Documente Academic

Documente Profesional

Documente Cultură

Syllabus Operations Management (2019-1) V 2.0

Încărcat de

Luis F. Bustamante BTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Syllabus Operations Management (2019-1) V 2.0

Încărcat de

Luis F. Bustamante BDrepturi de autor:

Formate disponibile

Course Syllabus

Gestión de Operaciones

(Operations Management)

March – July 2019

Term VIII

Choy Pun, Augusto Carlos

I. General Course Information

Subject: Gestión de Operaciones (Operations Management)

Pre- Planeamiento y Control Code: 02857

requisite: de la Producción

(Production Planning

and Control)

Precedent: None Semester: 2019-1

Credits: 3 Term: VIII

Weekly 4 hours Course type: In-class

Hours:

Type Obligatory Course Augusto Choy P.

Career(s) Industrial and Coordinator: achoy@esan.edu.pe

Commercial Engineering

II. Summary

The course provides the student with theoretical and practical knowledge and is

oriented to the analysis of the operational environment of organizations, be it a service,

productive or transformation organization. It covers the following topics: The function of

operations, strategies and systems approach of operations management, productivity

indicators, management techniques, the study of methods and measurement of work,

location, forecasts, design, capacity and distribution of facilities, elements of inventory

management, design of service operations, materials requirement planning and Just-in-

Time manufacturing.

III. Course Objectives

Effectively recognize and analyze the different methodologies, processes and tools

used to improve the productivity of organizations and implicitly oriented to control

and improve the management of operations in both goods and services, which will

allow the student to contribute efficiently in improving the operational process of

organizations.

IV. Learning Results

At the end of the course, the students:

Compare the results of observed time, standard time and supplemental work

time.

Apply productivity concepts to both production and service activities

Identify how to locate and size a plant.

Identify how to plan and locate services.

Identify plant layout types.

Develop the planning and design of a process.

V. Methodology

“Gestion de Operaciones” (Operations Management) Course Syllabus 2

Classes will be conducted stimulating the active participation of students, the teacher

will fulfill his role as a guide, a mentor and motivator in the learning process. Teamwork

will be combined to reinforce the learning process and develop in the participant the

necessary skills to perform successfully.

It is desirable that before each class the participant read, from the recommended text,

the topic addressed, so that he or she may formulate pertinent questions. Likewise,

after each class, the participant should also complement the topic worked on with the

texts indicated in the supplementary bibliography and, if necessary, consult with the

professor.

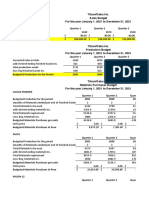

VI. Evaluation

The evaluation system is comprehensive and continuous with the objective of

promoting learning in the student. The final grade is composed of Continuous

Evaluation (PEP) (60%), Mid-Term exam – (EP) (20%) and Final exam – (EF) (20%).

The Final Grade (PF) is calculated using the following formula:

PF = (0,20 x EP) + (0,60 x PEP) + (0,20 x EF)

Where:

PF = Final Grade Promedio Final

EP = Mid-Term Exam Examen Parcial

PEP = Continuous Evaluation Promedio de Evaluación Permanente

EF = Final Exam Examen Final

The Average Permanent Evaluation is calculated based on the student’s learning

process follow-up: Reading Controls / Quizzes / Cases / Presentations / research

work / Class contribution. The weighted average of these marks results in the

corresponding score.

The Continuous Evaluation portion is calculated as follows:

AVERAGE PERMANENT EVALUATION (PEP) 60%

Weight

Type of Evaluation Description

%

Involvement in discussions,

Class contribution 5

attendance and punctuality

Moodle Quizzes Five quizzes (2% each) 10

Three Theory Quizzes (5

Theory Quizzes 15

marks each)

Application Quizzes (PC) Four tests (5 marks each) 20

Three research articles (10

Essays with Presentation 30

marks each)

Four Team Deliverables (5

Applied Integral Work 20

marks each)

VII. Programmed Content

“Gestion de Operaciones” (Operations Management) Course Syllabus 3

WEEK CONTENTS ACTIVITIES / EVALUATION

LEARNING UNIT I: INTRODUCTION TO OPERATIONS MANAGEMENT AND ITS

APPLICATION IN DIFFERENT SECTORS

LEARNING OUTCOME:

Compare the results of observed time, standard time and supplemental work time.

Apply productivity concepts to both production and service activities

1. INTRODUCTION Presentation: Course

1. Operations Management (OM) Methodology

2. What is OM? Guideline - review for Final

3. Organizing to Produce Goods and Research Work

Services Guideline - Review for UESAN

1° 4. Description of OM written work presentation (APA

5. What OM Managers do? Standards)

March 21 6. Operations for Goods and Services Guideline - Effective

- 27 7. The Productivity Challenge Presentations

8. Current Challenges in OM

MiniCases:

- Hazel

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply Assignment: Research paper 1

due end of week 2

Chain Management. (12th Ed) Boston. Pearson. Ch. 1

2. Operations Strategy in a Global Presentations:

Environment - Operations Strategy

1. Global View of Operations and Supply -

Chains MiniCases:

2. Developing Missions and Strategies - Uber Technologies, Inc

3. Achieving Competitive Advantage AUTOEVALUATION N°1

2° through Operations Heizer. Operations Management

4. Issues in Operations Strategy …, 12th Ed. Ch 1

March 28 5. Strategy Developing and Implementation online test time: 30/03/2019 5:00

– April 03 p.m.

6. Strategic Planning, Core competencies

and Outsourcing

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply

Chain Management. (12th Ed) Boston. Pearson. Ch. 2

“Gestion de Operaciones” (Operations Management) Course Syllabus 4

WEEK CONTENTS ACTIVITIES / EVALUATION

3. TAKT TIME, CYCLE TIME AND LEAD TIME Presentations:

1. Takt Time -

2. Standard Time Exercises:

3. Cycle Time

3° 4. Lead Time Assignment: Research Article 1

Test 1: LU I

April 04 - AUTOEVALUATION N°2

10 Heizer. Operations Management

…, 12th Ed. CH 2

online test time: 10/04/2019 6:00

p.m.

LEARNING UNIT II: PRODUCTIVITY AND COMPETITIVENESS

LEARNING OUTCOME:

Apply productivity concepts to both production and service activities.

4. Productivity and Competitivity Presentations:

1. Definition of Productivity -

4° 2. Definition of Competitivity -

3. What is Productivity and how is it MiniCases:

April 11 – Measured -

17 4. Productivity Trends -

(Holidays -

April -

18,19 and Theory Quiz 1:

20) - Article 1

5. LEAN Presentations:

1. Lean Systems - Lean Systems

2. Lean Characteristics Taking Stock

3. Benefits and Risks - Questions about Lean

4. Principles

Deliverable 1

5. Lean Product Design

5° 6. Lean Process Design

April 22 - 7. Lean Manufacturing, Planning and

27 Control

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply

Chain Management. (12th Ed) Boston. Pearson. Ch.

16

“Gestion de Operaciones” (Operations Management) Course Syllabus 5

WEEK CONTENTS ACTIVITIES / EVALUATION

6. LEAN TOOLS Presentations:

1. Lean Tools - Lean Tools

2. Value Stream Mapping -

3. Process Improvement through 5W2H MiniCases:

4. Lean and Six Sigma - Arnold Palmer Hospital

5. JIT Delivery and the Supply Chain

6° 6. Lean and ERP AUTOEVALUATION N°3

April 29 – 7. Transition to Lean Heizer. Operations Management

May 04 8. Planning of a Succesful Conversion …, 12th Ed. CH 16

online test time: 04/05/2019 6:00

9. Conversion Obstacles

p.m.

10. Cooperative Spirit

11. Lean Services

12. Operations Strategy

13. Kanban

7. PRODUCT DESIGN Presentations:

1. Design of Goods and Services - Product Design

2. Process Selection and Control MiniCases:

3. Manufacturing and Services - De Mar’s Product

4. Product Development Continuum Strategy

7° -

May 06 - - 8. Mid-term Exam Briefing

11 Assignment: Research Article 2

Test 2: LU II

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply

Chain Management. (12th Ed) Boston. Pearson. Ch. 5

8°

May 13 - MID-TERM EXAMS

18

LEARNING UNIT III: PLANT LOCATION AND SIZING

LEARNING OUTCOME:

Identify how to locate and size a plant.

Identify how to plan and locate services.

9° 9. LOCATION STRATEGIES Presentations: Lab Sessions

May 20 - 1. Location and Capacity - Location Strategies

25 2. Actors that affect location decisions MiniCases:

- Rochester Manufacturing

3. Methods of Evaluating Location -

Alternatives

Deliverable 2

4. Capacity and Constraint

Management AUTOEVALUATION N°4

Heizer. Operations Management

5. Bottleneck Analysis

…, 12th Ed. CH 5

6. Break Even Analysis online test time: 25/05/2019 6:00

7. Reducing Risk with Incremental p.m.

Changes

8. Expected Monetary Value (EMV)

to Capacity Decisions

“Gestion de Operaciones” (Operations Management) Course Syllabus 6

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply

Chain Management. (12th Ed) Boston. Pearson. Ch.7

10. MAINTENANCE AND RELIABILITY Presentations: Lab Sessions

1. The Strategic Importance of - Maintenance and

Maintenance and Reliability Reliability

2. Reliability -

3. Maintenance Exercises:

10° 4. Total Productive Maintenance (TPM) - Maintenance Exercises

May 27 – -

June 01 -

MiniCases:

Heizer, J. Render, B. & Munson, C. (2017). - Frito Lay

Operations Management, Sustainability and Supply Assignment: Research Article 3

Chain Management. (12th Ed) Boston. Pearson.

Ch.17 Test 3: LU III

.

“Gestion de Operaciones” (Operations Management) Course Syllabus 7

WEEK CONTENTS ACTIVITIES / EVALUATION

LEARNING UNIT IV: ADVANCED TOPICS

LEARNING OUTCOME:

Identify plant layout types.

Develop the planning and design of a process.

11. LAYOUT STRATEGIES Presentations:

- Layout Strategies

1. The Strategic Importance of -

Layout Decisions -

2. Types of Layout MiniCases:

3. Warehouse and Storage Layouts -

11° 4. Fixed Position Layout -

5. Process Oriented Layout -

June 03 -

-

08

Theory Quiz 2:

- Article 2

AUTOEVALUATION N°5

Heizer, J. Render, B. & Munson, C. (2017). Heizer. Operations Management

Operations Management, Sustainability and Supply …, 12th Ed. CH 17

Chain Management. (12th Ed) Boston. Pearson. Ch. 9 online test time: 08/06/2019 6:00

p.m.

Presentations:

12. Human Resources (HR), Job Design and - Job Design

Work Measurement

MiniCases:

1. HR Strategy for Competitive -

Advantage -

2. Labor Planning -

12° -

June 10 - 3. Job design

4. Ergonomics and the Work Final Project Advance

15

Environment

Heizer, J. Render, B. & Munson, C. (2017).

Operations Management, Sustainability and Supply

Chain Management. (12th Ed) Boston. Pearson. Ch.

10

13. Project Manajement Presentations:

1. Project Cycle - Project Management

2. Work Breakdown Structure MiniCases:

13° 3. Gantt Charts - Mexican Crazy Quilt

June17 - 4. Pert and CPM -

22 Test 4: LU IV

Stevenson, W.J. (2015). Operations Management.

(12th Ed.) NY: Mc Graw Hill [] Ch. 17

Project Work

14° Deliverable 3

June 24 - Theory Quiz 3:

29 - Article 3

“Gestion de Operaciones” (Operations Management) Course Syllabus 8

WEEK CONTENTS ACTIVITIES / EVALUATION

15° COURSE REVIEW Final Project Presentation

July 01 - EXAM BRIEFING Deliverable 4

06

16°

July 08 -

FINAL EXAMS

13

“Gestion de Operaciones” (Operations Management) Course Syllabus 9

VIII. Bibliography

Mandatory Readings:

• Heizer, J. Render, B. & Munson, C. (2017). Operations Management,

Sustainability and Supply Chain Management. (12th Ed) Boston. Pearson.

• James, T. (2011) Operations Strategy. (2011 Ed) Ventus Publishing ApS,

BookBoon.com

• Stevenson, W.J. (2015). Operations Management. (12th Ed.) NY: Mc Graw Hill.

Other Reading:

Chase, R. (2014). Administración de Operaciones: producción y cadena de

suministros. México: McGraw-Hill Educación. [TS155, C3A2, 2014]

Other relevant books in ESAN Library:

Heizer, J. & Render, B. (2009). Principios de Administración de Operaciones.

México: Pearson Educación. [TS155,

H372O, 2009]

Miranda González, F. (2014). Dirección de operaciones: casos prácticos y recursos

didácticos. Madrid: Ediciones Paraninfo. [TS155 M573]

Nahmias, Steven. (2007). Análisis de la producción y las Operaciones. México D.

F.: Compañía Editorial Continental. [TS155, N112 ,2007]

IX. Lab Support

Lab sessions on weeks 9 and 10 for Statistical Process Control

X Professors

“Gestion de Operaciones” (Operations Management) Course Syllabus 10

Choy Pun,

Augusto

achoy@esan.edu.

pe

“Gestion de Operaciones” (Operations Management) Course Syllabus 1

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 19.lewin, David. Human Resources Management in The 21st CenturyDocument12 pagini19.lewin, David. Human Resources Management in The 21st CenturymiudorinaÎncă nu există evaluări

- Cirque de Soleil Case StudyDocument2 paginiCirque de Soleil Case StudyAnand Prasad0% (1)

- Acctg 202 Di Pa FinalDocument10 paginiAcctg 202 Di Pa FinalJoshua CabinasÎncă nu există evaluări

- Announcement Invitation For Psychotest (October)Document17 paginiAnnouncement Invitation For Psychotest (October)bgbfbvmnmÎncă nu există evaluări

- Freehold and LeaseholdDocument3 paginiFreehold and LeaseholdDayah AyoebÎncă nu există evaluări

- InvoiceDocument1 paginăInvoicetanya.prasadÎncă nu există evaluări

- SAG - Front Office Services NC IIDocument6 paginiSAG - Front Office Services NC IImiles1280Încă nu există evaluări

- DO Section 5-6Document46 paginiDO Section 5-6Gianita SimatupangÎncă nu există evaluări

- Mms-Ente-Case StudyDocument2 paginiMms-Ente-Case Studyvivek ghatbandheÎncă nu există evaluări

- Lazaro Vs SSSDocument2 paginiLazaro Vs SSSFatima Briones100% (1)

- Competitors and CustomersDocument2 paginiCompetitors and Customerslk de leonÎncă nu există evaluări

- Fundamentals of Corporate Finance 4th Edition Parrino Test BankDocument35 paginiFundamentals of Corporate Finance 4th Edition Parrino Test BankbrumfieldridleyvipÎncă nu există evaluări

- Introduction of Icici BankDocument6 paginiIntroduction of Icici BankAyush JainÎncă nu există evaluări

- Real Estate Private EquityDocument46 paginiReal Estate Private EquityShobhit GoyalÎncă nu există evaluări

- BCG MatrixDocument1 paginăBCG MatrixFritz IgnacioÎncă nu există evaluări

- OpinionLab v. Iperceptions Et. Al.Document34 paginiOpinionLab v. Iperceptions Et. Al.PriorSmartÎncă nu există evaluări

- Monthly Progress Report ofDocument50 paginiMonthly Progress Report ofHamayet RaselÎncă nu există evaluări

- TVE Phase-1 Addendum No 8Document1 paginăTVE Phase-1 Addendum No 8Anonymous Un3Jf6qÎncă nu există evaluări

- Male, 26 Years: Email: Mip@tapmi - Edu.in Mob: +91 7008878125 Roll No.: 18S723Document1 paginăMale, 26 Years: Email: Mip@tapmi - Edu.in Mob: +91 7008878125 Roll No.: 18S723Kushal KanungoÎncă nu există evaluări

- CIMA Certificate Paper C4 Fundamentals of Business Economics Practice RevisionDocument241 paginiCIMA Certificate Paper C4 Fundamentals of Business Economics Practice RevisionNony Um'yioraÎncă nu există evaluări

- Share Holders Right To Participate in The Management of The CompanyDocument3 paginiShare Holders Right To Participate in The Management of The CompanyVishnu PathakÎncă nu există evaluări

- Strategic Management ModelsDocument24 paginiStrategic Management ModelsAnubhav DubeyÎncă nu există evaluări

- Internal Audit Checklist (For Core Processes) : Issue Number: Effective Date: Document CodeDocument5 paginiInternal Audit Checklist (For Core Processes) : Issue Number: Effective Date: Document CodejulyenfortunatoÎncă nu există evaluări

- Workplace Housekeeping: Training Slides OnDocument42 paginiWorkplace Housekeeping: Training Slides Onamit yadavÎncă nu există evaluări

- Case StudyDocument4 paginiCase Studychandu1113Încă nu există evaluări

- Latihan AdvanceDocument9 paginiLatihan AdvanceMellya KomaraÎncă nu există evaluări

- Huaman Repite PlatoDocument2 paginiHuaman Repite PlatoNkma CzrÎncă nu există evaluări

- Web Based Crime Management SystemDocument22 paginiWeb Based Crime Management SystemZain Ul Abedin SaleemÎncă nu există evaluări

- Introduction To Operation ManagementDocument78 paginiIntroduction To Operation ManagementNico Pascual IIIÎncă nu există evaluări

- B2B E-Marketplace Adoption in Agriculture: Zheng XiaopingDocument8 paginiB2B E-Marketplace Adoption in Agriculture: Zheng XiaopingNikhil MalhotraÎncă nu există evaluări