Documente Academic

Documente Profesional

Documente Cultură

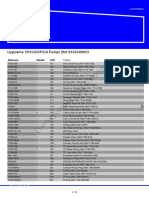

Test Plan: Pump Specification

Încărcat de

BaytolgaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Test Plan: Pump Specification

Încărcat de

BaytolgaDrepturi de autor:

Formate disponibile

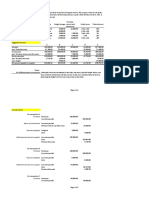

9520A420 Issue No: 1

Test Plan

Perkins vista 83.0 KW @ 230 Date: 00/00/00

PUMP SPECIFICATION

Rotation: Clockwise.

Governor type: Mechanical all-speed.

Gov. Link Length: 41.5 ± 0.5 mm.

Gov. Link Length: 10.1 ± 0.5 mm.

(DP210 Workshop Manual Section 4.6.4)

Plunger Diameter: 7.0 mm (4 off).

Drive Type: Supported shaft.

Transfer pressure: adjustable.

Viscosity compensating device in end plate.

Cambox pressurising valve.

Servo Advance with:

- Speed advance, LLA & CA

Torque trimmer.

Boost control.

Solenoid voltage: See Service Instruction Note DT294.

OEM Code: 2644C311 Setting Code: -/2/2490

OEM Code: 2644C336 Setting Code: -/2/2490

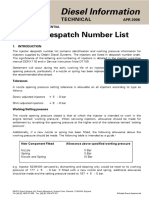

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and the

following test benches: HA3000/HA2500/HA700/AVM/PGM

Test Fluid: ISO 4113 at 40 ± 2°C.

Inlet feed pressure: 5.0 psi

Backleak pressure: 0.0 psi

Nozzles: YDB287 (BDL0S6889)

Nozzle Opening Pressure: 172 + 3 - 0 bar.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy.

H.P. pipes: 6 x 1.8 x 450 mm

PRE-TEST NOTES

Screw transfer pressure adjuster fully in and then 4.5 turns

out before commencing test

No additional shimming is required.

CA solenoid to be de-energised unless otherwise stated.

Torque trimmer plug to be wound out until thread appears.

Boost control initial shimming: 1.5 mm.

Boost stroke : 5.7 to 5.9 mm.

Latch valve adjuster, if fitted, screw fully in then

8 turns out

Turn light load adjuster valve fully in ,then 1 turns out.

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

1. Priming (C) 200 Obtain delivery from all injectors

and backleak.

Close throttle.

Stabilise. Cycle speed between 100 to 500 rpm 3 times.

Set boost pressure to 15.0 psi.

Open throttle.

2. Transfer Press. (S) 1150 90 to 92 psi

3. Delivery (S) 1150 109.0 ± 0.5 mm3/st.

4. Governor (S) 1300 12.0 to 16.0 mm3/st.

Stabilise. Cycle speed between 100 to 1310 rpm 2 times.

Stabilise and run at 1150 rpm until backleak temperature

is 38°C min.

5. Back leakage. (C) 1150 Flow rate 500 to 1000 cm3/min.

6. Cambox Press. (C) 1150 6 to 10 psi

7. Transfer Press. (C) 1150 Press at test(6 ) + 82.0 to 84.0psi

Run test machine down to 0 rpm.

8. Transfer Press. (C) 100 Minimum 12 psi.

9. Transfer Press (C) 1150 As test (7 ) ± 1.0 psi

If incorrect repeat from test (6 ).

Stop test machine.

Remove pressure gauges and fit stop solenoid or plug.

10. Advance (S) 500 0° (Datum advance gauge)

11. Advance (C) 700 0.6° Max.

12. Advance (C) 1050 1.3 to 1.7°.

13. Advance (C) 1150 1.3 to 1.7°.

Stop test machine.

Energise CA solenoid.

14. Advance (C) 700 3.3 to 5.5°.

De-energise CA solenoid.

15. Advance - (S) 1150 4.8 to 5.2° 47.0 to 51.0mm3/st

Light load Adjust throttle/torque screw

& LLA valve.

Run test machine down to 0 rpm.

16. Advance - (C) 1150 4.8 to 5.2° 49.0 ± 2.0mm3/st.

Light load Use throttle/Torque screw.

17. Advance - (C) 1150 8.8 to 9.2° 35.0 ± 8.0mm3/st.

Light load Use throttle/Torque screw.

18. Advance - (C) 700 1.8 to 2.2° 72.0 ± 8.0mm3/st.

Light load Use throttle/Torque screw.

If correct continue with test (19), if not, adjust shimming

and then repeat test(s) (from test 15).

Open throttle.

Stop test machine.

Fit CPS tool

Set boost pressure to 15.0 psi.

19. Torque Trimmer (S) 1150 Datum CPS reading to 0.0mm.

20. Torque Trimmer (S) 700 Adj CPS to -0.65 to -0.71mm

CPS

Run test machine down to 0 rpm.

Stabilise and run at 1175rpm for 5 secs

21. Torque Trimmer (C) 1150 As test (19) ± 0.05 mm

CPS

22. Torque Trimmer (C) 950 Check CPS is +0.20 to -0.20mm

CPS

23. Torque Trimmer (C) 525 Check CPS is -0.8 to -1.2mm

CPS

24. Torque Trimmer (C) 1100 As test (21) ± 0.1 mm

CPS

Set boost pressure to zero.

25. Torque Trimmer (C) 1100 As test (24) - 4.10 ± 0.30 mm

CPS

Set boost pressure to 8.5 ± 0.3 psi.

26. Torque Trimmer (C) 1100 As test (24) ± 0.3 mm

CPS

If correct continue with test (27), if not, adjust shimming

and then repeat test(s) (19 to 26 ).

Set boost pressure to 1.0 ± 0.3 psi.

27. Torque Trimmer (C) 1100 As test (25) ± 0.2 mm

CPS

If correct continue with test (28), if not, adjust shimming

and then repeat test(s) (19 to 27 ).

Set boost pressure to zero.

Screw latch valve adjuster fully in.

28. Latch Valve (C) 280 CPS = - 3.0 to - 7.0 mm

If incorrect, adjust LV pre-load

& repeat test

Run test machine down to 0 rpm.

29. Torque Trimmer (C) 250 As test (28) + 3.0 ± 5.0 mm

CPS

30. Torque Trimmer (C) 300 As test (29) - 5.0 ± 3.0 mm

CPS

If incorrect or adjusted, stop machine and repeat from test (28).

31. Delivery (C) 100 Minimum 60.0 mm3/st.

32. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 3.0 mm3/st.

Stop test machine.

Close throttle.

33. Idle delivery (S) 450 12.0 to 16.0 mm3/st. Throttle closed.

34. Delivery (C) 550 Maximum 3.0 mm3/st.

Stop test machine.

Fit Max Fuel adjuster tool

Open throttle.

Set boost pressure to 15.0 psi.

35. Max. Delivery (S) 1150 109.0 ± 0.5 mm3/st.

Max. spread 5.0 mm3/st.

36. Delivery S/C 700 As test (35) + 3.0 ± 1.0 mm3/st.

Set boost pressure to zero.

37. Delivery (C) 500 71.0 to 77.0 mm3/st.

Set boost pressure to 15.0 ± 0.2 psi.

38. Delivery (C) 1150 Record delivery mm3/st.

39. Governor (S) 1280 12.0 to 16.0 mm3/st.

40. Gov. cut-off (C) 1330 Maximum 3.0 mm3/st.

41. Delivery (C) 1150 Throttle as test (39).

Minimum as test (38) - 1.0 mm3/st.

42. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 182.50°

speed (S) 1150 Trigger level 25 %

.

ISO OVERCHECK PROCEDURE

.

The Overcheck section of this plan has been developed in

conjunction with the Original Equipment Manufacturer.

Providing all values are achieved, the pump settings will

maintain the original homologated engine performance. Failure to

attain any one of the values will indicate a pump setting or

function failure and require further investigation.

.

PRE-OVERCHECK NOTES

Dynamic timing - record zero angle - (refer to DT339)

Drive shaft lock bolt to remain locked until zero angle

recorded.

CA advance motor to be de-energised unless otherwise stated.

No adjustments to be made unless otherwise stated.

Close throttle.

Stabilise. Cycle speed between 100 to 500 rpm 3 times.

Set boost pressure to 15.0 psi.

Open throttle.

Stabilise. Cycle speed between 100 to 1290 rpm 2 times.

Stabilise and run at 1200 rpm until backleak temperature

is 38°C min.

43. Gov. cut-off (C) 1330 Maximum 3.0 mm3/st.

Fully unscrew the Maximum speed adjusting screw.

44. Advance (S) 500 0° (Datum advance gauge)

45. Advance (C) 700 0.7° Max.

46. Advance (C) 1150 1.2 to 1.8°.

47. Advance - (C) 1150 4.8 to 5.2° 49.0 ± 4.0mm3/st.

Light load Use throttle/Torque screw.

48. Advance - (C) 1150 8.8 to 9.2° 35.0 ± 9.0mm3/st.

Light load Use throttle/Torque screw.

49. Advance - (C) 700 1.8 to 2.2° 72.0 ± 10.0mm3/st.

Light load Use throttle/Torque screw.

Stop test machine.

Energise CA solenoid.

50. Advance (C) 700 3.5 to 5.5°.

De-energise CA solenoid.

Set boost pressure to zero.

Move throttle lever to closed position for tests (51 ).

51. Delivery (C) 550 Maximum 3.0 mm3/st.

Open throttle.

52. Delivery (C) 100 Minimum 60.0 mm3/st.

53. Shut-off - (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 3.0 mm3/st.

Run test machine down to 0 rpm.

Set boost pressure to 15.0 psi.

Run test machine down to 1100 rpm.

54. Delivery (C) 1150 106.0 to 112.0 mm3/st.

55. Delivery (C) 700 As test (54) + 2.0 ± 3.0 mm3/st.

Set boost pressure to zero.

56. Delivery (C) 500 70.0 to 78.0 mm3/st.

Set boost pressure to 15.0 psi.

57. Governor (S) 1280 12.0 to 16.0 mm3/st.

58. Gov. cut-off (C) 1330 Maximum 3.0 mm3/st.

59. Dynamic timing Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 182.50°

speed (S) 1150 Trigger level 25 %

S-ar putea să vă placă și

- 9521A030H DATA CatalogDocument3 pagini9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 8520A060A TestplanDocument2 pagini8520A060A TestplanBaytolga can100% (1)

- Test Plan: Pump SpecificationDocument3 paginiTest Plan: Pump SpecificationBaytolgaÎncă nu există evaluări

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 paginiTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 9320a217 TabelaDocument4 pagini9320a217 TabelaLIONN SOFTWARESÎncă nu există evaluări

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 paginiTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215Încă nu există evaluări

- 3042f843 Plano de TesteDocument1 pagină3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Test Plan: 9320A530: Pump SpecificationDocument4 paginiTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovÎncă nu există evaluări

- Test Plan 8523a320Document2 paginiTest Plan 8523a320taniaÎncă nu există evaluări

- 3340F401G Plano de Teste DelphiDocument2 pagini3340F401G Plano de Teste DelphiJunior Iung100% (1)

- DP200 Pompa 9320a214g-1Document3 paginiDP200 Pompa 9320a214g-1BaytolgaÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©LIONN SOFTWARESÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©murillo_rodriguez8382100% (1)

- StanadyneDocument4 paginiStanadynemurillo_rodriguez8382Încă nu există evaluări

- (AD - DIESEL) - (21-01-2020) : Parts ListDocument17 pagini(AD - DIESEL) - (21-01-2020) : Parts ListVyacheslav ShatalovÎncă nu există evaluări

- 2005 PDFDocument5 pagini2005 PDFMihai-Eugen PopaÎncă nu există evaluări

- DATODocument1 paginăDATOMiguel RojasÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- 9412Document3 pagini9412Mihai-Eugen Popa100% (1)

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration DataMiguel RojasÎncă nu există evaluări

- Test SheetDocument3 paginiTest SheetNemo NeoÎncă nu există evaluări

- Plano de Teste DB 2435-5686 John Deere 5425Document4 paginiPlano de Teste DB 2435-5686 John Deere 5425GiovaniBalzani100% (1)

- 3233F390Document2 pagini3233F390Zeeshan AhmadÎncă nu există evaluări

- 606 9291Document2 pagini606 9291Сергей ВладимировичÎncă nu există evaluări

- Injection Pump Test Specifications 093000-677#Document3 paginiInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- STANADYNEDocument4 paginiSTANADYNECHRISTIAN LOZANOÎncă nu există evaluări

- Bosch Nozzle Injectors Cross References PDF List PDFDocument11 paginiBosch Nozzle Injectors Cross References PDF List PDFGustampa TampaÎncă nu există evaluări

- 7540Document10 pagini7540pruebaÎncă nu există evaluări

- PT Fuel System Parts ListDocument31 paginiPT Fuel System Parts Listfinanceiro engetemanÎncă nu există evaluări

- 3031 PDFDocument4 pagini3031 PDFMihai-Eugen Popa100% (1)

- F 002 A0z 755 Spare PartsDocument17 paginiF 002 A0z 755 Spare PartsGowtham100% (1)

- 606 9460Document2 pagini606 9460Alex PakitoÎncă nu există evaluări

- EE4760Document2 paginiEE4760OFFICE DANACÎncă nu există evaluări

- Fuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Document2 paginiFuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Ravikant Saini100% (1)

- PRD Spec 2 5Document6 paginiPRD Spec 2 5Cesar Orlando Laura AlipazÎncă nu există evaluări

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 paginiTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorJam B100% (3)

- 0 460 413 028Document2 pagini0 460 413 028Yunus RazviÎncă nu există evaluări

- Inj - P Ump Cal Ibration DataDocument3 paginiInj - P Ump Cal Ibration DataСергей ВладимировичÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument6 paginiDpico: Inj. Pump Calibration DataGiovaniBalzaniÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument4 paginiDpico: Inj. Pump Calibration DataGiovaniBalzaniÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©Mr CupuÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- 9320A090H ParçalarDocument10 pagini9320A090H ParçalarBaytolgaÎncă nu există evaluări

- Despiece Bomba dp210 9320A452HDocument10 paginiDespiece Bomba dp210 9320A452HKevin TtitoÎncă nu există evaluări

- Pump Test Specifications: InjectionDocument3 paginiPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- Test PlanDocument4 paginiTest PlanOFFICE DANACÎncă nu există evaluări

- Bar TablosuDocument34 paginiBar TablosuMükremin Songür100% (2)

- Dpico: Inj. Pump Calibration DataDocument3 paginiDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- 9161Document5 pagini9161BaytolgaÎncă nu există evaluări

- Two-Spring Nozzle Holder Calibration Data: For IsuzuDocument61 paginiTwo-Spring Nozzle Holder Calibration Data: For IsuzuLuis MirandaÎncă nu există evaluări

- 2 SP NHDocument63 pagini2 SP NHJhonny VasquezÎncă nu există evaluări

- Temp 753Document2 paginiTemp 753Neelakandan Krishnan100% (1)

- Test SpecificationsDocument2 paginiTest SpecificationsBest Auto Tech100% (1)

- S-Type S-Type S-Type S-Type S-Nozzle S-Nozzle S-Nozzle S-NozzleDocument11 paginiS-Type S-Type S-Type S-Type S-Nozzle S-Nozzle S-Nozzle S-NozzleTommy Campos100% (1)

- Injection Pump Test Specifications 196000-517#Document4 paginiInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Data Kalibrasi Injection Pump Forklift MitsubishiDocument3 paginiData Kalibrasi Injection Pump Forklift Mitsubishinarama100% (1)

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 paginiInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungÎncă nu există evaluări

- 7030Document3 pagini7030pruebaÎncă nu există evaluări

- db4429 5514Document4 paginidb4429 5514WillianPachecoÎncă nu există evaluări

- 9323A271G Catalog DATADocument4 pagini9323A271G Catalog DATALIONN SOFTWARESÎncă nu există evaluări

- 9320A275K Parçalar PDFDocument10 pagini9320A275K Parçalar PDFBaytolgaÎncă nu există evaluări

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 paginăInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaÎncă nu există evaluări

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 paginiInjection Pump Test Specifications 093000-573#: ApproxBaytolgaÎncă nu există evaluări

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 paginăInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaÎncă nu există evaluări

- tp04 Fuel Pump Test Data in LineDocument1 paginătp04 Fuel Pump Test Data in LineBaytolgaÎncă nu există evaluări

- 104740-1022 W IsuzuDocument4 pagini104740-1022 W IsuzuBaytolgaÎncă nu există evaluări

- 780 7540 Doowon PDFDocument10 pagini780 7540 Doowon PDFAndy Anderson Limachi PeraltaÎncă nu există evaluări

- Brand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1Document44 paginiBrand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1BaytolgaÎncă nu există evaluări

- DP200 Pompa 9320a214g-1Document3 paginiDP200 Pompa 9320a214g-1BaytolgaÎncă nu există evaluări

- Direct Evolution EnhancementDocument2 paginiDirect Evolution EnhancementBaytolgaÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©BaytolgaÎncă nu există evaluări

- 104740-6142 9 460 620 023 Opel-Isuzu Test PlanDocument5 pagini104740-6142 9 460 620 023 Opel-Isuzu Test PlanBaytolgaÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©BaytolgaÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©BaytolgaÎncă nu există evaluări

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 paginiS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaÎncă nu există evaluări

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 paginiTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolgaÎncă nu există evaluări

- Test Plan: 9320A210: Pump SpecificationDocument7 paginiTest Plan: 9320A210: Pump SpecificationBaytolgaÎncă nu există evaluări

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 paginăS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaÎncă nu există evaluări

- 104745-7770 - NissanDocument3 pagini104745-7770 - NissanBaytolgaÎncă nu există evaluări

- DP200 Pompa 9320a214g-1Document3 paginiDP200 Pompa 9320a214g-1BaytolgaÎncă nu există evaluări

- 780 7540 Doowon PDFDocument10 pagini780 7540 Doowon PDFAndy Anderson Limachi PeraltaÎncă nu există evaluări

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pagini096000-4860 Toyata Hilux-4 Runner PDFBaytolgaÎncă nu există evaluări

- 104740-0976 - Ford RangerDocument6 pagini104740-0976 - Ford RangerBaytolgaÎncă nu există evaluări

- 104745-7770 - NissanDocument3 pagini104745-7770 - NissanBaytolgaÎncă nu există evaluări

- 101401-7321 - Isuzu Şampi̇yonDocument4 pagini101401-7321 - Isuzu Şampi̇yonBaytolgaÎncă nu există evaluări

- 104748-0230 - Mazda - Kia Ceres 2200 AyniDocument2 pagini104748-0230 - Mazda - Kia Ceres 2200 AyniBaytolga100% (1)

- 9161Document5 pagini9161BaytolgaÎncă nu există evaluări

- Olp Lesson PlanDocument2 paginiOlp Lesson Planapi-654865620Încă nu există evaluări

- Pset 2Document13 paginiPset 2rishiko aquinoÎncă nu există evaluări

- Lecture 7Document68 paginiLecture 7Gay TonyÎncă nu există evaluări

- Historic Trial of Ali Brothers and Shankaracharya-1921Document276 paginiHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- ABM 221-Examples (ALL UNITS)Document10 paginiABM 221-Examples (ALL UNITS)Bonface NsapatoÎncă nu există evaluări

- 31504647-Antenna System (On Tower) Installation Standard ModelDocument27 pagini31504647-Antenna System (On Tower) Installation Standard ModelBadr AmerÎncă nu există evaluări

- A Person On A Position of Air Traffic ControllerDocument7 paginiA Person On A Position of Air Traffic ControllerMUHAMMAD RAMZANÎncă nu există evaluări

- Tuan Nor Akmal Imanina Binti Tuan MasorDocument2 paginiTuan Nor Akmal Imanina Binti Tuan MasorIzza RosliÎncă nu există evaluări

- Selling AIESEC To Your TargetsDocument7 paginiSelling AIESEC To Your TargetspijoowiseÎncă nu există evaluări

- Jerehy's ReportDocument65 paginiJerehy's Reportkupetroleum3Încă nu există evaluări

- TM GUIDE (Basic Competencies)Document19 paginiTM GUIDE (Basic Competencies)Emelito T. ColentumÎncă nu există evaluări

- Progress Test-The 7-Th GradeDocument2 paginiProgress Test-The 7-Th GradebabystelutaÎncă nu există evaluări

- Ifrs 15Document24 paginiIfrs 15Madhu Sudan DarjeeÎncă nu există evaluări

- Impact of Technology On Our LivesDocument3 paginiImpact of Technology On Our LivesKim ErandioÎncă nu există evaluări

- Exercise Chapter 4 This Is How You Do ItDocument10 paginiExercise Chapter 4 This Is How You Do ItAgustina WidiyantiÎncă nu există evaluări

- Register A Custom Table in Apps SchemaDocument5 paginiRegister A Custom Table in Apps SchemaIapps ErpSolutionsÎncă nu există evaluări

- Unit 8 Atomic Fluorescence Spectrometry PDFDocument23 paginiUnit 8 Atomic Fluorescence Spectrometry PDFCh AswadÎncă nu există evaluări

- Frogs and ToadsDocument6 paginiFrogs and ToadsFaris AlarshaniÎncă nu există evaluări

- 11 My Immigration Story - Tan Le QuestionsDocument3 pagini11 My Immigration Story - Tan Le QuestionsMallika Nand NairÎncă nu există evaluări

- The Role of Leadership On Employee Performance in Singapore AirlinesDocument42 paginiThe Role of Leadership On Employee Performance in Singapore Airlineskeshav sabooÎncă nu există evaluări

- Cel2106 SCL Worksheet 6Document3 paginiCel2106 SCL Worksheet 6HarryJoy JackÎncă nu există evaluări

- Position Trading Maximizing Probability of Winning TradesDocument91 paginiPosition Trading Maximizing Probability of Winning Tradescarlo bakaakoÎncă nu există evaluări

- Sheiko 13week Beginner ProgramDocument16 paginiSheiko 13week Beginner ProgramAnders DahlÎncă nu există evaluări

- Term Paper Gender RolesDocument5 paginiTerm Paper Gender Rolesea8d1b6n100% (1)

- Handout No. 03 - Purchase TransactionsDocument4 paginiHandout No. 03 - Purchase TransactionsApril SasamÎncă nu există evaluări

- Listening 3b Skills Test 1aDocument3 paginiListening 3b Skills Test 1aPticaSelicaÎncă nu există evaluări

- Newsite KPI Check. - Ver2Document4.183 paginiNewsite KPI Check. - Ver2nasircugaxÎncă nu există evaluări

- The Mystery of Putins DissertationDocument16 paginiThe Mystery of Putins DissertationDoinaCebanuÎncă nu există evaluări

- Comparative Analysis of State Bank of India With Other Credit SchemesDocument97 paginiComparative Analysis of State Bank of India With Other Credit SchemesVKM2013Încă nu există evaluări

- Assessment 3 Comparative Analysis Primary Vs Secondary SourcesDocument5 paginiAssessment 3 Comparative Analysis Primary Vs Secondary SourcesMATOZA, YLJOE V.Încă nu există evaluări