Documente Academic

Documente Profesional

Documente Cultură

1A-Acrolon 890

Încărcat de

Stuart PhamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1A-Acrolon 890

Încărcat de

Stuart PhamDrepturi de autor:

Formate disponibile

Protective ACROLON 890

& ACRYLIC POLYURETHANE

Marine

Coatings

PARt A B65-C SeRieS

PARt B B65VC0001

Revised: 08/12

Product descriPtion recommended uses

ACROLON 890, is a two-component, polyester modified aliphatic Use over prepared metal or masonry substrates in industrial

acrylic polyurethane coating. It’s designed for use in industrial environments such as:

environments. Acrolon 890 has good gloss retention,

durability and chemical resistance.

• Steel structures finish coating

• Good gloss and color retention • Exteriors of containers or tanks

• Good Application

• Fast dry • Bridges or conveyers

• Good chemical and abrasion resistance • Offshore platforms

• A kinds of heavy duty maintenance enamel for use in high visibility • Marine applications

areas

• Acceptable for use in high performance architectural

Product characteristics applications

Finish: High Gloss, Semi- Gloss aPPlication conditions

Colors: Wide range of colors available Temperature: 4.4°C minimum, 43°C maximum

(air, surface and material)

Volume solids: 68%±2%

Mixing ratio: Part A:Part B = 10 :1 (by Volume) At least 3°C above dew point

Relative humidity: 85% maximum

VOC: 290 g/L

surface PreParation

Recommended Spreading Rate per coat:

Minimum Maximum Surface must be clean, dry, and in sound condition. Remove all

Wet microns 75 150 oil, dust, grease, dirt, loose rust, and other foreign material to

ensure adequate adhesion.

Dry microns 50 100

Theoretical Coverage 13.6m2/L@50 microns dft Minimum recommended surface preparation:

NOTE: Brush or roll application may require multiple coats to * Iron & Steel: SSPC-SP6/ NACE 3/ Sa 2

achieve maximum film thickness and uniformity of appearance. (ISO 8501-1:2007), 25-50 microns profile

Drying Schedule @ 90 microns wet * Galvanizing: SSPC-SP1

-5°C 5°C 10°C 25°C 35°C

50% RH

* Concrete/Masonry: SSPC-SP13 / NACE 6

To touch: 12hours 5hours 3hours 1 hours 40 mins

Primer required

To handle: 24hours 12hours 10hours 4 hours 2 hours

To recoat with polyurethane enamel: Surface Preparation Standards

minimum: - 12hours 10hours 4 hours 2 hours Condition of

Surface

ISO 8501-1

BS7079:A1

Swedish Std.

SIS055900 SSPC NACE

To cure: 16days 12days 11days 7 days 5 days White Metal Sa 3 Sa 3 SP 5 1

Near White Metal Sa 2.5 Sa 2.5 SP 10 2

If maximum recoat time is exceeded, abrade surface before recoating. Commercial Blast Sa 2 Sa 2 SP 6 3

Brush-Off Blast Sa 1 Sa 1 SP 7 4

Drying time is temperature, humidity, and film thickness dependent. Hand Tool Rusted C St 2 C St 2 SP 2 -

Cleaning Pitted & Rusted D St 2 D St 2 SP 2 -

Pot Life: 3 hours 2.5 hours 2.5 hours 2 hours 1.5hours Power Tool Rusted C St 3 C St 3 SP 3 -

Cleaning Pitted & Rusted D St 3 D St 3 SP 3 -

Sweat-in-Time: Not recommended

36 months, unopened,containers

Shelf Life: at 25°C

Part A 12 months, unopened,containers

Part B

at 25°C

Flash Point: 28°C, Closed Cup, mixed

Reducer/Clean Up: R8KP1

www.sherwin.com.cn continued on back

Protective ACROLON 890

& E

Marine

Coatings

PARt A B65-C SeRieS

PARt B B65VC0001

on

aPPlication equiPment ordering information

Package:

The following is a guide. Changes in pressures and tip sizes Part A : 18.2 Litres in 20L pail

may be needed for proper spray characteristics. Always Part B : 1.8 Litres in 4L pail

purge spray equipment before use with listed reducer. Any For more package detail, please contact local Sherwin-

reduction must be compliant with existing VOC regulations Williams Customer Service Center.

and compatible with the existing environmental and

application conditions. tinting

Reducer/Clean Up: Tint Part A with colorants to achieve wide range of colors at 100%

Reducer ...................... R8KP1 tint strength.

Use of any other solvent than xylene or R08KP0001may

affect the performance or compliance of this product for its safety Precautions

intended service Refer to the MSDS sheet before use.

Published technical data and instructions are subject to change without notice. Contact

Airless Spray your Sherwin-Williams representative for additional technical data and instructions.

Pump............................ 45:1 minimum

Pressure ...................... 15 Mpa minimum disclaimer

Hose ............................ 9.5mm ID The information and recommendations set forth in this Product Data Sheet are

Tip ................................ 0.013" - 0.017"(0.33-0.43mm) based upon tests conducted by or on behalf of The Sherwin-Williams Company.

Filter ............................. none Such information and recommendations set forth herein are subject to change and

pertain to the product offered at the time of publication. Consult your Sherwin-

Reduction ..................... as needed up to 10% by volume Williams representative to obtain the most recent Product Data Information and

Application Bulletin.

Conventional Spray

Gun ............................... Binks 95 Warranty

Fluid Nozzle .................. 66 The Sherwin-Williams Company warrants our products to be free of manufacturing

Air Nozzle ...................... 68 PB defects in accord with applicable Sherwin-Williams quality control procedures.

Liability for products proven defective, if any, is limited to replacement of the

Atomization Pressure .... 0.5 Mpa defective product or the refund of the purchase price paid for the defective product

Fluid Pressure ............... 0.2 Mpa as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED,

Reduction ...................... as needed up to 10% by volume STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING

Keep pressure pot at level of applicator to avoid blocking MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

of fluid line due to weight of material. Blow back coating

in fluid line at intermittent shutdowns, but continue agitation

at pressure pot.

Brush

Brush ............................ Nylon/Polyester Natural Bristle

Reduction ..................... as needed up to 10% by volume

Roller

Brush ............................ 3/8"-1/2" woven with phenolic core

Reduction ..................... as needed up to 10% by volume

If specific application equipment is not listed above,

equivalent equipment may be substituted.

www.sherwin.com.cn

S-ar putea să vă placă și

- 2 Principles of Roof Truss DesignDocument10 pagini2 Principles of Roof Truss Designabhi aroteÎncă nu există evaluări

- Long Range Acoustic DeviceDocument2 paginiLong Range Acoustic Devicebingwazzup100% (2)

- Signals & Systems (Solved Problems)Document7 paginiSignals & Systems (Solved Problems)Lohith CoreelÎncă nu există evaluări

- Isolation and Purification of AlkaloidsDocument14 paginiIsolation and Purification of AlkaloidsLuděk SpurnýÎncă nu există evaluări

- Modeling and Optimization of An Auto-Thermal Ammonia Synthesis Reactor Using The Gravitational Search AlgorithmDocument8 paginiModeling and Optimization of An Auto-Thermal Ammonia Synthesis Reactor Using The Gravitational Search AlgorithmJen ChavezÎncă nu există evaluări

- Durometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDocument2 paginiDurometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDarwin_Sidney100% (1)

- ST 37Document7 paginiST 37rendra.farisrÎncă nu există evaluări

- ANSYS Stress LinearizationDocument15 paginiANSYS Stress LinearizationTiago CandeiasÎncă nu există evaluări

- Introduction To Vehicle Electronic Systems and Fault DiagnosisDocument20 paginiIntroduction To Vehicle Electronic Systems and Fault Diagnosisyogita patil100% (1)

- Backend Physical Design InterviewDocument10 paginiBackend Physical Design InterviewRohith Raj50% (2)

- Unibar Shopprimer LV: BarilDocument2 paginiUnibar Shopprimer LV: BarilFlori SmăduÎncă nu există evaluări

- Dynamic Balancing MachineDocument4 paginiDynamic Balancing Machine.x100% (1)

- BC 3004 CementDocument1 paginăBC 3004 CementRAJÎncă nu există evaluări

- Web Publish 2361972 1 A 1 Pintura DroDocument12 paginiWeb Publish 2361972 1 A 1 Pintura DroJuan Arturo Hernandez RamosÎncă nu există evaluări

- Final ESCO NB PDFDocument1 paginăFinal ESCO NB PDFRio CahyantoÎncă nu există evaluări

- Cross Cut Adhesion Test Basic Cutter m44Document4 paginiCross Cut Adhesion Test Basic Cutter m44Madidj_2014Încă nu există evaluări

- Pds Fastron Gold 5w-30 API SNDocument2 paginiPds Fastron Gold 5w-30 API SNyusuf_miftahulÎncă nu există evaluări

- Thermo Fisher Scientific XL3 XL2 Hardware OverviewDocument37 paginiThermo Fisher Scientific XL3 XL2 Hardware OverviewMAmar100% (1)

- C Tape Datasheet PDFDocument2 paginiC Tape Datasheet PDFIftikhar Ahmed KhalidÎncă nu există evaluări

- Astm A105Document1 paginăAstm A105Isaac SamuelÎncă nu există evaluări

- Rr212403 Automobile Engineering DrawingDocument4 paginiRr212403 Automobile Engineering DrawingSrinivasa Rao GÎncă nu există evaluări

- Hes B008-03 Hexagon NutsDocument5 paginiHes B008-03 Hexagon NutsPreetam KumarÎncă nu există evaluări

- Asian Paints Apcothane CF 674 PDFDocument1 paginăAsian Paints Apcothane CF 674 PDFANUP KUMAR MITRAÎncă nu există evaluări

- Pts Ip Paint SystemDocument51 paginiPts Ip Paint SystemshiqinmkÎncă nu există evaluări

- TC Epilux 455 HB MIODocument1 paginăTC Epilux 455 HB MIOTarun KaushalÎncă nu există evaluări

- 65-1501 Victor Maquinas VCM200 & Accesorios CorteDocument2 pagini65-1501 Victor Maquinas VCM200 & Accesorios CortecarlosÎncă nu există evaluări

- Spraying Device LD/U3 Arc Spraying: Parts List PL 96939 EN 09Document16 paginiSpraying Device LD/U3 Arc Spraying: Parts List PL 96939 EN 09a.n.87711990100% (1)

- Sigmaprime 700Document7 paginiSigmaprime 700Trịnh Minh KhoaÎncă nu există evaluări

- Product Data: Hempadur Multi-Strength 35530Document2 paginiProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarÎncă nu există evaluări

- Kansai Paint System Guide: Environmental CorrosivelyDocument16 paginiKansai Paint System Guide: Environmental Corrosivelyscribdfreeasus100% (1)

- Niton XL3t GOLDD Env MiningDocument1 paginăNiton XL3t GOLDD Env MiningYandapalli ParasharÎncă nu există evaluări

- Pentens: Description Technical & Physical DataDocument2 paginiPentens: Description Technical & Physical DataArdian YuliantoÎncă nu există evaluări

- Thermal Spray Materials Guide 022006 PDFDocument176 paginiThermal Spray Materials Guide 022006 PDFHemant BhatnagarÎncă nu există evaluări

- 023 147 Ind ReqDocument2 pagini023 147 Ind ReqKishore KumarÎncă nu există evaluări

- PDS Hempel's Thinner 08700 en-GBDocument1 paginăPDS Hempel's Thinner 08700 en-GBvitharvanÎncă nu există evaluări

- Kit 138 New Bresle Salt PDFDocument2 paginiKit 138 New Bresle Salt PDFDian FaraÎncă nu există evaluări

- FlowTek S20Document2 paginiFlowTek S20Gabriel Andrés Barcha AnguloÎncă nu există evaluări

- Asian Paints PuDocument2 paginiAsian Paints PuAkash BadwaikÎncă nu există evaluări

- MAT1020Document8 paginiMAT1020Rodolfo NallisÎncă nu există evaluări

- Dichtol Sealer Broschure ENDocument12 paginiDichtol Sealer Broschure ENgersom100% (1)

- Tig 4300i AC/DC DetailsDocument24 paginiTig 4300i AC/DC DetailsaswanthÎncă nu există evaluări

- Hempel's Silicone Acrylic 56940Document2 paginiHempel's Silicone Acrylic 56940jeya vasanthÎncă nu există evaluări

- Tabla Torqueo de PernosDocument1 paginăTabla Torqueo de PernosErnesto LinaresÎncă nu există evaluări

- Rust-O-Cap FC: Technical DataDocument1 paginăRust-O-Cap FC: Technical DataGunjan GaganÎncă nu există evaluări

- Price List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBDocument4 paginiPrice List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBsandeepsmartÎncă nu există evaluări

- Sa515 GR 70 and Sa516 GR 70 t2776 PDFDocument3 paginiSa515 GR 70 and Sa516 GR 70 t2776 PDFvtbkÎncă nu există evaluări

- ASTM D 714 - 87 r00Document6 paginiASTM D 714 - 87 r00Abi PutraÎncă nu există evaluări

- Setup Guide No 4 Weld Inspection WeldcheckDocument7 paginiSetup Guide No 4 Weld Inspection WeldcheckcarlosÎncă nu există evaluări

- Paint Data Sheet - National Synthetic Enamel Gloss IDocument3 paginiPaint Data Sheet - National Synthetic Enamel Gloss Iaakh0% (1)

- Rigaku Radioflex RF-EGM2 Series Brochure - VISCODocument4 paginiRigaku Radioflex RF-EGM2 Series Brochure - VISCOrhinemineÎncă nu există evaluări

- Comparison List Copper Bronze 2011 1Document7 paginiComparison List Copper Bronze 2011 1NaldoVicenteÎncă nu există evaluări

- PDS Hempadur 45883Document2 paginiPDS Hempadur 45883Fredy Xavier DomínguezÎncă nu există evaluări

- As 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiDocument7 paginiAs 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiThaiminh VoÎncă nu există evaluări

- B833Document5 paginiB833DuongthithuydungÎncă nu există evaluări

- 3500-00 Simathane Gloss (Finish Coat)Document3 pagini3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoÎncă nu există evaluări

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 paginiStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KÎncă nu există evaluări

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocument7 paginiCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248Încă nu există evaluări

- 拋光等級Document1 pagină拋光等級ykc3850% (2)

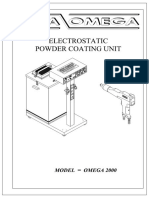

- ESTA-OMEGA 2000 - Electrostatic Powder Coating UnitDocument19 paginiESTA-OMEGA 2000 - Electrostatic Powder Coating UnitRenato AbalosÎncă nu există evaluări

- High Carbon Steel Shot GritDocument2 paginiHigh Carbon Steel Shot Gritabdulaziz mohammedÎncă nu există evaluări

- Jotun MSDSDocument2 paginiJotun MSDSMichael AlbuquerqueÎncă nu există evaluări

- Nox-Rust 311 HMDocument1 paginăNox-Rust 311 HMNavin JoshiÎncă nu există evaluări

- Door Closers Catalogue DormakabaDocument84 paginiDoor Closers Catalogue Dormakabastanislaus krisbangkitÎncă nu există evaluări

- Astm A179 PDFDocument1 paginăAstm A179 PDFgaminÎncă nu există evaluări

- 1A-Acrolon 890Document2 pagini1A-Acrolon 890Stuart PhamÎncă nu există evaluări

- ZBT 10005012573 enDocument5 paginiZBT 10005012573 enCARLOSÎncă nu există evaluări

- Carboguard 635: Selection & Specification DataDocument5 paginiCarboguard 635: Selection & Specification DataPrakashÎncă nu există evaluări

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 paginiProtective & Marine Coatings: Acrolon™ 218 Hshector gomezÎncă nu există evaluări

- Evaluating The Dual Porosity of Landfilled Municipal Solid WasteDocument9 paginiEvaluating The Dual Porosity of Landfilled Municipal Solid WasteMary PinÎncă nu există evaluări

- Instrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHDocument39 paginiInstrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHMika ForwardÎncă nu există evaluări

- Introductory Circuit Theory by Guillemin ErnstDocument580 paginiIntroductory Circuit Theory by Guillemin ErnstJunaid IqbalÎncă nu există evaluări

- Questions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedDocument14 paginiQuestions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedKevin AzizÎncă nu există evaluări

- Mathematics (T) Coursework: Title: Mathematical Investigation (Am - GM)Document1 paginăMathematics (T) Coursework: Title: Mathematical Investigation (Am - GM)Elil MathhyÎncă nu există evaluări

- Fsec CR 1537 05Document613 paginiFsec CR 1537 05Amber StrongÎncă nu există evaluări

- Max31856 PDFDocument30 paginiMax31856 PDFDiego Fernando ArpiÎncă nu există evaluări

- English Download FanProtectionDocument14 paginiEnglish Download FanProtectionSubhankar UncertainityÎncă nu există evaluări

- Phy ATP (5054) Class 10Document57 paginiPhy ATP (5054) Class 10Maryam SiddiqiÎncă nu există evaluări

- College Physics Global 10th Edition Young Solutions ManualDocument25 paginiCollege Physics Global 10th Edition Young Solutions ManualSaraSmithdgyj100% (57)

- A1040 MiraDocument4 paginiA1040 MiramichelditommasoÎncă nu există evaluări

- False-Position Method of Solving A Nonlinear Equation: Exact RootDocument6 paginiFalse-Position Method of Solving A Nonlinear Equation: Exact Rootmacynthia26Încă nu există evaluări

- Higher School Physics Linear Motion Q&ADocument9 paginiHigher School Physics Linear Motion Q&AGkid GkidÎncă nu există evaluări

- Centrifugal Pump Test RigDocument4 paginiCentrifugal Pump Test RigSameer Tamboli100% (1)

- Chapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemDocument15 paginiChapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemAnonymous 5HYsyrddpÎncă nu există evaluări

- 2nd Semester Latest 21Document75 pagini2nd Semester Latest 21Mugars Lupin ArseneÎncă nu există evaluări

- Tests For Gas Permeability of ConcreteDocument6 paginiTests For Gas Permeability of ConcreteAzuriak1Încă nu există evaluări

- SPE Swab Surge Field Validations PDFDocument5 paginiSPE Swab Surge Field Validations PDFAbhayÎncă nu există evaluări

- Lab Session 3Document7 paginiLab Session 3m.sheraz malikÎncă nu există evaluări

- Stiffness Analysis of FramesDocument37 paginiStiffness Analysis of FramesCarolina VacaÎncă nu există evaluări

- Chapter 8 CoordinatesDocument13 paginiChapter 8 CoordinatesWei ZhaoÎncă nu există evaluări

- Mathematical Modelling of Stress-Strain Curves of Masonry MaterialsDocument13 paginiMathematical Modelling of Stress-Strain Curves of Masonry Materialsarif septaÎncă nu există evaluări