Documente Academic

Documente Profesional

Documente Cultură

Tankguard Special Ultra Jotun Paint

Încărcat de

Gurdeep Sungh AroraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tankguard Special Ultra Jotun Paint

Încărcat de

Gurdeep Sungh AroraDrepturi de autor:

Formate disponibile

Technical Data Sheet

Approved 8380;8500 1,2 8380 phenolic/novolac ^(ValidationDate) 1

epoxy

Tankguard Special Ultra

Product description

This is a two component polyamine cured phenolic/novolac epoxy coating. Specially designed tank coating with

excellent chemical resistance and a turn-around time of 5 days after carriage of methanol. Developed as a

3-coat system for optimum chemical resistance in atmospheric and immersed environments. Suitable for

properly prepared carbon steel, galvanised steel and stainless steel substrates. It can be applied down to +5 °C

surface temperature.

Typical use

Marine:

Specially designed as an internal tank coating for chemical tanks. This coating has excellent resistance to a wide

range of products with very little chemical absorption making it highly suitable for frequent changes of cargo.

Refer to Marine Product Resistance List on www.jotunprl.com.

Other

Approvals and certificates

Approved to UK Defence Standard 80-97 issue 5, annex G for resistance to Avtur F-34 FSII aviation fuel

In compliance with Federal Drug Authority, USA, FDA Title 21, Part 175.300, approved for exposure to dry foods

Additional certificates and approvals may be available on request.

Colours

light red, yellow, light grey

Product data

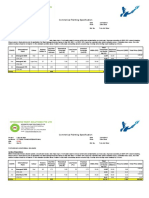

Property Test/Standard Description

Solids by volume ISO 3233 70 ± 2 %

Gloss level (GU 60 °) ISO 2813 semi gloss (35-70)

Flash point ISO 3679 Method 1 28 °C

Density calculated 1.6 kg/l

VOC-US/Hong Kong US EPA method 24 (tested) 300 g/l

(CARB(SCM)2007, SCAQMD rule 1113, Hong Kong)

VOC-EU IED (2010/75/EU) (theoretical) 342 g/l

VOC-China GB/T 23985-2009 (tested) 298 g/l

VOC-Korea Korea Clean Air Conservation Act (tested) 367 g/l

The provided data is typical for factory produced products, subject to slight variation depending on colour.

All data is valid for mixed paint.

Gloss description: According to Jotun Performance Coatings' definition.

Date of issue: 14 March 2019 Page: 1/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Tankguard Special Ultra

Film thickness per coat

Typical recommended specification range

Dry film thickness 80 - 150 μm

Wet film thickness 115 - 215 μm

Theoretical spreading rate 8.8 - 4.7 m²/l

Maximum recommended film thickness is often exceeded in overlap zones and in difficult-to-spray areas. This

product can be applied up to 50 % higher than maximum specified film thickness without loss of technical

properties.

Surface preparation

To secure lasting adhesion to the subsequent product all surfaces shall be clean, dry and free from any

contamination.

Surface preparation summary table

Surface preparation

Substrate Minimum Recommended

Carbon steel Sa 2½ (ISO 8501-1) Sa 2½ (ISO 8501-1)

Stainless steel The surface shall be hand or machine Abrasive blast cleaning to achieve a

abraded with non-metallic abrasives surface profile using non-metallic

or bonded fibre machine or hand abrasive media which is suitable to

abrasive pads to impart a scratch achieve a sharp and angular surface

pattern to the surface. profile.

Galvanised steel The surface shall be clean, dry and Sweep blast-cleaning using non-

appear with a rough and dull profile. metallic abrasive leaving a clean,

rough and even pattern.

Application

Application methods

The product can be applied by

Spray: Use airless spray.

Brush: Recommended for stripe coating and small areas. Care must be taken to achieve the

specified dry film thickness.

Roller: Roller application only to be used for scallops, ratholes, small pipes etc.

Date of issue: 14 March 2019 Page: 2/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Tankguard Special Ultra

Product mixing ratio (by volume)

Tankguard Special Ultra Comp A 4 part(s)

Tankguard Special Ultra Comp B 1 part(s)

Thinner/Cleaning solvent

Thinner: Jotun Thinner No. 23

Guiding data for airless spray

Nozzle tip (inch/1000): 17-23

Pressure at nozzle (minimum): 150 bar/2100 psi

Drying and Curing time

Substrate temperature 5 °C 10 °C 15 °C 23 °C 30 °C 40 °C

Surface (touch) dry 24 h 16 h 6h 4h 3h 2h

Walk-on-dry 36 h 24 h 10 h 7h 4h 3h

Dry to over coat, minimum 36 h 24 h 20 h 16 h 14 h 10 h

Dried/cured for immersion 15 d 7d 5d 4d 3d 2d

Dried/cured for service 30 d 14 d 10 d 7d 4d 3d

For maximum overcoating intervals, refer to the Application Guide (AG) for this product.

Drying and curing times are determined under controlled temperatures and relative humidity below 85 %, and

at average of the DFT range for the product.

Hot cure is optional but is needed to carry certain aggressive cargoes. Please see Jotun Marine Tank Coating

Notes section III for details.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Walk-on-dry: Minimum time before the coating can tolerate normal foot traffic without permanent marks,

imprints or other physical damage.

Dry to over coat, minimum: The recommended shortest time before the next coat can be applied.

Dried/cured for immersion: Minimum time before the coating can be permanently immersed in sea water.

Dried/cured for service: Minimum time before the coating can be permanently exposed to the intended

environment/medium.

Date of issue: 14 March 2019 Page: 3/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Tankguard Special Ultra

Induction time and Pot life

Paint temperature 5 °C 10 °C 15 °C 23 °C 30 °C

Induction time 30 min 25 min 20 min 15 min 10 min

Pot life 4h 3h 3h 2h 1.5 h

Heat resistance

Temperature

Continuous Peak

Dry, atmospheric 140 °C 150 °C

Immersed, sea water 80 °C 90 °C

Immersed, crude oil 120 °C 130 °C

Further resistance information can be found in Marine Product Resistance List available on Jotun's website, or

contact your local Jotun office.

Peak temperature duration max. 1 hour.

The temperatures listed relate to retention of protective properties. Aesthetic properties may suffer at these

temperatures.

Note that the coating will be resistant to various immersion temperatures depending on the specific chemical

and whether immersion is constant or intermittent. Heat resistance is influenced by the total coating system. If

used as part of a system, ensure all coatings in the system have similar heat resistance.

Product compatibility

Depending on the actual exposure of the coating system, various primers and topcoats can be used in

combination with this product. Some examples are shown below. Contact Jotun for specific system

recommendation.

Previous coat: itself only

Subsequent coat: itself only

Packaging (typical)

Volume Size of containers

(litres) (litres)

Tankguard Special Ultra Comp A 16 20

Tankguard Special Ultra Comp B 4 5

The volume stated is for factory made colours. Note that local variants in pack size and filled volumes can vary

due to local regulations.

Storage

Date of issue: 14 March 2019 Page: 4/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Tankguard Special Ultra

The product must be stored in accordance with national regulations. Keep the containers in a dry, cool, well

ventilated space and away from sources of heat and ignition. Containers must be kept tightly closed. Handle

with care.

Shelf life at 23 °C

Tankguard Special Ultra Comp A 12 month(s)

Tankguard Special Ultra Comp B 12 month(s)

In some markets commercial shelf life can be dictated shorter by local legislation. The above is minimum shelf

life, thereafter the paint quality is subject to re-inspection.

Caution

This product is for professional use only. The applicators and operators shall be trained, experienced and have

the capability and equipment to mix/stir and apply the coatings correctly and according to Jotun's technical

documentation. Applicators and operators shall use appropriate personal protection equipment when using this

product. This guideline is given based on the current knowledge of the product. Any suggested deviation to suit

the site conditions shall be forwarded to the responsible Jotun representative for approval before commencing

the work.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do

not inhale spray mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable

cleanser, soap and water. Eyes should be well flushed with water and medical attention sought immediately.

Colour variation

When applicable, products primarily meant for use as primers or antifoulings may have slight colour variations

from batch to batch. Such products may fade and chalk when exposed to sunlight and weathering.

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are often

used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product

itself. Minor product variations may be implemented in order to comply with local requirements. Jotun reserves

the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs

and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom)

version will prevail.

Date of issue: 14 March 2019 Page: 5/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

S-ar putea să vă placă și

- Tankguard Plus Jotun PaintDocument5 paginiTankguard Plus Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Tank Guard Plus For 160 Deg CDocument5 paginiTank Guard Plus For 160 Deg CTahir aminÎncă nu există evaluări

- Datasheet Jotun-Tankguard StorageDocument5 paginiDatasheet Jotun-Tankguard Storagebudi handoyoÎncă nu există evaluări

- Tankguard HB Classic Jotun PaintDocument5 paginiTankguard HB Classic Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Jotun Tankguard HBDocument5 paginiJotun Tankguard HBrheriÎncă nu există evaluări

- Tankguard StorageDocument5 paginiTankguard StorageBiju_PottayilÎncă nu există evaluări

- Tankguard HB: Technical Data SheetDocument5 paginiTankguard HB: Technical Data Sheetabet_singkong8930Încă nu există evaluări

- Tankguard StorageDocument5 paginiTankguard Storageabdulgafoor54Încă nu există evaluări

- Jotatemp 1000 - TDSDocument5 paginiJotatemp 1000 - TDSTopik Budi Oetomo100% (1)

- Jotatemp 1000 CeramicDocument5 paginiJotatemp 1000 CeramicNabeel K SÎncă nu există evaluări

- Tankguard DW Jotun PaintDocument6 paginiTankguard DW Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Tankguard Plus: Technical Data SheetDocument5 paginiTankguard Plus: Technical Data SheetKris WilliamsÎncă nu există evaluări

- Marathon 1000GF Technical Data SheetDocument5 paginiMarathon 1000GF Technical Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- Jotatemp 540 Zinc Technical Data SheetDocument5 paginiJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- TDS 11480 Pilot ACR Euk GBDocument5 paginiTDS 11480 Pilot ACR Euk GBeeng gilangÎncă nu există evaluări

- Alkyd Primer Technical Data SheetDocument5 paginiAlkyd Primer Technical Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- Pilot QD Primer: Technical Data SheetDocument5 paginiPilot QD Primer: Technical Data SheetPavloÎncă nu există evaluări

- Jotaprime 500: Technical Data SheetDocument5 paginiJotaprime 500: Technical Data SheetRudhi AfghaniÎncă nu există evaluări

- TDS 1531 Hardtop Flexi Euk GBDocument5 paginiTDS 1531 Hardtop Flexi Euk GBEnergía Metal Raid PeruÎncă nu există evaluări

- Tankguard HB ClassicDocument5 paginiTankguard HB ClassicMuhammad Iqbal Al HaidarÎncă nu există evaluări

- Tankguard AR: Technical Data SheetDocument5 paginiTankguard AR: Technical Data SheetAzar SKÎncă nu există evaluări

- Tankguard Storage: Technical Data SheetDocument5 paginiTankguard Storage: Technical Data SheetEngTamerÎncă nu există evaluări

- Tankguard SF: Technical Data SheetDocument5 paginiTankguard SF: Technical Data SheetRifki ArifinÎncă nu există evaluări

- Marathon: Technical Data SheetDocument5 paginiMarathon: Technical Data SheetOkinawa TeakÎncă nu există evaluări

- TDS 48342 Jotatemp 1000 Euk GBDocument5 paginiTDS 48342 Jotatemp 1000 Euk GBhenryÎncă nu există evaluări

- Marathon: Technical Data SheetDocument5 paginiMarathon: Technical Data SheetPablo Ahumada G.Încă nu există evaluări

- Tankguard 412 Jotun PaintDocument6 paginiTankguard 412 Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- TDS - Tankguard Storage - Issued 04.08.2014Document5 paginiTDS - Tankguard Storage - Issued 04.08.2014Arya Kemal Pratama PutraÎncă nu există evaluări

- JT TDSDocument5 paginiJT TDSKingsman 86Încă nu există evaluări

- TDS - Tankguard SF - Issued 04.08.2014Document5 paginiTDS - Tankguard SF - Issued 04.08.2014Arya Kemal Pratama PutraÎncă nu există evaluări

- Jotafloor Top Coat PDFDocument5 paginiJotafloor Top Coat PDFJay Ram DhakalÎncă nu există evaluări

- Jotun - Technical Data Sheet - Tankguard Storage - 09.2019Document5 paginiJotun - Technical Data Sheet - Tankguard Storage - 09.2019Victor PomboÎncă nu există evaluări

- Pilot QD Primer: Technical Data SheetDocument5 paginiPilot QD Primer: Technical Data SheetDavisTranÎncă nu există evaluări

- Marathon 1000 GFDocument5 paginiMarathon 1000 GFNabeel K SÎncă nu există evaluări

- TDS 9440 Tankguard DW Euk GBDocument6 paginiTDS 9440 Tankguard DW Euk GBSajjad k. AmhawiÎncă nu există evaluări

- Tankguard Zinc Jotun PaintDocument5 paginiTankguard Zinc Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Barrier SmartpackDocument5 paginiBarrier SmartpackMhd EbalÎncă nu există evaluări

- TDS 574 Marathon Euk GBDocument5 paginiTDS 574 Marathon Euk GBsbry.anwrÎncă nu există evaluări

- Jotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - EnglishDocument5 paginiJotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - Englishlong chanÎncă nu există evaluări

- Penguard Express ZP: Technical Data SheetDocument5 paginiPenguard Express ZP: Technical Data Sheetinfospinster0% (1)

- TDS 2063 Tankguard 412 Euk GBDocument6 paginiTDS 2063 Tankguard 412 Euk GBAhmad SyawalÎncă nu există evaluări

- Barrier 80 PDFDocument5 paginiBarrier 80 PDFBalaji GuruÎncă nu există evaluări

- TDS 15520 Jotaguard 630 Euk GBDocument5 paginiTDS 15520 Jotaguard 630 Euk GBNilu RohmanÎncă nu există evaluări

- Marathon 1000XHB Technical Data SheetDocument5 paginiMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- Resist 78: Technical Data SheetDocument5 paginiResist 78: Technical Data SheetRohit KambleÎncă nu există evaluări

- TDS 44902 Tankguard NCV N Euk GBDocument5 paginiTDS 44902 Tankguard NCV N Euk GBzattie89Încă nu există evaluări

- Resist 65: Technical Data SheetDocument5 paginiResist 65: Technical Data Sheetchristian210789Încă nu există evaluări

- Technical Data Sheet - Jotun Jotatemp 540 ZincDocument5 paginiTechnical Data Sheet - Jotun Jotatemp 540 ZincPolem IskandarÎncă nu există evaluări

- Jotamastic 87 AluminiumDocument5 paginiJotamastic 87 AluminiumBiju_PottayilÎncă nu există evaluări

- Hardtop Flexi Technical Data SheetDocument5 paginiHardtop Flexi Technical Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- Jotamastic Plus: Technical Data SheetDocument5 paginiJotamastic Plus: Technical Data SheetRamlialianÎncă nu există evaluări

- Jotamastic 87 TDSDocument5 paginiJotamastic 87 TDSSathishkumar SrinivasanÎncă nu există evaluări

- GRP and Buildings: A Design Guide for Architects and EngineersDe la EverandGRP and Buildings: A Design Guide for Architects and EngineersÎncă nu există evaluări

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesDe la EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesÎncă nu există evaluări

- Essential Rubber Formulary: Formulas for PractitionersDe la EverandEssential Rubber Formulary: Formulas for PractitionersEvaluare: 3 din 5 stele3/5 (1)

- Analisys and application of dry cleaning materials on unvarnished pain surfacesDe la EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesÎncă nu există evaluări

- Corrosion and Fouling Control in Desalination IndustryDe la EverandCorrosion and Fouling Control in Desalination IndustryÎncă nu există evaluări

- Gas Sweetening and Processing Field ManualDe la EverandGas Sweetening and Processing Field ManualEvaluare: 4 din 5 stele4/5 (7)

- Luxaprime1501 Etch PrimerDocument2 paginiLuxaprime1501 Etch PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 paginiLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime1500 Etching Wash PrimerDocument2 paginiLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime1801 Chromate Free Etch PrimerDocument2 paginiLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 paginiLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Alcoat Data SheetDocument2 paginiAlcoat Data SheetGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 paginiLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Hydraulic Bolt Tensioners EnerpacDocument2 paginiHydraulic Bolt Tensioners EnerpacGurdeep Sungh AroraÎncă nu există evaluări

- Luxaprime1200 Alkyd QD PrimerDocument2 paginiLuxaprime1200 Alkyd QD PrimerGurdeep Sungh AroraÎncă nu există evaluări

- Albond and Alcast Extra HS MonolithicsDocument2 paginiAlbond and Alcast Extra HS MonolithicsGurdeep Sungh AroraÎncă nu există evaluări

- Albond HS CastableDocument2 paginiAlbond HS CastableGurdeep Sungh AroraÎncă nu există evaluări

- Kaowool Papers Morgan CeramicsDocument3 paginiKaowool Papers Morgan CeramicsGurdeep Sungh AroraÎncă nu există evaluări

- Pyro Bloc ModulesDocument2 paginiPyro Bloc ModulesGurdeep Sungh AroraÎncă nu există evaluări

- New Storage & Shelf Life Feb 2014 PDFDocument2 paginiNew Storage & Shelf Life Feb 2014 PDFGurdeep Sungh AroraÎncă nu există evaluări

- Jotamastic 90 Jotun PaintDocument6 paginiJotamastic 90 Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- For V Shaped Pulleys: - Quick and Easy InstallationDocument3 paginiFor V Shaped Pulleys: - Quick and Easy InstallationGurdeep Sungh AroraÎncă nu există evaluări

- Barrier 80 PDFDocument5 paginiBarrier 80 PDFBalaji GuruÎncă nu există evaluări

- Esab GasEquipment PDFDocument44 paginiEsab GasEquipment PDFGurdeep Sungh AroraÎncă nu există evaluări

- Tankguard DW Jotun PaintDocument6 paginiTankguard DW Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Barrier Smart Pack Jotun PaintDocument5 paginiBarrier Smart Pack Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Tankguard Zinc Jotun PaintDocument5 paginiTankguard Zinc Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Tankguard 412 Jotun PaintDocument6 paginiTankguard 412 Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- House Painting 1000211256Document25 paginiHouse Painting 1000211256adiseif100% (1)

- Sprinturf Maintenance Manual 2009Document33 paginiSprinturf Maintenance Manual 2009Jeff StallardÎncă nu există evaluări

- 2 Quality Standard in Construction - necCPSDocument102 pagini2 Quality Standard in Construction - necCPSSuraj PantÎncă nu există evaluări

- Shark SC630 Manual enDocument23 paginiShark SC630 Manual enkrievkalnsgÎncă nu există evaluări

- Scholl Concepts Australia - 2013 BrochureDocument8 paginiScholl Concepts Australia - 2013 BrochurejebaÎncă nu există evaluări

- Ahtn Supplementary Explanatory Notes (Sen), Edition 2012 PDFDocument180 paginiAhtn Supplementary Explanatory Notes (Sen), Edition 2012 PDFjrickyÎncă nu există evaluări

- Surface CoatingDocument29 paginiSurface CoatingAbdullah RamzanÎncă nu există evaluări

- Corrosion PDFDocument17 paginiCorrosion PDFSakshi SaraogiÎncă nu există evaluări

- Part - I - Civil Estimate / BOQ: Municipal Corporation of Greater MumbaiDocument36 paginiPart - I - Civil Estimate / BOQ: Municipal Corporation of Greater MumbaihajarÎncă nu există evaluări

- R 1113Document29 paginiR 1113kncorbetÎncă nu există evaluări

- Global Cellulose Ether GradeDocument23 paginiGlobal Cellulose Ether GradeWANGYUSHENG Kima Chemical Co LtdÎncă nu există evaluări

- Asian Paint Minor AnshulDocument38 paginiAsian Paint Minor AnshulRajat JaatÎncă nu există evaluări

- 7.5m Air Rider Material PaintDocument5 pagini7.5m Air Rider Material PaintAgus SalimÎncă nu există evaluări

- Flex-Pro Pu: Technical Data SheetDocument4 paginiFlex-Pro Pu: Technical Data SheetKenneth CabacunganÎncă nu există evaluări

- International Tubulars FzeDocument4 paginiInternational Tubulars FzeMuhammad SuhaibÎncă nu există evaluări

- MAINCOTE™ AEH-20 Acrylic-Epoxy Hybrid Resin: Regional Product Availability DescriptionDocument2 paginiMAINCOTE™ AEH-20 Acrylic-Epoxy Hybrid Resin: Regional Product Availability DescriptionXuxo XuxitoÎncă nu există evaluări

- DBE For Paint Stripping ApplicationsDocument5 paginiDBE For Paint Stripping ApplicationsGhufran SaeedÎncă nu există evaluări

- 18-010E - Rev1 - 6EY17 Intercooler Case CorrosionDocument2 pagini18-010E - Rev1 - 6EY17 Intercooler Case CorrosionG_ARVALIS8470Încă nu există evaluări

- Paints and CoatingsDocument2 paginiPaints and CoatingsMartin Lizarbe WilliamsÎncă nu există evaluări

- Report Wakiso Site Interior PaintigDocument2 paginiReport Wakiso Site Interior PaintigkitstonÎncă nu există evaluări

- Neoshield Plus Matt - TDSDocument2 paginiNeoshield Plus Matt - TDSaboali8686Încă nu există evaluări

- K01587 - 20200217130259 - Chapter 8 - Paint, Varnish, Liquer, InksDocument26 paginiK01587 - 20200217130259 - Chapter 8 - Paint, Varnish, Liquer, InksAbdulRahim059Încă nu există evaluări

- Excel Sheet For Price CalculationDocument3 paginiExcel Sheet For Price CalculationSachin KothvalÎncă nu există evaluări

- Paint ChipDocument6 paginiPaint ChipatirahÎncă nu există evaluări

- Guia de Aditivos para Resolucao de ProblemasDocument20 paginiGuia de Aditivos para Resolucao de ProblemasFabiano DesangiacomoÎncă nu există evaluări

- Step 1 General Color Control ProcessesDocument16 paginiStep 1 General Color Control ProcessesWilliam AutometalÎncă nu există evaluări

- Dulux Easy Clean - Doc - Dulux-Easy-CleanDocument3 paginiDulux Easy Clean - Doc - Dulux-Easy-CleanantosevicÎncă nu există evaluări

- Paint Estimating Calculations PDFDocument2 paginiPaint Estimating Calculations PDFGaurav Tripathi50% (2)

- SABIC® SABICOL 1618 - Global - Technical - Data - SheetDocument2 paginiSABIC® SABICOL 1618 - Global - Technical - Data - SheetAbhishek Mathur100% (1)

- Jotun Thinner No. 17: Technical Data SheetDocument2 paginiJotun Thinner No. 17: Technical Data Sheetheru firmansyahÎncă nu există evaluări