Documente Academic

Documente Profesional

Documente Cultură

Biofuel Paper Published

Încărcat de

Jaffar MastoiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Biofuel Paper Published

Încărcat de

Jaffar MastoiDrepturi de autor:

Formate disponibile

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/259042230

INTRODUCTION TO BIO-FUEL AND ITS PRODUCTION FROM ALGAE: AN

OVERVIEW

Article · January 2013

CITATIONS READS

2 1,713

2 authors, including:

Sarbjeet Singh Gujral

Cosmetica Laboratories Inc.

21 PUBLICATIONS 27 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

NOVEL TRICYCLIC INDOLE-BASED COMPOUNDS IN THE PREVENTION OF ALZHEIMER’S DISEASE View project

Synthesis and Characterization of Asymmetrical Gemini Surfactants View project

All content following this page was uploaded by Sarbjeet Singh Gujral on 12 July 2014.

The user has requested enhancement of the downloaded file.

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

Review Article

Pharmaceutical Sciences

INTRODUCTION TO BIO-FUEL AND ITS PRODUCTION FROM ALGAE: AN OVERVIEW

Aman Kothari1, Sarbjeet Singh Gujral*2

1

Northern India Engineering College (Aff. To G.G.S. Indraprastha University)

2

Maharaja Surajmal Institute of Pharmacy, New Delhi (Aff. To G.G.S. Indraprastha University)

*Corresponding Author Email: sarbjeet_singh18@yahoo.in

ABSTRACT

In today's scenario where there is too much dependence on fuel for meeting the requirements of the common

masses and industries, and due to failure in the replenishment of non-renewable natural sources, arises an urge to

supplement the requirements from renewable natural resources. Biofuel or in simple language fuel obtained from

biological sources like crop wastes, exhausted mineral oils or fats etc. is a cogent alternative but none has proven

to be a complete surrogate for petroleum and coal due to various reasons. In this context, a path breaking

development of mass production of biofuel form algae comes into picture. In this following article the production

of biofuel and methods of obtaining the same has been discussed.

KEY WORDS

Bio-fuel, Algae.

INTRODUCTION as an alternate source of energy to the present

Now-a-days the common notion around the day liquid fuels.

world is to reduce the consumption of fossil fuels So what is a biofuel?

and bring down effects of global warming. It will A biofuel is a type of fuel whose energy is

be an ideal state to live in a pollution free world derived from biological carbon fixation. Biofuels

without cutting on power requirements, include fuels derived from biomass conversion,

however for this kind of environment we as well as solid biomass, liquid fuels and various

urgently need to reduce our dependency on biogases.

fossil fuels. Thinking tanks find it difficult to Classification of biofuel: biofuel can be classified

come up with such an alternative fuels which as:

could replace conventional fuels. No energy

source has still been proven perfect. Like some

fuels are environment friendly but not effective

biofuel

for mass production due to high initial prices etc.

environmental friendly fuel derived from natural first

source is termed as biofuel.[1]. Bio-fuel has generation

biofuel

become attention-grabbing topic; this is

attributed to the higher demands of fuel, power,

second

depletion of fossil fuels, green house effect, rise

generation

269

in crude oil prices. Thus this is being worked out biofuel.

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

FIRST GENERATION BIOFUEL fermentation [acetone, ethanol] yields butanol.

Bioalcohol (Without modification to the engine or car), [2]

Alcohol is produced by fermentation, generally and is less corrosive and less water soluble than

from carbohydrates from starch rich plants like ethanol.

sugarcane, molasses to name a few and Biodiesel

Bioethanol is a type of alcohol. Ethanol is also The most common biofuel in Europe is Biodiesel.

being produced from cellulose biomass which is Trans-esterification from oils or fats yields a

being derived from non-food sources such as liquid similar in composition to the crude oil by-

trees and grasses. Use of ethanol as a fuel is not product diesel (see chemical reaction for the

new to the industry as earlier also it has been synthesis of biofuel from transesterification of

used as an additive up to 15% with gasoline fuel oils below). Chemically, it consists mostly of fatty

to increase the octane number of it, in turn acid methyl (or ethyl) esters. Animal fats,

increasing efficiency. Biobutanol (also called vegetable oils, jatropha, mahua, mustard, flax,

biogasoline) is often claimed to provide a direct sunflower, palm oil, hemp, field pennycress,

replacement for gasoline, because it can be used pongamia pinnata and algae are amentionable

directly in a gasoline engine. Methanol is few of biodiesel feedstocks. Pure biodiesel

currently produced from natural gas, a non- (B100) is the lowest emission diesel fuel.

renewable fossil fuel. It can also be produced In a number of countries, 5% biodiesel blend is

from biomass as biomethanol. Methanol could widely used and is available at thousands of gas

be an alternative to the hydrogen economy, stations.[3][4] Biodiesel is an oxygenated fuel,

compared to today's hydrogen production from meaning that it contains a reduced carbon

natural gas. Butanol is considered of higher value content and higher hydrogen and oxygen

as compared to other bio-fuels as it can be content than conventional diesel. This improves

directly used with the current gasoline engines the combustion of biodiesel and reduces the

(without modification to the engine or car),[2] particulate emissions from un-burnt carbon.

and they would produce more energy. ABE

Production of biodiesel

R R CoA Ligase ATP Co.A

Glycerol-3-phosphate

270

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

AcylCoA

1,2-diacylglycerol-3-phosphare 1-Acylglycerol-3-phosphate

Hydrolysis, fattyCoA

NaOH,MeOH

Triacylglycerol (fat) (saponification) biodiesel

Fig:2 Chemical reactions involving production of biodiesel from exhausted fats/oils

The estimated world consumption of biodiesel uses elevated temperatures and pressure in the

is as follows:[15] presence of a catalyst to break down the long

chains.[7]

Vegetable oil

Lower quality oil can and has been used for this

purpose. Used vegetable oil is increasingly being

processed into biodiesel, or (more rarely)

cleaned of water and particulates and used as a

fuel. Vegetable oil fuel must be heated to reduce

its viscosity to that of diesel, either by electric

coils or heat exchangers. This is easier in warm

or temperate climates. Oils and fats can be

hydrogenated to give a diesel substitute. The

Green diesel resulting product is a straight chain hydrocarbon

Green diesel result from hydrocracking of with a high cetane number, low in aromatics and

biological oil feedstocks which include vegetable sulfur and does not contain oxygen.

oils and animal fats.[5][6] Long chain Hydrogenated oils can be blended with diesel in

271

hydrocarbons aree broken down into smaller all proportions.[8]

chains in hydrocracking which is a method that Biogas

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

Biogas is methane(CH4) produced by anaerobic hydrocarbons). A derivative of solid biofuel is

digestion of organic material by anaerobic biochar, which is produced by biomass pyrolysis.

microbes.[9] It can be produced either from Bio-char made from agricultural waste can

biodegradable waste materials, and the use of substitute for wood charcoal. As wood stock

energy crops fed into anaerobic digesters to becomes inadequate this alternative is gaining

supplement gas yields. Farmers produce biogas ground. For example, in eastern Democratic

from manure from their cows and other farm Republic of Congo, biomass briquettes are

wastes by using an anaerobic digester (AD).[10] marketed as alternatives to charcoal to protect

Virunga National Park from deforestation related

Syngas with charcoal production.[13]

Syngas is a mixture of hydrogen, carbon Second generation biofuels (advanced biofuels)

monoxide and other hydrocarbons. Partial These are also known as advanced biofuels.

combustion of biomass, the process proceeds Many of the biofuel in this class has been derived

with combustion with an amount of oxygen that from algae and more recently from microalgae

is not sufficient to convert the biomass which are genetically modified version of algae

completely to carbon dioxide and water.[8] of common use. Co-cultures of Shewanella and

Before partial combustion the biomass is dried, Synechococcus which have been genetically

and sometimes pyrolysed. modified has is now commercially utilized for

• Can be used directly in internal combustion biofuel production but many of such biofuels are

engines, turbines.[11] under development, examples of these include

• Can be used to produce methanol, hydrogen, Cellulosic ethanol, Algae fuel [14]. BioDME,

to produce a diesel substitute, or a mixture Fischer-Tropsch diesel, DMF, bio-hydrogen,

of alcohols that can be blended into biohydrogen diesel.

gasoline. Gasification normally relies on

temperatures >700°C. Why biofuel from algae is more preferred to

Solid biofuels biofuel from plant courses?

Solid bio-fuels include wood, sawdust, grass

trimmings, domestic refuse, charcoal,

agricultural waste, non-food energy crops, and

dried manure. One of the disadvantages of using

the oldest solid bio-fuel wood is the amount

smoke it creates. Advantage of solid biomass fuel

is that it is often a by-product, a residue or

waste-product of other processes, such as Even though many crops like corn can be utilized

farming, animal husbandry and forestry, this way for the production of biofuel, but none of the

we do not invest separately to get the fuel.[12] methods can be utilized effectively when yield is

In theory this means there is no competition a major concern. Biofuel from plant source gives

between fuel and food production, although this very low yield per hectare of land. Fuel obtained

is not always the case.[30] from Algae yields considerably more energy than

The other disadvantages of raw biomass are that other bio-fuels (per unit area). Algae can be

grown on land that has become unsuitable for

272

it emits considerable amounts of pollutants such

as particulates and PAHs (polycyclic aromatic agriculture, and arable lands as well. This

advantage is also commercially exploited for

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

mass production of biofuels. Companies include • sonication for cell interruption for example

Solazyme, Sapphire Energy and OPXBIO. Further using solvents to extract algal cells without

the yield can be increased by using photo-bio disrupting cellular functions

reactors which can drastically change the yield of • Extraction bypass schemes that try to obtain

the biofuels from few kgs. to gallons. [16] algal systems that exude products directly

into the growth medium.

Mechanical Disruption (i.e., Cell Rupture)

For the biofuels dependent on the accretion of

intra-cell lipids to be successful,

• extracting solvent should infiltrate through

the lipid enclosing matrix

• Physically contact the lipid material

• Solvate the lipid

Fig: a photo bio-reactor Use elevated temperatures and pressures which

Algae-based biofuels has both its pros and cons force the solvent into the required biopolymer

which includes: contact and be compensated for by effective

Pros mechanical disruption. Mechanical disruption

• Reduction in the use of Crude Oil based fuel can include bead mills (or bead-beating), cell

• Reduction in carbon dioxide (CO2) levels homogenizers, autoclaving [17], ultrasounds.

• Increased energy output as compared to Non-mechanical techniques include processes

other bio-fuel substituent such as freezing, acid, base, and enzyme

• Reduction in degradation of land due to oil reactions [17], use of organic solvents, and

mining osmotic shock to name a few. The use of

• Renewable source of energy can be grown microwaves to disturb cells and augment

anywhere provided temperature conditions efficiency of vegetable lipid and oil extraction is a

are met noteworthy advancement [18], even if

Cons applications outside methodical labs are blurred.

• High initial cost as in case of every other Treatment of sewage sludge with pulsed

renewable source of energy sonication has enhanced methane gas

• Needs some rare elements in extraction of production and reduction in biosolids in sludge

fuel digestion [19].

• Requirement of proper temperature Organic Co-solvent Mixtures

conditions and sizeable amount of land for In the co-solvent extraction procedure [20], after

growth the reaction is accomplished, water is added to

Methods of extraction of biofuel from algae: the co-solvent (chloroform) mixture until a two-

Lipid Extraction from algae phase system develops where water and

Lipid extraction from algae is one of the methods chloroform break up into two immiscible layers.

for the production of biofuel .Lipid extraction Lipids can be recovered for analysis as they

includes the subsequent approaches: separate to the chloroform layer. Subsequently,

• Solvent-based extraction depending on other combinations of co-solvents projected for

microwaves

273

the extraction of lipids: hexane/isopropanol for

tissue [21]; hexane/ethanol for microalgae [22];

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

and hexane/isopropanol for microalgae [23]. The suggested that the water will form a solvent

hexane system is supported because hexane and covering around the lipids, making it difficult for

alcohol will readily separate into two separate less polar solvents such as chloroform to

phases when water is added, thereby improving connect, solubilise, and extract the lipids.

downstream separations. Likewise, less volatile Direct Transesterification of Lipids into Fatty

and hazardous alcohols have been suggested in Acid Methyl Esters (FAMES)

place of methanol. One example is the Lepage and Roy (1984) offered the direct

hexane/ethanol extraction co-solvent system transesterification of human milk without prior

[24]. In other cases, single alcohol (e.g., 1- extraction or refining for improved recovery of

butanol and ethanol) solvents have been tested fatty acids. In general, the approach proposed a

[23]. In these applications, the alcohol is first one-step reaction that added the alcohol and

added as the extracting solvent. Separation is acid catalyst directly to the biomass sample and

then achieved by adding both hexane and water followed with heating at 100˚C for an hour under

in proportions that create a two phase system sealed conditions would increase fatty acid

(hexane and an aqueous hydroalcoholic) that concentrations measured, and provide relatively

partition the extracted lipids into the nonpolar high recoveries of volatile medium chain

hexane [25]. triglycerides, and eliminate the need to use

The results suggest that the most vital condition antioxidants to protect unsaturated lipids.

when selecting a co-solvent system to extract Efforts in this direction have shown that when

lipids is: employing direct transesterification with an acid

• The capability of a more polar co-solvent to catalyst (i.e., acetyl chloride), the efficiency of

disturb the cell membrane and thus make it the reaction improved when a second “less

adequately porous and polar” solvent for example diethyl ether or

• The ability of a second less polar co-solvent toluene were mixed with the methanol to alter

to better match the polarity of the lipids the polarity of the reaction medium [27]. These

being extracted. results suggest that the usefulness of the second

Application of Organic Two-Solvent Systems for co-solvent depends upon its ability to solubilise

Lipid Extraction from Microalgae: the target lipids along with its miscibility with

The sequence of solvent addition also affects methanol. However the earlier co-solvent

extraction [26]. Starting from freeze dried systems stay largely bench-scale methods which

biomass, it has been verified that, the extraction are difficult to scale up to industrial processes

of lipids was notably more efficient when due to solvent toxicity and the low carrying

solvents were added in order of increasing capacity of the solvents. As a result, single

polarity (i.e. chloroform, methanol, and then solvent systems at elevated temperature and

water)[26]. The results can be justified as, in pressure have the following advantages:

terms of initial contact of the biomass with • High temperature and pressure increase the

nonpolar solvents deteriorating the connection rate of mass transfer and degree of solvent

between the lipids and cell structure, preceding access

their dissolution in the monophasic system of • Increased pressures reduce the dielectric

water, chloroform, and methanol. These results constant of otherwise immiscible solvent [28].

274

have a key influence on liquid phase extraction Accelerated Solvent Extraction

systems applied to moist biomass as, it is

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

Accelerated solvent extraction was proposed in [34], functional ingredients from microalgae [35],

the mid 1990s [29], using the technique on 1 - 30 and saponins from oil-seeds [36]. In technique

g samples of dried biomass. It uses organic the water, under condition consideration,

solvents at high pressure and temperatures becomes less polar and organic compounds tend

usually above their boiling point. The process to be more soluble than at room temperature. In

involves, enclosing a solid sample in a sample addition, products can easily be separated as the

cartridge which is prior filled with an extraction water is cooled back down to room temperature,

fluid and used to statically extract the sample and products miscible at the high temperature

under elevated temperature (50 - 200˚C) and and pressure become immiscible at lower

pressure (500 - 3000 psi) conditions for short temperatures. A major constraint, however, is

time periods (5 - 10 min). Compressed gas is the difficulty with proposing a large scale system

used to remove the sample extract from the cell and the high-energy load required to heat the

into a collection vessel. This method is applicable system up to subcritical temperatures.

to solid and semi-solid samples that can be Additional energy challenges are created as a

retained in the cell during the extraction phase. large-scale design would require a considerable

Apart from improving yields and reducing cooling system to cool down the product to

extraction time, Accelerated Solvent Extraction room temperature to avoid product degradation.

can also be applied to efface co-extractable Heterotrophic Production

material from various processes, to selectively One of the many other methods for extraction

extract polar compounds from lipid-rich samples. and fractionation is the production of oils using

Accelerated Solvent Extraction process is more heterotrophic algae. In this approach non-

effective if extracting solvent, sample-solvent photosynthetic algae are developed using sugars

ratio, extraction temperature, and time have as energy source and using traditional industrial

been optimized [30]. The performance of fermentation equipment [37]. Several companies

Accelerated Solvent Extraction was compared to have contrived algae that secrete oil into the

that of traditional Folch method for microalgae fermentation media which can be recovered and

grown on dairy manure effluent [31]. The later refined into a biofuel; this methodology

Accelerated Solvent Extraction method, drastically reduces capital and operating cost for

depending on the solvent, extracted 85 - 95% of the extraction procedure. The benefits of this

the fatty acid substance in the reaped approach range from the use of conventional

microalgae compared to 44 - 55% of the fatty fermentation systems ease of scale-up, averting

acids by the Folch method in the first solvent expensive extraction schemes, ability to maintain

extraction cycle. the integrity of the fermentation catalyst to the

Subcritical Water Extraction use of sugar-based feedstock.

This method is based on the use of water, at Direct Production of Biofuels from Algae

temperatures below the critical temperature, Heterotrophic growth has certain benefits in

and pressure high enough to keep it in the liquid terms of process cost as it can eliminate many

state [32]. The technique, was initially applied to process steps and also permits for maintaining

biomass hemicellulose as a pre-treatment to its controlled conditions. Such a system can

use as a fermentation substrate [33]. However, engender very high biomass and a high

275

now it has been tested for the selective proportion of that biomass as lipid. There are

extraction of essential oils from plant matter several biofuels that can be produced directly

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

from algae, including alcohols, alkanes, and hydrogen.

Alcohols [38]

Fig: scheme for production of ethanol in algae

Production of alcohols like ethanols is headspace of the reactor, purified, and stored.)

accomplished through the creation and storage This expertise is estimated to yield 4,000 - 6,000

of starch during photosynthesis inside the algae, gallons per acre per year, with prospective

or by feeding sugar to the algae directly, and increaseing up to 10,000 gallons per acre per

subsequent anaerobic fermentation of these year within a few years with noteworthy

carbon sources to produce ethanol under dark research. It is theoretically estimated that one

conditions. Algae, such as Chlorella vulgaris and ton of CO2 is converted into approximately 60 -

Chlamydomonas perigranulata, are competent of 70 gallons of ethanol with this technology.

yielding ethanol and other alcohols during Alkanes

heterotrophic fermentation of starch [39]. If In addition to alcohols, alkanes may be produced

alcohols can be mined directly from the algal directly by heterotrophic metabolic pathways

culture media, the process can be considerably using algae. Rather than growing algae in ponds

less energy demanding than competitive algal or enclosed in plastic tubes that utilize sunlight

biofuel processes. This process usually consists and photosynthesis, algae can be grown inside

of closed photo-bioreactors employing sea-water closed reactors without sunlight. The algae are

with metabolically superior cyanobacteria [40]. fed sugars, the cheap availability of which is a

(One key aspect of the system is that a source of key consideration for cost-effective production

cheap carbon, such as a power plant, is typically of biofuels; these sugars are themselves

used to supply CO2 to the bioreactors to available from renewable feedstock such as

accelerate the algae growth. An example of this lignocellulosic biomass, in a pressure and heat-

process technology links sugar production to controlled environment.

algal photosynthesis. There are claims that this Hydrogen

process may consume more than 90% of the Biological production of hydrogen technologies

system’s CO2 through photosynthesis, wherein a present wide range of methods to generate

portion of the carbon in these sugars is hydrogen which include indirect biophotolysis,

276

converted into ethanol. The ethanol is secreted direct biophotolysis, photo-fermentation, and

into the culture media and is collected in the dark-fermentation. Yet several challenges wait to

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

be addressed before biological hydrogen dwarfed by the shortcomings such as the process

production can be considered a viable being energy demanding, intricacy in separating

technology, some of which are the constraint of the glycerol, and require elimination of alkaline

photosynthetic hydrogen production by catalyst from the product and treatment of

accretion of a proton gradient, competitive alkaline wastewater. A solution to these

inhibition of photosynthetichydrogen production limitations is the use of biocatalysts (lipases) in

by CO2, necessity for bicarbonate binding at transesterification of triacylglycerols for

photosystem II (PSII) for efficient photosynthetic biodiesel manufacturing [45]. One vital point

action, and competitive drainage of electrons by that needs to be addressed is the solvent and

oxygen in algal hydrogen production. temperature limitations of the enzymes in order

to facilitate efficient biocatalytic processing.

CONVERSION OF ALGAL EXTRACTS Although enzymatic approaches have become

Chemical Transesterification more attractive, the process stands unproven at

This process is engaged to change triacylglycerols a large scale mainly due to the rather high price

extracted from algae to fatty acid methyl esters of lipase and its ephemeral life caused by the

(FAMe), which is simply a process of effects of excessive methanol and co-product

replacement of an alcohol group from an ester glycerol. The presence of solvents is occasionally

by another alcohol [41]. It can be achieved via necessary to augment the solubility of the

catalytic or non-catalytic reaction systems using triacylglycerols during the extraction process,

different heating systems required to initiate the and the enzymes used in the downstream

reaction. This technology is relatively mature and change must be able to fulfil their purpose in the

has been verified to be a standard in the presence of these solvents to varying degrees to

conversion of vegetable oils into biodiesel [42]. enable cost-effective biofuel production [46].

Vaporizing under high vacuum, biodiesel is Solvent engeering method can also be used to

separated from the ether. Acid catalyzed enhance the lipase lipase-catalyzed methanolysis

transestrification is another way of converting of triacylglycerols for biodiesel production

algal extracts. This involves soluble bases being [47][48]. Much research is still necessary in

replaced liquid acid catalyst some of which are discovery, engineering, and optimization of

H2SO4, HCl [43]. Acid catalysts have advantages, enzymatic processes, which are competent of

yet they at present are not chosen due to their producing the reactions in a range of

lower activity than the conventional environments and on different types of oil

transesterification alkaline catalysts. Recently, it feedstocks [49]. Bioprospecting for the enzymes

has been verified that HPA-catalyzed in extreme environments may produce enzymes

transesterification of vegetable oil accomplishes with convincing characteristics that are more

higher reaction pace than standard mineral acids suitable for industrial applications [50]. Enzyme

due to their higher acid strength [44]. The immobilization would play a vital role in

apparent higher activity of certain HPAs with developing an economic method of biocatalytic

respect to polyoxometallates of higher strength transesterification [51].

resulted in lower pre-treatment temperatures. Catalytic Cracking

Biochemical Conversion (Enzymatic) Although catalytic transestrification is a very

277

The advantage of chemical processes giving high effective and relatively economical, these

conversions of triscylglycerols to esters is catalysts require purification and removal from

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

the product stream, which increases the overall most importantly resist poisoning and the

cost of execution. One likely solution to this is leaching of active components. One particular

the improvement of immobilized heterogeneous concern is the consistency and the life of the

and/or homogeneous catalysts that are very catalysts in the reaction environment.

efficient and inexpensive [52]. Acid and basic

catalysts are usually classified as Brönsted or RECENT APPLICATIONS OF BIO-FUEL

Lewis catalysts. Lewis acid catalysts, AlCl3, ZnCl2 150mpg Algae-Powered Toyota Prius

to name a few; have been verified as a feasible One of the first successful test was an algae fuel

means of converting triacylglycerols into fatty powered vehicle which was a modified Toyota

acid methyl esters. One of the many other Prius known by the name Algaeus which gave a

methods include, catalysts derived from titanium mileage of about 63 kilometers on a litre of

compounds having the general formula ATixMO; green fuel. This car was launched in San-

where A is a hydrogen atom/an alkaline metal Francisco. It derived power from green fuel,

atom, M a niobium atom or a tantalum atom, which was developed by Sapphire Energy. The

and x is number less than 7; is employed in only drawback was its cost.

vegetable oil transesterification. The catalysts Engineers Tap Algae Cells for Electricity

achieved are steady and give high glycerol yield. Light energy is converted to chemical energy and

A typical FAME yield of 91% and glycerol yield of stored in bonds of sugar by plants during the

91% were obtained in a fixed-bed reactor at photosynthesis process. This is later utilized as

200˚C and 35 bar, using HTiNbO3 as the catalyst. their source of energy. The process of conversion

Vanadate metal compounds are stable, active takes place inside a chloroplast, which is

catalysts during transesterification, with TiVO4 believed to be the source of power. Chloroplasts

being the most active [53]. This catalyst is also are responsible for the green shade of the plants

more active than HTiNbO3, producing the same and algae. The actual process that takes place

yields with lower residence times. (no language during photosynthesis is that the water is broken

to edit in blue) Double-metal cyanide Fe-Zn down to oxygen, the negative charged electrons

proved to be promising catalysts resulting in and the positive charged protons. The electrons

active transesterification of oil. These catalysts are stored in the chloroplast, this reaches excited

are Lewis acids, hydrophobic (at reaction levels when leaves are exposed to sunlight. The

temperatures of about 170˚C), and insoluble. excited electrons pass through a number of

Moreover, they can be used even with oils layers of proteins where they are absorbed.

containing significant amounts of free fatty acids After this the energy from the electrons is used

and water, probably due to the hydrophobicity to make sugar until the entire energy is utilized.

of their surface. The catalysts are active in the The New Role of Microbes in Bio-Fuel

esterification reaction, reducing the Production

concentration of free fatty acids in non-refined Plants and microbes both are used to refine and

oil or in used oil. Other catalyst examples include synthesize to produce bio-fuel. This helps

MgO, CaO, and Al2O3. conserve fossil fuels and are considered to be

At these temperatures about (220-240 C), the conservational and renewable sources of energy.

process pressure is high (40 - 60 bar), which Recent studies indicate that microbes can

278

interprets to high construction requirements and generate fuel from proteins, as a substitute to

high plant design capital. The catalysts used must

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

using them for its growth. (The research is being [12] Frauke Urban and Tom Mitchell 2011. Climate change,

disasters and electricity generation. London: Overseas

carried out at university of california, LA)

Development Institute and Institute of Development

Studies

CONCLUSION [13] "Threat to Great Apes Highlighted at Virunga Meeting".

Summing up, bio-fuels based on algae are being America.gov. Retrieved 2010-07-14.

[14] Scott SA, Davey MP, Dennis JS, Horst I, Howe CJ, Lea-

seen as an alternative source of energy. It is still

Smith DJ, Smith AG. 2010. Biodiesel from algae:

in the embryonic stages as all results are being challenges and prospects. Current Opinion in

analyzed before starting the substitution primary Biotechnology. 21(3):277-86

source of energy, Crude Oil. The main factors [15]http://domesticfuel.com/wpcontent/uploads/2008/09/

that have to be looked upon the use of these worldbiodiesel.gif

[16]http://www.massey.ac.nz/massey/fms/Massey%20New

fuels are their production, the by-products of

s/2009/04/magazine-images/bio-reactor.jpg

their use, and the cost of production. The source [17] Mata et al., 2010

of energy from algae seems to be promising, [18] Cravotto et al., 2008; Virot et al., 2008

provided the above mentioned factors are taken [19] Rittman et al., 2008

[20] Bligh and Dyer, 1959

care of.

[21] Hara & Radin, 1978

[22] Cartens et al., 1996

REFERENCE [23] Nagle & Lemke, 1990

[1]Demirbas, A.(2009). "Political, economic and [24] Grima et al., 1994

environmental impacts of biofuels: A review". Applied [25] Fajardo et al., 2007

Energy86:S108S117.doi:10.1016/j.apenergy.2009.04.03 [26] Lewis et al., 2000

6. edit [27] Carvalho and Malcata, 2005

[2] "ButylFuel, LLC Main Page". Butanol.com. 2005-08-15. [28] Herrero et al., 2006

Retrieved 2010-07-14. [29] Richter et al., 1996

[3] "ADM Biodiesel: Hamburg, Leer, Mainz". Biodiesel.de. [30] Denery et al., 2004

Retrieved 2010-07-14. [31] Mulbry et al., 2009

[4] RRI Limited for Biodiesel Filling Stations. "Welcome to [32] Soto and Luque de Castro, 2001

Biodiesel Filling Stations". Biodieselfillingstations.co.uk. [33] Mok et. al., 1992

Retrieved 2010-07-14. [34] Eikani et al., 2007

[5] Brown, Robert; Jennifer Holmgren. "Fast Pyrolysis and [35] Herrero et al., 2006

Bio-Oil Upgrading". Retrieved 15 March 2012. [36] Gueçlue-Uestuendağ et al., 2007

[6] "Alternative & Advanced Fuels". US Department of [37] Barclay et al., 1994

Energy. Retrieved 7 March 2012. [38]http://media.treehugger.com/assets/images/2011/10/

[7] Knothe, Gerhard (2010), Biodiesel and renewable diesel: Algenol-algae-image1.jpg

A comparison, Progress in Energy and Combustion [39] Hon-Nami, 2006; Hirayama et al., 1998

Science [40] Hirano et al., 1997

[8] Evans, G. "Liquid Transport Biofuels - Technology Status [41] Demirbas, 2009

Report", National Non-Food Crops Centre, 2008-04-14. [42] Hossain et al., 2008

Retrieved on 2009-05-11. [43] Ataya et al., 2007

[9] Redman, G., The Andersons Centre. "Assessment of on- [44] L. Xu et al., 2008

farm AD in the UK", National Non-Food Crops Centre, [45] Svensson and Adlercreutz, 2008

2008-06-09. Retrieved on 2009-05-11. [46] Fang et al., 2006

[10] "BIOGAS: No bull, manure can power your farm." [47] Su and Wei, 2008

Farmers Guardian (25 September 2009): 12. General [48] Liao et al., 2003

OneFile. Gale. [49] Lopez-Hernandez et al., 2005

[11] Electricity from wood through the combination of [50] Guncheva et al., 2008

279

gasification and solid oxide fuel cells, Ph.D. Thesis by [51] Yamane et al., 1998

Florian Nagel, Swiss Federal Institute of Technology [52] McNeff et al., 2008

Zurich, 2008 [53] Cozzolino et al., 2006

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

Available Online through

www.ijpbs.com (or) www.ijpbsonline.com IJPBS |Volume 3| Issue 1 |JAN-MAR |2013|269-280

[54] Sheehan, John; et al. (July 1998). "A Look Back at the U. Biofuels from Algae". National Renewable Energy

S. Department of Energy's Aquatic Species Program: Laboratory. Retrieved 16 June 2012.

*Corresponding Author:

Sarbjeet Singh Gujral*

Maharaja Surajmal Institute of Pharmacy

(Aff. To GGS Indraprastha University) C-4, Janakpuri,

New Delhi-110058, India

Phone: 9871334787

E-mail ID: sarbjeet_singh18@yahoo.in

280

Page

International Journal of Pharmacy and Biological Sciences (e-ISSN: 2230-7605)

Sarbjeet Singh Gujral*et al Int J Pharm Bio Sci

www.ijpbs.com or www.ijpbsonline.com

View publication stats

S-ar putea să vă placă și

- Biotechnology Reports: Jaspreet Kaur, Anil Kumar Sarma, Mithilesh Kumar Jha, Poonam GeraDocument23 paginiBiotechnology Reports: Jaspreet Kaur, Anil Kumar Sarma, Mithilesh Kumar Jha, Poonam GeraolaragoncÎncă nu există evaluări

- 149 Ijmperdjun2019149Document8 pagini149 Ijmperdjun2019149TJPRC PublicationsÎncă nu există evaluări

- Biofuels FinalDocument4 paginiBiofuels Finalapi-326166436Încă nu există evaluări

- InTech-Biofuel Sources Extraction and DeterminationDocument28 paginiInTech-Biofuel Sources Extraction and DeterminationHadi WaisiÎncă nu există evaluări

- Production of Biodisel From Melon Seed: January 2013Document7 paginiProduction of Biodisel From Melon Seed: January 2013Richard Merck MendozaÎncă nu există evaluări

- Utilization of A Vegetable Oil Species Residue For Biogas ProductionDocument10 paginiUtilization of A Vegetable Oil Species Residue For Biogas ProductionMahendra Kumar MÎncă nu există evaluări

- A Review: Advantages and Disadvantages of BiodieselDocument6 paginiA Review: Advantages and Disadvantages of BiodieselBharath KumarÎncă nu există evaluări

- Production and Characterization of Biodiesel FromDocument15 paginiProduction and Characterization of Biodiesel FromInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Production of Biodiesel From Vegetable Oils: Grasas y Aceites March 2008Document4 paginiProduction of Biodiesel From Vegetable Oils: Grasas y Aceites March 2008KhadeejaÎncă nu există evaluări

- Phase 2 (JBD) 1Document45 paginiPhase 2 (JBD) 1naveenÎncă nu există evaluări

- Renewable Energy: Xiaolei Zhang, Song Yan, Rajeshwar D. Tyagi, Rao Y. SurampalliDocument12 paginiRenewable Energy: Xiaolei Zhang, Song Yan, Rajeshwar D. Tyagi, Rao Y. SurampalliArif HidayatÎncă nu există evaluări

- Biofuels WorksheetDocument3 paginiBiofuels WorksheetMan Iam StrongÎncă nu există evaluări

- Biofuel Paper Presentation Report SummaryDocument15 paginiBiofuel Paper Presentation Report SummaryManjesh ThilakÎncă nu există evaluări

- Biotechnology For Biofuels-EditedDocument4 paginiBiotechnology For Biofuels-EditedKARTHIK VINODÎncă nu există evaluări

- Catalytic Technologies For Biodiesel Fuel Production and Utilization of Glycerol A ReviewDocument32 paginiCatalytic Technologies For Biodiesel Fuel Production and Utilization of Glycerol A ReviewBaskarrajaÎncă nu există evaluări

- Optimized Conditions For The Design and Operation of A Vacuum Distillation ColumnDocument18 paginiOptimized Conditions For The Design and Operation of A Vacuum Distillation Columnhamz9k1Încă nu există evaluări

- Production of Biodiesel From Used Cooking OilDocument7 paginiProduction of Biodiesel From Used Cooking OilDennis OrlandoÎncă nu există evaluări

- BiofuelsDocument18 paginiBiofuelsAbdulsalam AbdulrahmanÎncă nu există evaluări

- Careers in Biofuels: Emily Richards January 2013 - Report 10Document12 paginiCareers in Biofuels: Emily Richards January 2013 - Report 10Minerva RodríguezÎncă nu există evaluări

- Biogas Technology in Sub Saharan AfricaDocument13 paginiBiogas Technology in Sub Saharan AfricaUTHSO NANDYÎncă nu există evaluări

- Review On The Extraction Methods of Crude Oil FromDocument20 paginiReview On The Extraction Methods of Crude Oil FromrobbyharlyÎncă nu există evaluări

- Biogas and Biofuel Project ReportDocument14 paginiBiogas and Biofuel Project Reportvedant hiwarkarÎncă nu există evaluări

- Article PublicationDocument8 paginiArticle Publicationrikaseo rikaÎncă nu există evaluări

- Journal of Cleaner Production Comparative Study 1-S2.0-S0959652622048107-MainDocument14 paginiJournal of Cleaner Production Comparative Study 1-S2.0-S0959652622048107-MainOmar KHELILÎncă nu există evaluări

- Biomass EnergyDocument13 paginiBiomass EnergyMayank AgarwalÎncă nu există evaluări

- GSOE9010 ProposalDocument4 paginiGSOE9010 ProposalShaheer Shabbir0% (1)

- Bharat Ecofuels Guide to BiofuelsDocument18 paginiBharat Ecofuels Guide to BiofuelsOnkar ChavanÎncă nu există evaluări

- Development of BiodieselsDocument9 paginiDevelopment of BiodieselsARJYA ROYÎncă nu există evaluări

- BiofuelsDocument28 paginiBiofuelsOctovianus PasandaÎncă nu există evaluări

- Biofuel Review: A Study on Biofuel as a Green Energy ResourceDocument6 paginiBiofuel Review: A Study on Biofuel as a Green Energy ResourcePradip PatelÎncă nu există evaluări

- Discussion BiofuelDocument7 paginiDiscussion BiofuelSiti Humaira IbrahimÎncă nu există evaluări

- Algae in Biofuel Group 1 (Rachna)Document12 paginiAlgae in Biofuel Group 1 (Rachna)rachnahm03Încă nu există evaluări

- Biomass Energy Conversion Processes & ApplicationsDocument28 paginiBiomass Energy Conversion Processes & ApplicationsAyush kumarÎncă nu există evaluări

- Research Paper On BiodieselDocument5 paginiResearch Paper On Biodieselgvzyr86v100% (1)

- Ijsred V2i1p18Document9 paginiIjsred V2i1p18IJSREDÎncă nu există evaluări

- Development of An Improved Biodiesel Plant: December 2015Document7 paginiDevelopment of An Improved Biodiesel Plant: December 2015Mafer UscangaÎncă nu există evaluări

- A Review On Fermentative Production of Biobutanol From BiomassDocument11 paginiA Review On Fermentative Production of Biobutanol From Biomassdicky saputraÎncă nu există evaluări

- A Biogas Decision Support System ToolDocument9 paginiA Biogas Decision Support System ToolHgagselim SelimÎncă nu există evaluări

- Biofuels Defined: Liquid Fuels from Living OrganismsDocument11 paginiBiofuels Defined: Liquid Fuels from Living OrganismsK.D. PatelÎncă nu există evaluări

- Uamerica 23 03405Document8 paginiUamerica 23 03405Rimy Cruz GambaÎncă nu există evaluări

- AlgaeDocument18 paginiAlgaeAhmed mohamedÎncă nu există evaluări

- A Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilDocument16 paginiA Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilElbanhawy4EverÎncă nu există evaluări

- Report On BiodieselDocument32 paginiReport On BiodieselEmmanuelÎncă nu există evaluări

- Biodiesel Production Using Second-Generation Feedstocks: A ReviewDocument18 paginiBiodiesel Production Using Second-Generation Feedstocks: A ReviewPadelisgiÎncă nu există evaluări

- Biodiesel Production Methods and Fuel Properties ReviewDocument13 paginiBiodiesel Production Methods and Fuel Properties ReviewKa HinaÎncă nu există evaluări

- Biodiesel Fuel For The Future A Brief ReviewDocument10 paginiBiodiesel Fuel For The Future A Brief ReviewalhassanÎncă nu există evaluări

- Synthesis Paper Title: BiofuelsDocument24 paginiSynthesis Paper Title: Biofuelspati_deeps234Încă nu există evaluări

- Bio Fuels Chemistry PresentationDocument24 paginiBio Fuels Chemistry Presentationtarik.coralic2008Încă nu există evaluări

- Investigating Biodiesel Concoction ProcessDocument7 paginiInvestigating Biodiesel Concoction ProcessJosh Aldrin SarioÎncă nu există evaluări

- Potentials and Challenges in Lignocellulosic Biofuel Production TechnologyDocument13 paginiPotentials and Challenges in Lignocellulosic Biofuel Production TechnologyandyÎncă nu există evaluări

- Navas BioresourBioprocess 2020Document13 paginiNavas BioresourBioprocess 2020KSVÎncă nu există evaluări

- Techno-Economic Conversion of Waste Fried Oil IntoDocument8 paginiTechno-Economic Conversion of Waste Fried Oil IntoridyanuraddienÎncă nu există evaluări

- Application of Biofuels in Diesel Engine A ReviewDocument4 paginiApplication of Biofuels in Diesel Engine A ReviewEditor IJTSRDÎncă nu există evaluări

- Biodiesel Production TechnologiesDocument23 paginiBiodiesel Production Technologiesolufowobi olumuyiwaÎncă nu există evaluări

- Biofuels Criteria DDocument1 paginăBiofuels Criteria Dmostafa alserafyÎncă nu există evaluări

- Comparative Techno-Economic Analysis of Biohydrogen Production Via Bio-Oil Gasification and Bio-Oil ReformingDocument10 paginiComparative Techno-Economic Analysis of Biohydrogen Production Via Bio-Oil Gasification and Bio-Oil ReformingVallery Rose RosarioÎncă nu există evaluări

- Review of Anaerobic Digestion Process For Biogas Production: March 2022Document17 paginiReview of Anaerobic Digestion Process For Biogas Production: March 2022lutfi ramadaniÎncă nu există evaluări

- Recent Research and Developments in Biodiesel Production From Renewable BioresourcesDocument11 paginiRecent Research and Developments in Biodiesel Production From Renewable BioresourcesRohit YadavÎncă nu există evaluări

- Design and Optimization of Biogas Energy SystemsDe la EverandDesign and Optimization of Biogas Energy SystemsÎncă nu există evaluări

- UntitledDocument29 paginiUntitledJaffar MastoiÎncă nu există evaluări

- HD JWT Magazine October 2021Document111 paginiHD JWT Magazine October 2021Jaffar MastoiÎncă nu există evaluări

- 1000 English Collocations. in 10 Minutes A Day PDFDocument128 pagini1000 English Collocations. in 10 Minutes A Day PDFMario Cesar de Oliveira100% (5)

- Economic Growth Jaffar MastoiDocument3 paginiEconomic Growth Jaffar MastoiJaffar MastoiÎncă nu există evaluări

- Check Your English Vocabulary For TOEICDocument81 paginiCheck Your English Vocabulary For TOEICRobby100% (27)

- Is It Time To Declare The End of Globalisation - Financial TimesDocument4 paginiIs It Time To Declare The End of Globalisation - Financial TimesJaffar MastoiÎncă nu există evaluări

- Masters Prospectus 2020Document128 paginiMasters Prospectus 2020Zahid AliÎncă nu există evaluări

- English - Grammar in EnglishDocument100 paginiEnglish - Grammar in Englishisam_702100% (1)

- Libya's War - Who Is Supporting Who - News - Al JazeeraDocument11 paginiLibya's War - Who Is Supporting Who - News - Al JazeeraJaffar MastoiÎncă nu există evaluări

- 100 Moral Stories - Islamic Mobility - XKPDocument173 pagini100 Moral Stories - Islamic Mobility - XKPIslamicMobility100% (4)

- Intro To Solar System PDFDocument26 paginiIntro To Solar System PDFJaffar MastoiÎncă nu există evaluări

- CSS Chronicles - January01Document72 paginiCSS Chronicles - January01Mian AliÎncă nu există evaluări

- AFGHANISTAN AND REGIONAL ConnectivityDocument7 paginiAFGHANISTAN AND REGIONAL ConnectivityJaffar MastoiÎncă nu există evaluări

- China Defence White PaperDocument6 paginiChina Defence White PaperAbhineta YaantrikÎncă nu există evaluări

- Monthly Global Point Current Affairs With MCQs Febriary 2019Document172 paginiMonthly Global Point Current Affairs With MCQs Febriary 2019Shaheryar HassanÎncă nu există evaluări

- A Constitutional History of Water in PakistanDocument19 paginiA Constitutional History of Water in PakistanRafay AlamÎncă nu există evaluări

- Magoosh Vocab Flashcard EbookDocument214 paginiMagoosh Vocab Flashcard EbookMohit G GuptaÎncă nu există evaluări

- Current Affairs Mcqs July-August 2019Document6 paginiCurrent Affairs Mcqs July-August 2019Jaffar MastoiÎncă nu există evaluări

- 1-Cyber Threat Landscape PakistanDocument19 pagini1-Cyber Threat Landscape PakistanJaffar MastoiÎncă nu există evaluări

- 2-SS Masood Ur Rehman Khattak No-1 2019Document21 pagini2-SS Masood Ur Rehman Khattak No-1 2019Mehmil AhmedÎncă nu există evaluări

- GRE Antonyms Word List - Concise TitleDocument17 paginiGRE Antonyms Word List - Concise TitleSahil Kumar100% (1)

- Multilateral Nuclear Information Sharing 2019 Report FinalDocument31 paginiMultilateral Nuclear Information Sharing 2019 Report FinalJaffar MastoiÎncă nu există evaluări

- Gender, Gender Concepts and Definitions Understanding Key Gender TermsDocument14 paginiGender, Gender Concepts and Definitions Understanding Key Gender TermsRobert ScottÎncă nu există evaluări

- Core PeripheryDocument28 paginiCore Peripheryapi-353782053Încă nu există evaluări

- Growing NuclearizationDocument15 paginiGrowing NuclearizationJaffar MastoiÎncă nu există evaluări

- Public International Law: Group Presentation: "Is International Law A True Law"?Document8 paginiPublic International Law: Group Presentation: "Is International Law A True Law"?Jaffar MastoiÎncă nu există evaluări

- 2-SS Masood Ur Rehman Khattak No-1 2019Document21 pagini2-SS Masood Ur Rehman Khattak No-1 2019Mehmil AhmedÎncă nu există evaluări

- 2019 WDR Report La Naturaleza Cambiante Del Trabajo - Banco MundialDocument151 pagini2019 WDR Report La Naturaleza Cambiante Del Trabajo - Banco MundialCristianMilciadesÎncă nu există evaluări

- 4 - M. Ijaz Islamic Modes of Financing - June2012Document7 pagini4 - M. Ijaz Islamic Modes of Financing - June2012Abd Al RahmanÎncă nu există evaluări

- Manual Huawei Hg655bDocument36 paginiManual Huawei Hg655bAnonymous nJm0Ff8z0sÎncă nu există evaluări

- Cap 3 CutoffDocument51 paginiCap 3 CutoffYashraj KajaveÎncă nu există evaluări

- 07 AlarmManagement enDocument39 pagini07 AlarmManagement enLuis RodriguezÎncă nu există evaluări

- Infiltration Ventilation LeakageDocument42 paginiInfiltration Ventilation LeakageBulut YildizÎncă nu există evaluări

- American English File Starter Ichecker - File 3Document3 paginiAmerican English File Starter Ichecker - File 3Daniel AugustoÎncă nu există evaluări

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesDocument11 paginiMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiÎncă nu există evaluări

- Ball MillsDocument8 paginiBall MillsBoy Alfredo PangaribuanÎncă nu există evaluări

- Extent, Yield, and SelectivityDocument10 paginiExtent, Yield, and SelectivityKristopher Ray Simbulan PamintuanÎncă nu există evaluări

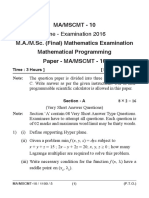

- Ma-Mscmt-10 J16Document5 paginiMa-Mscmt-10 J16Dilip BhatiÎncă nu există evaluări

- Sectional Results: Sofistik 2020Document28 paginiSectional Results: Sofistik 2020ec05226Încă nu există evaluări

- Isolation of Caffeine from TeaDocument6 paginiIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonÎncă nu există evaluări

- Genesis of Spalling in Tandem Mill Work-RollsDocument9 paginiGenesis of Spalling in Tandem Mill Work-Rolls54321qazÎncă nu există evaluări

- NM Group Plumbing WorkDocument33 paginiNM Group Plumbing WorkNM GROUPÎncă nu există evaluări

- Appendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckDocument35 paginiAppendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckMICHAEL TADESSEÎncă nu există evaluări

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDocument3 paginiWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamÎncă nu există evaluări

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDocument5 paginiXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezÎncă nu există evaluări

- EA 4b ArchiMate Views and Viewpoints PDFDocument41 paginiEA 4b ArchiMate Views and Viewpoints PDFanon_834023132Încă nu există evaluări

- Time Table Spring 2017 18Document10 paginiTime Table Spring 2017 18SuvamÎncă nu există evaluări

- Chapter 4-EDocument42 paginiChapter 4-EMahrouz MadoÎncă nu există evaluări

- Wheel Loader L50E: 2 EngineDocument4 paginiWheel Loader L50E: 2 EngineInjeletro Diesel100% (1)

- LKPRDocument58 paginiLKPRcatchman86Încă nu există evaluări

- M-III (II ECE-B, 1st SEM)Document63 paginiM-III (II ECE-B, 1st SEM)venkatesh sripadÎncă nu există evaluări

- Brandt M FR Btd500blnDocument74 paginiBrandt M FR Btd500blnStéphane JoussetÎncă nu există evaluări

- 5SL43407RC Datasheet enDocument5 pagini5SL43407RC Datasheet enDiana Martinez SifuentesÎncă nu există evaluări

- Engineering QuotesDocument10 paginiEngineering QuotesGendakenÎncă nu există evaluări

- Twice As Sharp Operators ManualDocument34 paginiTwice As Sharp Operators ManualLeonardo CHTZÎncă nu există evaluări

- Human-Environment InteractionDocument3 paginiHuman-Environment Interactionapi-299100358Încă nu există evaluări

- Green Aviation SeminarDocument19 paginiGreen Aviation SeminarAromalSPillaiÎncă nu există evaluări

- PI Digital Panel Indicator - B0Document7 paginiPI Digital Panel Indicator - B0dtoxidÎncă nu există evaluări

- MEITRACK MVT100 User Guide V2.4Document19 paginiMEITRACK MVT100 User Guide V2.4MeitrackÎncă nu există evaluări