Documente Academic

Documente Profesional

Documente Cultură

PSM2 PDF

Încărcat de

anon_916493434Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PSM2 PDF

Încărcat de

anon_916493434Drepturi de autor:

Formate disponibile

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Fluid Characterisation

Introduction

Usually referred to as PVT (pressure, volume, temperature), correct fluid

characterisation and modelling is critical part to all aspects of petroleum

engineering since all fluid flow, whether through reservoir rock, tubing or

pipeline, depends on PVT properties.

Fluid property data is usually found by laboratory measurement of

bottomhole or recombined surface samples and summarised in a PVT

report. The most useful results are from the separator or flash

experimental procedures.

Predicted properties are usually determined by:

1. black oil model correlations (volumetric parameters) or

2. mathematical models using compositional analysis (equations of

state)

Since equations of state are complex and require significant

mathematical manipulation to represent multiphase oil and gas

properties, it is most convenient - and usually more than accurate

enough - to use a properly matched black oil model.

A matched black oil model can be used to determine the following oil, gas

and water properties:

1. wellbore related: phase proportions and volumes, densities,

viscosities, interfacial tension

2. reservoir related: fluid compressibilities, viscosities

Fluid components

Reservoir fluids have a fairly simple chemistry, being composed primarily

of hydrocarbons (i.e. hydrogen and carbon atoms).

A typical crude oil is 85% carbon (C), 13% hydrogen (H) and 2% other

impurities (N2, CO2, H2S).

The more carbon atoms, the heavier (and longer) the molecule e.g. C70

and greater is tar.

A light oil has more lighter components (e.g. C1-C6) and less heavy

components (e.g. C20+).

© The Robert Gordon University 2008 1

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Most hydrocarbons are simple “straight chain” combinations e.g. the 4

common gases:

H H H H H H H H H H

H C H H C C H H C C C H H C C C C H

H H H H H H H H H H

Methane Ethane Propane Butane

(CH4) (C2H6) (C3H8) (C4H10)

Some have circular or “ring” structures e.g. naphthenes (e.g.

cyclohexane) and aromatics:

Other (less desirable) components include asphaltenes and waxes

(typically C25-C35):

The lightest straight chain liquids (i.e. C5 to C10) form the main

components of petrol or gasoline

Octane numbers refer to a mixture of these components that have the

same ignition performance as a theoretical mixture of octane (C8 -

handles compression best) and pentane (C5 - worst i.e. causes

“knocking”). A 93 octane number fuel would perform like a 93:7%

mixture of octane and pentane.

© The Robert Gordon University 2008 2

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Typical Oil Compositions:

ns:

70

Volatile (“light”) oil (42° API)

Am ount of e a ch com pone nt (m ol %)

60

50

40

30

20

10

+

7

18

19

10

12

13

16

1

C2

C5

C8

0

C

C1

C1

C1

C1

C

C

C2

Com pone nt

70

Black (“normal”) oil (30° API)

Am ount of e a ch com pone nt (m ol %)

60

50

40

30

20

10

0

+

14

15

16

17

18

19

10

11

12

13

1

20

C

C

C

C

C

Com pone nt

70

Biodegraded (“heavy”) oil (20° API)

Am ount of e a ch com pone nt (m ol %)

60

50

40

30

20

10

0

+

0

11

12

14

15

17

18

9

9

C1

C2

C4

C7

8

C

20

C1

C1

C1

C1

C

Com pone nt

© The Robert Gordon University 2008 3

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Fluid Types

Hydrocarbon fluids can be classified according to their position on the

phase diagram at reservoir conditions:

Volatile oil Gas condensate

Liquid Gas

Black oil critical Wet gas

Heavy

point

oil

Pbubble Dry gas

Pressure Pdew

10% gas

5% liquid

10% liquid

Temperature

A path plotted on the phase envelope from reservoir pressure and

temperature to wellhead and separator pressure and temperature will

describe the phase distribution, i.e. percent of oil and gas at any point.

In terms of API gravity and gas-oil ratios (GORs), typical characteristics

of each fluid type are as follows:

S.G. API Gravity GOR (scf/stb) GOR

(liquid)

(sm3/sm3)

Heavy oil 0.93 12 – 25 < 100 < 20

Black oil 0.85 25 – 40 100 – 2,500 20 – 450

Volatile oil 0.81 40 – 50 2,500 – 4,500 450 – 800

Gas 0.75 50 – 70 4,500 – 50,000 > 800

condensate

Wet gas 50 – 70 50,000 –100,000

Dry gas n/a < 10 stb/mmscfd liquid

© The Robert Gordon University 2008 4

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Black Oil Correlations

Black oil correlations are more correctly termed volumetric correlations

since this is their principal application.

They can be applied to heavy oils, black oils, volatile oils, gas-

condensates and gases.

Widely used correlations include Standing, Glaso, Lasater and Vasquez-

Beggs. In the majority of cases, the Standing correlation will give

accurate results. For volatile oils, the Lasater correlation often gives a

better representation.

All correlations require surface measured oil and gas parameters (oil and

gas gravity and GOR). Measured properties at bubble point conditions are

used to match the correlation:

Bubble point (Pb) @ T

Oil gravity (°API)

Black Oil Model GOR (scf/stb) @ P,T

Gas gravity (S.G.)

Solution GOR (scf/stb) Formation Volume Factor (Bo)

(rb/stb) @ P,T

The calculated results of Pb, GOR and Bo are usually expressed in

graphical form:

Solution GOR

GOR Bo

(scf/stb) (rb/stb)

Pbubble Pressure Pbubble Pressure

Oil density can be determined at any pressure and temperature using the

following equation:

350.4 . γ o + GOR ( P, T ) . γ g . 0.0764

ρ o ( P, T ) = [lb/cuft]

Bo ( P, T ) . 5.614

where γo = oil specific gravity = 141.5/(131.5 + oAPI)

γg = gas specific gravity

© The Robert Gordon University 2008 5

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

For low to medium GOR oils, Bo is the controlling influence.

For high GOR (volatile) oils, the right hand side of the equation becomes

significant.

Although simple to use, correlations have limitations depending on their

experimental origins.

Wherever possible, correlations must be matched or validated with

laboratory data.

Required match data is Pbubble, Bo and μo at the bubble point.

Gas-Condensate Applications

This is simply a gas which deposits liquids when the pressure is dropped

from initial reservoir conditions.

Liquid (condensate) dropout starts at the dew point, increases to a

maximum then decreases again.

This behaviour is called retrograde, hence the term retrograde gas-

condensate.

Rich gas

Liquid condensate

critical

point Lean gas

condensate

Pbubble

Pdew

Pressure Gas

10% gas

5% liquid

10% liquid

Temperature

© The Robert Gordon University 2008 6

Pg Dip / MSc / Energy Programme Fluid Characterisation

Production System Modelling (ENM204)

Downhole samples is usually difficult to obtain correctly, so surface

sampling (gas and liquid) is used.

Surface samples are then analysed and recombined in a ratio determined

from stabilised well test rates.

Recombination ratio usually expressed as a gas-oil ratio (GOR) or

condensate-gas ratio (CGR).

Typical gas-condensate characteristics are:

CGR (stb/mmscf) GOR (scf/stb)

Rich yield condensate 200+ < 5000

(vol oil)

Medium yield condensate 100 – 200 5,000 – 50,000

Light yield condensate 20 – 100 10,000 – 50,000

PVT laboratory measurements usually include:

1. constant composition expansion (CCE) to find pressure-volume

relationships (Pdew, rel vol & z)

2. constant volume depletion (CVD) to find condensate yield or liquid

dropout behaviour

Produced CGR

(stb/mmscf)

Pdew Pressure

© The Robert Gordon University 2008 7

S-ar putea să vă placă și

- Voulme 1 Hydraulic Presses Design of Press Body PDFDocument32 paginiVoulme 1 Hydraulic Presses Design of Press Body PDFStephane Durel MbidaÎncă nu există evaluări

- MP3127 LT 3 210 FlygtDocument7 paginiMP3127 LT 3 210 Flygtİlge Cem TarımcıoğluÎncă nu există evaluări

- Cummins Actuator PDFDocument3 paginiCummins Actuator PDFLuciano PereiraÎncă nu există evaluări

- Family of Dry-Type Distribution TransformersDocument4 paginiFamily of Dry-Type Distribution TransformersComsip400Încă nu există evaluări

- Optimize the CX335 compressor-limiter titleDocument16 paginiOptimize the CX335 compressor-limiter titleDrixÎncă nu există evaluări

- TB02200004E - Tab 6Document40 paginiTB02200004E - Tab 6Ayman SaberÎncă nu există evaluări

- Poster Ex2Document1 paginăPoster Ex2jim0410168Încă nu există evaluări

- Vol12 Tab13 PDFDocument99 paginiVol12 Tab13 PDFJuanFuentesBecerraÎncă nu există evaluări

- Starting/Charging ConnectorDocument15 paginiStarting/Charging ConnectorRenato BautistaÎncă nu există evaluări

- Starting/Charging ConnectorDocument15 paginiStarting/Charging ConnectorRenato BautistaÎncă nu există evaluări

- Performance Curves for 50 Hz MLS3 PumpDocument3 paginiPerformance Curves for 50 Hz MLS3 PumpDheeraj ThakurÎncă nu există evaluări

- Call Forward DefaultDocument14 paginiCall Forward DefaultWeerayut YoungklaiÎncă nu există evaluări

- 1pot. Memanjang - Layout1Document1 pagină1pot. Memanjang - Layout1NOtail AksÎncă nu există evaluări

- Bicycle Manual Road Bike: Pure CyclingDocument63 paginiBicycle Manual Road Bike: Pure CyclingSan Ban CastroÎncă nu există evaluări

- Bai 4Document13 paginiBai 4van hoanÎncă nu există evaluări

- Achievement Chart (HSK)Document1 paginăAchievement Chart (HSK)Marivic C. AcostaÎncă nu există evaluări

- Frenos Disco BL - m525 - 02Document1 paginăFrenos Disco BL - m525 - 02CbaÎncă nu există evaluări

- Fire Hydrant Parts List: TritonDocument1 paginăFire Hydrant Parts List: TritonReaz UddinÎncă nu există evaluări

- Fire Hydrant Parts List: TritonDocument1 paginăFire Hydrant Parts List: TritonAmjed HÎncă nu există evaluări

- Cold - Coffe vERSION-Piano - 1Document1 paginăCold - Coffe vERSION-Piano - 1Rubén SollosoÎncă nu există evaluări

- DB 460 CBV - Eng 2011Document2 paginiDB 460 CBV - Eng 2011Engkus KuswayaÎncă nu există evaluări

- MILLING JIG - Sheet - 2Document1 paginăMILLING JIG - Sheet - 2Dinesh NewalkarÎncă nu există evaluări

- Si 1560Document2 paginiSi 1560Brian FuentesÎncă nu există evaluări

- Day Running Lights Wiring PDFDocument2 paginiDay Running Lights Wiring PDFAnonymous OFfJVrQY6Încă nu există evaluări

- Achievement Progress Chart Training Activity MatrixDocument3 paginiAchievement Progress Chart Training Activity Matrixkelvsgarcia22Încă nu există evaluări

- BP9763 A3 Sheet 03Document1 paginăBP9763 A3 Sheet 03Miguel MotaÎncă nu există evaluări

- GCLB PDFDocument6 paginiGCLB PDFMiguel Angel MartinÎncă nu există evaluări

- Glowworm Betacom C July 09 PDFDocument68 paginiGlowworm Betacom C July 09 PDFAftab MajeedÎncă nu există evaluări

- Optional Gasket Kit: "134-S" SeriesDocument47 paginiOptional Gasket Kit: "134-S" SeriesginoÎncă nu există evaluări

- Hallelujah Cello CohenDocument1 paginăHallelujah Cello CohenLoana TorresÎncă nu există evaluări

- Air - From - Orchestral - Suite - No. - 3 - BWV - 1068 - in - D - Major - Bach (1) TubaDocument1 paginăAir - From - Orchestral - Suite - No. - 3 - BWV - 1068 - in - D - Major - Bach (1) Tubabenedek.stegura379Încă nu există evaluări

- Sun KingDocument1 paginăSun KingTheodore TurnerÎncă nu există evaluări

- Bintang Racing Team Performance DataDocument1 paginăBintang Racing Team Performance Data2CTOE12 Ghilman HilmaniÎncă nu există evaluări

- Đề 07Document1 paginăĐề 07An nguyenhoangÎncă nu există evaluări

- Wall CladsDocument1 paginăWall CladsKatPalaganasÎncă nu există evaluări

- STYLE 2775 Product Bronco Hydrant Support: Parts List SheetDocument2 paginiSTYLE 2775 Product Bronco Hydrant Support: Parts List SheetFarmaceuticaÎncă nu există evaluări

- Territory Management DashboardDocument5 paginiTerritory Management DashboardQuazi Aritra ReyanÎncă nu există evaluări

- Page A (Eyes) Pages A & A1 Pages B & B1 Pages C & C1Document12 paginiPage A (Eyes) Pages A & A1 Pages B & B1 Pages C & C1Jacquelin CuriocaÎncă nu există evaluări

- AS119-4L-30 - Ver.7 DimensionDocument1 paginăAS119-4L-30 - Ver.7 DimensionmilicevicbpÎncă nu există evaluări

- Ignition Transformer For MS5001Document3 paginiIgnition Transformer For MS5001Chidiebere Samuel OkogwuÎncă nu există evaluări

- Wireless Features Description: Calling Number Identification RestrictionDocument14 paginiWireless Features Description: Calling Number Identification RestrictionmichaelbondÎncă nu există evaluări

- Pefd Fixx 3Document1 paginăPefd Fixx 3Rafi Theda PrabawaÎncă nu există evaluări

- Parweld Pez 400Document1 paginăParweld Pez 400pablotorres_cÎncă nu există evaluări

- Solfeo I Ritmos Hojas 1 A 4Document4 paginiSolfeo I Ritmos Hojas 1 A 4GAZAMUSICCLARINETEÎncă nu există evaluări

- Prélude From Suite No. 1 in G Major BWV 1007 (Cello)Document2 paginiPrélude From Suite No. 1 in G Major BWV 1007 (Cello)LaineyÎncă nu există evaluări

- El Final - Rostros Ocultos (Atzin)Document3 paginiEl Final - Rostros Ocultos (Atzin)Lili Star Moon100% (1)

- Stomach Organ Meridian and PMC Muscle Class 5Document2 paginiStomach Organ Meridian and PMC Muscle Class 5RukaphuongÎncă nu există evaluări

- Sonata in E Flat For 'Cello & Continuo, (RV 39) : Tenor RecorderDocument3 paginiSonata in E Flat For 'Cello & Continuo, (RV 39) : Tenor RecorderdngrxÎncă nu există evaluări

- 6-DZM-14Document1 pagină6-DZM-14Muhammad KahlilÎncă nu există evaluări

- Ranking Primera Categoria 1Document1 paginăRanking Primera Categoria 1juanjius007Încă nu există evaluări

- 2008 Automation Summit A Users Conference: Presenter: CompanyDocument16 pagini2008 Automation Summit A Users Conference: Presenter: Companymusic4andrsÎncă nu există evaluări

- Concerto For Two Violins in D Minor BWV 1043 1st Mvt. Violin I - BachDocument3 paginiConcerto For Two Violins in D Minor BWV 1043 1st Mvt. Violin I - BachHirun PungsuwanÎncă nu există evaluări

- Sample Point Summary ListDocument1 paginăSample Point Summary ListazharÎncă nu există evaluări

- Etude No.19 Op.60 Carcassi - MatteoDocument2 paginiEtude No.19 Op.60 Carcassi - MatteonounchloomanÎncă nu există evaluări

- Screw Jack REHAN PDFDocument1 paginăScrew Jack REHAN PDFVinayak NaikÎncă nu există evaluări

- PAW Patrol and Friends Free Printable BadgesDocument2 paginiPAW Patrol and Friends Free Printable BadgesCmccÎncă nu există evaluări

- Cello Suite No.1 in G Major BWV1007 Prludium For TromboneDocument2 paginiCello Suite No.1 in G Major BWV1007 Prludium For TromboneasdasdÎncă nu există evaluări

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredDe la EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredÎncă nu există evaluări

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialDe la EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialÎncă nu există evaluări

- Spe-151134-Ms-P Ceil PDFDocument12 paginiSpe-151134-Ms-P Ceil PDFanon_916493434Încă nu există evaluări

- Spe 162948 MS P PDFDocument7 paginiSpe 162948 MS P PDFanon_916493434Încă nu există evaluări

- Golden Rules Well Test InterpretationDocument1 paginăGolden Rules Well Test Interpretationmhuf89Încă nu există evaluări

- Well Integrity AnalysisDocument39 paginiWell Integrity Analysishammad091Încă nu există evaluări

- MT DiffusionDocument37 paginiMT DiffusionIbrahim LaxmidharÎncă nu există evaluări

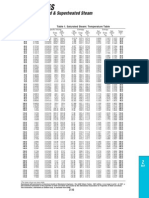

- Steam Tables: Properties of Saturated & Superheated SteamDocument11 paginiSteam Tables: Properties of Saturated & Superheated SteamARNOUXÎncă nu există evaluări

- 2024 Arxiv Ni3In2S2Document19 pagini2024 Arxiv Ni3In2S2Arvind MauryaÎncă nu există evaluări

- POWERGUARD 6051 Pds I2Document1 paginăPOWERGUARD 6051 Pds I2JOSEÎncă nu există evaluări

- Howard B. - Petroleum Engineers Handbook, Part 4Document331 paginiHoward B. - Petroleum Engineers Handbook, Part 4khanhnn81100% (3)

- Lesson 11 - Steam Power CyclesDocument12 paginiLesson 11 - Steam Power CyclesabinmwangiÎncă nu există evaluări

- Cadac Catalogue 2018Document33 paginiCadac Catalogue 2018MoodÎncă nu există evaluări

- Pressure Notes EditedDocument7 paginiPressure Notes EditedSharuvindan NairÎncă nu există evaluări

- Stars and Galaxies 9th Edition Seeds Test BankDocument20 paginiStars and Galaxies 9th Edition Seeds Test Bankngocalmai0236h100% (31)

- Knudsen Number PDFDocument4 paginiKnudsen Number PDFBharath Reddy100% (1)

- Xi CH 4 GasesDocument5 paginiXi CH 4 GasesYa WritesÎncă nu există evaluări

- Module 4Document26 paginiModule 4Carms GameÎncă nu există evaluări

- Kleenheat Presentation 2014Document32 paginiKleenheat Presentation 2014scata1117Încă nu există evaluări

- BulkCatalogDocument32 paginiBulkCatalogSud HaldarÎncă nu există evaluări

- Gcesoln 7Document7 paginiGcesoln 7api-3734333Încă nu există evaluări

- Post Lab ReportDocument3 paginiPost Lab ReportMelwyn FranciscoÎncă nu există evaluări

- Thermal Lab Manual GuideDocument100 paginiThermal Lab Manual GuideNegese TeklearegayÎncă nu există evaluări

- R407CDocument4 paginiR407CPanji SegaraÎncă nu există evaluări

- Rotameter Equations and DerivationsDocument2 paginiRotameter Equations and DerivationsJoy RoyÎncă nu există evaluări

- Pressure MeasurementsDocument13 paginiPressure MeasurementsCB CañeteÎncă nu există evaluări

- Exchange InteractionDocument3 paginiExchange InteractionCharudatta GalandeÎncă nu există evaluări

- Ch20 EmulsionSelectionDocument7 paginiCh20 EmulsionSelectionKee SarakarnkosolÎncă nu există evaluări

- WeedaDocument3 paginiWeedaTryj1Încă nu există evaluări

- Characteristics of The AtmosphereDocument40 paginiCharacteristics of The AtmosphereLina Gutierrez GÎncă nu există evaluări

- I04IA019EN-A Micropore Size Analysis of Porous CarbonsDocument4 paginiI04IA019EN-A Micropore Size Analysis of Porous CarbonsDwi Sandi Argo ArnowoÎncă nu există evaluări

- Stratosphere - SKYbrary Aviation SafetyDocument3 paginiStratosphere - SKYbrary Aviation SafetyĐoàn Hồng NgọcÎncă nu există evaluări

- P V P V: Gas LawsDocument3 paginiP V P V: Gas LawsAntoine John GalichaÎncă nu există evaluări

- Prandtl Number Pr Thermal Conduktivity k, W/m.K Temperatur (˚C) Density ρ, kg/m³ Specific Heat Cp, J/kg.K Thermal Diffusivity α, m²/s Dinamic Viscosity Ϥ, kg/m.s Kinematic ViscosityDocument6 paginiPrandtl Number Pr Thermal Conduktivity k, W/m.K Temperatur (˚C) Density ρ, kg/m³ Specific Heat Cp, J/kg.K Thermal Diffusivity α, m²/s Dinamic Viscosity Ϥ, kg/m.s Kinematic ViscosityWindy LusiaÎncă nu există evaluări

- Mass Transfer: CHE 246 Separation ProcessesDocument54 paginiMass Transfer: CHE 246 Separation ProcessesnorazifahÎncă nu există evaluări