Documente Academic

Documente Profesional

Documente Cultură

4597-AAB-SC-09 R0v1 31

Încărcat de

danieldumapitDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

4597-AAB-SC-09 R0v1 31

Încărcat de

danieldumapitDrepturi de autor:

Formate disponibile

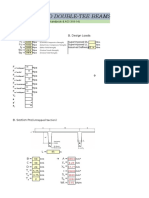

One Za'abeel | 4597-AAB-SC-09

4-3 Typical End Mullion Bracket.xmct

Section Page 8 of 17

Design and Engineering Dept.

______________________________________________________________________________________________________________________________

⌂ This subsec on verifies the shear failure of bolt material in transverse loading.

≡

Design Parameters / Analysis

tpa := 25.00⋅ mm

nf := 2

nsp := 1

Direct Shear Forces

( )

Fysf_d := F2 ÷ nf⋅ nsp = 0.20⋅ kN

Fzsf_d := F3 ÷ ( nf⋅ nsp) = 0.00⋅ kN

Shear Force Due to Moment

T

af := ( 0.00 0.00 ) ⋅ mm

T

bf := ( 75.00 − 75.00 ) ⋅ mm

+ bf = 11250.00⋅ mm

af

2 2 2

Jf :=

i := 1 ← Number of the Most Stressed Fastener

r fa := af = 0.00⋅ mm r fb := bf = 75.00 mm ← Coordinates of the Most Stressed Fastener

i i

M f_tb := M1 = 0.03⋅ kN⋅ m ← Torsion / Bending Moment at the Fastener Group Centroid

( )

Fysf_tb := M f_tb ⋅ r fa ÷ Jf⋅ nsp = 0.00⋅ kN ← Shear Force along Y Axis Due to Torsion / Bending Moment

Ac ng on the Most Stressed Fastener

( )

Fzsf_tb := M f_tb ⋅ r fb ÷ Jf⋅ nsp = 0.20⋅ kN ← Shear Force along Z Axis Due to Torsion / Bending Moment

Ac ng on the Most Stressed Fastener

← Design Shear Force on the Most Stressed Fastener

F sf := ( Fysf_d + Fysf_tb) 2 + ( Fzsf_d + Fzsf_tb) 2 = 0.28⋅ kN

Material Proper es BS EN ISO 3506 / BS EN 20898

Fastener

Size Grade / Alloy Group

ϕ := d⋅ mm = 16.00 mm Yb := y ⋅ MPa = 450.00⋅ MPa

2 2

As := as⋅ mm = 156.67⋅ mm Ub := u⋅ MPa = 700.00⋅ MPa

Connected Material

Grade

ρ ys := ρ ⋅ MPa = 275.00⋅ MPa

Ys := y ⋅ MPa = 275.00⋅ MPa

Us := u⋅ MPa = 430.00⋅ MPa

Code Based Checking BS 5950 Sec on 6.3.2

ρ s := 0.40⋅ Ub = 280.00⋅ MPa ← Limi ng Stress of Fastener

Ρsf := iftpa >

ϕ

, ρ s⋅ As

9⋅ ϕ , ρ ⋅ As ← Design Shear Resistance of Fastener Material

s = 31.12⋅ kN

3 8⋅ ϕ + 3⋅ tpa

Design Criteria : F sf ≤ Ρsf Code Check : Safe! ; Utilization Ratio = 0.91%

▄▄▄

31 of 72

TempVer20.0_012018 | Engineer: D. Dumapit | Checked: S.M. Lomboy Jr.

S-ar putea să vă placă și

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDe la EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 33Document1 pagină4597-AAB-SC-09 R0v1 33danieldumapitÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 28Document1 pagină4597-AAB-SC-09 R0v1 28danieldumapitÎncă nu există evaluări

- Bolt AnalysisDocument1 paginăBolt AnalysisNajibullah AziziÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 39Document1 pagină4597-AAB-SC-09 R0v1 39danieldumapitÎncă nu există evaluări

- Ii. Analysis and Design Verifica On: A) Connec On On Typical MullionDocument1 paginăIi. Analysis and Design Verifica On: A) Connec On On Typical MulliondanieldumapitÎncă nu există evaluări

- Mathcad - Tul Pondasi Tapak p1100x100Document4 paginiMathcad - Tul Pondasi Tapak p1100x100andre novanÎncă nu există evaluări

- Beam Design RusselDocument155 paginiBeam Design RusselRonald CostalesÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 34Document1 pagină4597-AAB-SC-09 R0v1 34danieldumapitÎncă nu există evaluări

- Mathcad - Cracked Rect Section Deflection Analysis of Continuous BeamDocument6 paginiMathcad - Cracked Rect Section Deflection Analysis of Continuous BeamSteven Raynaldo HÎncă nu există evaluări

- Design of Singly Reinforced Concrete BeamDocument4 paginiDesign of Singly Reinforced Concrete BeamAnton_Young_1962Încă nu există evaluări

- Base Plate TopDocument7 paginiBase Plate TopUpendra WalinjkarÎncă nu există evaluări

- Design RCC Beam Using Flexure PDFDocument8 paginiDesign RCC Beam Using Flexure PDFBaharulHussainÎncă nu există evaluări

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 paginiTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitÎncă nu există evaluări

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 paginiTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitÎncă nu există evaluări

- YolooooooooDocument1 paginăYolooooooooGaiusChrisA.EvaÎncă nu există evaluări

- RCD Formulas DomingoDocument3 paginiRCD Formulas DomingoSteve Baria100% (1)

- Glass Check 550mm X 1550mmDocument7 paginiGlass Check 550mm X 1550mmAniket InarkarÎncă nu există evaluări

- Design of Singly Reinforced Concrete Beam PDFDocument3 paginiDesign of Singly Reinforced Concrete Beam PDFAnton_Young_1962Încă nu există evaluări

- Design of Coping Beam (Portal) : A. Basic DataDocument7 paginiDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaÎncă nu există evaluări

- Design of One-Way SlabDocument4 paginiDesign of One-Way SlabAnton_Young_1962Încă nu există evaluări

- Practical Lesson 4Document11 paginiPractical Lesson 4marjory.dezÎncă nu există evaluări

- Mathcad - B1X 5.5 MDocument12 paginiMathcad - B1X 5.5 Mandre novanÎncă nu există evaluări

- Aisc360 Box Steel DesignDocument3 paginiAisc360 Box Steel DesignHattori HanzoÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 30Document1 pagină4597-AAB-SC-09 R0v1 30danieldumapitÎncă nu există evaluări

- Design ProcedureDocument62 paginiDesign ProcedureMarvsÎncă nu există evaluări

- 4597-AAB-SC-09 R0v1 38Document1 pagină4597-AAB-SC-09 R0v1 38danieldumapitÎncă nu există evaluări

- Stair DesignDocument2 paginiStair DesignAngelika Caguioa BiayÎncă nu există evaluări

- Hinge Connection Design: A Reference CodeDocument3 paginiHinge Connection Design: A Reference CodeGaurav BhabadÎncă nu există evaluări

- Ese-2016: Test Series: Subjectwise Test No. 10 (Conventional)Document11 paginiEse-2016: Test Series: Subjectwise Test No. 10 (Conventional)CgpscAspirantÎncă nu există evaluări

- 厐ջ儸ջ써 - Tul Wing Wall Abt RappDocument9 pagini厐ջ儸ջ써 - Tul Wing Wall Abt Rappandre novanÎncă nu există evaluări

- Block ShearDocument6 paginiBlock ShearVermuch CasioÎncă nu există evaluări

- Mathcad 13 Column Design PDFDocument34 paginiMathcad 13 Column Design PDFEvilsÎncă nu există evaluări

- Balok Kolom Braced UnDocument3 paginiBalok Kolom Braced UnIkbal ImanudinÎncă nu există evaluări

- Column Base PlateDocument10 paginiColumn Base PlateVon San JoseÎncă nu există evaluări

- E.3.1 Cheap Removal Process - Cutting ForceDocument34 paginiE.3.1 Cheap Removal Process - Cutting ForceMesfin SisayÎncă nu există evaluări

- Report BoltDocument1 paginăReport BoltMong is not hereÎncă nu există evaluări

- Steel Beam Design: 3Rd Floor - Frame C & D - 1 ReactionsDocument11 paginiSteel Beam Design: 3Rd Floor - Frame C & D - 1 ReactionsAllan Añavisa Ostique Jr.Încă nu există evaluări

- Notes Design Process PDFDocument11 paginiNotes Design Process PDFDak KaizÎncă nu există evaluări

- Wind Load: The University of ManilaDocument20 paginiWind Load: The University of ManilaJaztine SantiagoÎncă nu există evaluări

- Square and Rectangular HSS and Box-Shaped Members: Material Proper TiesDocument2 paginiSquare and Rectangular HSS and Box-Shaped Members: Material Proper Tiesengineer.mmÎncă nu există evaluări

- Design of T BeamDocument5 paginiDesign of T BeamAnton_Young_1962Încă nu există evaluări

- Example: Cracked Prestressed Cross-Section: Rak.43-3110 Halkeillut Poikkileikkaus 1Document39 paginiExample: Cracked Prestressed Cross-Section: Rak.43-3110 Halkeillut Poikkileikkaus 1renandÎncă nu există evaluări

- 厐ջ儸ջ써 - Tulpoer Pier-rappDocument9 pagini厐ջ儸ջ써 - Tulpoer Pier-rappandre novanÎncă nu există evaluări

- Design of Beam TRB-1B, TRCB-1: 31 Pearl Street Doña Juana Subdivision, Rosario, Pasig CityDocument3 paginiDesign of Beam TRB-1B, TRCB-1: 31 Pearl Street Doña Juana Subdivision, Rosario, Pasig CityKhenneth ChiaÎncă nu există evaluări

- Connector Check PDFDocument2 paginiConnector Check PDFUpendra WalinjkarÎncă nu există evaluări

- Cantilever Beam Design - I BeamDocument1 paginăCantilever Beam Design - I Beamberylqz5878Încă nu există evaluări

- Elliptical ShellDocument3 paginiElliptical Shellyogaraj sÎncă nu există evaluări

- Prestressed Double Tee Beams (Version 1)Document7 paginiPrestressed Double Tee Beams (Version 1)benjaminÎncă nu există evaluări

- Combined Loading of Rods 1 - Uniaxial Stress StateDocument17 paginiCombined Loading of Rods 1 - Uniaxial Stress StatePeet89Încă nu există evaluări

- 05 - Flex BDocument23 pagini05 - Flex BNathan MolongwanaÎncă nu există evaluări

- Perhitungan Final Sekali Baja NUR FAJRIAHDocument54 paginiPerhitungan Final Sekali Baja NUR FAJRIAHNur FajriahÎncă nu există evaluări

- Ma - TUL WING WALL ABT RENGATDocument9 paginiMa - TUL WING WALL ABT RENGATandreÎncă nu există evaluări

- Base Design (Blocks) - Commented On 26.09.2017Document4 paginiBase Design (Blocks) - Commented On 26.09.2017tsinghal_19Încă nu există evaluări

- Columns DesignDocument60 paginiColumns DesignifsrebraÎncă nu există evaluări

- Ridge Connection Design RSP-1.Document121 paginiRidge Connection Design RSP-1.Asaru DeenÎncă nu există evaluări

- Mathcad - PAUTA CONTROL PDFDocument4 paginiMathcad - PAUTA CONTROL PDFjavier apablazaÎncă nu există evaluări

- Mathcad - Bolted Joint Design and Analysis PDFDocument34 paginiMathcad - Bolted Joint Design and Analysis PDFJorge Aliaga DominguezÎncă nu există evaluări

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 paginiE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Calculation Sheet Connection New Column To ExistingDocument4 paginiCalculation Sheet Connection New Column To ExistingDamar BudiÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 40Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 40danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 18Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 18danieldumapitÎncă nu există evaluări

- Par Al Plan View of Structure: Ii. Structural SystemDocument1 paginăPar Al Plan View of Structure: Ii. Structural SystemdanieldumapitÎncă nu există evaluări

- C.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthDocument1 paginăC.4 Torsional Strength, Chapter H: Nominal Axial Strength, Sec On E7 Nominal Axial StrengthdanieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 44Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 44danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 35Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 35danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 41Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 41danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 31Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 31danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 61Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 61danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 42Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 42danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 39Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 39danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 43Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 43danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 17Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 17danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 34Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 34danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 36Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 36danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 38Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 38danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 32Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 32danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 60Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 60danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 37Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 37danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 30Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 30danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 55Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 55danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 66Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 66danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 65Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 65danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 56Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 56danieldumapitÎncă nu există evaluări

- 8 Installation Data: Profis Anchor 2.8.8Document1 pagină8 Installation Data: Profis Anchor 2.8.8danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 63Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 63danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 64Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 64danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 62Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 62danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 80Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 80danieldumapitÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 57Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 57danieldumapitÎncă nu există evaluări

- KTTC2 Thành Đ TDocument68 paginiKTTC2 Thành Đ TKhoa PhanÎncă nu există evaluări

- AADE-11-NTCE-21 Lost Circulation Control and Wellbore Strengthening: Looking Beyond Particle Size DistributionDocument10 paginiAADE-11-NTCE-21 Lost Circulation Control and Wellbore Strengthening: Looking Beyond Particle Size DistributionWaleed Barakat MariaÎncă nu există evaluări

- Anchoring PDFDocument2 paginiAnchoring PDFengineer63Încă nu există evaluări

- Mix Design For Concrete Grade M 25Document7 paginiMix Design For Concrete Grade M 25fevahe756Încă nu există evaluări

- (765001-) S-Series Combines S650, S660, S670, S680, S690 PDFDocument2 pagini(765001-) S-Series Combines S650, S660, S670, S680, S690 PDFRafael DelaiÎncă nu există evaluări

- Manual de Usuario de Calentador EléctricoDocument12 paginiManual de Usuario de Calentador Eléctricohxzg7d7w8dÎncă nu există evaluări

- J//CF / - $ Cy R Cjti: " ' (Vkvjl-1. - Yrsi'Ji'F 4Document1 paginăJ//CF / - $ Cy R Cjti: " ' (Vkvjl-1. - Yrsi'Ji'F 4Paulo GomesÎncă nu există evaluări

- Peikko GroundDocument16 paginiPeikko GroundQWE2342ER3F5C54V5V45Încă nu există evaluări

- Water Balance and Water BudgetDocument17 paginiWater Balance and Water BudgetCt Kamariah Md SaatÎncă nu există evaluări

- Advanced Geotechnical Engineering PDFDocument4 paginiAdvanced Geotechnical Engineering PDFAnil MarsaniÎncă nu există evaluări

- 291 en Concrete Shear Wall v01Document11 pagini291 en Concrete Shear Wall v01ismal sirajÎncă nu există evaluări

- Notas de Aula de Geotécnica - Prof Reno Reine Castello (1998)Document144 paginiNotas de Aula de Geotécnica - Prof Reno Reine Castello (1998)João Victor DiasÎncă nu există evaluări

- 콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Document108 pagini콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Jin-hwan KimÎncă nu există evaluări

- Models For Punching Shear Capacity in Concrete SlabsDocument166 paginiModels For Punching Shear Capacity in Concrete SlabsZoran BonicÎncă nu există evaluări

- 3 Angularly Deflected Double Bell Coupling Joint: New Product ofDocument2 pagini3 Angularly Deflected Double Bell Coupling Joint: New Product ofJose Leo MissionÎncă nu există evaluări

- CH 5 Cross DrinageDocument40 paginiCH 5 Cross DrinageAbuye HDÎncă nu există evaluări

- Materials Science and Engineering A: Relationship Between Fatigue Limit and Vickers Hardness in SteelsDocument6 paginiMaterials Science and Engineering A: Relationship Between Fatigue Limit and Vickers Hardness in Steelsesmaeel ghafariÎncă nu există evaluări

- Assignment OneDocument2 paginiAssignment OneARÎncă nu există evaluări

- Well FoundationDocument56 paginiWell FoundationSriram Nandipati67% (3)

- Rate Analysis SI-PR - DNIT FinalDocument87 paginiRate Analysis SI-PR - DNIT FinalShashikant VermaÎncă nu există evaluări

- Slab/Mat Panels StaticDocument13 paginiSlab/Mat Panels StaticDavid JohnÎncă nu există evaluări

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Fluid Mechanics FM Pattern 2019Document2 paginiBe - Mechanical Engineering - Semester 4 - 2023 - February - Fluid Mechanics FM Pattern 2019loharjay772Încă nu există evaluări

- Assignment 2 Solution 2019Document7 paginiAssignment 2 Solution 2019Mohit JaiswalÎncă nu există evaluări

- Composite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞDocument32 paginiComposite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞŞebnem Gül İlarslanÎncă nu există evaluări

- A Seminar Topic Report On Stability of High-Rise Building Bachelor of Technology IN Civil EngineeringDocument7 paginiA Seminar Topic Report On Stability of High-Rise Building Bachelor of Technology IN Civil Engineeringmrcopy xeroxÎncă nu există evaluări

- Trial Mix Design Report PDFDocument38 paginiTrial Mix Design Report PDFTimothy HughesÎncă nu există evaluări

- Civil Engineering: Year ofDocument4 paginiCivil Engineering: Year ofdipinnediyaparambathÎncă nu există evaluări

- JICA Assisted Guwahati Water Supply Project (ID P-201)Document33 paginiJICA Assisted Guwahati Water Supply Project (ID P-201)Alakesh PhukanÎncă nu există evaluări

- Bridge ReportDocument53 paginiBridge ReportJean Kian86% (7)

- Standard Terminology Relating To Fatigue and Fracture TestingDocument25 paginiStandard Terminology Relating To Fatigue and Fracture TestingMAURO MORESCOÎncă nu există evaluări