Documente Academic

Documente Profesional

Documente Cultură

Manuel

Încărcat de

Collin Ngu0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări1 paginăfillet weld

Titlu original

Manuel.txt

Drepturi de autor

© © All Rights Reserved

Formate disponibile

TXT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentfillet weld

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări1 paginăManuel

Încărcat de

Collin Ngufillet weld

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca TXT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

A fillet weld is the most common weld type in steel building construction.

According to EN 1993?1?8, 4.3.2.1 (1) [1], fillet welds may be used for connecting

structural parts where the fusion faces form an angle between 60�� and 120��.

The effective throat thickness a of a fillet weld should be taken as the height of

the largest triangle (with equal or unequal legs) that can be inscribed within the

fusion faces and the weld surface, measured perpendicular to the outer side of this

triangle, see Figure 01.

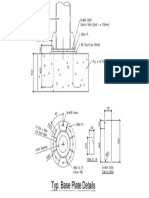

Figure 01 - Throat Thickness a of Fillet Weld (a) and Deep Penetration Fillet Weld

(b)

Design Resistance of Fillet Welds

According to EN 1993?1?8 [1], the design resistance of a fillet weld is usually

determined using Directional Method or Simplified Method. The Directional Method is

described below.

A uniform distribution of stress is assumed on the throat section of the weld,

leading to the normal stresses and shear stresses shown in Figure 02, as follows:

�ҡ� is the normal stress perpendicular to the throat

��|| is the normal stress parallel to the axis of the weld

�ӡ� is the shear stress (in the plane of the throat) perpendicular to the axis of

the weld

��|| is the shear stress (in the plane of the throat) parallel to the axis of th

S-ar putea să vă placă și

- AxiTrader Setup GuideDocument10 paginiAxiTrader Setup GuideCollin NguÎncă nu există evaluări

- F2150RA xhe-dynamic Crane SpecsDocument16 paginiF2150RA xhe-dynamic Crane SpecsCollin NguÎncă nu există evaluări

- AxiTrader Setup GuideDocument10 paginiAxiTrader Setup GuideCollin NguÎncă nu există evaluări

- NewDocument1 paginăNewCollin NguÎncă nu există evaluări

- NewDocument1 paginăNewCollin NguÎncă nu există evaluări

- ForexDocument1 paginăForexCollin NguÎncă nu există evaluări

- ColumnDocument1 paginăColumnCollin NguÎncă nu există evaluări

- tb0006 PDFDocument12 paginitb0006 PDFCollin NguÎncă nu există evaluări

- Base PlateDocument1 paginăBase PlateCollin NguÎncă nu există evaluări

- Authorisation Letter v2Document1 paginăAuthorisation Letter v2Collin NguÎncă nu există evaluări

- Koei JIS PDFDocument49 paginiKoei JIS PDFTimoÎncă nu există evaluări

- BS5950 BOLT AND WELD CAPACITIESDocument1 paginăBS5950 BOLT AND WELD CAPACITIESHelena DomičićÎncă nu există evaluări

- Bca 3Document5 paginiBca 3Collin NguÎncă nu există evaluări

- 2018 Android N Models User Manual AUDocument22 pagini2018 Android N Models User Manual AUCollin NguÎncă nu există evaluări

- CriteriaDocument5 paginiCriteriaCollin NguÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.6Document6 pagini1 Input Data: Profis Anchor 2.6.6Collin NguÎncă nu există evaluări

- Plane Sections Remain Plane. Y: CompressionDocument5 paginiPlane Sections Remain Plane. Y: CompressionakanyilmazÎncă nu există evaluări

- Roof Drainage Calculator - FloPlastDocument2 paginiRoof Drainage Calculator - FloPlastCollin NguÎncă nu există evaluări

- Example1 Timber DesignDocument3 paginiExample1 Timber DesignCollin NguÎncă nu există evaluări

- Thermal Values Within Tensile Fabric StructuresDocument4 paginiThermal Values Within Tensile Fabric StructuresCollin NguÎncă nu există evaluări

- Energy Use and Lighting - Birdair, IncDocument3 paginiEnergy Use and Lighting - Birdair, IncCollin NguÎncă nu există evaluări

- Exercise 8.4Document13 paginiExercise 8.4Socio JiwapatriaÎncă nu există evaluări

- 官人Document21 pagini官人Collin NguÎncă nu există evaluări

- m26 Specification For Lighting ColumnsDocument24 paginim26 Specification For Lighting ColumnsCollin NguÎncă nu există evaluări

- Guttermaster Print PageDocument1 paginăGuttermaster Print PageCollin NguÎncă nu există evaluări

- CriteriaDocument5 paginiCriteriaCollin NguÎncă nu există evaluări

- Structural Analysis HandoutDocument2 paginiStructural Analysis HandouthgorÎncă nu există evaluări

- STRUCTURAL GLASS DESIGN REPORTDocument1 paginăSTRUCTURAL GLASS DESIGN REPORTsamgivp2869100% (4)

- Canopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNDocument1 paginăCanopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNCollin NguÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Stress On Foundations: Motor Serie: MGL 200 SDocument2 paginiStress On Foundations: Motor Serie: MGL 200 SDavy MarceloÎncă nu există evaluări

- Combined - Physics AssignmentDocument25 paginiCombined - Physics Assignment387 OORJA SINGHÎncă nu există evaluări

- 108590202A GU Basic Laboratory Skills A4 en LRDocument92 pagini108590202A GU Basic Laboratory Skills A4 en LRΔΑΝΑΗ ΓΙΑΝΝΑΡΗÎncă nu există evaluări

- Masonry: Essential QuestionsDocument7 paginiMasonry: Essential QuestionsDiane de OcampoÎncă nu există evaluări

- Melcs Sses Science g1 g3Document7 paginiMelcs Sses Science g1 g3Joy U. Presentacion100% (3)

- A Grand Tour of Physics: Quantum MechanicsDocument27 paginiA Grand Tour of Physics: Quantum MechanicsrickyjamesÎncă nu există evaluări

- Class 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 MarksDocument13 paginiClass 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 Markswb csÎncă nu există evaluări

- 2019-Warp-Chine On Pentamaran Hydrodynamics Considering To Reduction in Ship Power EnergyDocument6 pagini2019-Warp-Chine On Pentamaran Hydrodynamics Considering To Reduction in Ship Power EnergyDAMORA RHAKASYWIÎncă nu există evaluări

- Shock & Vibration Response Spectra Rev DDocument460 paginiShock & Vibration Response Spectra Rev DTom IrvineÎncă nu există evaluări

- Grade 12 Mathematics: Paper 1Document11 paginiGrade 12 Mathematics: Paper 1Chey1242Încă nu există evaluări

- Series E Environmental Coils: Coils and Electronic ControlsDocument18 paginiSeries E Environmental Coils: Coils and Electronic ControlsMMM-MMMÎncă nu există evaluări

- B Basic of BTG - B-2 Basic of TurbineDocument83 paginiB Basic of BTG - B-2 Basic of TurbineBayu Dwi AsmaraÎncă nu există evaluări

- Law of MotionDocument30 paginiLaw of MotionMark Francis HernandezÎncă nu există evaluări

- Well LoggingDocument8 paginiWell LoggingDivyansh Singh ChauhanÎncă nu există evaluări

- Service Manual Type MAVS Check Synchronising RelayDocument36 paginiService Manual Type MAVS Check Synchronising RelaydobathinhÎncă nu există evaluări

- What Are Valence Electrons?: Oxidation StateDocument3 paginiWhat Are Valence Electrons?: Oxidation StateexoisnineÎncă nu există evaluări

- National Atmospheric Research Laboratory Advertisement No - Narl/Rmt/Ra & Rf/01/2020 Date: 11.03.2020Document2 paginiNational Atmospheric Research Laboratory Advertisement No - Narl/Rmt/Ra & Rf/01/2020 Date: 11.03.2020Srikanth RollaÎncă nu există evaluări

- This Study Resource WasDocument9 paginiThis Study Resource WasJacob ClintonÎncă nu există evaluări

- P DeltaDocument22 paginiP DeltayazidÎncă nu există evaluări

- Tor Qui MetroDocument68 paginiTor Qui MetroVíc Mac IIÎncă nu există evaluări

- DP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesDocument36 paginiDP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesAntonio FedatoÎncă nu există evaluări

- Printed AntennasDocument463 paginiPrinted AntennasvasikasÎncă nu există evaluări

- Information/Data Required For Wax Modelling: A) B) C) D) E)Document6 paginiInformation/Data Required For Wax Modelling: A) B) C) D) E)AYAUWU LOVEDAY100% (1)

- E3x ZD - E65z En5 01Document12 paginiE3x ZD - E65z En5 01Teguh WidiantoÎncă nu există evaluări

- Basics of Reservoir EngineeringDocument68 paginiBasics of Reservoir Engineeringyarra suryatejaÎncă nu există evaluări

- 01 Vajhm23Document6 pagini01 Vajhm23jigyeshÎncă nu există evaluări

- Mastery Test in Physical Science - Gr.11Document3 paginiMastery Test in Physical Science - Gr.11kert mendozaÎncă nu există evaluări

- Dokumen - Tips - Intumescent Binders Our Portfolio For Intumescent Coatings Product Solid ContentDocument6 paginiDokumen - Tips - Intumescent Binders Our Portfolio For Intumescent Coatings Product Solid ContentHazem RamadanÎncă nu există evaluări

- PN 31274Document16 paginiPN 31274Ivan DÎncă nu există evaluări

- Secret of The Stars - How To Receive What You DeserveDocument61 paginiSecret of The Stars - How To Receive What You DeserveNakita JosephÎncă nu există evaluări