Documente Academic

Documente Profesional

Documente Cultură

Pressure Switch Danfoss - DKRCC - PI.CA0.B3.22 - KP - MS PDF

Încărcat de

AbdoEmanuelMalverdiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pressure Switch Danfoss - DKRCC - PI.CA0.B3.22 - KP - MS PDF

Încărcat de

AbdoEmanuelMalverdiDrepturi de autor:

Formate disponibile

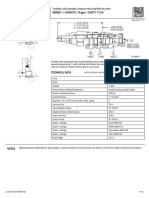

Installation guide

Pressure switch

KP 15, KP 17W, KP 17B, KP 25

060R9747

060R9747

Refrigerants:

R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D,

R448A, R449A, R450A, R452A, R507A, R513A

For complete list of approved refrigerants, go to http://products.danfoss.com/all-products/

KP 15 KP 15, KP 17B KP 15, KP 17W, KP 25

man. (LP) / man. (HP) reset auto. (LP) / man. (HP) reset auto. (LP) / auto (HP) reset

CAUTION:

Do not install these controls on ammonia systems.

Ambient temperatures / Mounting requirements Test pressure (Ptest)

t1 min.: -40 °F (-40 °C)

- 1 3 °F (- 25 °C) (PED approved products)

t1 max.: 149 °F ( 65 °C)

ptest max.

510 psig (35 bar pe)

ptest max.

285 psig (20 bar pe)

CAUTION:

Do not mount the control in a position where dirt,

sediment, or oil will affect the operation of the control.

Enclosure

max 1/8 in

(3 mm)

A: 10 – 32 UNC

Threads (4 holes) B: Enclosure ~NEMA1

CAUTION:

The mounting panel must be plane to avoid damage of control.

© Danfoss | DCS (jmn) | 2016.10 DKRCC.PI.CA0.B3.22 | 520H11520 | 1

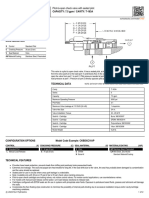

Connections Assembly

CAUTION:

Disconnect power supply before wiring connections are made or service to avoid possible electrical shock or damage

to equipment. Do never touch live parts with your fingers or with any tool.

Wiring

All wiring should conform to the National

Electrical Code and local regulations. Contact load ratings

SPDT 120 V AC 16 FLA, 96 LRA

Controls with low pressure (LP) signal Controls with low pressure (LP) 240 V AC 8 FLA, 48 LRA

and high pressure (HP) signal)

240 V DC 12 W pilot duty

Terminal block Terminal block See label inside cover

Function

CAUTION: CAUTION:

Use terminal screws furnished Use terminal screws furnished

in the contact block. in the contact block.

Use tightening torque 20 lb. in (2.3 Nm). Use tightening torque 20 lb. in (2.3 Nm).

Use copper wire only. Use copper wire only.

Low pressure (LP) side: Low pressure (LP) side: Note!

A-C close on LP rise A-C close on LP rise = Load

A-C open on LP drop A-C open on LP drop

= Signal option

High pressure (HP) side: High pressure (HP) side:

A-C open on HP rise A-C open on HP rise

A-C close on HP drop A-C close on HP drop = Bellows movement

on pressure rise

LP signal option: LP signal option:

A-B close on LP drop A-B close on LP drop

= Bellows movement

HP signal option: on pressure drop

See label for current wiring inside cover. A-D close on HP rise

2 | 520H11520 | DKRCC.PI.CA0.B3.22 © Danfoss | DCS (jmn) | 2016.10

Manual tripping

(Electrical contacts/wiring test)

LP side HP side

Use screw

driver only

Note:

Trip: On controls with LP and/or HP man. reset, push corresponding

use FINGERS ONLY! (Do NOT use screwdriver) LP and/or HP man. reset knob during tripping.

Manual reset

To resume control operation after safety cut-out,

push man. reset knob as indicated.

Note:

LP man. reset is possible only after system pressure

has risen above cut-in value.

HP man. reset is possible only after system pressure

has dropped below cut-out value.

Convertible reset Reset options

Insert a screwdriver into the slot on the lock disc and turn

it to desired reset configuration. Do not turn the screw

on the lock disc as it may damage the convertible reset

mechanism.

LP man. LP auto. LP auto. LP man.

HP man. HP man. HP auto. HP auto.

Note:

Do not select automatic reset if safety of the system requires

manual reset.

Note:

Selected reset configuration may be protected against

unauthorized actions applying a seal.

Adjustment spindle(s) location

KP 15 KP 15, KP 17B KP 15, KP 17W, KP 25

A. MAN./MAN. RESET B. AUTO/MAN. RESET C. AUTO./AUTO. RESET

© Danfoss | DCS (jmn) | 2016.10 DKRCC.PI.CA0.B3.22 | 520H11520 | 3

Setting

Low pressure (LP) side setting High pressure (HP) side setting

KP 15A with LP man. reset only

KP 15, KP 17W, KP 17B and KP 25 KP 15A with convertible LP auto. KP 15, KP 17W, KP 17B and KP 25

with LP auto. reset only man. reset with HP auto. or man. reset

HP scale

LP scale LP scale

1 1 1

2 2

2

1. Adjust range spindle 1. Adjust range spindle 1. Adjust range spindle

to desired CUT-IN value. to desired CUT-IN value. to desired CUT-OUT value.

2. Adjust differential spindle to desired 2. DIFFRENTIAL (DIFF.) is fixed. 2. DIFFRENTIAL (DIFF.) is fixed.

DIFFERENTIAL (DIFF.) value. Value printed on scale plate. Value printed on scale plate.

CUT-IN minus DIFFERENTIAL CUT-IN equals CUT-OUT plus CUT-OUT minus DIFFERENTIAL

equals CUT-OUT DIFFERENTIAL equals CUT-IN

Example: Example: Example:

CUT-IN – DIFF. = CUT-OUT CUT-OUT + DIFF. = CUT-IN CUT-OUT – DIFF. = CUT-IN

30 psig – 10 psi = 20 psig 12 psig + 10 psi = 22 psig 203 psig – 58 psi = 145 psig

(2.1 bar) (0.7 bar) (1.4 bar) (0.8 bar) (0.7 bar) (1.5 bar) (14 bar) (4 bar) (10 bar)

Adjustment

LP differential

Decrease KP 15:

LP range 360° 2 psi (0.15 bar)/rev

Increase KP 15:

360° 10 psi (0.7 bar)/rev Increase KP 25:

360° 1.5 psi (0.1 bar)/rev

Decrease KP 25:

360° 7 psi (0.5 bar)/rev Lockplate

HP range

Increase

360°

KP 15:

33.5 psi (2.3 bar)/rev

Decrease

360°

15/64 in

(6 mm)

Note:

Remove lockplate before adjustment.

Replace lockplate after adjustment (if desired).

4 | 520H11520 | DKRCC.PI.CA0.B3.22 © Danfoss | DCS (jmn) | 2016.10

S-ar putea să vă placă și

- Dkrci Pi C00 C2 22Document4 paginiDkrci Pi C00 C2 22Muhamad Zul Faisal Salleh MustafaÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Pressure Switch: Installation GuideDocument4 paginiPressure Switch: Installation GuideRobson SpricigoÎncă nu există evaluări

- Pressostato Intruções Montagem PDFDocument2 paginiPressostato Intruções Montagem PDFninaninoninos100% (1)

- DKRCC Pi CD0 A4 02Document2 paginiDKRCC Pi CD0 A4 02blizanacÎncă nu există evaluări

- Yuken 8 EDFHG-AMN English LeafletDocument4 paginiYuken 8 EDFHG-AMN English LeafletJose2806Încă nu există evaluări

- BYPASSDocument2 paginiBYPASSSting DâuÎncă nu există evaluări

- Piston Pump PVDocument16 paginiPiston Pump PVtreinamentoÎncă nu există evaluări

- 4-2 Directional Spool Valve 4WE6DDocument2 pagini4-2 Directional Spool Valve 4WE6DRaphael SasdelliÎncă nu există evaluări

- 4-3 Directional Spool Valve 4WE-6-GDocument2 pagini4-3 Directional Spool Valve 4WE-6-GRaphael SasdelliÎncă nu există evaluări

- Valvula Proporcional Norgren Vp50sDocument1 paginăValvula Proporcional Norgren Vp50sBase SistemasÎncă nu există evaluări

- 3 En230 B R4VPDocument11 pagini3 En230 B R4VPAlessandro OliveiraÎncă nu există evaluări

- 4-3 Directional Spool Valve 4WE 6 HDocument2 pagini4-3 Directional Spool Valve 4WE 6 HRaphael SasdelliÎncă nu există evaluări

- Group 4 Electrical Component Specification: Part Name Symbol Specifications CheckDocument10 paginiGroup 4 Electrical Component Specification: Part Name Symbol Specifications CheckAl FurkhanÎncă nu există evaluări

- Liquid Level Controller - Water Level Controller - Level Controller - GIC IndiaDocument5 paginiLiquid Level Controller - Water Level Controller - Level Controller - GIC IndiaPrasadPurohitÎncă nu există evaluări

- Dual Pressure SwitchDocument2 paginiDual Pressure SwitchRakibul HassanÎncă nu există evaluări

- Serie PsanDocument13 paginiSerie PsanCesar Fernando Mendez VargasÎncă nu există evaluări

- P-107 Quick GuideDocument2 paginiP-107 Quick GuidesunhuynhÎncă nu există evaluări

- XEPV.3... P V E B: Roportional Alve With Lectronic ON OardDocument3 paginiXEPV.3... P V E B: Roportional Alve With Lectronic ON OardPitupyÎncă nu există evaluări

- 4-3 Directional Spool Valve 4WE6EDocument2 pagini4-3 Directional Spool Valve 4WE6ERaphael SasdelliÎncă nu există evaluări

- 4-3 Electrical Komponen SpecDocument9 pagini4-3 Electrical Komponen Specibnu malkanÎncă nu există evaluări

- Danfoss Presostat PDFDocument2 paginiDanfoss Presostat PDFSinisa MalesevicÎncă nu există evaluări

- Relief, Bi-Directional CR10-28Document2 paginiRelief, Bi-Directional CR10-28tungÎncă nu există evaluări

- Valvula Proporcional Norgren Vp51Document1 paginăValvula Proporcional Norgren Vp51Base SistemasÎncă nu există evaluări

- Valvula Proporcional Norgren Vp51Document1 paginăValvula Proporcional Norgren Vp51Base SistemasÎncă nu există evaluări

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Document12 paginiDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981Încă nu există evaluări

- AD30TC Testissue9-2Document4 paginiAD30TC Testissue9-2Bruno EstevesÎncă nu există evaluări

- Scheda Tecnica Hmk12aaDocument4 paginiScheda Tecnica Hmk12aaMarcos EvansÎncă nu există evaluări

- Cocon QTZ PN 16 Pressure Independent Control Valve: ApplicationDocument6 paginiCocon QTZ PN 16 Pressure Independent Control Valve: ApplicationBeshoyÎncă nu există evaluări

- Xfpn-025kpg - Sensor de PresionDocument3 paginiXfpn-025kpg - Sensor de PresionElias ChavezÎncă nu există evaluări

- m731 e K3 v04 5554 en PDFDocument22 paginim731 e K3 v04 5554 en PDFtsdcnÎncă nu există evaluări

- CODA Full en Us LetterDocument2 paginiCODA Full en Us Lettercesar5984Încă nu există evaluări

- Model Ps10: Pressure SwitchDocument6 paginiModel Ps10: Pressure SwitchNatasha HickmanÎncă nu există evaluări

- Rexroth SM 18 RE64124Document14 paginiRexroth SM 18 RE64124Darshan Makwana100% (1)

- R1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineDocument33 paginiR1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineajisardadiÎncă nu există evaluări

- PPDB en Us A4Document1 paginăPPDB en Us A4Felipe DiazÎncă nu există evaluări

- DENSO Brushless Alt SpecsDocument1 paginăDENSO Brushless Alt SpecsmnvijaybabuÎncă nu există evaluări

- Calibrated Differential Switch: Series Cdpd1H, Cdpd2H, Vcdpd1H, Vcdpd2HDocument2 paginiCalibrated Differential Switch: Series Cdpd1H, Cdpd2H, Vcdpd1H, Vcdpd2HEliecer DiazÎncă nu există evaluări

- General Description Technical Information Series D FL: Proportional Directional Control ValvesDocument7 paginiGeneral Description Technical Information Series D FL: Proportional Directional Control ValvesMohamed RiyazÎncă nu există evaluări

- Walvoil Fliud PowerDocument112 paginiWalvoil Fliud PowerVipulÎncă nu există evaluări

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 paginăModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoÎncă nu există evaluări

- Z2FS 6 New Series... 40BDocument6 paginiZ2FS 6 New Series... 40Bnemi90Încă nu există evaluări

- PVDB Full en Us LetterDocument2 paginiPVDB Full en Us LetterIsrael RuizÎncă nu există evaluări

- For Ultra High Purity (UHP)Document15 paginiFor Ultra High Purity (UHP)Alessandra ReclaÎncă nu există evaluări

- CKBDXCV ApDocument2 paginiCKBDXCV ApŁukasz OlszewskiÎncă nu există evaluări

- Banco Con Control Electrico Proporcional L218Document60 paginiBanco Con Control Electrico Proporcional L218Agustín TorresÎncă nu există evaluări

- Needle Valves With and Without Reverse Flow Check Direct-Acting Manifold Mounted - 350 BarDocument4 paginiNeedle Valves With and Without Reverse Flow Check Direct-Acting Manifold Mounted - 350 BarPaulo ArrudaÎncă nu există evaluări

- Aquativeplus Ac/Dc: Actuator Valve (Solenoid) Converting Electric To Hydraulic CommandDocument4 paginiAquativeplus Ac/Dc: Actuator Valve (Solenoid) Converting Electric To Hydraulic CommandErnesto Jimenez RodriguezÎncă nu există evaluări

- Series 190 Electrical ConnectorDocument4 paginiSeries 190 Electrical ConnectorAmit SurtiÎncă nu există evaluări

- SLK-KTG1-OPR-CL-TBN-007 Bypass System Check ListDocument1 paginăSLK-KTG1-OPR-CL-TBN-007 Bypass System Check ListoksaÎncă nu există evaluări

- Electro-Prop ValveDocument2 paginiElectro-Prop Valvemaikel.mÎncă nu există evaluări

- Ta-Compact-P NPT en LowDocument8 paginiTa-Compact-P NPT en LowThanhÎncă nu există evaluări

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 paginiModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaÎncă nu există evaluări

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 3 / Capacity: 60 GPM / Cavity: T-17ADocument1 paginăModel Pilot-To-Open Check Valve With Standard Pilot: Series 3 / Capacity: 60 GPM / Cavity: T-17Acorsini999Încă nu există evaluări

- Stps 30170 CDocument9 paginiStps 30170 CKichin_AÎncă nu există evaluări

- PBFB en Us A4Document1 paginăPBFB en Us A4operacion hydratekÎncă nu există evaluări

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 paginiModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMÎncă nu există evaluări

- Datasheet Teste Bacteria No FODocument5 paginiDatasheet Teste Bacteria No FOAbdoEmanuelMalverdiÎncă nu există evaluări

- Rolling Element Bearing Methodology Application Guide - 164934 PDFDocument36 paginiRolling Element Bearing Methodology Application Guide - 164934 PDFAbdoEmanuelMalverdiÎncă nu există evaluări

- NR 10 EnglishDocument18 paginiNR 10 EnglishAbdoEmanuelMalverdiÎncă nu există evaluări

- Screw Pump 40 - 80 Bar - Olaer - de PDFDocument12 paginiScrew Pump 40 - 80 Bar - Olaer - de PDFAbdoEmanuelMalverdiÎncă nu există evaluări

- Wedge VbeltDocument1 paginăWedge VbeltAbdoEmanuelMalverdiÎncă nu există evaluări

- 6260 p0408 S enDocument3 pagini6260 p0408 S enDavid BarrosÎncă nu există evaluări

- Social Computing in The EnterpriseDocument17 paginiSocial Computing in The EnterpriseJustin Souter100% (2)

- Tutorial On Earned Value Management Systems: Dennis J. FraileyDocument14 paginiTutorial On Earned Value Management Systems: Dennis J. FraileySheetal IyerÎncă nu există evaluări

- Electromagnetic ArmourDocument7 paginiElectromagnetic ArmourLissete VergaraÎncă nu există evaluări

- Do 5510Document2 paginiDo 5510Dandy Harris FirdiandaÎncă nu există evaluări

- Electronically Controlled Brake System (EBS)Document18 paginiElectronically Controlled Brake System (EBS)Sherzad Chem100% (4)

- LogDocument130 paginiLogZaheerabbas KhanÎncă nu există evaluări

- LED Lights Coding On Non LED Equipped Vehicles - OBDelevenDocument18 paginiLED Lights Coding On Non LED Equipped Vehicles - OBDelevenMarko ŠtambukÎncă nu există evaluări

- Discussion NTM2Document2 paginiDiscussion NTM2neenoonaaÎncă nu există evaluări

- Strategic Management Term PaperDocument18 paginiStrategic Management Term PaperOchena RajkonnaÎncă nu există evaluări

- CHD Candidate Guidebook PDFDocument20 paginiCHD Candidate Guidebook PDFsyammc0% (1)

- List of Accredited Software and - or Hardware (CRM - POS) As of 11-Dec-2018Document310 paginiList of Accredited Software and - or Hardware (CRM - POS) As of 11-Dec-2018Verscel Malalis GuisadioÎncă nu există evaluări

- Avanza Xenia Wiring DiagramDocument5 paginiAvanza Xenia Wiring DiagramFazri Putugerah100% (2)

- Airport Qualification and Familiarization ChartsDocument3 paginiAirport Qualification and Familiarization Chartsjackygdp645Încă nu există evaluări

- Intership SeminarDocument18 paginiIntership SeminarChandan K HÎncă nu există evaluări

- Plantronics Voyager Pro Plus ManualDocument10 paginiPlantronics Voyager Pro Plus Manualbsd_storesÎncă nu există evaluări

- Vehicle Safety Inspection ChecklistDocument2 paginiVehicle Safety Inspection ChecklistALMEDA INCÎncă nu există evaluări

- FlucsPro Ver 6 - 0 Web Training Notes Rev1Document32 paginiFlucsPro Ver 6 - 0 Web Training Notes Rev1dharshan balajiÎncă nu există evaluări

- Debug Steps For LACPDocument8 paginiDebug Steps For LACPEsteban MÎncă nu există evaluări

- EnCase Forensics Edition Primer - Getting StartedDocument37 paginiEnCase Forensics Edition Primer - Getting StartedJason KeysÎncă nu există evaluări

- ACS880 - Diode Supply CNTRL Prog - FW Manual - Rev BDocument126 paginiACS880 - Diode Supply CNTRL Prog - FW Manual - Rev BerrikcoyÎncă nu există evaluări

- Planning Guide PMP450i CambiumDocument237 paginiPlanning Guide PMP450i CambiumPedro MarroquinÎncă nu există evaluări

- LC320W01 Sla1Document33 paginiLC320W01 Sla1Robert TocaÎncă nu există evaluări

- Traffic Load Computation Using Matlab Simulink Model Blockset1Document6 paginiTraffic Load Computation Using Matlab Simulink Model Blockset1raghavÎncă nu există evaluări

- Different Types of Control Valves - Instrumentation ToolsDocument13 paginiDifferent Types of Control Valves - Instrumentation Toolsprabhanshu241991Încă nu există evaluări

- Nha Balut Tondo Manila - Less 1tDocument20 paginiNha Balut Tondo Manila - Less 1tTechnical Unit SjmdoÎncă nu există evaluări

- Block 1-Data Handling Using Pandas DataFrameDocument17 paginiBlock 1-Data Handling Using Pandas DataFrameBhaskar PVNÎncă nu există evaluări

- IEM PI 0100 - Competency Model For PI Oral InterviewDocument6 paginiIEM PI 0100 - Competency Model For PI Oral InterviewJani AceÎncă nu există evaluări

- 4.11.-Eaton CCM Freedom - Nema Contactor and StartersDocument37 pagini4.11.-Eaton CCM Freedom - Nema Contactor and Startersmartinel noob y baty mozÎncă nu există evaluări