Documente Academic

Documente Profesional

Documente Cultură

Belman Wafer Check Lug Velan

Încărcat de

Aditya B. RyantoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Belman Wafer Check Lug Velan

Încărcat de

Aditya B. RyantoDrepturi de autor:

Formate disponibile

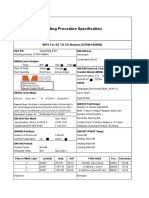

INSPECTION CERTIFICATE

EN 10204-3.1B

CERT#: B5848

CUSTOMER : CV. ANUGERAH P.O.#: 05731 Rev: 1 Q’TY: 10 Pcs DATE: Jan.25.2016

VELAN FIG.# 002T ITEM# NA DESCRIPTION 4“ 150# LUG DUAL PLATE CHECK VALVE

DESIGN AND TEST STANDARD :

B16.34 API-594 API-598 API-603 OTHERS :

API-598 TESTING REQUIREMENTS FOR STEEL VALVES (GATE-GLOBE-CHECK-BALL) VEL-NDT-571

TYPE OF TEST SHELL SEAT L.P. AIR ON SEAT H.P. WATER SEAT

100% (ALL) 100% (GA&GL) 100% GA ( SIDE A&B ) 100 % (GL.&S.C.)

PSI 450 315 NA 315

TIME (sec.) 60 60 NA 60

RESULTS OK OK NA OK

Velan certified that all valve(s) described above are in compliance with purchase order and specification

requirements. This test report represents the actual attributes of the valves furnished and the test rusults are in

full complience with applicable specification and purchase order requirements

VALVE COMPONENTS - TEST REPORT (EN 10204-2.2)

VALVE ITEMS SPECIFICATION VALVE ITEMS SPECIFICATION

BODY ASTM A 216 WCB SPRING 316 STAINLESS STEEL

STEM ASTM A182 F304 PLUG NUT ASTM. A194 L7

WEDGE/DISC ASTM A182 F304 RING PTFE

SEAT BUNA-N PACKING BUNA-N

Velan certified that items are in full compliance with the listed material specification and all purchase order

requirements.

* DIMENSIONAL EXAMINATION : ACC. * MARKING (MSS-SP-25) : ACC. * VISUL (MSS-SP-55) : ACC

FOUNDRY MILL CERTIFICATES TO EN 10204 - 3.1B (ENCLOSED)

* BODY NO SERIAL NO

052151 630861

052151 630862

052151 630863

052151 630833

PY

IED T RUE CO

CERTIF

...

..............

CUSTOMER’S INSPECTOR ..........................

...... GERAH OZZIE RODRIGUES

CV. ANU Q.C. DOCUMENTATION MANAGER

FORM VK-QC-B03 RE. A

MATERIAL TEST RESULTS

INSPECTION CERTIFICATE

CUSTOMBER : CV ANUGERAH VELAN ITEM Q,TY FIGURE NUMBER DWG.

VELN REF. : SINGAPORE

DATE : Nov.25,2015 CERT NO. C5848 NA 10 Pcs PK12-002T-1D-B -

CUST. P.O # 05731 Rev.1

DESCRIP 4” 150# DUAL CHECK VALVES RF. TYPE LUG

:

YIELD & TENSILE = Mpa

SUPPLIER ASTM CHEMICAL COMPOSITION MECHANICAL PROPERTIES

MATERIAL MATERIAL REMARKS

HEAD CODE SPECIFICATION C Mn P S Si Ni Cr Mo Cu V YIELD TENSILEELONG % RA. % HARD.

ASTM A216-93 0.19 0.89 0.020 0.024 0.52 0.06 0.09 0.05 0.03 0.003 300.0 561.6 35.0 51.2 142 BODY 10

GR.WCB 0.20 0.82 0.011 0.012 0.44 0.06 0.03 0.04 0.02 0.002 321.5 532.8 31.2 46.7 146 BODY 10

0.19 0.83 0.012 0.010 0.43 0.05 0.03 0.04 0.03 0.002 319.8 520.7 30.3 46.9 145 BODY 10

052151 0.19 0.82 0.011 0.0.15 0.43 0.03 0.06 0.04 0.03 0.002 316.7 543.6 31.1 48.2 148 BODY 10

CERTIFIED TRUE COPY

0.19 0.89 0.007 0.012 0.44 0.05 0.07 0.03 0.03 0.002 297.8 556.1 32.4 46.8 148 BODY 10

.................................................

0.19 0.83 0.011 0.015 0.42 0.06 0.07 0.08 0.02 0.003 301.5 552.1 32.0 45.9 146 BODY 10

0.18 0.84 0.017 0.015 0.44 0.06 0.07 0.04 0.03 0.003 301.9 553.1 32.0 45.9 142 BODY 10

CV ANUGERAH

0.19 0.89 0.011 0.015 0.42 0.06 0.07 0.05 0.03 0.002 302.0 523.8 31.9 45.7 144 BODY 10

0.20 0.89 0.012 0.016 0.43 0.05 0.06 0.04 0.03 0.003 302.0 551.1 32,0 45.6 148 BODY 10

0.20 0.87 0.012 0.016 0.44 0.06 0.07 0.05 0.03 0.003 301.9 512.2 32.7 45.8 142 BODY 10

HEAT TREATMENT MATERIAL WCB HEAT AT 1700 ‘F HOLD 3 HRS COOL: AIR WE HEREBY CERTIFY THAT THE ABOVE STATEMENTS

NORMALIZIED AND VALUES SPECIFIED ARE TRUE, CORRECT AND CO-

NFORM TO APPLICABLE ORDER SPECIFICATIONS AND

HYDRO TEST API-598 RESULTS ACCEPTABLE REQUIREMENTS AS CONTAINED IN THE RECORDS OF

VELAN

INSPECTION VALVE DESIGN TO API-594

DIMENSIONAL AND/OR VISUAL ACCEPTABLE OZZIE RODRIGUES

Q.C. DOCUMENTATION MANAGER

S-ar putea să vă placă și

- Kaeser Compressor Sigma Control ManualDocument154 paginiKaeser Compressor Sigma Control Manualsancsa_7483% (12)

- WN RF Flanges SCH 40 CL 150 19Document1 paginăWN RF Flanges SCH 40 CL 150 19Mohamed RaafatÎncă nu există evaluări

- MTR's PO# 2113-06-12 PDFDocument14 paginiMTR's PO# 2113-06-12 PDFAgustinaDeWinneÎncă nu există evaluări

- Certificate of Conformity 2016 PDFDocument2 paginiCertificate of Conformity 2016 PDFRaul AviñaÎncă nu există evaluări

- Setco PDFDocument3 paginiSetco PDFPrafullachandra ParikhÎncă nu există evaluări

- API Welding Procedure Specification PDFDocument3 paginiAPI Welding Procedure Specification PDFBob LeeÎncă nu există evaluări

- PO28184-3-3156WA-10 (SWING CHECK VALVE 3in CLASS 150 316SS)Document3 paginiPO28184-3-3156WA-10 (SWING CHECK VALVE 3in CLASS 150 316SS)Francis Alberto Espinosa PerezÎncă nu există evaluări

- Certificate of Compliance: - Quality & Logistics ManagerDocument3 paginiCertificate of Compliance: - Quality & Logistics ManagersitaÎncă nu există evaluări

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 paginăLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCÎncă nu există evaluări

- Cert of ConformityDocument1 paginăCert of ConformityBharatbhushanÎncă nu există evaluări

- Erection and Painting of Steel StructureDocument11 paginiErection and Painting of Steel StructureomarcadÎncă nu există evaluări

- TSR016 Ball ValvesDocument18 paginiTSR016 Ball Valvesbmanojkumar16Încă nu există evaluări

- Material Test Report: ISO EN 10204 2004-3.1Document4 paginiMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SÎncă nu există evaluări

- Mill Test Certificate: Zibo Camel Material Co., LTDDocument1 paginăMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisÎncă nu există evaluări

- Kia Sorento 2015 Service ManualDocument20 paginiKia Sorento 2015 Service ManualMaria100% (56)

- Assure Solutions: Hydro Test ReportDocument1 paginăAssure Solutions: Hydro Test ReportKailas NimbalkarÎncă nu există evaluări

- The Klinger Group: Mill Test CertificateDocument1 paginăThe Klinger Group: Mill Test Certificatepayman fakhri100% (3)

- Welding Specification ChartDocument189 paginiWelding Specification ChartVivek SatapathyÎncă nu există evaluări

- Material Test Certificate - HOSESnDocument1 paginăMaterial Test Certificate - HOSESnJohn MaÎncă nu există evaluări

- Ball Valve MTCDocument1 paginăBall Valve MTCAdnanAtifÎncă nu există evaluări

- Inspection Test Plan Fuel Gas Conditioning SkidDocument19 paginiInspection Test Plan Fuel Gas Conditioning SkidDin AizuÎncă nu există evaluări

- Wps PQR Spec IndexDocument1 paginăWps PQR Spec IndexTridib DeyÎncă nu există evaluări

- Mfjo694 MRB 0001 IndexDocument2 paginiMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Acsr Din en 50182 PDFDocument1 paginăAcsr Din en 50182 PDFAdim CoMed ProÎncă nu există evaluări

- Fault Displays in The ZIDDocument20 paginiFault Displays in The ZIDAnthony50% (2)

- Pipe Fitting Weight ChartDocument1 paginăPipe Fitting Weight Chartab5918590Încă nu există evaluări

- MTC For SCN-574 PDFDocument154 paginiMTC For SCN-574 PDFthomasÎncă nu există evaluări

- Oriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesDocument18 paginiOriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesTejas ShahÎncă nu există evaluări

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 paginiPt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairÎncă nu există evaluări

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 paginăMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatÎncă nu există evaluări

- 11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolDocument1 pagină11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolLeomarini100% (1)

- P1064 00 M05 116 R1 Mechanical SupplyDocument8 paginiP1064 00 M05 116 R1 Mechanical SupplyNarayana MugalurÎncă nu există evaluări

- Certificado de Valvulas K18H010 Mill Test Certificate PDFDocument3 paginiCertificado de Valvulas K18H010 Mill Test Certificate PDFdsoto_108536Încă nu există evaluări

- Astm C 31-2021Document7 paginiAstm C 31-2021Mohammed Ali100% (3)

- Ferrite Content ReportDocument2 paginiFerrite Content ReportJawad MunirÎncă nu există evaluări

- DATABASE Kawasan Industri PolugadungDocument20 paginiDATABASE Kawasan Industri PolugadungRina Rachman100% (1)

- 750V DC Traction SystemDocument26 pagini750V DC Traction SystemShashi Bhusan Singh100% (2)

- Material EquivalentsDocument25 paginiMaterial EquivalentsAditya B. Ryanto100% (6)

- Material EquivalentsDocument25 paginiMaterial EquivalentsAditya B. Ryanto100% (6)

- Ball Valve Passport 10x8 2500#Document43 paginiBall Valve Passport 10x8 2500#Alejandro RojasÎncă nu există evaluări

- Neway Gate 6 X 150 RFDocument6 paginiNeway Gate 6 X 150 RFcomercial 3Încă nu există evaluări

- Certified Mill Test Report: S O L D T O S H I P T ODocument1 paginăCertified Mill Test Report: S O L D T O S H I P T OMohamed RaafatÎncă nu există evaluări

- PTR-4068 Thermal Cycle Test of Stainless Steel Swagelok FKB Series Medium-Pressure Ball Valves 20ksiDocument3 paginiPTR-4068 Thermal Cycle Test of Stainless Steel Swagelok FKB Series Medium-Pressure Ball Valves 20ksiCricri CriÎncă nu există evaluări

- Tube S2 HFS MTCDocument1 paginăTube S2 HFS MTCunnamed90Încă nu există evaluări

- OMR pipe fittings certificate analysisDocument1 paginăOMR pipe fittings certificate analysisslimane AIT-IDIRÎncă nu există evaluări

- Quality Certificated 123Document1 paginăQuality Certificated 123Zaid Raslan Ayoub100% (1)

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 paginăWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- Electrode Brand Name and Class MirfaDocument13 paginiElectrode Brand Name and Class MirfaAnonymous rYZyQQot55Încă nu există evaluări

- QAP ASSURANCE PLAN ALFA LAVAL PRESSURE REDUCING STATIONDocument1 paginăQAP ASSURANCE PLAN ALFA LAVAL PRESSURE REDUCING STATIONajmainÎncă nu există evaluări

- MSDS SwakDocument4 paginiMSDS Swaktolkien9Încă nu există evaluări

- Made in Italy - EuropeDocument8 paginiMade in Italy - EuropeenenickÎncă nu există evaluări

- SATR-W-2019 Rev 7 (05-NOVT-16 To 10-NOV-16) - 019Document2 paginiSATR-W-2019 Rev 7 (05-NOVT-16 To 10-NOV-16) - 019asiqÎncă nu există evaluări

- ARCC Hydrotest Packages Summary ReportDocument4 paginiARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqÎncă nu există evaluări

- Reservior Skid Assl Qap AlfaDocument1 paginăReservior Skid Assl Qap AlfaajmainÎncă nu există evaluări

- Mill Test RecordDocument3 paginiMill Test RecordAnonymous bXmSNRÎncă nu există evaluări

- Master list of WPS and PQR documentsDocument6 paginiMaster list of WPS and PQR documentschandraÎncă nu există evaluări

- Form UT, MT, PT, RTDocument5 paginiForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Tubing Data ChartsDocument30 paginiTubing Data ChartsIvo NunesÎncă nu există evaluări

- Valve Material Test ReportDocument7 paginiValve Material Test ReportJimyTeránAgudeloÎncă nu există evaluări

- Tool Fab - WorkshopDocument347 paginiTool Fab - Workshophrdsby100% (1)

- WPS for SS to CS WeldingDocument1 paginăWPS for SS to CS WeldingLipika GayenÎncă nu există evaluări

- Lithika - 001Document1 paginăLithika - 001Harkesh RajputÎncă nu există evaluări

- Test certificate for pressure control valveDocument1 paginăTest certificate for pressure control valvesubrata dashÎncă nu există evaluări

- Welder Qualification Register 01Document3 paginiWelder Qualification Register 01Andrei UrsacheÎncă nu există evaluări

- Ayari Maher: Qualified Welder I.D.CardDocument10 paginiAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukÎncă nu există evaluări

- FRA20-034-3 - Filttro YDocument1 paginăFRA20-034-3 - Filttro YHuber Pucuhuayla RojasÎncă nu există evaluări

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018De la EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018Încă nu există evaluări

- Wiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsDe la EverandWiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsÎncă nu există evaluări

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsDe la EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsÎncă nu există evaluări

- Codification of Statements on Standards for Attestation Engagements, January 2018De la EverandCodification of Statements on Standards for Attestation Engagements, January 2018Încă nu există evaluări

- General Service Solenoid Valves: ConstructionDocument3 paginiGeneral Service Solenoid Valves: ConstructionAditya B. RyantoÎncă nu există evaluări

- Introduction To The Incoterms 2010Document3 paginiIntroduction To The Incoterms 2010Dani RebahuÎncă nu există evaluări

- DatasheetDocument3 paginiDatasheetAditya B. RyantoÎncă nu există evaluări

- Manual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Document20 paginiManual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Aditya B. RyantoÎncă nu există evaluări

- Gate Valve CataogueDocument4 paginiGate Valve CataogueAditya B. RyantoÎncă nu există evaluări

- Ico3s Iom ManualDocument2 paginiIco3s Iom ManualAditya B. RyantoÎncă nu există evaluări

- Select Actuator Damper RetrofitDocument2 paginiSelect Actuator Damper RetrofitAditya B. RyantoÎncă nu există evaluări

- Kwik-Clamp Sizing Chart for Sanitary FerrulesDocument1 paginăKwik-Clamp Sizing Chart for Sanitary FerrulesAditya B. RyantoÎncă nu există evaluări

- B16-34 Clarifications 2009Document77 paginiB16-34 Clarifications 2009RobertReinboldÎncă nu există evaluări

- Route SheetDocument8 paginiRoute Sheetmuhammad zulfikarÎncă nu există evaluări

- Manifolds and Connectors For Fluidic ApplicationsDocument16 paginiManifolds and Connectors For Fluidic ApplicationsNéstor Valles VillarrealÎncă nu există evaluări

- Warriorfeed 404Document70 paginiWarriorfeed 404JUANÎncă nu există evaluări

- Biostone C20 Safety Data SheetDocument10 paginiBiostone C20 Safety Data Sheetchoton_iiiÎncă nu există evaluări

- Culasi Phase 1 (BOX CULVERT) - Recover-ModelDocument1 paginăCulasi Phase 1 (BOX CULVERT) - Recover-ModelEmman De los ReyesÎncă nu există evaluări

- Operating and Maintenance InstructionsDocument8 paginiOperating and Maintenance InstructionsRaja TouseefÎncă nu există evaluări

- AASHTO M 320-10 Performance Graded Asphalt BinderDocument7 paginiAASHTO M 320-10 Performance Graded Asphalt BinderplavingalneemaÎncă nu există evaluări

- VIBRATORY ROLLER OPERATOR'S MANUALDocument43 paginiVIBRATORY ROLLER OPERATOR'S MANUALkadaimamak100% (1)

- 500 Grinders: What I LearnedDocument19 pagini500 Grinders: What I LearnedMbah SajanÎncă nu există evaluări

- Pe Plastics The Facts v7 Tue 19-10-1Document81 paginiPe Plastics The Facts v7 Tue 19-10-1Ajeya SaxenaÎncă nu există evaluări

- Laboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD ProcessDocument8 paginiLaboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD Processpedro aguilarÎncă nu există evaluări

- Balancing Equations Ultimate GuideDocument4 paginiBalancing Equations Ultimate GuideH HiÎncă nu există evaluări

- I S 613 - 2000Document11 paginiI S 613 - 2000Hariprasad gantyalaÎncă nu există evaluări

- Housing & CouplingDocument12 paginiHousing & Couplingmajid fardniaÎncă nu există evaluări

- CSA-Li 2018Document9 paginiCSA-Li 2018Subramanian MoorthyÎncă nu există evaluări

- Smart' Polymers and What They Could Do in Biotechnology and MedicineDocument6 paginiSmart' Polymers and What They Could Do in Biotechnology and MedicineAlexander KritikopoulosÎncă nu există evaluări

- ASTM C192 (Group 7)Document38 paginiASTM C192 (Group 7)Raine Fair Haven AiÎncă nu există evaluări

- Spitzer Dry Bulk Tankers GuideDocument31 paginiSpitzer Dry Bulk Tankers GuidealiÎncă nu există evaluări

- Dutile IronDocument9 paginiDutile IronSaravanan ManiÎncă nu există evaluări

- Efficient Selection of Agitators: Sulzer PumpsDocument2 paginiEfficient Selection of Agitators: Sulzer PumpsjokishÎncă nu există evaluări

- Guide to Understanding Operations ProcessesDocument75 paginiGuide to Understanding Operations ProcessesrajeeevaÎncă nu există evaluări