Documente Academic

Documente Profesional

Documente Cultură

Kinglong Multipurpose Cooperative

Încărcat de

Catherine0 evaluări0% au considerat acest document util (0 voturi)

126 vizualizări8 paginiTitlu original

KINGLONG MULTIPURPOSE COOPERATIVE.docx

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

126 vizualizări8 paginiKinglong Multipurpose Cooperative

Încărcat de

CatherineDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

KINGLONG MULTIPURPOSE COOPERATIVE

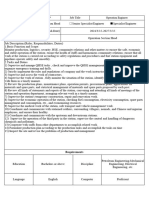

TABLE OF ORGANIZATION AND DESIGNATION FOR TECHNICAL SERVICES SECTION

(A PROPOSAL)

TECHNICAL SERVICES SECTION

Person Responsible: Technical Facilitator/Supervisor

Required- 1

Actual- 0

Responsibilities:

1. Work Schedule supervision

upon receiving the Job order.

2. Responsible for the

supervision of parts.

3. Initiate the Person Responsible

(PR) draft and monitor all

purchase request.

4. Responsible for the

documentation of Job Orders.

5. Monitors the Backlogs.

6. Submit weekly breakdown

report to head.

7. Responsible for Data gathering

and analysis for budgeting and

forecasting.

8. Weekly PMS and Servicing

schedules.

9. Monthly Progress reports.

Qualifications:

1. Preferably a Licensed Engineer

(Mechanical/Electrical).

2. Candidate must possess at least

Bachelor’s/ College Degree in

Engineering (Mechanical or

Electrical);

3. At least 1 Year(s) working

experience in related field;

4. 1-4 Yrs. Experienced employee

specialized in Engineering;

5. Knowledgeable on the process and

role of technical functions;

6. Has above average skill levels as

to communication and negotiation;

7. Can write technical related

reports;

8. Flexible and Output-driven.

MECHANICAL PLANNER PMS SECTION HEAD SHOP SERVICES

Short Term Planner Required-1

Long Term Planner

Required-1 Actual-0

Required-1

Actual-0

Actual-0

Responsibilities:

Responsibilities: 1. Lead the maintenance function

Responsibilities:

1. Schedule upon and implementation on all

1. Follow-Up to

receiving the JO from operational equipment and

purchasing; Light Heavy

End-user; facilities.

2. Update the PR Equipment Equipment

2. Responsible for 2. In charge of training the PMS

monitoring to be

Purchase of parts; staff.

submitted to the

3. Responsible for the 3. Deliver daily reports of

Short term

documentation of J.O; maintenance compliance.

planner;

4. Monitors the

3. Inform short term

backlogs;

planner if ordered

parts are ready for 5. Submit daily Qualifications:

withdrawal; breakdown report to 1. Candidate must possess at least

4. Designs and Planning head. Professional License in

studies/ Engineering (Mechanical).

experiments; 2. At least 2 years of working

5. Data gathering and Qualifications: experience in the related field.

analysis for 1. Candidate must 3. Preferably specialized in

budgeting and possess at least Maintenance/ Repair.

forecasting. Professional

6. Schedules the License (Passed

weekly PMs and Board/Professional

Servicing. Exam);

2. Knowledgeable in

Qualifications: Data analysis and

1. Candidate must Predictive

possess at least approach

Professional engineering;

License (Passed 3. At least 2 years of

Board/Professional working

Exam); experience in the

2. Knowledgeable in related field.

Data analysis and

Predictive

approach

engineering;

3. At least 2 years of

working

experience in the

related field.

Cost clerk Chief Mechanic

Required-1 Required-1

Actual-0 Actual-1

Expeditor/History Clerk Mechanics (Lubemen and Tire men)

Required-1 Required-5

Actual-0 Actual-2

Electrician

Required-2

Actual-1

Welder

Required-2

Actual-1

Table 1. Technical Services Section Designations of Workforce

Figure 1. Job Order Request Flow chart

QUARRY PERSON RESPONSIBLE

DAILY LOG SHEET TECHNICAL

(PR)

FACILITATOR/SUPERVISOR

END (The record will be forwarded

NON-QUARRY USER to the department manager)

SHORT TERM PLANNER

Figure 2. Equipment Log Flow Chart

HOUSEKEEPING If no issue arises.

OPERATOR’S OPERATIONS

(The operator is CHECKLIST

responsible for the

keepsake and order of (Refer to the list of If issue arises.

his unit) JOB ORDER REQUEST

Figure 3. Operator’s Daily Preventive Routine

Once the repair is

finished the

technicians and the

supervisor will fill up

documents attached in

The supervisor the J.O. folder, as

together with his If there are parts follows;

When all jobs are

men and the short needed to repair

identified, the Repair or

term planner will the equipment, the

supervisor will Maintenance

check the machine 1 2 short-term 3

assign technicians checklist.

for additional planner, and

to do the jobs as Release paper

repair works and supervisor will do

specified. J.O. info. form

list down all jobs a part survey.

to be performed.

4

After all the documents are filled up, the

supervisor will put the documents in the J.O.

folder and submit it to the Short term

planner for final release of equipment.

5

Figure 4. Work flow of Process of Technical Service Section

WORK

PLAN WORK SCHEDULE WORK

IDENTIFICATION

ANALYSIS RECORD HISTORY EXECUTE WORK

(FOR IMPROVEMENT)

Figure 5. Basic Maintenance Management Process

S-ar putea să vă placă și

- Iso RISK AND OPPORTUNITY ASSESSMENT RECORDDocument5 paginiIso RISK AND OPPORTUNITY ASSESSMENT RECORDMuhammad Awais89% (19)

- HOWO A7 The Operation and Maintenance Manual PDFDocument160 paginiHOWO A7 The Operation and Maintenance Manual PDFCatherine86% (7)

- Gas Laws Simulation LabDocument3 paginiGas Laws Simulation Labbob100% (1)

- Cs2 Larkin MotelDocument4 paginiCs2 Larkin Motelteha_zaiÎncă nu există evaluări

- Job Description - Infra PMDocument7 paginiJob Description - Infra PMApreil AnyawÎncă nu există evaluări

- GES-RO - Design Engineer (Eng-E3) - EN + BatchDocument4 paginiGES-RO - Design Engineer (Eng-E3) - EN + BatchGabiBaciuÎncă nu există evaluări

- Job Vacancy Hydrology DesignerDocument2 paginiJob Vacancy Hydrology DesignerFirnoÎncă nu există evaluări

- Process Manual: PurposeDocument5 paginiProcess Manual: PurposeamarÎncă nu există evaluări

- NIGER ProjectDocument32 paginiNIGER ProjectAli JafferyÎncă nu există evaluări

- Job Description Senior Engineer - Maintenance - ReliabilityDocument6 paginiJob Description Senior Engineer - Maintenance - ReliabilityO'mbuba TheMechanicÎncă nu există evaluări

- Alejandro L. Taid .: Manuel L. Quezon University, ManilaDocument6 paginiAlejandro L. Taid .: Manuel L. Quezon University, ManilaSky Alejandro TaidÎncă nu există evaluări

- Communications Management Plan TemplateDocument9 paginiCommunications Management Plan TemplateBea GarciaÎncă nu există evaluări

- S0773 - Senior Team Manager - Central EngineeringDocument4 paginiS0773 - Senior Team Manager - Central EngineeringMubasher AbbasÎncă nu există evaluări

- Engineering Management Plan and Organise Engineering Resources For Projects and ProposalsDocument12 paginiEngineering Management Plan and Organise Engineering Resources For Projects and ProposalsirfanÎncă nu există evaluări

- Performance Improvement Plan (PAP)Document4 paginiPerformance Improvement Plan (PAP)Ali Hydar OthmanÎncă nu există evaluări

- JD Qatar Long Term BasisDocument38 paginiJD Qatar Long Term BasisMuhamad SyamsudinÎncă nu există evaluări

- JD Electrical and Instrumentation EngineerDocument5 paginiJD Electrical and Instrumentation EngineerNamiJen LobatoÎncă nu există evaluări

- Job Description For QAQC EngineerDocument2 paginiJob Description For QAQC EngineerSafriza ZaidiÎncă nu există evaluări

- JD - Asset Integrity EngineerDocument2 paginiJD - Asset Integrity Engineerwhah11100% (1)

- JD Lead Asset Integrity Engineer - R02 - WoDocument3 paginiJD Lead Asset Integrity Engineer - R02 - WoInalegwu23Încă nu există evaluări

- UTeM SPORT CENTRE MANAGEMENT SYSTEM PROPOSALDocument11 paginiUTeM SPORT CENTRE MANAGEMENT SYSTEM PROPOSALimanmiaÎncă nu există evaluări

- PPM !a.drawioDocument1 paginăPPM !a.drawioPravin ManogaranÎncă nu există evaluări

- Sales Support Department SupervisorDocument3 paginiSales Support Department SupervisorMay-an FernandezÎncă nu există evaluări

- Technician JDDocument3 paginiTechnician JDMulgi YonÎncă nu există evaluări

- Leadership AssignmentDocument13 paginiLeadership AssignmenthiranmayiÎncă nu există evaluări

- RFP - Oracle Advanced Collection: SLT MobitelDocument12 paginiRFP - Oracle Advanced Collection: SLT MobitelscsrajÎncă nu există evaluări

- IPM Reviewer L123 PDFDocument10 paginiIPM Reviewer L123 PDFJulie Faith Aquimba BulanÎncă nu există evaluări

- Job Description Rigger Co-OrdinatorDocument10 paginiJob Description Rigger Co-OrdinatordlgrantÎncă nu există evaluări

- JD OE Utility Operation and MaintenanceDocument3 paginiJD OE Utility Operation and MaintenanceSaurabh MishraÎncă nu există evaluări

- Mobilization Plan Kafd-2Document15 paginiMobilization Plan Kafd-2azozinlcÎncă nu există evaluări

- Restructuring Project Sample Docs For P2 - PractDocument33 paginiRestructuring Project Sample Docs For P2 - PractManjunath BantwalÎncă nu există evaluări

- Job Description: Designation: Shift Engineer Function: Engineering-Central Engineering ServicesDocument2 paginiJob Description: Designation: Shift Engineer Function: Engineering-Central Engineering ServicesManoj DhageÎncă nu există evaluări

- PMP Comprehensive NotesDocument29 paginiPMP Comprehensive NotesMohammed AhmedÎncă nu există evaluări

- Lesson 7 - Maintenance ManagementDocument28 paginiLesson 7 - Maintenance ManagementJacques OsmeñaÎncă nu există evaluări

- PnP1 - Job OrderDocument4 paginiPnP1 - Job OrderKenneth Bryan VillagonezaÎncă nu există evaluări

- Inspection Engineer 1691669896Document3 paginiInspection Engineer 1691669896ArhamÎncă nu există evaluări

- PMP 2019 - AllDocument23 paginiPMP 2019 - AllKhanh Dinh DuyÎncă nu există evaluări

- T3.M4.L3.S6.Project Closure ReportDocument12 paginiT3.M4.L3.S6.Project Closure Reportchérif hadamineÎncă nu există evaluări

- JobDescription EstatesTechnicianDocument7 paginiJobDescription EstatesTechnicianMuhammad Dian Luthfy LubisÎncă nu există evaluări

- PPM !a.drawioDocument1 paginăPPM !a.drawioPravin ManogaranÎncă nu există evaluări

- PMP Comprehensive NotesDocument27 paginiPMP Comprehensive NotesAhmed Awed100% (1)

- QP - Supervisor StructureDocument72 paginiQP - Supervisor StructureAnnamneedi PrasadÎncă nu există evaluări

- OB Escription Job Title: Purpose of The PositionDocument3 paginiOB Escription Job Title: Purpose of The PositionyagolainÎncă nu există evaluări

- Job PlanningDocument11 paginiJob PlanningYasserÎncă nu există evaluări

- Advt Inhouse WebsiteDocument8 paginiAdvt Inhouse WebsiteAdhara MukherjeeÎncă nu există evaluări

- Grade A SSE PrioritiesDocument2 paginiGrade A SSE PrioritiesronakjoharytÎncă nu există evaluări

- Tender Program Peer Review (TPPR) : Project No & Project NameDocument9 paginiTender Program Peer Review (TPPR) : Project No & Project NamemukhleshÎncă nu există evaluări

- AWR - Format 2Document13 paginiAWR - Format 2mohanÎncă nu există evaluări

- RFP - Level 3 NVQ in Mechanical TechnicianDocument12 paginiRFP - Level 3 NVQ in Mechanical TechnicianMahmoudÎncă nu există evaluări

- Adminstrative ClosureDocument1 paginăAdminstrative Closureadel hajebÎncă nu există evaluări

- T2 VSA With RequirementDocument8 paginiT2 VSA With RequirementSandeep K Malhotra100% (3)

- E-Grocery Wbs DictionaryDocument3 paginiE-Grocery Wbs DictionaryTaha AmourÎncă nu există evaluări

- Job Specification - Technical ManagerDocument3 paginiJob Specification - Technical ManagerMian ZainÎncă nu există evaluări

- Universidad Autónoma de Nuevo León Facultad de Ingeniería Mecánica y EléctricaDocument6 paginiUniversidad Autónoma de Nuevo León Facultad de Ingeniería Mecánica y EléctricaFrancisco NiñoÎncă nu există evaluări

- Lesson 1 - The Field of Engineering ManagementDocument3 paginiLesson 1 - The Field of Engineering ManagementJ BÎncă nu există evaluări

- Software Engineering 2 43424 2715Document2 paginiSoftware Engineering 2 43424 2715Saif AhmadzaiÎncă nu există evaluări

- JD Offshore PlannerDocument4 paginiJD Offshore PlannerTreasure321Încă nu există evaluări

- Module 7 - Progress Measurement - 1 Content OverviewDocument8 paginiModule 7 - Progress Measurement - 1 Content OverviewPatrick MugaÎncă nu există evaluări

- Eppi-Jd-03-10 Foundry Tech. Cen. StaffDocument19 paginiEppi-Jd-03-10 Foundry Tech. Cen. StaffEunice Fetalver (EPPI)Încă nu există evaluări

- $valueDocument2 pagini$valuePrabhav PatelÎncă nu există evaluări

- Business Requirements Ver 1.02Document21 paginiBusiness Requirements Ver 1.02Рудик ГалстянÎncă nu există evaluări

- Kpa) (10,000 K) K) (673 /KG M Kpa (0.4615Document4 paginiKpa) (10,000 K) K) (673 /KG M Kpa (0.4615CatherineÎncă nu există evaluări

- Memorandum: Kinglong Employees Multipurpose Cooperative Km.4, Brgy. Luna, Surigao CityDocument1 paginăMemorandum: Kinglong Employees Multipurpose Cooperative Km.4, Brgy. Luna, Surigao CityCatherineÎncă nu există evaluări

- SAG - Scaffolding Works (Supported Type) NC IIDocument2 paginiSAG - Scaffolding Works (Supported Type) NC IICatherineÎncă nu există evaluări

- Thermodynamic Property TableDocument34 paginiThermodynamic Property TableCatherineÎncă nu există evaluări

- Chapter 2 PDFDocument20 paginiChapter 2 PDFCatherineÎncă nu există evaluări

- June 13-19, 2021: Sunday Absent Holiday Leave No DutyDocument4 paginiJune 13-19, 2021: Sunday Absent Holiday Leave No DutyCatherineÎncă nu există evaluări

- Amendment Surigao AlphaDocument2 paginiAmendment Surigao AlphaCatherineÎncă nu există evaluări

- QTY Unit Particulars: Alpha Stone CrusherDocument2 paginiQTY Unit Particulars: Alpha Stone CrusherCatherineÎncă nu există evaluări

- Antisol S® PDFDocument2 paginiAntisol S® PDFCatherineÎncă nu există evaluări

- 2nd ReportDocument1 pagină2nd ReportCatherineÎncă nu există evaluări

- Preliminary ReportDocument6 paginiPreliminary ReportCatherineÎncă nu există evaluări

- Sunday Absent Holiday Leave: Under ObservationDocument1 paginăSunday Absent Holiday Leave: Under ObservationCatherineÎncă nu există evaluări

- Organization and Designation For Technical Services Department (TSD)Document3 paginiOrganization and Designation For Technical Services Department (TSD)CatherineÎncă nu există evaluări

- Alpha Crushing Plant Production ProjectionDocument3 paginiAlpha Crushing Plant Production ProjectionCatherineÎncă nu există evaluări

- Fabrication and Thermal Conductivity Testing of Coir FiberDocument72 paginiFabrication and Thermal Conductivity Testing of Coir FiberCatherineÎncă nu există evaluări

- CalculationsDocument8 paginiCalculationsCatherineÎncă nu există evaluări

- 177 GlimmerDocument2 pagini177 GlimmerCatherineÎncă nu există evaluări

- Kinglong Employees Multipurpose Cooperative: Daily Operations List (Dol)Document2 paginiKinglong Employees Multipurpose Cooperative: Daily Operations List (Dol)CatherineÎncă nu există evaluări

- 7 Years by Lukas GrahamDocument1 pagină7 Years by Lukas GrahamCatherineÎncă nu există evaluări

- Fabrication of MetalsDocument7 paginiFabrication of MetalsCatherineÎncă nu există evaluări

- Travel OrderDocument1 paginăTravel OrderCatherineÎncă nu există evaluări

- Waste Water Flows and Characteristics: Presented By: Nikka Gem A. LumanaoDocument24 paginiWaste Water Flows and Characteristics: Presented By: Nikka Gem A. LumanaoCatherineÎncă nu există evaluări

- Improving The Citizen Experience: How The Anti-Red Tape Act Is Shaping Public Service Delivery in The PhilippinesDocument12 paginiImproving The Citizen Experience: How The Anti-Red Tape Act Is Shaping Public Service Delivery in The PhilippinesMary Jane Araza CastilloÎncă nu există evaluări

- NSSF ActDocument38 paginiNSSF Actokwii2839Încă nu există evaluări

- Warehouse Receipt Law ReviewerDocument6 paginiWarehouse Receipt Law ReviewerElaine Villafuerte Achay100% (6)

- Office of The City Prosecutor: Counter - AffidavitDocument6 paginiOffice of The City Prosecutor: Counter - AffidavitApril Elenor JucoÎncă nu există evaluări

- Chapter 2 Quiz - Business LawDocument3 paginiChapter 2 Quiz - Business LawRayonneÎncă nu există evaluări

- Application FormsDocument3 paginiApplication FormsSyed Mujtaba Ali BukhariÎncă nu există evaluări

- Famous Slogan PDFDocument16 paginiFamous Slogan PDFtarinisethy970Încă nu există evaluări

- Manu Social Order and LawsDocument13 paginiManu Social Order and LawsAmit KumarÎncă nu există evaluări

- Acts Punishable: Elements of Illegal Sale (ID)Document5 paginiActs Punishable: Elements of Illegal Sale (ID)Jenny wicasÎncă nu există evaluări

- Solvency PPTDocument1 paginăSolvency PPTRITU SINHA MBA 2019-21 (Kolkata)Încă nu există evaluări

- Scope of Inspection For Ammonia TankDocument3 paginiScope of Inspection For Ammonia TankHamid MansouriÎncă nu există evaluări

- Heirs of William Sevilla vs. Sevilla G.R. No. 150179 April 30, 2003Document40 paginiHeirs of William Sevilla vs. Sevilla G.R. No. 150179 April 30, 2003misseixihÎncă nu există evaluări

- Dokumenti/ Këshilli I Europës Tregon Pse U Refuzuan Kandidatët e Qeverisë Shqiptare Për Gjyqtar Në StrasburgDocument4 paginiDokumenti/ Këshilli I Europës Tregon Pse U Refuzuan Kandidatët e Qeverisë Shqiptare Për Gjyqtar Në StrasburgAnonymous pPe9isQYcSÎncă nu există evaluări

- PrpaDocument80 paginiPrpaRaymund Pabalan0% (1)

- Processes To Compel AppearanceDocument34 paginiProcesses To Compel AppearanceNayem Miazi100% (2)

- Eacsb PDFDocument297 paginiEacsb PDFTai ThomasÎncă nu există evaluări

- People V Oloverio - CrimDocument3 paginiPeople V Oloverio - CrimNiajhan PalattaoÎncă nu există evaluări

- In The High Court of Calcutta: I.P. Mukerji and Md. Nizamuddin, JJDocument4 paginiIn The High Court of Calcutta: I.P. Mukerji and Md. Nizamuddin, JJsid tiwariÎncă nu există evaluări

- 5000 English Frequency WordsDocument234 pagini5000 English Frequency WordsAlice Turnbull100% (1)

- AP Euro Chapter 13 Outline Notes TemplateDocument8 paginiAP Euro Chapter 13 Outline Notes TemplateEstdur Keem100% (1)

- 10 FixedAsset 21 FixedAsset InitSettingsDocument32 pagini10 FixedAsset 21 FixedAsset InitSettingsCrazy TechÎncă nu există evaluări

- AND9201/D The Effect of Pan Material in An Induction Cooker: Application NoteDocument9 paginiAND9201/D The Effect of Pan Material in An Induction Cooker: Application NoteRajesh RoyÎncă nu există evaluări

- Student Result - Aakash BYJU'sDocument4 paginiStudent Result - Aakash BYJU'sManvi GoyalÎncă nu există evaluări

- 2020 Omnibus AffidavitDocument1 pagină2020 Omnibus AffidavitJAKE FRANCIS LUMBRESÎncă nu există evaluări

- 20 Rules of Closing A Deal PDFDocument21 pagini20 Rules of Closing A Deal PDFbioarquitectura100% (9)

- Aetna V WolfDocument2 paginiAetna V WolfJakob EmersonÎncă nu există evaluări

- Gentlemen of The JungleDocument2 paginiGentlemen of The JungleClydelle Garbino PorrasÎncă nu există evaluări

- OSHAD-SF - TG - Managament of Contractors v3.0 EnglishDocument18 paginiOSHAD-SF - TG - Managament of Contractors v3.0 EnglishGirish GopalakrishnanÎncă nu există evaluări