculate the pump shaft horsepower:

Pump efficiency is calculated as…

𝑚𝑊

𝑃=

ɳ

61372.4 ∗ 2941

𝑃=

0.7

P = 2.57*108 J/hr

P = 71625.48 J/s

P = 96.05 hp

Figure: Efficiency of Pump

Calculate Electric-Motor Horsepower & Estimate its Efficiency:

Figure: Efficiency of Electric motor

On the basis of horsepower the selected motor is squirrel cage Induction motor having power

range of 1 to 5,000 hp.

Efficiency of motor is selected to be = 0.91

𝑃𝑃

The power of motor is calculated as = PE = 𝑃𝐸 = ɳ

96

𝑃𝐸 =

0.91

PE = 105.5 hp

Select a Standard Electric Motor Horsepower:

Figure: Horsepower Selection

Hence the selected motor is of 125 hp.

Net Positive Suction Head NPSH:

1 𝑃𝑎 − 𝑃𝑣

𝑁𝑃𝑆𝐻 = ( − ℎ𝑓𝑠 ) − 𝑍𝑎

𝑔 ʃ

Absolute pressure at the surface of reservoir = Pa = 1.2 bar = 1.2*105 Pa

Vapor pressure of Selexol = Pv = bar = 1000Pa

Friction losses in suction line = hfs = 0

Za = 0

1 1.2 ∗ 105 − 1000

𝑁𝑃𝑆𝐻 = ( − 0) − 0

9.8 1009

NPSH = 11.79 m

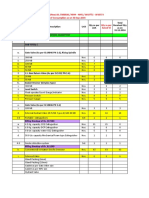

Specification Sheet

Identification

Item Pump

Item No. P-1

No. Required 1

Type Centrifugal

Function

To increase pressure from 1.2 bar to 30 bar

Feed Flow Rate 61372.4 kg/hr

Inlet Pressure 1.2 bar

Outlet Pressure 30 bar

Power of pump 96.05 hp

Power of electric motor 105.5 hp

NPSH 11.8 m

1. Silla, Harry. Chemical Process Engineering Design and Economics. USA

2. Jennifer Dyment , Suphat Watanasiri. Acid Gas Cleanin using DEPG Physical Solvents

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- DrizlyDocument10 paginiDrizlyAhmer SohailÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Delivery AppsDocument17 paginiDelivery AppsAhmer SohailÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Overview of Financial Reports: 1. Balance SheetDocument5 paginiOverview of Financial Reports: 1. Balance SheetAhmer SohailÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- ZenHire Competitor AnalysisDocument12 paginiZenHire Competitor AnalysisAhmer SohailÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Qarshi Industries (PVT.) LTDDocument1 paginăQarshi Industries (PVT.) LTDAhmer SohailÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Project Deadline DatesDocument1 paginăProject Deadline DatesAhmer SohailÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Internal Telephone Directory Hattar (All 03 Units)Document4 paginiInternal Telephone Directory Hattar (All 03 Units)Ahmer SohailÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- CostDocument12 paginiCostAhmer SohailÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Proposed Inverters Room For Future Solar ProjectsDocument2 paginiProposed Inverters Room For Future Solar ProjectsAhmer SohailÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Projects Updates: 260 KW Solar Power ProjectDocument2 paginiProjects Updates: 260 KW Solar Power ProjectAhmer SohailÎncă nu există evaluări

- Group # 01: Production of 163 Tonns Per Day of Ammonium Sulfate From Acid Gase Waste StreamDocument47 paginiGroup # 01: Production of 163 Tonns Per Day of Ammonium Sulfate From Acid Gase Waste StreamAhmer SohailÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Travel List (Local) Travel List (Foreign)Document1 paginăTravel List (Local) Travel List (Foreign)Ahmer SohailÎncă nu există evaluări

- ADM-PSL-FM-18 Application Form of Executives & Managers (72.5.2.2)Document1 paginăADM-PSL-FM-18 Application Form of Executives & Managers (72.5.2.2)Ahmer SohailÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Production of Ammonium Sulfate: Group-1Document35 paginiProduction of Ammonium Sulfate: Group-1Ahmer SohailÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Flow of A Film On The Outside of A Circular TubeDocument6 paginiFlow of A Film On The Outside of A Circular TubeShubh100% (6)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Distillation Column HAZOPDocument6 paginiDistillation Column HAZOPAhmer SohailÎncă nu există evaluări

- On The Sphericity of Coal and Char Particles: November 2014Document11 paginiOn The Sphericity of Coal and Char Particles: November 2014Ahmer SohailÎncă nu există evaluări

- 138 Rosy OutlookDocument3 pagini138 Rosy OutlookAhmer SohailÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Production of Ammonia From Coal Gasification: - Supervised by Dr. K Shahzad Baig Mr. Waqas AhmadDocument103 paginiProduction of Ammonia From Coal Gasification: - Supervised by Dr. K Shahzad Baig Mr. Waqas AhmadAhmer SohailÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- BOOKSDocument8 paginiBOOKSAhmer SohailÎncă nu există evaluări

- All Experiments Graphs..Document5 paginiAll Experiments Graphs..Ahmer SohailÎncă nu există evaluări

- Sr. No. Student Name Roll No. Group #1: Groups For Mini-Projects 2018Document1 paginăSr. No. Student Name Roll No. Group #1: Groups For Mini-Projects 2018Ahmer SohailÎncă nu există evaluări

- Control Valve: Mr. Mouto YDocument86 paginiControl Valve: Mr. Mouto YDuong NguyenÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- PSV 127 PDFDocument1 paginăPSV 127 PDFSuresh ramamoorthy RÎncă nu există evaluări

- PDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressDocument40 paginiPDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressVũ Văn QuangÎncă nu există evaluări

- Boundary LayerDocument12 paginiBoundary Layerhayder alaliÎncă nu există evaluări

- ACFr Og ARPIl DHu 8 S Yuww 7 UYmx KBDG ZT1-hge 3 C Ebwit 00 Ua CJ KUSLDOHpi KDocument50 paginiACFr Og ARPIl DHu 8 S Yuww 7 UYmx KBDG ZT1-hge 3 C Ebwit 00 Ua CJ KUSLDOHpi KKasper JensenÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- PumpsDocument45 paginiPumpsMehmood Ul Hassan100% (1)

- TG Filter Cross Reference2022-Rev04Document220 paginiTG Filter Cross Reference2022-Rev04Hamada BaamraniÎncă nu există evaluări

- Assignment CLB11003Document11 paginiAssignment CLB11003hazry khooÎncă nu există evaluări

- O & M Manual - Flow Nozzle AssemblyDocument4 paginiO & M Manual - Flow Nozzle Assemblyabdellah faqdaniÎncă nu există evaluări

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 paginăSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtÎncă nu există evaluări

- Calculation of Pipe Friction LossDocument33 paginiCalculation of Pipe Friction LossEyob AdÎncă nu există evaluări

- 12 Finally EditedDocument98 pagini12 Finally Editedelias chernetÎncă nu există evaluări

- 11 Physics Chapter 10 Assignment 5Document2 pagini11 Physics Chapter 10 Assignment 5nellai kumarÎncă nu există evaluări

- Exhaust Pipe Back-Pressure Calculation: T D Q L PDocument4 paginiExhaust Pipe Back-Pressure Calculation: T D Q L PSanda PribicÎncă nu există evaluări

- 416E, 422E and 428E Backhoe Loader Hydraulic SystemDocument2 pagini416E, 422E and 428E Backhoe Loader Hydraulic SystemFerney LaraÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- WTP Hydraulics 1Document6 paginiWTP Hydraulics 1Hemant Sonawadekar100% (3)

- Worksheet FlowDocument18 paginiWorksheet FlowRaymond VoongÎncă nu există evaluări

- PHD ThesisDocument181 paginiPHD ThesisArjen de JongÎncă nu există evaluări

- Navier StokeDocument2 paginiNavier StokeJayeshÎncă nu există evaluări

- Design Considerations: EM 1110-2-2901 30 May 97Document27 paginiDesign Considerations: EM 1110-2-2901 30 May 97Haider Zam JVÎncă nu există evaluări

- Fluidchiller ManualDocument111 paginiFluidchiller Manualknizam1971Încă nu există evaluări

- Friction Loss On SuctionDocument2 paginiFriction Loss On SuctionSathish LingamÎncă nu există evaluări

- Pressure Control ValveDocument38 paginiPressure Control ValvePrasanna KumarÎncă nu există evaluări

- Nyecorr 140 Commonly Asked QuestionsDocument2 paginiNyecorr 140 Commonly Asked QuestionsMarco JuarezÎncă nu există evaluări

- Spare List FFDocument3 paginiSpare List FFramesh epiliÎncă nu există evaluări

- PPR Sizing Tables&ChartsDocument22 paginiPPR Sizing Tables&ChartsChahbi RamziÎncă nu există evaluări

- Bouyancy ExamplesDocument5 paginiBouyancy ExamplesS_ELBEHERYÎncă nu există evaluări

- Reynolds Experiment (Body)Document13 paginiReynolds Experiment (Body)mutencoÎncă nu există evaluări

- Chemistry Project On Sterilization of WaterDocument14 paginiChemistry Project On Sterilization of WaterAbhiRawat100% (1)

- Siklus RankineDocument26 paginiSiklus RankineArialdi Almonda0% (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (543)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări