Documente Academic

Documente Profesional

Documente Cultură

FM Mag Gauge Tg-L381e PDF

Încărcat de

nnaemeka omekeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FM Mag Gauge Tg-L381e PDF

Încărcat de

nnaemeka omekeDrepturi de autor:

Formate disponibile

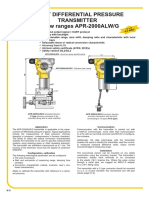

UP GRADED WITH WIDER LINEUP

FM MAG GAUGE

METAL TUBE LEVEL GAUGE

GENERAL

FM Mag Gauge is a float type metal tube level gauge. Liquid level is

indicated by clear and visible color flappers. This eliminates prob-

lems likely in indication by existing glass gauges.

In addition, special material of PVC, Fluorocarbon resin, Glass lining

etc. are ready to cover very corrosive liquid level measurement.

Alarm contacts and / or analog output unit can be additionally pro-

vided for remote monitoring and control purpose.

The certified High Pressure Gas Equipment Testing and Manufactur-

ing Plant guarantees high quality and reliability of FM Mag Gauges.

OPERATION PRINCIPLE

A float, in which a rounded shape magnet is integrated, is located in

a non-magnetic tube (called Chamber). This float moves up and

down depending on the liquid level in chamber with specified draft

line. Outside of the chamber, an indicator unit is installed, in which

plastic magnet rotating flappers are provided. The front surfaces of

such flappers are black and the other sides of flappers are coloured

in yellow for every 10mm and red for every 100mm. Then these flap-

pers are rotated by movement of float to indicate liquid level in colour

flappers.

FM-3100

Compact type

FM Mag Gauge can be provided with alarm contacts and/or analog

output (DC4~20mA) unit additionally onto this level indicator.

FEATURES

A reed switch in aluminum case at the setting point is ● Metal tube

actuated by the magnet in moving float. Water-tight construction, Free from breakage and leakage.

intrinsically safe system with the safety relay,

and flameproof enclosure are available. ● Clear and visible indication

The 4 to 20 mA output type has the detection By colour flappers, Liquid level in tanks is easily observed even

mechanism of float location (liquid level) from a distance. Free from blurs and smudges which are common

along chamber. for Glass Gauges.

The detector consists of a series

● Covering high pressure and temperature

of reed switches and

precision type resistances which HPGSL*1 approved version is also available.

are actuated by the magnet inside *1 High Pressure Gas Safety Law

float. The voltage signal of liquid

● Wide selection of material

level is converted to 4 to 20 mA

signal for transmitting. Standard stainless steel, PVC, Fluorocarbon resin, Glass lining .....

Water-tight construction and Wide selection range is ready to meet corrosive liquid level mea-

flameproof enclosure are available. surement.

Special material of MA276 and Titanium are also available.

● Full function

Indication, alarm contacts as well as analog output.

One unit of FM Mag Gauge covers all necessary functions of level

monitoring and control.

TG-L381-9E JUL. 2006K

TG-L381-12E OCT. 2011K

FM MAG GAUGE

STANDARD SPECIFICATION SUGGESTIONS

Measuring object : Max. viscosity 600mPa.s and without ● On liquid level indication

sticking and crystallization. The indicator flappers are actuated by magnet in float. There are dif-

Available range : Refer to pages of subject models. ferent types of float for models, but the position of magnet and ac-

Maximum OP. Press. : Refer to pages of subject models. tual liquid level (Draft line to float) are different depending on the liq-

Temp. range : Refer to pages of subject models. uid density. Thus, the position where specific indicator flapper rotates

Level indication : By colour flappers and the position of actual liquid level are different slightly. This gap

Interval of flappers : Standard version FM 10mm is fixed and shifted upward in fixed value. This gap (A) is indicated

Fine version FMS *1 5mm in Approval drawing. The zero line of indicator is to be located above

Indication accuracy : Standard version FM ±15mm actual liquid zero point by distance of A. Refer to instruction manual

Fine version FMS* ±10mm for details.

Process connection. : Standard; Tank side through 1"(25mm) flanges Also, be careful for minimum density for the float. Operation problem

Details are to be referred to pages of may occur in case of lower density than designed density.

subject models. Interface measurement and / or extreme low and high density liquid

Material : To be referred to pages of subject models. measurement are available on request. Consult factory for details.

*1 FMS type is applicable for FM-1200 type made of stainless

steel.

쏄 The indication can follow up to 2cm/s in liquid level changing

speed.

Consult factory for jacket type.

A

DESCRIPTION OF MODEL CODE

Model code of FM Mag Gauge is described as follows;

1) Only for local indicator

FM-■ 1■2■ 3-■ 4

2) Local indicator+Alarm contacts

FM-■ 1■2■ 3-■ 4■5■6■7

3) Local indicator+Analog output

FM-■ 1■2■ 3-■ 4 /■

8■9 1■0

4) Local indicator+Alarm contacts+Analog output

FM-■ 1■2■ 3-■ 4■5■6■7 /■ 8■9■10

/■8■ 9 1■

0 to be added to the end of code indication 2)

1 Press., Temp. class (2 digit)

2 Chamber, Nozzle material

Indicator

3 Float material and density range

4 Conn. flange rating

Enclosure of alarm (Water-tight, intrinsic

5

safety, flameproof) ● Heating and heat insulation

Alarm

6 No. of contact In case of necessity of heating and thermal insulation for sticky liq-

7 No. of terminal box uids etc., thermal insulation is to be provided only for chamber por-

Enclosure of analog unit (Water-tight, tion as shown below. Do not cover indicator, alarm and analog unit

8

intrinsic safety, flameproof) by thermal insulation material. The heating or insulation on these

Analog output

9 Direction of sensor parts might causes damages or malfuntioning of indication, alarm or

10 Direction of convertor transmitting mechanism.

Refer to pages of subject models for details of model code.

INSULATING PLATE

CHAMBER

INDICATOR

INSULATION MATERIAL

2 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

MODEL SELECTION GUIDANCE

Different types and materials are available for FM Mag Gauge. Refer to the following table for selection.

(The floats made of titanium alloy may have different shape and dimensions from values in this guidance. Consult Tokyo Keiso before order-

ing.)

● FOR MODERATE TEMPERATURE

(Up to 120oC. The some gauges made of plastics like PVC have limited upper temperature as mentioned below.)

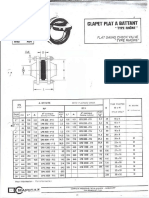

MAX. OP. PRESS.*1 AVAILABLE RANGE (mm)

MODEL CHAMBER MATERIAL FLOAT MATERIAL TEMP. RANGE

MPa Min. Max.

FM-121 SUS304 *2 *6

SUS316,SUS316L

2 SUS316

or Titanium (TP340) ---10~120˚C 3 0~250 0~4380

3 SUS316L

Z Special metallic material To be consulted

FM-124 PVC(HPVC) 0~2000

PVC(HPVC) 0~60˚C(80) 0.2 0~250

5 Stainless steel+PVC lining 0~4000

FM-126 Stainless steel+ETFE lining *3 *4

NBR balloon

7 Stainless steel+PFA lining + 0~100˚C 0.2 0~250 0~3500

FM-128 Stainless steel+PTFE lining PFA lining

FM-129 Stainless steel+Glass lining Glass 0~60˚C 0.2 0~250 0~3000

FM-131 SUS304 *5 *2

Titanium (TP340)

2 SUS316

or -10~120˚C 5 0~250 0~4380

3 SUS316L

Titanium alloy

Z Special metallic material

FM-141 SUS304 *5 *8

Glass epoxy balloon

2 SUS316

or 0~120˚C 7.3 0~250 0~4380

3 SUS316L

Titanium alloy

Z Special metallic material

FM-311 SUS304

2 SUS316 SUS316 -10~120˚C 1 0~250 0~2000

3 SUS316L

● FOR HIGH TEMPERATURE

(121~300oC. Use MODERATE TEMPERATURE version for up to 120oC.)

MAX. OP. PRESS.*1 AVAILABLE RANGE (mm)

MODEL CHAMBER MATERIAL FLOAT MATERIAL TEMP. RANGE

MPa Min. Max.

FM-161 SUS304 SUS316,SUS316L *5 *7

2 SUS316 Or Titanium

121~300oC 2 0~250 0~4380

3 SUS316L (TP340)

Z Special metallic material To be consulted

FM-171 SUS304 *5 *9

Titanium (TP340)

2 SUS316

or 121~285oC 3.9 0~250 0~4380

3 SUS316L

Titanium alloy

Z Special metallic material

FM-181 SUS304 *5

2 SUS316

Titanium alloy 121~285oC 7 0~250 0~4380

3 SUS316L

9 Special metallic material

*1 : Subject to flange connection rating

*2 : For the services lower than –10°C, the indicator with non-frost acrylic resin plate will be provided. Consult factory for details.

*3 : Upto 0.75MPa on request as option.

*4 : Max. 2400mm for ETFE lining, and Max. 2500mm for PTFE lining for the vacuum service..

*5 : TP340, Titanium alloy, and Glass epoxy balloon may cause hydrogen embrittlement.

*6 : The maximum operating pressure of titanium float is 2.5 MPa.

*7 : The maximum operating temperature of titanium float is 250°C.

*8 : The maximum operating temperature of glass epoxy float is 100°C.

*9 : The maximum operating pressure of floats made of some materials is 4.4 MPa.

TG-L381-12E TOKYO KEISO CO., LTD. 3

FM MAG GAUGE

PRESSURE AND TEMPERATURE LIMITATION

Following graph shows the pressure and temperature limitation for each type of FM MAG GAUGEs excluding the limitation subject to the con-

nection flange rating. The colored or gray area shows the applicable range of each type.

● FM-3100 (SUS, Chamber size: 1 inch)

1 Pressure (MPa)

FM-3100

0.5 Liquid density: 0.85g/cm3 or more

Float material: SUS316L

−10 0 120 Temperature (˚C)

● FM-1200, FM-1600 (SUS, Chamber size 2 inches)

2

Pressure (MPa) *1

(1)

1.33

1.33

1 FM-1200 FM-1600

(3)

(1) (2) (3) (4)

−10 0 120 250 300 Temperature (˚C)

(1) FM-1200 Float material SUS316 Liquid density 0.6g/cm3 or more

(2) FM-1200 Float material Titanium (TP340) Liquid density 0.39g/cm3 or more

(3) FM-1600 Float material SUS316 Liquid density 0.65g/cm3 or more

(4) FM-1600 Float material Titanium (TP340) Liquid density 0.39g/cm3 or more

*1: Negative pressure is available up to Full Vacuum, but it may be unavailable,

depending on the specification. Consult Tokyo Keiso for availability.

● FM-1300, FM-1700 (SUS, Chamber size 2 inches)

5

Pressure (MPa)

4

3.9

3 FM-1300

FM-1700

2 (5)

1 (6)

−10 0 120 285 Temperature (˚C)

(5) FM-1300 Float material Titanium (TP340) Liquid density 0.6g/cm3 or more

(6) FM-1700 Float material Titanium (TP340) Liquid density 0.68g/cm3 or more

● FM-1400 (SUS, Chamber size 2 inches)

7.3

Pressure (MPa)

6

FM-1400

4

(7)

2

−10 0 100 Temperature (˚C)

(7) FM-1400 Float material Glass epoxy Liquid density 0.8g/cm3 or more

4 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-1210,1220,1230,12Z0

Standard metallic type for low pressure and moderate temperature

1

FM-12 23 0 series are standard type Mag gauge with SUS304,

MODEL CODE

SUS316, or SUS316L material. (titanium float is used for some

ranges.)

AVAILABLE RANGES OF PRODUCTS

10mm(Accuracy 15mm)

Range : Min. 0~250mm Flapper pitch

5mm (Accuracy 10mm)

Max. 0~4380mm (3420mm for FMS)

Max. Op. Press.: 3MPa SUS304

(Max. 2.5MPa for titanium float) SUS316

Chamber material

(Subject to connection flange rating) SUS316L

Negative pressure is available up to Full Vacuum, Other

but it may be unavailable, depending on the

0.39~0.45

specification. Consult Tokyo Keiso for availability.

0.44~0.52

Temp. range : · FM-1200 TP340

0.5~0.6

–10~120˚C Titanium

(Down to –60˚C available on request. The indi- 0.55~0.7

cator with non-frost acrylic resin plate is avail- 0.62~0.8

able.) 3

Density range (g/cm ) 0.6~0.7

· FMS-1200 Float material 0.65~0.8

–10~80˚C

0.7~0.9 SUS316

0.8~1.0 or

DIMENSIONS SUS316L

0.9~1.4

R1/2

1.0~1.5

1.25~2.0

E

25A JIS 10KFF

25A JIS 10KRF

57 120

1" JPI 150#RF

⵰60.5

(H+120)

1" ANSI 150#RF

H

H

(H+120)

25A JIS 20KRF

F

Connection flange rating

1" JPI 300#RF

1" ANS I300#RF

25A JIS 5KFF

Indication gap

Other 1" (25A) flanges

*C

Special

R1/2

* Actual length "C" may be extended depending on

FLOAT AVAILABILITY AND SIZES

the float type as is the case of gas filled type.

Consult factory for details. Density Design Float

No.

(g/cm3) C E Material L

INDICATOR INSTALLATION ANGLE A 0.39~0.45 450 200 470

0 0.44~0.52 350 200 380

TP340 48.5

1 0.5~0.6 280 200 300

1. Standard Titanium

2 0.55~0.7 250 200 270

3 0.62~0.8 210 200 220

A

N 0.6~0.7 485 160 520

L

Draft

P 0.65~0.8 385 150 410

5 0.7~0.9 305 130 SUS316 320

2

6 0.8~1.0 235 110 or 250

7 0.9~1.4 195 110 SUS316L 200

8 1.0~1.5 165 100 170

9 1.25~2.0 165 100 170

3 Max. operating press. is 1.33MPa for float No. A to 3.

Max. operating press. is 2.0MPa for float No. N to 9.

Consult factory for details when max. press. exceeds these values.

TG-L381-12E TOKYO KEISO CO., LTD. 5

FM MAG GAUGE

FM-121Z0,122Z0,123Z0,12ZZ0

Double tube type for liquefied gas

1Z

FM-12 2Z 0 are metal tube level gauge for liquefied gas with SUS304,

3Z MODEL CODE

SUS316, or SUS316L material.

A double tube type has the effectiveness that inhibits the sudden

rise and dive of a float by boiling and bumping of liquefied gas. FM-12 Description

And use an orifice plate in flange connection part (upper) according

1Z SUS304

to operational situation.

Chamber 2Z SUS316

AVAILABLE RANGES OF PRODUCTS material 3Z SUS316L

Range :Min. 0~250mm 4Z Other

Max. 0~4380mm A 0.39~0.45

Max. Op. Press. :2.5MPa 0 0.44~0.52

TP340

(Subject to connection flange rating) Densitiy range (g/cm )3

1 0.5~0.6 Titanium

Temp. range :–10~120oC Float material

2 0.55~0.7

(Down to –60oC available on request. The indica-

tor with non-frost acrylic resin plate is available.) 3 0.62~0.8

Z Special

0 25A JIS 10KFF

DIMENSIONS 1 25A JIS 10KRF

2 1" JPI 150#RF

R1/2

3 1" ANSI 150#RF

4 25A JIS 20KRF

2X 2 hole

E

Connection flange rating

Upper part of 5 1" JPI 300#RF

chamber

6 1" ANSI 300#RF

F

7 25A JIS 5KFF

65 130

60.5 8 Other 1" (25A) flanges

(H+120)

76.3 (Inside pipe)

9 Special

H

76.3

H

(Outside pipe)

F

2X 5 hole

Lower part of

chamber

Indication gap

R1/2

INDICATOR INSTALLATION ANGLE FLOAT AVAILABILITY AND SIZES

Densitiy Design Float

No.

(g/cm3) C E Material L

1. Standard Ar Gas Sealed

A 0.39 ~ 0.45 780 200 790 0.91(MPa) 48.5

0 0.44 ~ 0.52 580 200 610

1 0.5 ~ 0.6 450 200 470

TP340

A

2 0.55 ~ 0.7 380 200 400

Titanium

L

Draft

The direction to install indicator can not be changed at site. 3 0.62 ~ 0.8 320 200 330

Max. operating press. is 1.96MPa.

Consult factory for details when max. press. exceeds this value.

6 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-1240,1250

Made of PVC for low pressure and moderate temperature

FM-1240 series are level gauge with PVC material for both cham- MODEL CODE

ber and float to cover corrosive liquids.

FM-1250 has a PVC lined stainless steel chamber which offers

better mechanical durability than pure PVC chambers.

Flapper pitch 10mm (Accuracy 15mm)

AVAILABLE RANGES OF PRODUCTS

PVC

Range :Min. 0~250mm

Max. 0~2000mm *2 Chamber material H HPVC

Max. Op. Press. :0.2MPa St. Stl.+PVC lining

Temp. range :0~60oC (HPVC : 0~80°C) 0.75~0.9 (0.7~0.8)

0.8~1.0 (0.75~0.9)

Density range (g/cm3)

0.9~1.3 (0.85~1.2)

DIMENSIONS Float material *1

1.05~1.7 (1.0~1.5)

R1/2 1.35~2.0 (1.35~2.0)

25A JIS 10KFF (t=21)

F

1" JPI 150#RF (t=19.7)

E

E

1" ANSI 150#RF (t=19.7)

Connection flange rating *3

25A JIS 5KFF (t=17)

t

57 120 Other 1" (25A) flanges

57 120

(H+120)

60

H+120

60.5

Special

H

H

H

*1: Float material is PVC or HPVC. ( ) indicates applicable den-

sity range for FM-125 ■ type (Stainless steel + PVC lining).

F

F *2: In case of material code 5, max.4000mm is available.

*3: Connection flange of lined version is Flat Face (20A or more).

The inside of parenthesis shows the thickness of flange.

Indication gap

Indication gap

t

C

C

FLOAT AVAILABILITY AND SIZES

R1/2 JIS10K50ARF For PVC version FM-124 ■ and HPVC version FM-124H ■

Density Design Float

PVC HPVC PVC lined SS No. 3

(g/cm ) C E L

FM-124■ FM-124H■ FM-125■ 48

5 0.75~0.9 290 120 300

6 0.8~1.0 250 120 250

7 0.9~1.3 200 120 200

8 1.05~1.7 150 120 150

L

9 1.35~2.0 140 120 150

INDICATOR INSTALLATION ANGLE

PVC,HPVC

1.Standard

For Stainless steel+PVC lining version FM-125 ■

Density Design Float

No. 3

(g/cm ) C E L 46

5 0.7~0.8 290 150 300 PVC

2 6 0.75~0.9 250 150 250

60˚ 7 0.85~1.2 200 160 200

L

8 1.0~1.5 150 170 150

9 1.35~2.0 140 180 150

60˚

TG-L381-12E TOKYO KEISO CO., LTD. 7

FM MAG GAUGE

FM-1260, 1270

Made of Fluorocarbon resin for low pressure and moderate temperature

This series of gauges is made of fluorocarbon resin and other anti-

corrosive materials.

MODEL CODE

AVAILABLE RANGES OF PRODUCTS

Range :Min. 0~250mm

Max. 0~3500mm Flapper pitch 10mm(Accuracy ±15mm)

Maximum range of ETFE lining type is 2400mm ETFE lining

Max. Op. Press. :0.2MPa Chamber material

PFA lining

Temp. range :0~100oC 0.72~0.75

Details of lining 0.75~0.8

ETFE lining : FM-126 ■ Lining thickness 1.6 mm 0.8~0.9

NBR+

PFA lining : FM-127 ■ Lining thickness 1.75 mm Density range (g/cm3) 0.9~1.0

PFA lining(1.5t)

Float material 1.0~1.3

*1

1.3~1.5

DIMENSIONS 1.5~2.0

Special

25A JIS 10K

F *4

Connection flange rating * 1" ANSI(JPI)#150

*2

Special

*5 * The flange face of lining type is equivalent to the raised face of

E

flange.

57 114

57 122 FLOAT AVAILABILITY AND SIZES

⵰60.5

⵰60.5

For ETFE lining version FM-126 ■

H=H0–(C+E+114)

*6

H

H+120

Density Design Float

No.

H0

3

(g/cm ) C E L

*F 42.6

A 0.72~0.75 400 190 400

B 0.75~0.8 370 190 345

*6

C 0.8~0.9 310 190 280 *3

Draft A

Indication gap

E 0.9~1.0 240 190 210

Indication gap

L

C

F 1.0~1.3 200 190 170

(134) 114

G 1.3~1.5 190 190 190

*2 H 1.5~2.0 190 190 190

Equivalent to JIS10K50ARF Equivalent to JIS10K50ARF

F Titanium+PFA lining available on request

*4

(Dimension will be changed. Consult factory for details.)

ETFE lining PFA lining *1 The float for vacuum services is made of either stainless steel

FM-126 ■ FM-127 ■ or titanium lined by ETFE.

*2 The blind flanges for vacuum services are made of carbon steel

lined by PTFE.

*3 The float for vacuum services has a different shape and sizes.

INDICATOR INSTALLATION ANGLE *4 Connection F

*5 Shape and dimension E

*6 Measuring range H

1. Standard

For PFA lining version FM-127 ■

Density Design Float

No. 3

(g/cm ) C E L

A 0.72~0.75 42.6

2 400 270 400

B 0.75~0.8 350 270 345

C 0.8~0.9 280 280 280 *3

Draft A

E 0.9~1.0 210 280 210

L

F 1.0~1.3 170 280 170

3

G 1.3~1.5 190 260 190

H 1.5~2.0 170 270 190

Titanium+PFA lining available on request

(Dimension will be changed. Consult factory for details.)

8 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-1280

Made of Fluorocarbon resin for low pressure and moderate temperature

This series of gauges is made of fluorocarbon resin and other anti-

MODEL CODE

corrosive materials.

AVAILABLE RANGES OF PRODUCTS

Range :Min. 0~250mm Flapper pitch 10mm(Accuracy 15mm)

Max. 0~3500mm *1 Chamber material 8 PTFE lining

Max. Op. Press. :0.2MPa 0.72~0.75

Temp. range :0~100oC 0.75~0.8

Details of lining 0.8~0.9

NBR+ *3

PTFE lining : FM-128 ■ Lining thickness 2 mm Density range (g/cm3) 0.9~1.0

PFA lining(1.5t)

: 3mm for vacuum application Float material 1.0~1.3

*1: Max. 2500mm for vacuum application 1.3~1.5

1.5~2.0

Special

DIMENSIONS

25A JIS 10K

Connection flange rating *2 1" ANSI(JPI)#150

Special

*4

F

*2 The flange face of lining type is equivalent to the raised face of

E

flange.

*3 The float for vacuum services is made of either stainless steel or

57 120 titanium lined by ETFE.

*4 Connection F

H=H0–(E+C+115)

*5 *5 Measuring range H

H

H+120

H0

FLOAT AVAILABILITY AND SIZES

Density Design Float

No.

(g/cm3) C E L

42.6

⵰60.5 A 0.72~0.75 400 260 400

Indication gap

B 0.75~0.8 350 260 345

C 0.8~0.9 280 270 280

Draft A

115

E 0.9~1.0 210 270 210

L

F 1.0~1.3 170 270 170

Equivalent to JIS10K50ARF F *4 G 1.3~1.5 190 260 190

H 1.5~2.0 190 270 190

* Titanium+PFA lining available on request

(Dimension will be changed. Consult factory for details.)

* Vacuum application of PTFE, dimension will be changed.

INDICATOR INSTALLATION ANGLE

1. Standard

TG-L381-12E TOKYO KEISO CO., LTD. 9

FM MAG GAUGE

FM-1290

Glass lining type for low pressure and moderate temperature

FM-1290 series is glass lining type for very corrosive services MODEL CODE

AVAILABLE RANGES OF PRODUCTS

Range :Min. 0~250mm Chamber material Stainless steel+Glass lining *3

Max. 0~3000mm 0.9~1.0

Max. Op. Press. :0.2MPa

1.0~1.1

Temp. range :0~60oC Density range (g/cm3)

1.1~1.25

(Float material : Glass)

1.2~1.4

DIMENSIONS

1.3~1.6

F 25A JIS 10KRF

1" JPI(ANSI)150#RF

50A JIS 10KRF

E

2" JPI(ANSI)150#RF

(114)

57 102

Connection flange *2 50A JIS 10KRF

(The connection flange 50A JIS 10KRF

codes 1,2,3,4 and 9

consist of tees or 2" JPI(ANSI)150#RF

φ60.5

H

Ho

reducing tees.) 2" JPI(ANSI)150#RF

H

Special

* 1 "H" length of 4 to 20 mA output type may become shorter.

A

Please contact TOKYO KEISO.

Indication gap

* 2 The flange face of lining type is equivalent to the raised face of

(114) (114)

flange

102 102

* 3 The flange is made of carbon steel lined by glass.

Figures in [ ] show those for JPI and ANSI flanges.

102 [114]

F

50A FLOAT AVAILABILITY AND SIZES

F

S type E type

50A Density Design Float

No. 3

(g/cm ) C E L 46

10

3 0.9~1.0 300 280 270

5 1.0~1.1 240 280 210

Draft A

6 1.1~1.25 200 280 175

L

7 1.2~1.4 190 280 160

INDICATOR INSTALLATION ANGLE

8 1.3~1.6 180 280 150

1. Standard

10 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-1310, 1320, 1330, 13Z0

Metallic type for medium pressure and moderate temperature

FM-1300 is a series of medium pressure metal tube level gauge MODEL CODE

with stainless steel chamber and titanium float.

AVAILABLE RANGES OF PRODUCTS Description

Range :Min. 0~250mm

SUS304

Max. 0~4380mm

Chamber SUS316

Max. Op. Press. :5MPa (Max.4.5MPa for titanium alloy float)

material SUS316L

(Subject to connection flange rating)

Temp. range :-10~120oC Special

0.55~0.62 Titanium alloy

(Max. 4.5MPa)

DIMENSIONS 0.6~0.64

0.64~0.7

Density range (g/cm3)

Float material 0.7~0.81 TP340

0.74~0.86 Titanium

R1/2

0.8~1.02

*1 0.96~1.3

E

Special material other than above

57 150 25A JIS 20KRF

(H+120)

60.5 1" JPI 300#RF

H

H

1" ANSI 300#RF

F 25A JIS 30KRF

Connection flange rating

25A JIS 40KRF

1" JPI 600#RF

Indication gap

1" ANSI 600#RF

C

Special

* 1 Shape and dimension E

R1/2

INDICATOR INSTALLATION ANGLE FLOAT AVAILABILITY AND SIZES

Density Design Float

No.

(g/cm3) C E L

48.5

1. Standard E 0.55 ~ 0.62 ∗ 200 ∗

--- --- --- --- ---

--- --- --- --- ---

Draft

Titanium

L

--- --- --- --- ---

Alloy

--- --- --- --- ---

2

--- --- --- --- ---

1 0.6 ~ 0.64 810 160 820 48.5

2 0.64 ~ 0.7 620 160 630

3 0.7 ~ 0.81 470 160 485

3 5 0.74 ~ 0.86 400 160 405

Draft

L

6 0.8 ~ 1.02 320 160 325

7 0.96 ~ 1.3 250 160 260

9 Special --- --- ---

∗ Consult factory for details.

TG-L381-12E TOKYO KEISO CO., LTD. 11

FM MAG GAUGE

FM-1410, 1420, 1430, 14Z0

Metallic type for high pressure and moderate temperature

FM-1400 is a series of high pressure metal tube level gauge with MODEL CODE

stainless steel chamber and titanium or glass epoxy float.

- Description

AVAILABLE RANGES OF PRODUCTS

Range :Min. 0~250mm 1 SUS304

Max. 0~4380mm

2 SUS316

Max. Op. Press. :7.3MPa Chamber material

3 SUS316L

(Subject to connection flange rating)

Temp. range :0~120oC (Glass epoxy : 0~100oC) Z Special

E 0.7 ~ 0.74

DIMENSIONS F 0.73 ~ 0.83 Titanium

G 0.8 ~ 0.96 alloy

Density range (g/cm3) H 0.9 ~ 1.2

Float materia

R1/2 6 0.8 ~ 1.0

7 0.9 ~ 1.2

Glass Epoxy

*1

E

8 1.0 ~ 1.4

9 Special

57 150 1 25A JIS 40KRF

(H+120)

60.5 2 1" JPI 600#RF

H

*2

H

*2 3 1" ANSI 600#RF

F Connection flange rating 4 25A JIS 63KRF

5 1" JPI 900#RF

6 1" ANSI 900#RF

Indication gap

9 Special

C

*1 Shape and dimension E

R1/2 *2 Measuring range H

FLOAT AVAILABILITY AND SIZES

Titanium Alloy floats

Density Design Float

No.

INDICATOR INSTALLATION ANGLE (g/cm3) C E L Spec. 48.5

E 0.7~0.74 ∗ 200 ∗

F 0.73~0.83 ∗ 200 ∗

1. Standard G 0.8~0.96 ∗ 200 ∗

7.3 MPa

Draft

∗ ∗

L

H 0.9~1.2 200

9

2

∗Consult factory for details.

Glass Epoxy floats

Density Design Float

No.

(g/cm3) C E L

46

6 0.8~1.0 290 120 280

3 7 0.9~1.2 210 110 200

8 1.0~1.4 170 100 155

L

12 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-3110, 3120, 3130

Compact size and metallic type for low pressure and moderate temperature

FM-3100 series is a small and lightweight Mag gauge with a cham-

ber (ø34) made of SUS304, SUS316 or SUS316L stainless steel

and SUS316L float.

AVAILABLE RANGES OF PRODUCTS MODEL CODE

Range : Min. 0~250mm

: Max. 0~2000mm 31 Description

Max. Op. Press.: 1MPa

(Subject to connection flange rating)

Flapper pitch FM 10mm (Accuracy–15mm)

Temp. range : -10~120˚C

: Alarm contact transmitter (Water-tight, intrinsic 1 SUS304

safety, flameproof) is available.*1

Chamber material *2 2 SUS316

3 SUS316L

1 0.85~0.97

DIMENSIONS

Density range (g/cm ) *

3 3 2 0.95~1.12

R1/2 SUS316L

Float material *4 3 1.10~1.42

4 1.40~2.0

E

0 10A JIS 10KFF

1 10A JIS 10KRF

2 10A JIS 5KFF

41 80

3 10A JIS 5KRF

Connection flange rating

H+100

34 4 15A (1/2") flanges *5

H

5 20A (3/4") flanges *5

6 25A (1") flanges *5

9 Special *6

H

*1 : Analog level transmitter is not applicable. FM-1000 series

is recommended.

*2,*4: FM-1000 series is recommended if special materials are

required.

(C)

*3 : FM-1000 series is recommended if special range of density

is required.

ø43

*5 : JIS10KFF, JIS10KRF, JPI #150 and ANSI #150 are

available.

R1

*6 : Consult factory for details.

INDICATOR INSTALLATION ANGLE FLOAT AVAILABILITY AND SIZES

Density Design Floot

No.

1. Standard (g/cm3) C E Material L 26

1 0.85~0.97 320 320

2 0.95~1.12 230 229

100 SUS316L

3 1.10~1.42 180 177

4 1.40~2.00 180 177

2

L

TG-L381-12E TOKYO KEISO CO., LTD. 13

FM MAG GAUGE

FM-1610, 1620, 1630, 16Z0

Metallic type for low pressure and high temperature

FM-1600 is a series of metal tube level gauge for high temperature

MODEL CODE

with stainless steel chamber and float (titanium float for low density

applications). A thermal insulation is provided between indicator

and chamber to cover high temperature. Description

SUS304

AVAILABLE RANGES OF PRODUCTS

Chamber SUS316

Range : Min. 0~250mm

material SUS316L

Max. 0~4380mm *

Max. Op. Press.: 2MPa (Titanium float : 1.6MPa) Other

(Subject to connection flange rating) 0.39~0.45

Temp. range : 121~300oC (Titanium float : 0~250°C) 0.44~0.52

1 TP340

(Select standard types of FM-12 23 0 series for the 0.5~0.6

temperature range of 0~120°C.) Titanium

0.55~0.7

* Observe heat expansion factor of stainless steel Density range (g/cm3) 0.62~0.8

chamber and vessel material to finalize measur-

Float material 0.65~0.8

ing range.

0.7~0.9

SUS316

DIMENSIONS 0.8~1.0 or

0.9~1.4 SUS316L

R1/2

1.0~1.5

25A JIS 10KFF

E

25A JIS 10KRF

1" JPI 150# RF

64 120 1" ANSI 150# RF

(H+120)

60.5 Connection flange rating 25A JIS 20KRF

H

1" JPI 300# RF

H

1" ANSI 300# RF

F 25A JIS 5KFF

Other 1"(25mm) flanges

Special

Indication gap

110

C

R 1/2

* Dimension will be changed.

Consult factory for details.

FLOAT AVAILABILITY AND SIZES

INDICATOR INSTALLATION ANGLE Density Design Float

No.

(g/cm3) C E Material L

A 0.39~0.45 620 200 650

1.Standard 0 0.44~0.52 490 200 TP340 520 48.5

1 0.5~0.6 390 200 Titanium 410

2 0.55~0.7 340 200 *(0.68MPa) 360

A

3 0.62~0.8 290 200 300

L

Draft

P 0.65~0.8 460 170 460

2 SUS316

Heating / thermal insulation are to be 5 0.7~0.9 400 170 400

or

conducted onto chamber portion only. 6 0.8~1.0 300 150 SUS316L 300

7 0.9~1.4 260 150 260

*(1.35MPa)

MIN.45 8 1.0~1.5 230 130 230

3 MIN.45 * Consult factory for details when max. press. exceeds these value.

14 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

FM-1710, 1720, 1730, 17Z0

Metallic type for medium pressure and high temperature

FM-1700 is a series of metal tube level gauge with stainless steel

MODEL CODE

chamber and titanium alloy float for high temperature and medium

pressure.

FM-17 Description

AVAILABLE RANGES OF PRODUCTS

Range : Min. 0~250mm 1 SUS304

Max. 0~4380mm * Chamber 2 SUS316

Max. Op. Press.: 3.9MPa material 3 SUS316L

(Max. 4.4MPa for TP340 float) Z Special

(Subject to connection flange rating)

F 0.66~0.68

Temp. range : 121~285oC

Titanium alloy

(Select standard types of FM-1300 series for the

temperature range of 0~120oC.) Max.3.9MPa

* Observe heat expansion factor of stainless steel

chamber and vessel material to finalize measur- 1 0.64~0.69

Density range (g/cm3)

ing range. 2 0.69~0.77

Float material TP340

3 0.77~0.88

DIMENSIONS Titanium

5 0.82~0.96 Max.4.4MPa

6 0.95~1.2

R1/2 7 1.1~1.5

9 Special

1 1" JPI 300# RF

E

2 1" ANSI 300# RF

3 1" JPI 600# RF

64 150

Connection flange rating 4 1" ANSI 600# RF

H+120

60.5 5 1" JPI 600# RTJ

H

6 1" ANSI 600# RTJ

9 Special

F *1

*1 Connection F

Indication gap

124

C

R1/2

FLOAT AVAILABILITY AND SIZES

INDICATOR INSTALLATION ANGLE No.

Density Design Float

(g/cm3) C E L

F 0.66~0.68 ∗ 200 ∗

A

1.Standard

48.5

Draft

L

2

Heating / thermal insulation are to be

1 0.64~0.69 820 200 820

A

conducted onto chamber portion only.

2 0.69~0.77 630 200 630

3 0.77~0.88 480 200 485 48.5

MIN.45

Draft

L

5 0.82~0.96 390 200 405

3 MIN.45

6 0.95~1.2 320 200 325

7 1.1~1.5 250 200 260

9 Special

∗Consult factory for details.

TG-L381-12E TOKYO KEISO CO., LTD. 15

FM MAG GAUGE

FM-1810, 1820, 1830, 18Z0

Metallic type for high pressure and high temperature

FM-1800 is a series of metal tube level gauge with stainless steel

MODEL CODE

chamber and titanium alloy float for high temperature and high

pressure.

FM-18 Description

AVAILABLE RANGES OF PRODUCTS 1 SUS304

Range :Min. 0~250mm Chamber 2 SUS316

Max. 0~4380mm * material 3 SUS316L

Max. Op. Press. :7MPa Z Special

(Subject to connection flange rating) F 0.76~0.77

Temp. range :121~285oC

G 0.79~0.89

(Select FM-1400 series for the temperature range Titanium alloy

Density range (g/cm3) H 0.86~0.98

of 0~120oC.) (Gas filled)

Float material I 0.95~1.2

* Observe heat expansion factor of stainless steel

chamber and vessel material to finalize measur- J 1.08~1.3

ing range. 9 Special

1 1" JPI 900#RF

DIMENSIONS 2 1" ANSI 900#RF

3 1" JPI 900#RTJ

4 1" ANSI 900#RTJ

R1/2

Connection flange 5 1" JPI 1500#RF

rating 6 1" ANSI 1500#RF

E

7 1" JPI 1500#RTJ

8 1" ANSI 1500#RTJ

64 (150)

9 Special

(H+120)

60.5

H

H

*2

*2

F *1

FLOAT AVAILABILITY AND SIZES

Density Design Float

No.

(g/cm3)

Indication gap

C E L 48.5

F 0.76~0.77 ∗ 200 ∗

C

G 0.79~0.89 ∗ 200 ∗

H 0.86~0.98 ∗ 200 ∗

R1/2 I 0.95~1.2 ∗ 200 ∗

Draft

L

J 1.08~1.3 ∗ 200 ∗

9 Special

INDICATOR INSTALLATION ANGLE ∗Consult factory for details.

*1 Connection F

*2 Measuring range H

1.Standard

2

Heating / thermal insulation are to be

conducted onto chamber portion only.

MIN.45

3 MIN.45

16 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

● Intrinsically safe version (FM - ■ ■ ■ -■ S ■ ■)

ADD-ON ALARM CONTACTS A safety relay is inserted into the contact loop of watertight version

to achieve Insrinsically safe loop.

Alarm contact (s) can be provided to all FM Mag Gauges. IS classification : Ex ia llC T6

A reed switch is located at side portion of chamber which is actu- (Subject to using of specified safety relay)

ated by the magnet in float. Watertight, Intrinsically safe as well as

Flameproof versions are available. Dimension of Safety Relay EB3C-R01A (1 point use)

MODEL CODE OF ALARM CONTACTS

FM- ■ ■ ■ - ■ ■

5■6■

7/ ■■■■

FM-1

Watertight (Non-explosion proof)

Enclosure EX-d, Flameproof

EX-i, Intrinsically safe

Contact No. of contact

Terminal box No. of terminal box

SPECIFICATION

● Watertight version (FM- ■ ■ ■-■ W■ ■)

Type of contact : 1 X SPST(Self-holding contact)

Contact capacity : 10W, AC/DC

Max. voltage ; AC,DC 100V

Fluid temp. : –10~200oC

Ambient temp. : –10~60oC Reed switch

Enclosure : Watertight

Terminal box

No. of contact : Depending on the length AC2A

of chamber

(No limitation)

Repeatability : ±15mm

(Equivalent to indicator accuracy)

Reset span : Max. 30mm (Fixed)

Alarm action : High or Low

(To be specified. Also

at field adjustable)

Setting range : 50mm

Min. gap between points :

50mm

(Shorter gap on request)

Accessory : Surge suppressor intergrated

40

(It is not attached to IS version)

Terminal box : The cable from a reed switch is

drawn and it is used for terminal ( 7) MVVS

connection.

Installed terminal : 8P, M3.5 screws

Cable entries : For alarm switches

127 Case : AC2A

4 entries with packing type cable gland, Welded Cover : SPCC

Max. cable dia. 7 mm Fitting : SUS

45

For alarm outlet

terminal box

1 X G3/4 (Female)

25

* Height of

102

T=H / 2—50 (mm)

Note 1: When installing the insulating material,

140

do not install it around the alarm sensor.

T

G3/4

TG-L381-12E TOKYO KEISO CO., LTD. 17

FM MAG GAUGE

● Flameproof enclosure version (FM-1■ ■ ■- ■ E ■ ■)

Individual reed switch and terminals are capcellated in one pres-

sure tight housing for each alarm contact.

Construction : Flameproof enclosure (d2G5) (No. T49972)

Type of contact : SPST (Self-holding contact)

Contact capacity : 10W, AC/DC

Max. voltage ; AC,DC 100V

No. of contact : Depending on the length of chamber

(No limitation)

Repeatability : ±15mm

(Equivalent to indicator accuracy)

Reset span : Max. 30mm (Fixed)

Alarm action : High or Low (To be specified.)

Setting range : From 100 mm above lower end to 100 mm

below upper end

Min. gap between points :

200mm (Shorter gap on request)

Fluid temp. : -10~200˚C

Amb. temp. : -10~60˚C˚

Accessory : Surge suppressor integrated

Built-in terminal : 2P (M3)

Installation : Clamping onto chamber

Cable entry : 1XG1/2 (Female)

Alarm contact signals are sent to the non-haz-

ardous area for further processing. The packing

type cable gland to be supplied by the custom-

ers.

Case, Cover:AC2A

76

146

55

77 G1/2 Terminal:M3

18 TOKYO KEISO CO., LTD. TG-L381-12E

FM MAG GAUGE

ADD-ON CURRENT LEVEL TRANSMITTER SPECIFICATION

Output span : Min. 0~250mm

Max. 0~4380mm

The 4 to 20mA 2-wire current transmitter can be additionally pro-

(Shorter output span than measuring range on

vided for all types of FM-1000 Mag Gauge even together with

request)

alarm contact (s).

Enclosure : 1) Watertight

FM-1■ ■ ■- ■ ■ ■ ■/ ■ W ■ ■

Watertight, Intrinsically safe and Flameproof versions are available

2) Flameproof

to meet area classification.

FM-1■ ■ ■- ■ ■ ■ ■/ ■ E ■ ■

MODEL CODE OF ANALOG TRANSMITTER Ex d IIB T6, RIIS certification No. TC14720

3) Intrinsically safe

FM-1 8 9 10 FM-1■ ■ ■- ■ ■ ■ ■/ ■ S ■ ■

Ex ia IIC T4, RIIS certification No. TC16354

W Watertight

Fluid temp. : –10~200˚C

Enclosure E Flameproof Amb. temp. : –10~55˚C

S Intrinsically safe Power supply: Nominal DC24V

R Right hand side Max. load resistance

Direction of sensor

L Left hand side Watertight (W) 600Ω

Flameproof (E) 600Ω

R Right hand side

Direction of Converter Intrinsically safe construction (600 – Resistance inside barrier) Ω

L Left hand side

When using MTL728+, 600 – 340 = 260Ω

Output accuracy : ±(0.2+10 H

×100)% F.S.

H : Measuring range(mm)

DIMENSION

Watertight (W) and Intrinsically safe (S) Flameproof version (E)

a. Sensor (Installed onto indicator housing)

157

55

22

Span : H

Chamber

To converter

Sensor

Indicator

115

100 Level

Left hand side Right hand side

WVVS 3 0.5

Span "H"

b. Convertor (Installed onto chamber)

136

0 Level

G3/4

136

*

Converter Chamber

33

200mm above ZERO

(110)

142

115 G3/4

MVVS

225

Indicator

MVVS 3 0.5

226

Left hand side Right hand side

To sensor Sensor, Converter

*: WITH CABLE GLAND

MODEL : SXC-22B

Note 1: The transmitter (14 to 20mA) shall be replaced or read- Outer diameter of cable: Up to Ø9.9 mm

justed after returning to Tokyo Keiso.

Note 2: When installing the insulating material, do not install it

around the detector.

TG-L381-12E TOKYO KEISO CO., LTD. 19

FM MAG GAUGE

Typical specification sheet

Use following sheet for your inquiry or ordering

Model code FM-1첸첸첸-첸첸첸첸 / 첸첸첸 Quantity

Fluid Density Viscosity

Pressure MPa Temperature °C

Measuring span Connection flange

(measuring range) mm size and rating

Other requirements

* Specification is subject to change without notice.

Head Office : Shiba Toho Building, 1 – 7 – 24 Shibakoen, Minato-ku, Tokyo 105 – 8558

Tel : +81-3 – 3431 – 1625 (KEY) ; Fax : +81-3 – 3433 – 4922

e-mail : overseas.sales@tokyokeiso.co.jp ; URL : http://www.tokyokeiso.co.jp

20 TG-L381-12E

S-ar putea să vă placă și

- FM Mag Gauge Tg-L381eDocument20 paginiFM Mag Gauge Tg-L381eSoriSori2008Încă nu există evaluări

- Apr 2000galwDocument3 paginiApr 2000galwANGEL FLORESÎncă nu există evaluări

- Diaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MADocument11 paginiDiaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MARida RoudiÎncă nu există evaluări

- Messko MTO Oil Level Indicator For TransformersDocument6 paginiMessko MTO Oil Level Indicator For TransformersMatias RiedelÎncă nu există evaluări

- Pressure SwitchDocument11 paginiPressure Switchaswinpisharat1997Încă nu există evaluări

- Product Data Sheet Rosemount Tgu 58 Tank Radar Gauge Parabolic Antenna en 182276Document6 paginiProduct Data Sheet Rosemount Tgu 58 Tank Radar Gauge Parabolic Antenna en 182276m azamÎncă nu există evaluări

- Magnetic Level Gauges & Level Transmitters: FeaturesDocument3 paginiMagnetic Level Gauges & Level Transmitters: Featuressunshine dreamÎncă nu există evaluări

- Variable Area Flow Meter Data Sheet Mt3809g Mt3809elf Mt3809tfe Mt3810Document24 paginiVariable Area Flow Meter Data Sheet Mt3809g Mt3809elf Mt3809tfe Mt3810anon_962727718Încă nu există evaluări

- LY16P09HXDocument3 paginiLY16P09HXTrujillo Flores AkinÎncă nu există evaluări

- Calibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksDocument1 paginăCalibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksArmando SixtoÎncă nu există evaluări

- Messko Betech Thermometer With Bellow-Type Technology.: Pe TechnoDocument4 paginiMessko Betech Thermometer With Bellow-Type Technology.: Pe TechnoPhạm Trung HiếuÎncă nu există evaluări

- E Brooks MT3809 OKDocument19 paginiE Brooks MT3809 OKravichandran0506Încă nu există evaluări

- Senso Control Quick CouplingsDocument22 paginiSenso Control Quick CouplingsMauricio Marin PinedaÎncă nu există evaluări

- (Level Switch) DS - MS50-EN - X - 07 - 2016Document8 pagini(Level Switch) DS - MS50-EN - X - 07 - 2016galih santosoÎncă nu există evaluări

- MI002 MitsubishiDocument1 paginăMI002 MitsubishiJOSE SALAZARÎncă nu există evaluări

- Masurarea DebituluiDocument400 paginiMasurarea Debituluimanuela.bibescuÎncă nu există evaluări

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 paginiPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaÎncă nu există evaluări

- Turbine Meter Series FMT-LX: The Best Way To Predict The FutureDocument5 paginiTurbine Meter Series FMT-LX: The Best Way To Predict The FuturepedroÎncă nu există evaluări

- RCM Flow Meter3Document4 paginiRCM Flow Meter3Jairo FlechasÎncă nu există evaluări

- TC-Klinger Magnetic Level Gauge Principles and Application Rev 2CDocument57 paginiTC-Klinger Magnetic Level Gauge Principles and Application Rev 2CcherylteoooÎncă nu există evaluări

- Cooper Analogue SensorsDocument2 paginiCooper Analogue SensorsvimalÎncă nu există evaluări

- Indicating Differential Pressure SwitchDocument2 paginiIndicating Differential Pressure SwitchFaisal ImranÎncă nu există evaluări

- Magtech Magnetic Level Indicator (For Light Oil Tank)Document12 paginiMagtech Magnetic Level Indicator (For Light Oil Tank)engremilfrancismÎncă nu există evaluări

- Air Gap DatasheetDocument6 paginiAir Gap DatasheetEmanuel CondeÎncă nu există evaluări

- DB FW F131 Dosiercomputer V1330Document12 paginiDB FW F131 Dosiercomputer V1330sathyanand tkÎncă nu există evaluări

- SFC1480FX SFC2480FX: SeriesDocument8 paginiSFC1480FX SFC2480FX: SeriesRekha KÎncă nu există evaluări

- Pss 1-6f2bDocument20 paginiPss 1-6f2bEverton LuizÎncă nu există evaluări

- Barografo FoxboreDocument16 paginiBarografo FoxboreojrfgmrfÎncă nu există evaluări

- Compact Pressure Switch For The Process Industry Model PCSDocument8 paginiCompact Pressure Switch For The Process Industry Model PCShakmisÎncă nu există evaluări

- Flow Meter-1 DatasheetDocument12 paginiFlow Meter-1 DatasheetDidik HariantoÎncă nu există evaluări

- Sitransf - FM MAG 5000Document12 paginiSitransf - FM MAG 5000Clara HerlinaÎncă nu există evaluări

- ABB Leaflet Comem BR-En 2018-06-07Document2 paginiABB Leaflet Comem BR-En 2018-06-07Dave ChaudhuryÎncă nu există evaluări

- Piston / Valve Design General Characteristics: Flow Switch 1.1. NovafixDocument2 paginiPiston / Valve Design General Characteristics: Flow Switch 1.1. NovafixJavier AffifÎncă nu există evaluări

- FNX SDF PDFDocument24 paginiFNX SDF PDFAnonymous SDeSP1Încă nu există evaluări

- Mag5000 SpecificationDocument12 paginiMag5000 SpecificationDavid PuenÎncă nu există evaluări

- Buccholtz Atus CatalogDocument4 paginiBuccholtz Atus Catalogindrajit mondalÎncă nu există evaluări

- Ingecon Sun Storage 1play TL M: List of Approved Power MetersDocument6 paginiIngecon Sun Storage 1play TL M: List of Approved Power MetersalarmaÎncă nu există evaluări

- Sitrans MAG 5000 & 6000Document12 paginiSitrans MAG 5000 & 6000RaulÎncă nu există evaluări

- Magnetic Coupling Level Switches NivomagDocument4 paginiMagnetic Coupling Level Switches NivomagJaime SeguraÎncă nu există evaluări

- Sitransf Fmmag50006000 Fi01 enDocument12 paginiSitransf Fmmag50006000 Fi01 enPhùng Thị PhươngÎncă nu există evaluări

- Indicador de Nivel MagneticoDocument6 paginiIndicador de Nivel MagneticoEdivan Laurindo FerreiraÎncă nu există evaluări

- Ds pv3331 en CoDocument7 paginiDs pv3331 en Co9033301054Încă nu există evaluări

- PS01Document11 paginiPS01Sherry HenryÎncă nu există evaluări

- LF TwoWireTrans 133TSDocument2 paginiLF TwoWireTrans 133TSBASHAMOHUDDIN SHEIKÎncă nu există evaluări

- Catalogue 72 1Document12 paginiCatalogue 72 1Mais OmarÎncă nu există evaluări

- Sgm66055a-5 4Document14 paginiSgm66055a-5 4wang seikeÎncă nu există evaluări

- HOLRKEDocument14 paginiHOLRKEOJÎncă nu există evaluări

- SGM6014 SGMicroDocument16 paginiSGM6014 SGMicrowang seikeÎncă nu există evaluări

- Models IAP10, IGP10, IAP20, and IGP20 IA Series Electronic Absolute and Gauge Pressure Transmitters Pss - 2a-1c13cDocument28 paginiModels IAP10, IGP10, IAP20, and IGP20 IA Series Electronic Absolute and Gauge Pressure Transmitters Pss - 2a-1c13cJose Alberto Soza MontesÎncă nu există evaluări

- Vortex TrainingDocument17 paginiVortex TrainingRexCrazyMindÎncă nu există evaluări

- IRM-3 DUO Manual EnglishDocument33 paginiIRM-3 DUO Manual EnglishThiago Takumi TanÎncă nu există evaluări

- Fuel Oil FlowmeterDocument6 paginiFuel Oil Flowmeterpaulus sumaryotoÎncă nu există evaluări

- Flow Transmitter (SIEMENS) PDFDocument10 paginiFlow Transmitter (SIEMENS) PDFjuliunÎncă nu există evaluări

- GF Brochure RevL VeriCal RevCDocument6 paginiGF Brochure RevL VeriCal RevCjakkyjeryÎncă nu există evaluări

- MAgnetrol 75 Seires LEvelDocument8 paginiMAgnetrol 75 Seires LEvelmarcoo8Încă nu există evaluări

- Om3 Om4 Om5 Oil Management System Technical Bulletin en GB 3842796Document10 paginiOm3 Om4 Om5 Oil Management System Technical Bulletin en GB 3842796Ezzedine AyariÎncă nu există evaluări

- Measurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020Document34 paginiMeasurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020neoph138Încă nu există evaluări

- Daiphrgm Metre G10&G20Document4 paginiDaiphrgm Metre G10&G20malaÎncă nu există evaluări

- Class 800 Steel Check ValvesDocument2 paginiClass 800 Steel Check Valvesnnaemeka omekeÎncă nu există evaluări

- Ball Valve - FlowtekDocument6 paginiBall Valve - Flowteknnaemeka omekeÎncă nu există evaluări

- Small Size Ball ValveDocument17 paginiSmall Size Ball Valvennaemeka omekeÎncă nu există evaluări

- CA44 and CA44S Carbon Steel Air and Gas Traps Flanged DN15 To DN25Document5 paginiCA44 and CA44S Carbon Steel Air and Gas Traps Flanged DN15 To DN25nnaemeka omekeÎncă nu există evaluări

- s07 PressurexmtrsDocument20 paginis07 Pressurexmtrsnnaemeka omekeÎncă nu există evaluări

- RBS TwoInch System Retriever KitDocument3 paginiRBS TwoInch System Retriever Kitnnaemeka omekeÎncă nu există evaluări

- Oliver Double Block and Bleed Valve CatalogDocument7 paginiOliver Double Block and Bleed Valve Catalognnaemeka omekeÎncă nu există evaluări

- Flat Swing Check Valve PDFDocument5 paginiFlat Swing Check Valve PDFnnaemeka omekeÎncă nu există evaluări

- Needle Valves: Forged Integral BonnetDocument12 paginiNeedle Valves: Forged Integral Bonnetnnaemeka omekeÎncă nu există evaluări

- Gate ValveDocument4 paginiGate Valvennaemeka omekeÎncă nu există evaluări

- Class 800 Steel Swing Check ValvesDocument2 paginiClass 800 Steel Swing Check Valvesnnaemeka omekeÎncă nu există evaluări

- Acris Isoria Mammouth: Butterfly Valves For High Corrosion, Ultra High Purity and General Industrial ApplicationsDocument12 paginiAcris Isoria Mammouth: Butterfly Valves For High Corrosion, Ultra High Purity and General Industrial Applicationsnnaemeka omekeÎncă nu există evaluări

- S/N Material QTY: 2 Bulkhead Penetration 8 PcsDocument9 paginiS/N Material QTY: 2 Bulkhead Penetration 8 Pcsnnaemeka omekeÎncă nu există evaluări

- Site Visit ReportDocument2 paginiSite Visit Reportnnaemeka omekeÎncă nu există evaluări

- Class XI Half SlybussDocument10 paginiClass XI Half SlybussDevansh AgarwalÎncă nu există evaluări

- Unijin Pressure Gauge p258Document2 paginiUnijin Pressure Gauge p258Nguyễn Đăng PhúcÎncă nu există evaluări

- ANSYS Stress LinearizationDocument15 paginiANSYS Stress LinearizationTiago CandeiasÎncă nu există evaluări

- Tests For Gas Permeability of ConcreteDocument6 paginiTests For Gas Permeability of ConcreteAzuriak1Încă nu există evaluări

- 413 Impurities Testing in MedicalDocument2 pagini413 Impurities Testing in MedicalIsmail MathakiyaÎncă nu există evaluări

- Failure Modes of Bolt and Nut Assemblies Under Tensile LoadingDocument11 paginiFailure Modes of Bolt and Nut Assemblies Under Tensile LoadingclevercogÎncă nu există evaluări

- Experiences of ISFOC On Concentration Photovoltaic: Francisca RubioDocument49 paginiExperiences of ISFOC On Concentration Photovoltaic: Francisca RubioHikary AcevesÎncă nu există evaluări

- Kobold Flow SensorDocument4 paginiKobold Flow SensorjilaypandyaÎncă nu există evaluări

- RT Finalpresenatation08 161118104713Document56 paginiRT Finalpresenatation08 161118104713sajay2010Încă nu există evaluări

- Space Time Continuum - Terence McKennaDocument6 paginiSpace Time Continuum - Terence McKennaKali23YugaÎncă nu există evaluări

- The Hubbard Coil MatrixDocument4 paginiThe Hubbard Coil MatrixAna Luisa Lynce100% (1)

- Mayan Calendar ExplainedDocument9 paginiMayan Calendar Explainedbresail40% (1)

- Lab 8 Ee ReportDocument10 paginiLab 8 Ee Reportshikazi ziki100% (1)

- XRSIM Lessons - Student PacketDocument59 paginiXRSIM Lessons - Student PacketWilliam Pinto HernándezÎncă nu există evaluări

- Leica ICD Brochure enDocument4 paginiLeica ICD Brochure enCsaba GibártiÎncă nu există evaluări

- Adavances in Positioning and FramesDocument407 paginiAdavances in Positioning and Framesoliwia.tolloczkoÎncă nu există evaluări

- R7222301 Mass Transfer & SeparationDocument2 paginiR7222301 Mass Transfer & SeparationsivabharathamurthyÎncă nu există evaluări

- Modeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Document51 paginiModeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Samuel ChanÎncă nu există evaluări

- Rotalk 23Document16 paginiRotalk 23Pramod AthiyarathuÎncă nu există evaluări

- Calculus OnlineDocument2 paginiCalculus Onlineapi-427949627Încă nu există evaluări

- General Solution For U-ShapeDocument12 paginiGeneral Solution For U-ShapeDiana SoareÎncă nu există evaluări

- CV 101Document4 paginiCV 101frco1504Încă nu există evaluări

- Sahana MSE.1Document29 paginiSahana MSE.1Dadi YashwantÎncă nu există evaluări

- 2nd Semester Latest 21Document75 pagini2nd Semester Latest 21Mugars Lupin ArseneÎncă nu există evaluări

- Chul Park The Limits of Two-Temperature ModelDocument13 paginiChul Park The Limits of Two-Temperature ModellazharÎncă nu există evaluări

- Yang Et Al. (2017)Document11 paginiYang Et Al. (2017)Francisco OppsÎncă nu există evaluări

- AppNote 07 FPSO and Offshore PlatformsDocument4 paginiAppNote 07 FPSO and Offshore PlatformsRao MadepalliÎncă nu există evaluări

- Document Trafag PD3.4Document7 paginiDocument Trafag PD3.4Rick Van den BosÎncă nu există evaluări

- Assignment Submit by 1 May Humidification Operations: H A K ADocument2 paginiAssignment Submit by 1 May Humidification Operations: H A K AHarshil ChangelaÎncă nu există evaluări

- Press Tool ReportDocument40 paginiPress Tool ReportIshu Bassan100% (2)